Method for producing copper-coated graphene lead wires

A copper-clad graphene and production method technology, applied in the direction of conductors, conductive materials, conductive materials, etc., can solve problems such as unusable, high resistivity, high brittleness, etc., and achieve the effect of solving difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

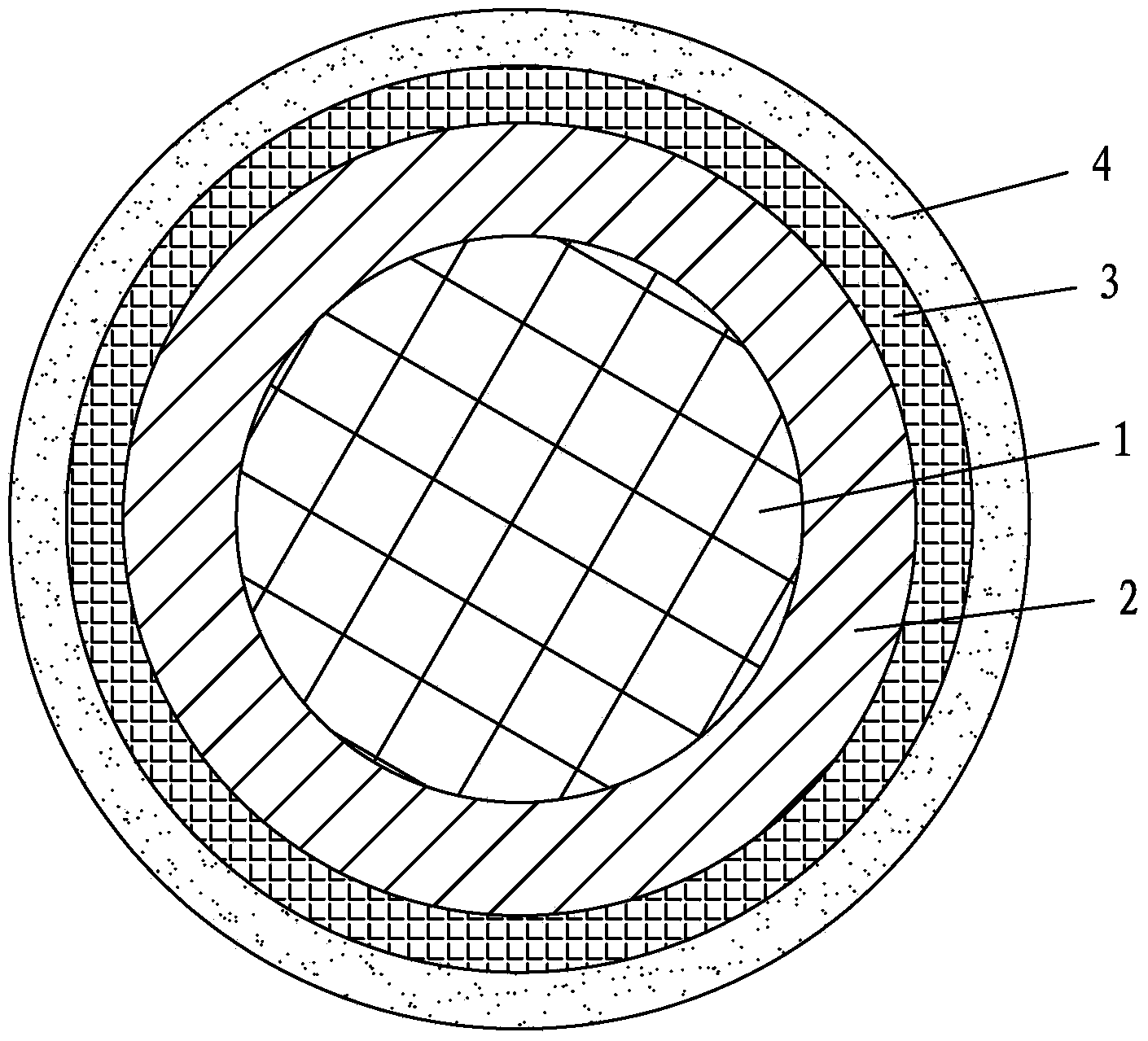

[0017] Embodiment one: see attached figure 1 Shown, a kind of production method of copper clad graphene wire, comprises the following steps:

[0018] 1) Inject graphene paste into the hollow copper tube;

[0019] 2) The copper pipe is stretched step by step into a wire with a diameter of 0.001mm by diamond die stretching method, and the stretching rate is 1.2 each time;

[0020] 3) Apply insulating varnish on the wire and dry it, repeat several times to form a paint film on the surface of the wire, and then apply self-adhesive varnish to form a self-adhesive layer;

[0021] 4) Cooling and take-up.

[0022] The copper-clad graphene wire produced in this embodiment is respectively a graphene core 1, a copper cladding 2, an insulating coating 3, and a self-adhesive layer 4 from the inside to the outside.

[0023] The graphene paste in this embodiment is a paste after mixing graphene (powder state) and additives such as solvent, resin, and surfactant.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com