Metal additive manufacturing device and method based on high-speed shot peening

A metal additive and high-speed shot peening technology, applied in the field of metal additive manufacturing, can solve the problems of deformation and cracking of molded parts, increase printing costs, inclusions, etc., achieve high temperature oxidation resistance, stress corrosion cracking resistance, and optimize the surface structure structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

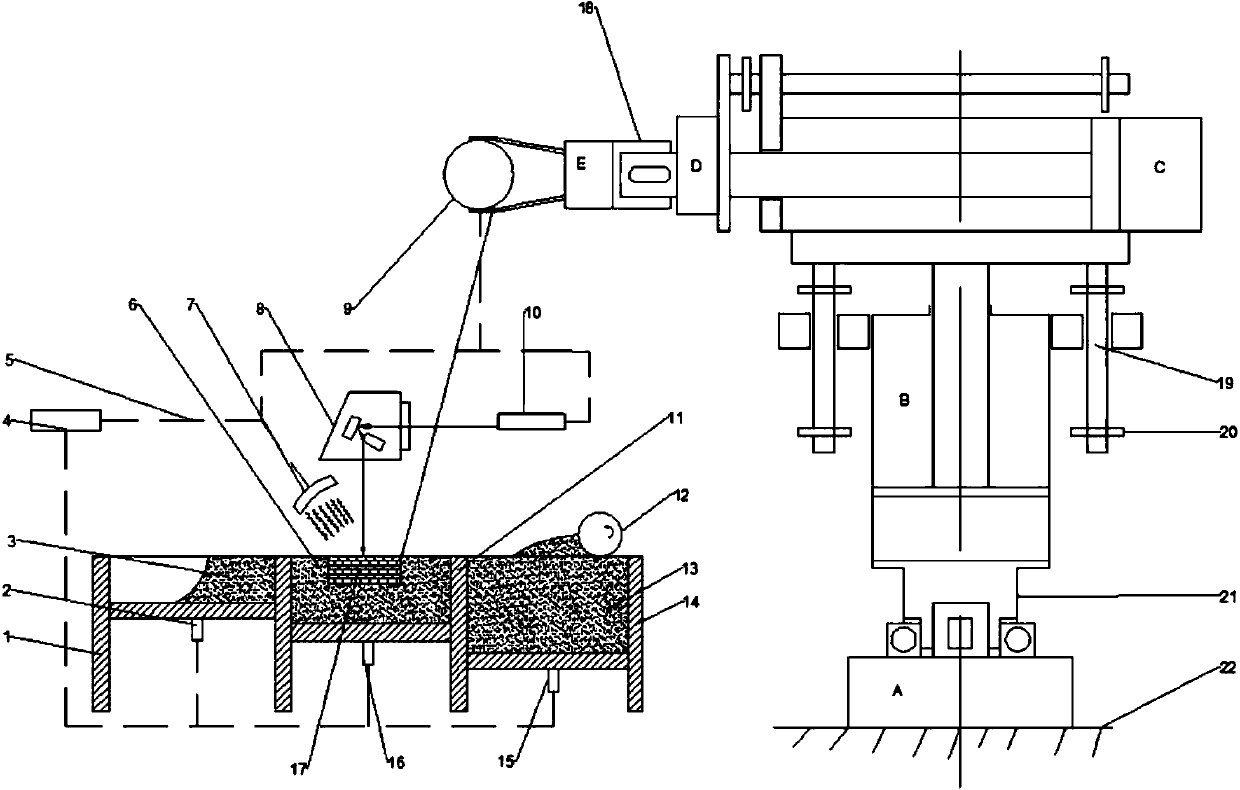

[0025] The present invention is further described below in conjunction with accompanying drawing:

