High-strength weather-resistant steels and production method thereof

A production method and weather-resistant steel technology, which is applied in the field of iron and steel smelting, can solve the problem that steel cannot achieve high strength and high weather resistance at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

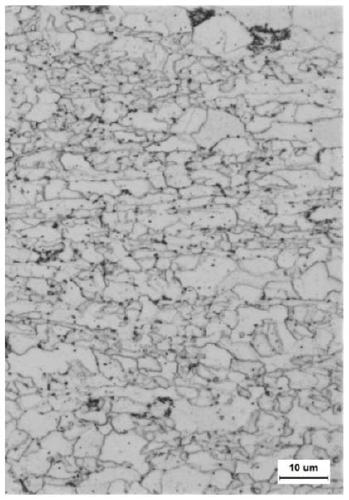

Embodiment 1

[0025] As a specific embodiment of the present invention, the high-strength weathering steel contains the following chemical composition by weight percentage: C: 0.06%, Si: 0.23%, Mn: 1.48%, P: 0.0055%, S: 0.0045%, Ni: 0.19%, Cr: 0.47%, Cu: 0.32%, Als: 0.010%, N: 0.0034%, Ti: 0.11%, Nb: 0.03%, and the balance is Fe and unavoidable impurity elements. The details are shown in Table 1 below:

[0026] Table 1 Unit: wt%

[0027]

[0028] It is smelted in a vacuum induction furnace, and then the smelted molten steel is poured into a water-cooled copper mold for cooling and setting to obtain an ingot. Cut off the riser of the ingot and heat it to 1200 degrees Celsius for 2 hours of heat preservation. After the heat preservation is completed, the ingot is forged into a billet of 80mm×80mm.

[0029] Rolling: Reheat the billet to 1200°C and keep it warm for 2-3 hours to fully austenitize, then carry out two-stage controlled rolling and controlled cooling, the first-stage rolling te...

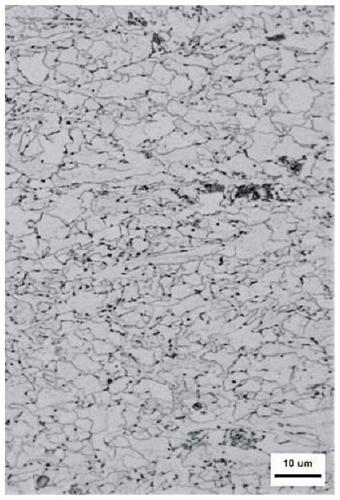

Embodiment 2

[0036] As a specific embodiment of the present invention, the high-strength weathering steel contains the following chemical composition by weight percentage: C: 0.06%, Si: 0.24%, Mn: 1.50%, P: 0.0065%, S: 0.0045%, Cr: 0.48%, Cu: 0.33%, Als: 0.012%, N: 0.0042%, Ti: 0.13%, Nb: 0.034%, and the balance is Fe and unavoidable impurity elements. Specifically as shown in Table 3 below,

[0037] Table 3 Unit: wt%

[0038]

[0039] It is smelted in a vacuum induction furnace, and then the smelted molten steel is poured into a water-cooled copper mold for cooling and setting to obtain an ingot. Cut off the riser of the ingot and heat it to 1200 degrees Celsius for 2 hours of heat preservation. After the heat preservation is completed, the ingot is forged into a billet of 80mm×80mm.

[0040] Rolling: Reheat the billet to 1200°C and keep it warm for 2-3 hours to fully austenitize, then carry out two-stage controlled rolling and controlled cooling, the first-stage rolling temperature ...

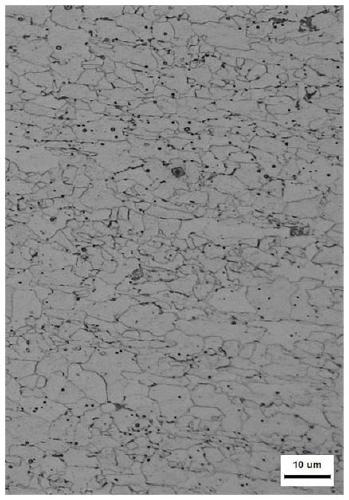

Embodiment 3

[0047] As a specific embodiment of the present invention, the high-strength weathering steel contains the following chemical composition by weight percentage: C: 0.07%, Si: 0.26%, Mn: 1.45%, P: 0.0058%, S: 0.0062%, Cu: 0.33%, Als: 0.013%, N: 0.0035%, Ti: 0.12%, Nb: 0.036%, and the balance is Fe and unavoidable impurity elements. Specifically, as shown in Table 5 below,

[0048] Table 5 Unit: wt%

[0049]

[0050] It is smelted in a vacuum induction furnace, and then the smelted molten steel is poured into a water-cooled copper mold for cooling and setting to obtain an ingot. Cut off the riser of the ingot and heat it to 1200 degrees Celsius for 2 hours of heat preservation. After the heat preservation is completed, the ingot is forged into a billet of 80mm×80mm.

[0051] Rolling: Reheat the billet to 1200°C and keep it warm for 2-3 hours to fully austenitize, then carry out two-stage controlled rolling and controlled cooling, the first-stage rolling temperature is 1120-11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com