Ultralow-carbon high-temperature-resistant welding wire and preparation method thereof

A high-temperature, ultra-low carbon technology, used in welding equipment, welding media, manufacturing tools, etc., to achieve the effect of reducing intergranular corrosion, lowering melting point, good weldability and casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

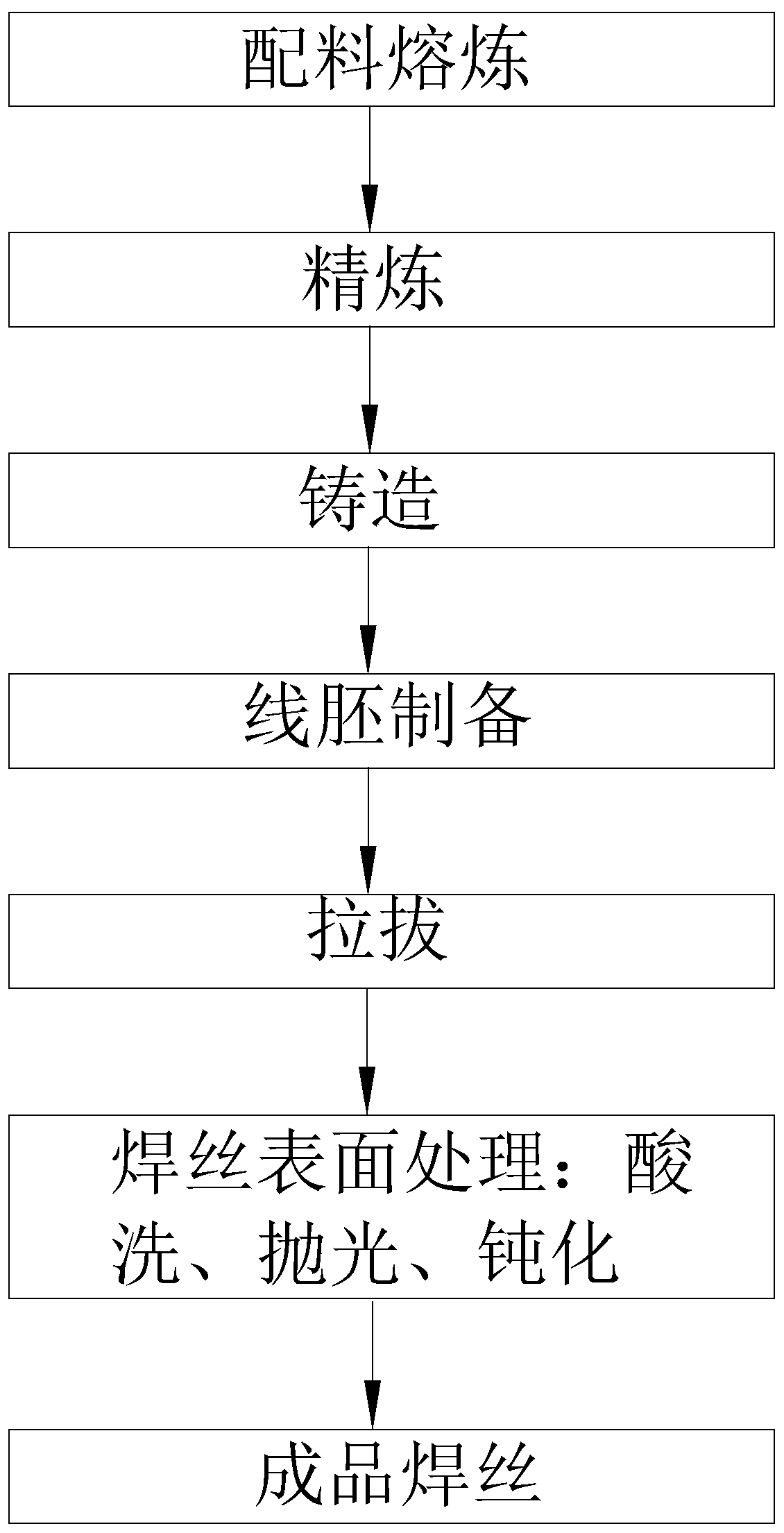

Method used

Image

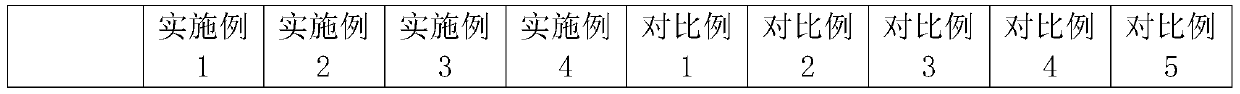

Examples

Embodiment 1

[0034] The chemical composition of an ultra-low carbon high temperature resistant welding wire is calculated by mass percentage: C is 0.02%, Cr is 23.5%, Si is 2.5%, Ni is 13.2%, Ti is 0.8%, Mn is 0.28%, Zr is 0.35% %, Sc is 0.45%, Mo is 0.22%, Nb is 0.41%, Mg is 4.3%, Al is 0.9%, P is 0.05%, S is 0.04%, V is 0.33%, B is 1.45%, and the balance is Fe and other unavoidable impurity elements.

[0035] The preparation method of the ultra-low carbon high temperature resistant welding wire specifically includes the following steps:

[0036] Step 1. Ingredients smelting: Weigh each component according to the ratio, and then put it into a heating furnace for smelting, and the smelting temperature is 1850°C;

[0037] Step 2. Refining: After all the components in the heating furnace are melted, add a refining agent and stir evenly. The refining agent accounts for 0.3% of the total mass of the alloy liquid, and the refining temperature is 1600°C;

[0038] Step 3. Casting: After refinin...

Embodiment 2

[0043] The chemical composition of an ultra-low carbon high temperature resistant welding wire is calculated by mass percentage: C is 0.03%, Cr is 22.8%, Si is 2.8%, Ni is 13.6%, Ti is 0.6%, Mn is 0.35%, Zr is 0.41% %, Sc is 0.52%, Mo is 0.22%, Nb is 0.41%, Mg is 4.3%, Al is 0.9%, P is 0.05%, S is 0.04%, V is 0.33%, B is 1.45%, and the balance is Fe and other unavoidable impurity elements.

