900MPa grade hot rolling non-tempering thin steel sheet and preparation method thereof

A thin steel plate, non-quenching and tempering technology, applied in the field of alloy steel, can solve the problems of excessive internal stress, high energy consumption, poor plate shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

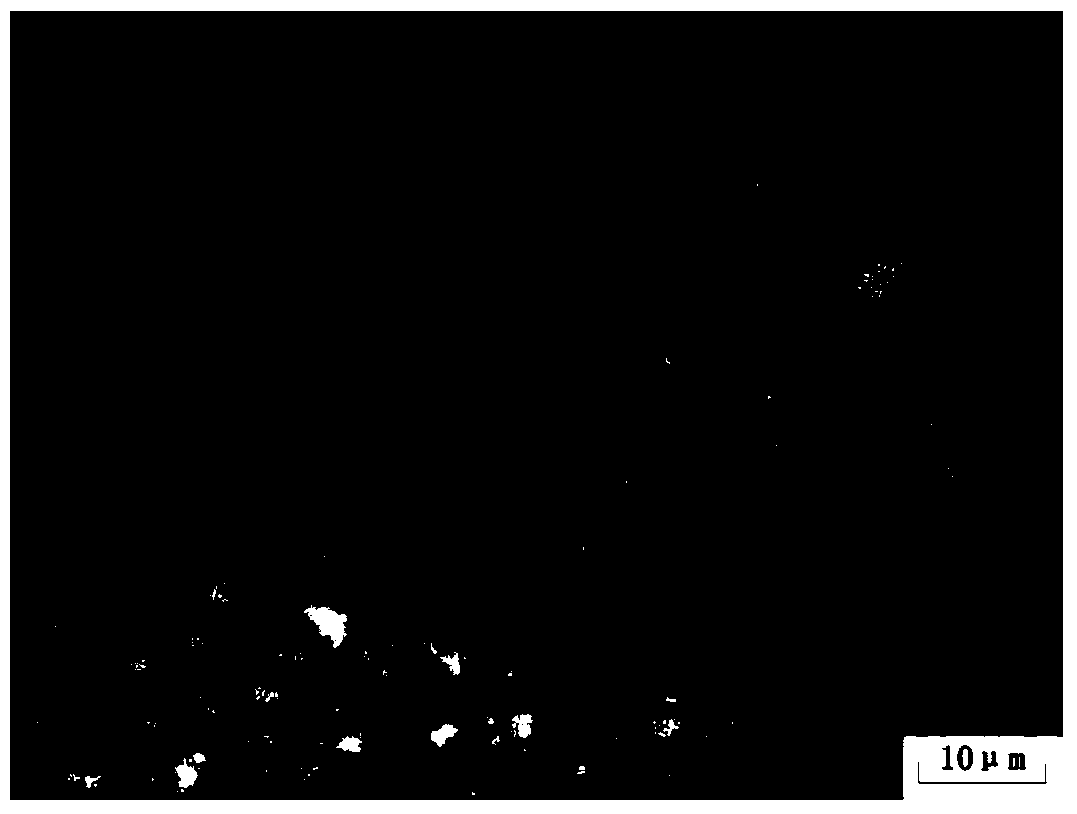

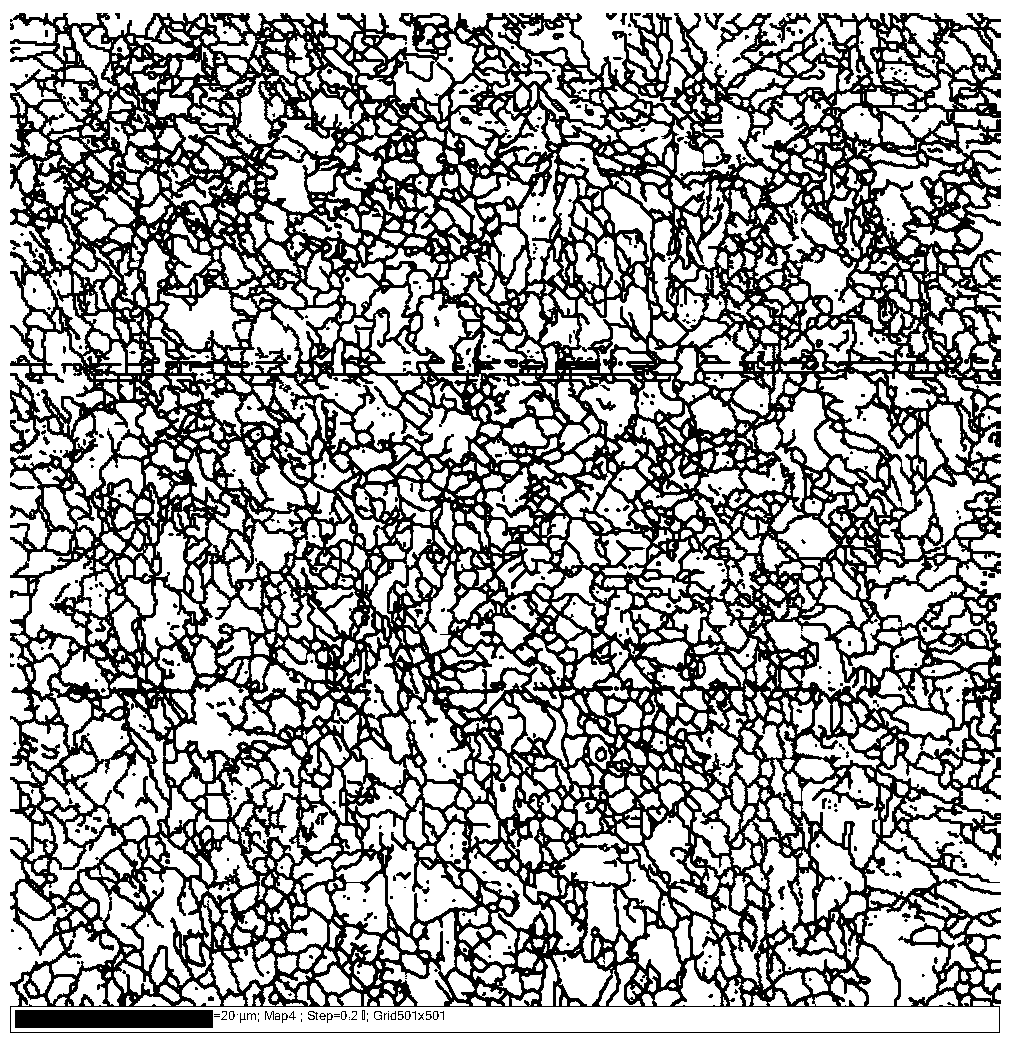

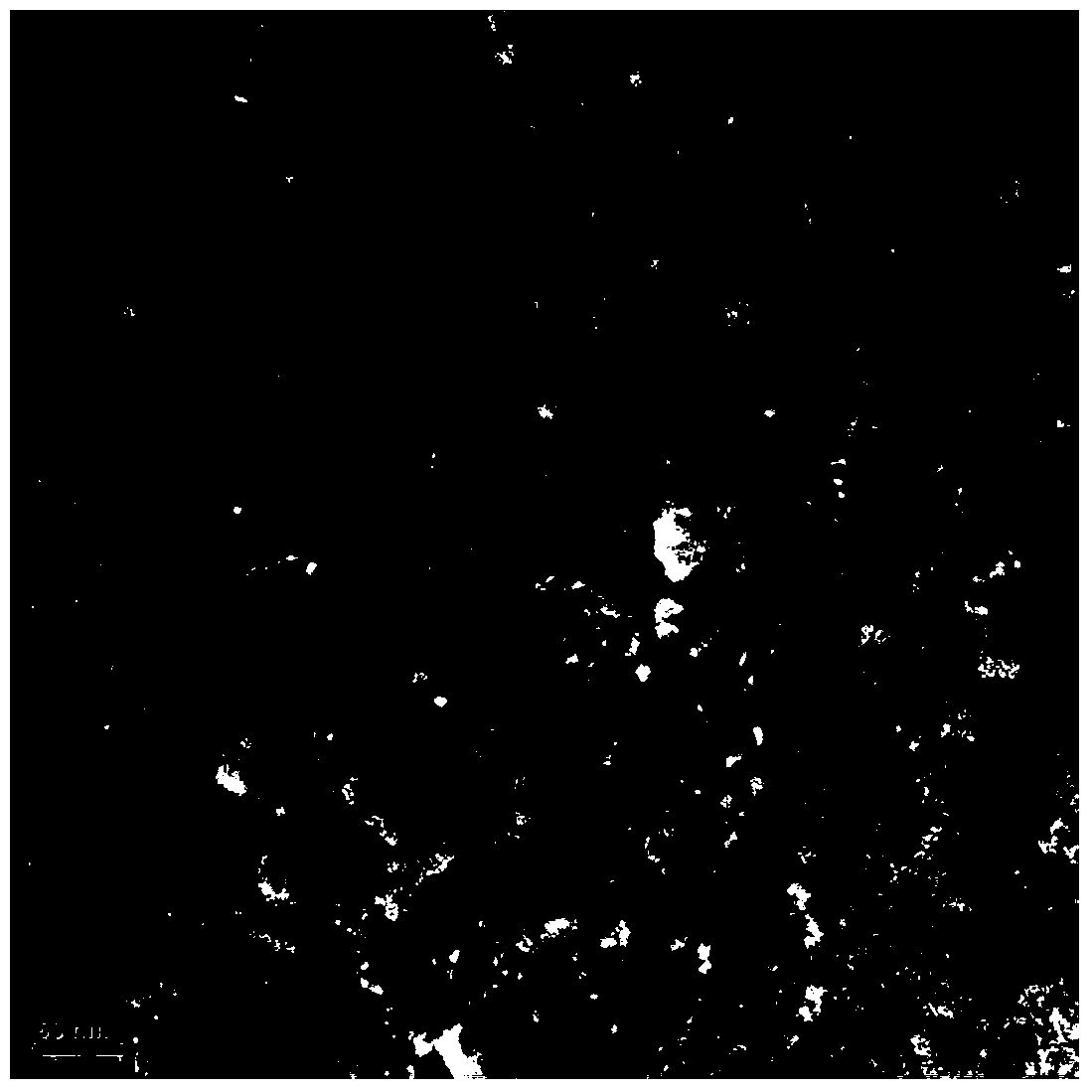

[0031] The test steel was smelted in a laboratory vacuum induction furnace, a total of 5 furnaces, and the chemical composition is shown in Table 1. The above-mentioned steel ingot is cast into a 50kg round ingot, and then forged into a billet with a size of 100mm (length)*80mm (width)*60mm (thickness). The above-mentioned steel billet is rolled into a steel plate with a thickness of 4mm by a laboratory reversible rolling mill. After rolling, simulate laminar flow cooling with a cooling rate greater than 20°C / s. Then put the steel plate in a resistance furnace for 1 hour and then air cool to room temperature to simulate coiling. process. Table 2 shows the heating temperature, final rolling temperature, and coiling temperature used, as well as the measured grain size and mechanical properties of the steel plate. The steel plate grain size is measured on the EBSD grain boundary diagram by the intercept method, the tensile sample is taken from the rolling direction of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com