Aluminium bronze of sand-casting high-pressure pump head

A high-pressure pump and aluminum bronze technology, applied in the field of aluminum bronze, can solve the problems of high volume, low plasticity, and high aluminum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

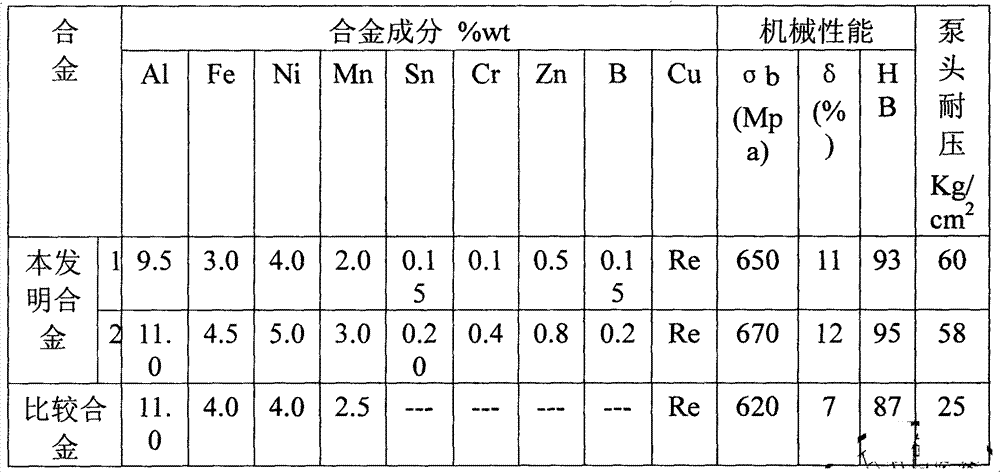

[0007] The compositions of alloys 1 and 2 of the present invention are shown in the table below, and the general-purpose pump head aluminum bronze alloy is used as a comparative alloy, melted in an intermediate frequency electric furnace, refined with cryolite, degassed with dry nitrogen, and poured into a sand mold at 1160°C , cast into the pump head and tensile test rod of the same size, and carry out cutting processing. The pump head is subjected to a pressure test, and the test rod is subjected to a tensile test. The results are shown in Table 1.

[0008] Table 1 Test result of the present invention

[0009]

[0010] Due to the addition of beneficial elements, the alloy of the invention refines the crystal grains, changes the structure, improves the mechanical properties, increases the elongation by nearly 70%, and more than doubles the pressure resistance of the pump head casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com