[0044] The preparation method of the ultra-low carbon high temperature resistant welding wire specifically includes the following steps:

[0045] Step 1. Ingredients smelting: weigh each component according to the ratio, and then put them into the heating furnace for smelting;

[0046] Step 2, refining: After all the components in the heating furnace are melted, add a refining agent and stir evenly, and the refining agent accounts for 0.4% of the total mass of the alloy liquid;

[0047] Step 3, Casting: After refining, let it stand for 30 minutes, remove the slag on the surface of the al...

Embodiment 3

[0052] The chemical composition of an ultra-low carbon high temperature resistant welding wire is calculated by mass percentage: C is 0.01%, Cr is 22.0%, Si is 3.5%, Ni is 12.0%, Ti is 1.2%, Mn is 0.1%, Zr is 0.5% %, Sc is 0.6%, Mo is 0.1%, Nb is 0.5%, Mg is 3.0%, Al is 1.2%, P is 0.07%, S is 0.05%, V is 0.4%, B is 1.6%, and the balance is Fe and other unavoidable impurity elements.

[0053] The preparation method of the ultra-low carbon high temperature resistant welding wire specifically includes the following steps:

[0054] Step 1. Ingredients smelting: weigh each component according to the ratio, and then put them into the heating furnace for smelting;

[0055] Step 2, refining: After all the components in the heating furnace are melted, add a refining agent and stir evenly, the refining agent accounts for 0.5% of the total mass of the alloy liquid;

[0056] Step 3. Casting: After refining, let it stand for 20 minutes, remove the slag on the surface of the alloy liquid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com