780 MPa-grade low-carbon low-alloy hot-dip galvanized TRIP steel and rapid heat treatment method thereof

A rapid heat treatment and hot-dip galvanizing technology, applied in heat treatment furnaces, heat treatment equipment, hot-dip galvanizing processes, etc., can solve the problems of increasing the cost of precious metals, and achieve the effects of superior performance, increased elongation, and increased tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

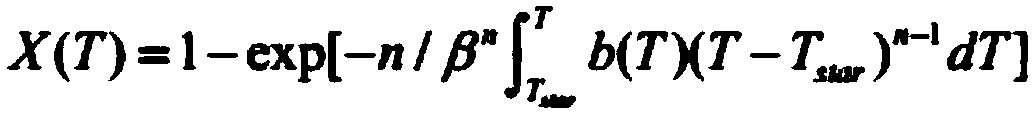

Method used

Image

Examples

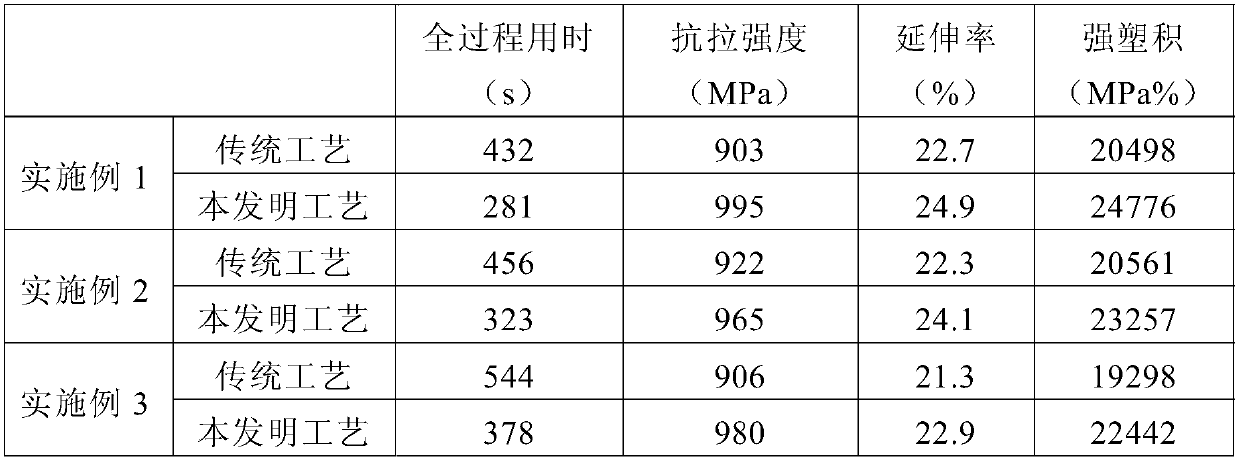

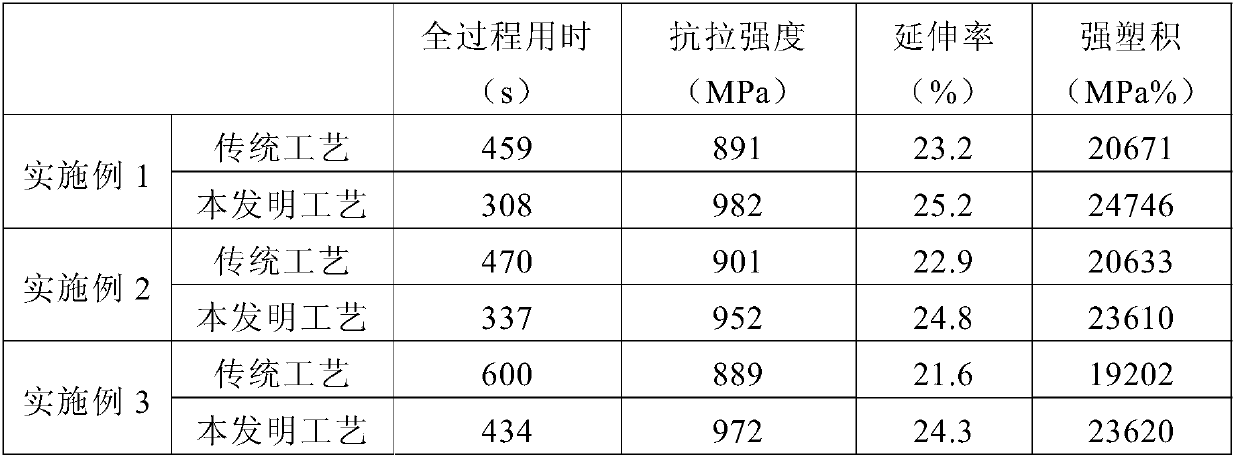

Embodiment 1

[0060] The chemical composition of the selected raw material steel is calculated by weight percentage: C-0.16%, Mn-1.6%, Si-1.4%, and the balance is Fe and unavoidable impurity elements. The steel plate before heat treatment is cold-rolled strip steel, and the cold-rolling reduction rate is 65%. The microstructure of steel plate after cold rolling is composed of pearlite and ferrite.

[0061] GI product heat treatment process steps are as follows:

[0062] 1) Heat the steel plate to 770°C at a heating rate of 300°C / s and keep it warm for 40s;

[0063] 2) Cool the steel plate to 410°C at a cooling rate of 40°C / s and keep it warm for 215s;

[0064] 3) Heating from 410°C to 460°C for hot-dip galvanizing;

[0065] 4) Rapid cooling to room temperature at a cooling rate of 50°C / s.

[0066] The heat treatment steps of GA products are as follows:

[0067] 1) Heat the steel plate to 770°C at a heating rate of 300°C / s and keep it warm for 40s;

[0068] 2) The steel strip is cooled...

Embodiment 2

[0077] The chemical composition of the selected raw material steel is calculated by weight percentage: C-0.22%, Mn-2.2%, Si-1.2%, and the balance is Fe and unavoidable impurity elements. The steel plate before heat treatment is cold-rolled strip steel, and the cold-rolling reduction rate is 55%. The microstructure of steel plate after cold rolling is composed of pearlite and ferrite.

