Tensile strength 1000 MPa-grade cold-rolled complex phase steel and preparation method thereof

A technology for tensile strength, multiphase steel, applied in the field of steel rolling, can solve the problem of carbon content deteriorating welding performance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

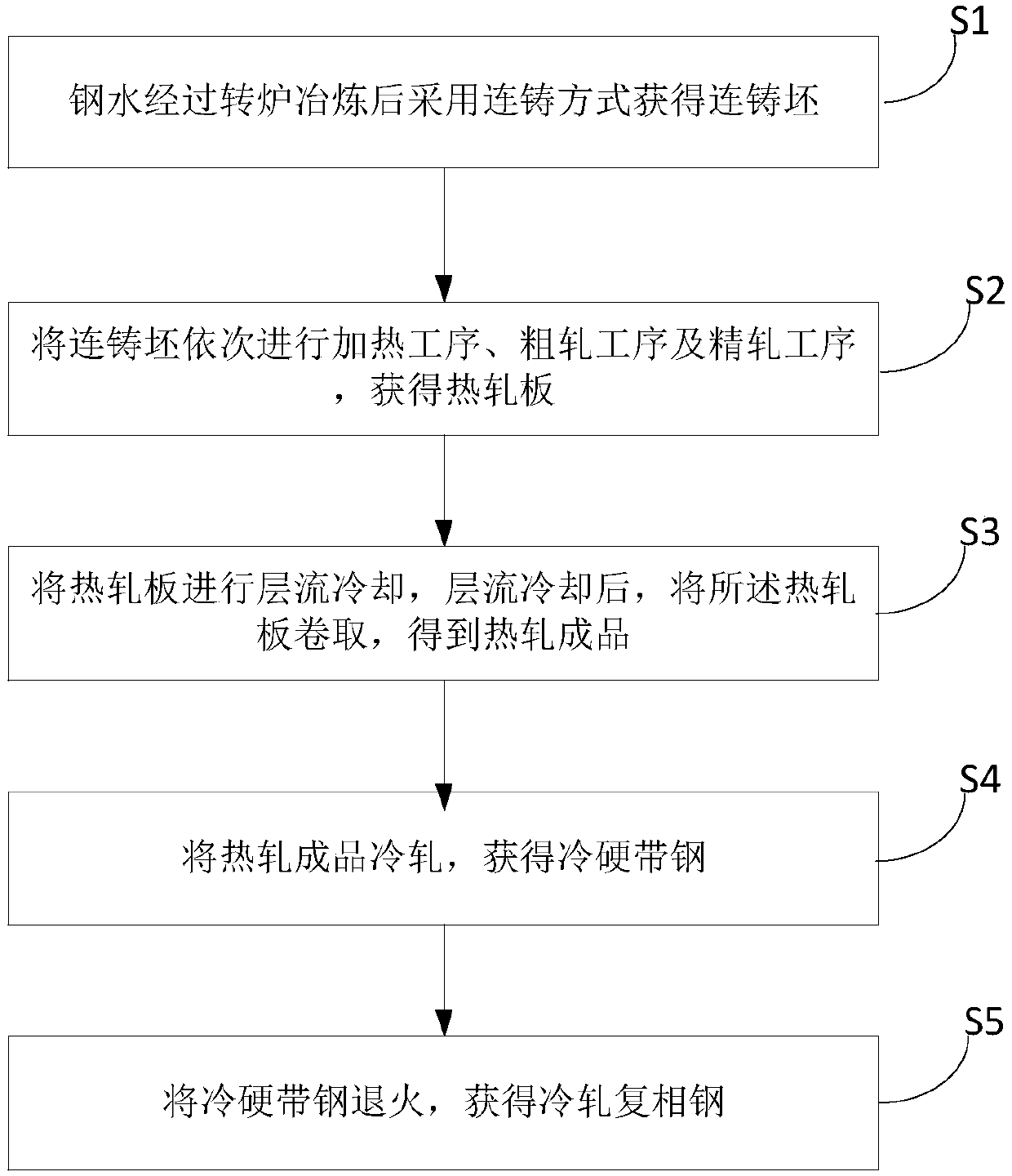

[0047] figure 1 It is a schematic flow chart of a preparation method of a tensile strength 1000MPa grade cold-rolled multiphase steel according to an embodiment of the present invention, combined with figure 1 , the method includes:

[0048] S1: After the molten steel is smelted in a converter, the continuous casting slab is obtained by continuous casting. The chemical composition of the continuous casting slab is: C: 0.07-0.13%, Si: 0.2-0.4%, Mn: 1.8-2.5%, Cr: 0.2-0.6%, Mo: 0.1-0.4%, P: ≤0.02%, S: ≤0.015%, Nb: 0.02-0.06%, Ti: 0.02-0.06%, the balance is iron and other unavoidable impurity elements;

[0049] S2: The continuous casting slab is sequentially subjected to a heating process, a rough rolling process and a finishing rolling process to obtain a hot-rolled plate;

[0050] S3: Perform laminar cooling on the hot-rolled sheet, and after laminar cooling, coil the hot-rolled sheet to obtain a hot-rolled finished product;

[0051] S4: Cold rolling the hot-rolled finished p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com