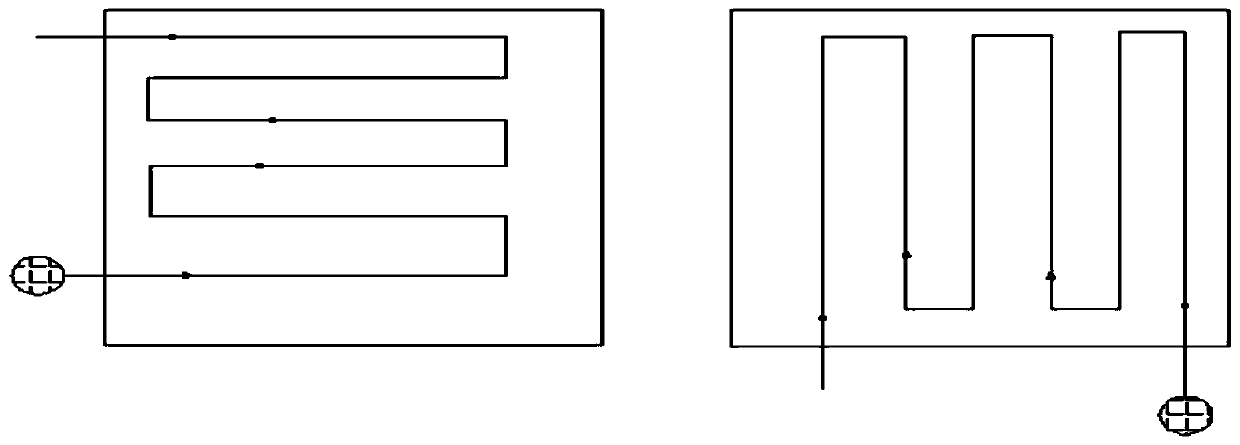

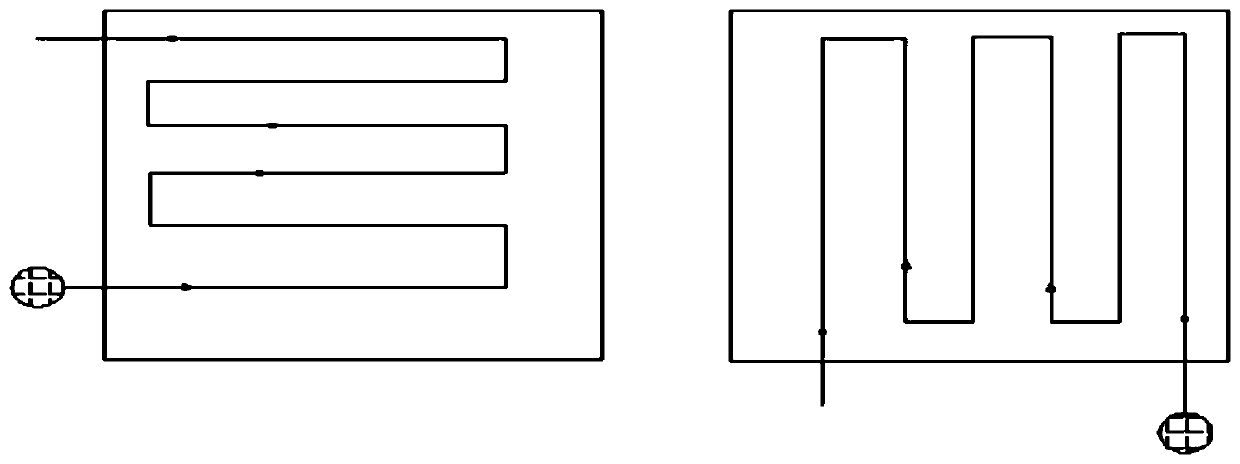

[0026] see Figure 1 to Figure 3 , a metal additive manufacturing device based on high-speed shot peening, including shot peening 9, shot peening adjustment mechanism, recycling material box 1, forming box 11, material storage box 14, metal powder preheater 7, X-Y scanning mirror 8, The controller 4 and the continuous laser 10; the recovery material box 1, the molding box 11 and the material storage box 14 are arranged side by side on a plane to form a box group, and the side of the box group is fixedly provided with a shot peening adjustment mechanism, which is connected to the shot peening 9, Shot peening 9 is aimed at molding box 11; metal powder preheater 7 and X-Y scanning mirror 8 are arranged above molding box 11; continuous laser 10 is arranged above storage box 14; metal powder preheater 7, continuous laser 10 and Shot peening 9 is connected to controller 4, and X-Y sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com