Continuous casting method of large-length hollow ductile cast iron sections and method for arcing hollow ductile cast iron sections after local continuous heating

A technology of ductile iron and hollow profiles is applied in the field of continuous casting of large-length ductile iron hollow profiles to achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

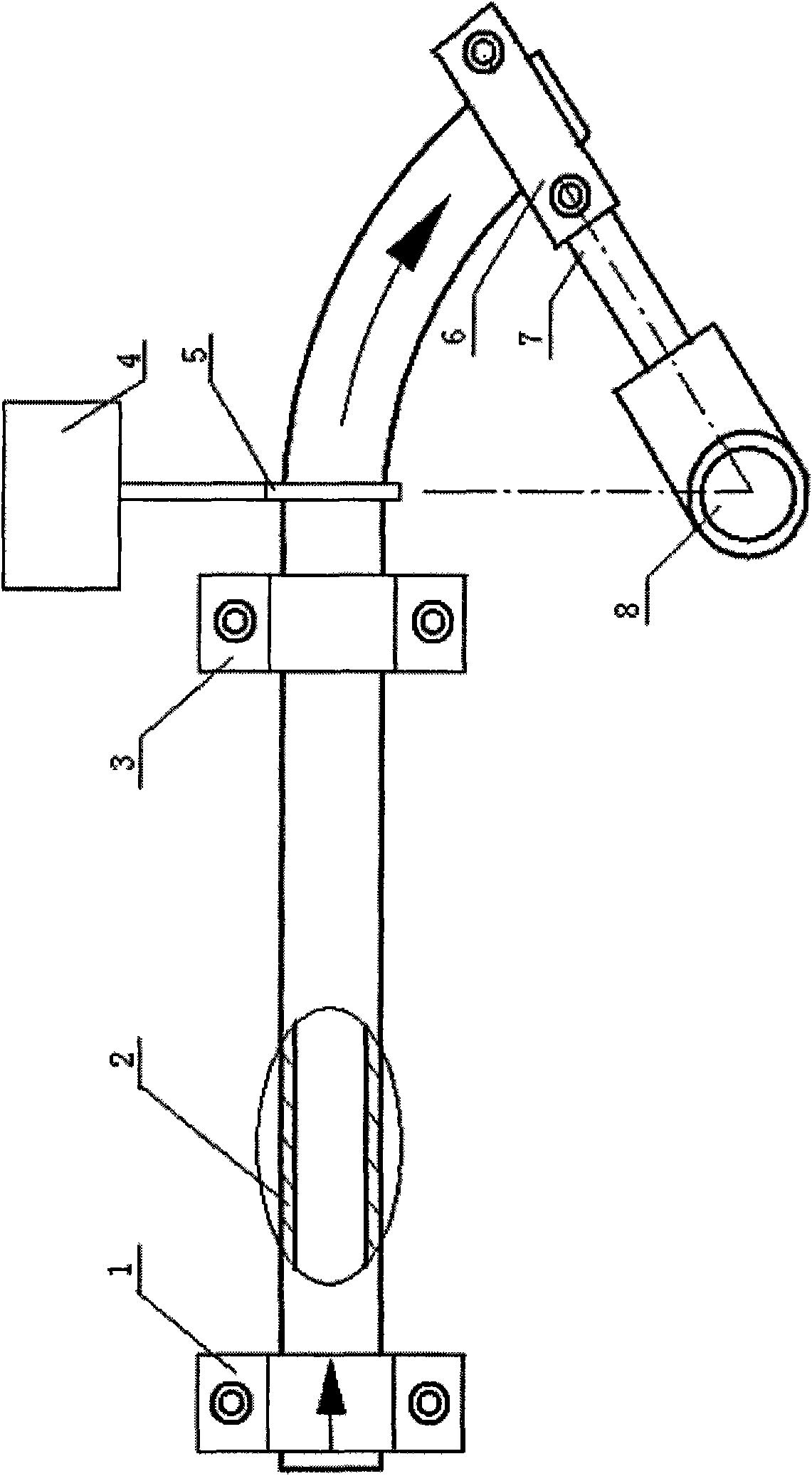

Image

Examples

Embodiment Construction

[0026] Concrete implementation of the present invention:

[0027] 1. Use pig iron (70%), scrap steel (15%), and returned materials (15%) to melt and prepare molten iron with special components suitable for continuous casting technology. The final composition ratio of the material is as follows: C: 3.4-3.6, Si: 2.8-3.2, Mn: 0.40-0.60, S≤0.1, P≤0.1, Fe: balance. Among them, the silicon content of the original molten iron is 2.2-2.6%, and the remaining part is supplemented by inoculation with flow.

[0028] 2. The induction melting temperature of molten iron is 1450-1500℃.

[0029] 3. About 1.3% nodulizer is put into the bottom of embankment ladle, covered with nodular iron filings and compacted.

[0030] 4. Pour the smelted molten iron into the ladle for spheroidizing reaction.

[0031] 5. Pour the molten iron in the ladle into a special continuous casting holding furnace, its furnace body structure and continuous casting drawing method.

[0032] 6. After drawing a hollow pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com