Method for vertically manufacturing tubular pile

A vertical pipe and vertical technology, applied in the direction of manufacturing tools, reinforced molding, ceramic molding machines, etc., can solve problems such as difficulties in making solid pipe piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

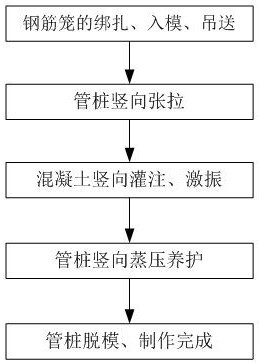

[0028] Such as figure 1 As shown, a method for vertically manufacturing pipe piles is based on vertical pipe pile mold vibration platform, vertical concrete aggregate pumping system, vertical pipe pile tensioning platform, and vertical pipe pile steam curing platform for vertical production The pipe pile method, the vertical pipe pile mold vibration platform includes a bottom vertical vibration system, a side horizontal vibration system, and a rigid support system, and the vertical concrete aggregate pumping system includes a sliding support truss, a winch Lifting system, rigid pumping pipeline, concrete pump, the vertical pipe pile tensioning platform includes a bottom anchor, a side support, and a top tensioning system, and the vertical pipe pile steam curing platform refers to a porous vertical The steam curing box for pipe piles includes vertical maintenance holes, mold vertical maintenance system, and steam curing system. The specific production steps of pipe piles are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com