[0078] GI product heat treatment steps are as follows:

[0079] 1) Heat the strip steel plate to 800°C at a heating rate of 30°C / s and keep it warm for 90s;

[0080] 2) The steel strip is cooled to 430°C at a cooling rate of 100°C / s, and held for 200s;

[0081] 3) The strip steel is heated from 430°C to 470°C for hot-dip galvanizing;

[0082] 4) After galvanizing, cool to room temperature at a cooling rate of 150°C / s.

[0083] The heat treatment steps of GA products are as follows:

[0084] 1) Heat the steel plate to 800°C at a heating rate of 30°C / s, and keep it warm for 90s;

[0085] 2) ...

Embodiment 3

[0094] The chemical composition of the selected raw material steel is calculated by weight percentage: C-0.18%, Mn-2.0%, Si-1.6%, and the balance is Fe and unavoidable impurity elements. The steel plate before heat treatment is cold-rolled strip steel, and the cold-rolling reduction rate is 65%. The microstructure of steel plate after cold rolling is composed of pearlite and ferrite.

[0095] GI product heat treatment steps are as follows:

[0096] 1) Heat the steel plate to 850°C at a heating rate of 200°C / s and keep it warm for 65s;

[0097] 2) The steel strip is cooled to 420°C at a cooling rate of 80°C / s, and held for 300s;

[0098] 3) The strip steel is heated from 420°C to 465°C for hot-dip galvanizing;

[0099] 4) Cool to room temperature at a cooling rate of 100°C / s.

[0100] The heat treatment steps of GA products are as follows:

[0101] 1) Heat the steel plate to 850°C at a heating rate of 200°C / s and keep it warm for 65s;

[0102] 2) The steel strip is cooled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com