Annealing method of ultrahigh-strength hot-forming steel

A hot forming and intense heating technology, applied in the field of heat treatment of high-strength automotive steel, can solve the problems of high energy consumption and long production cycle, and achieve the effects of improving production efficiency, saving costs and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

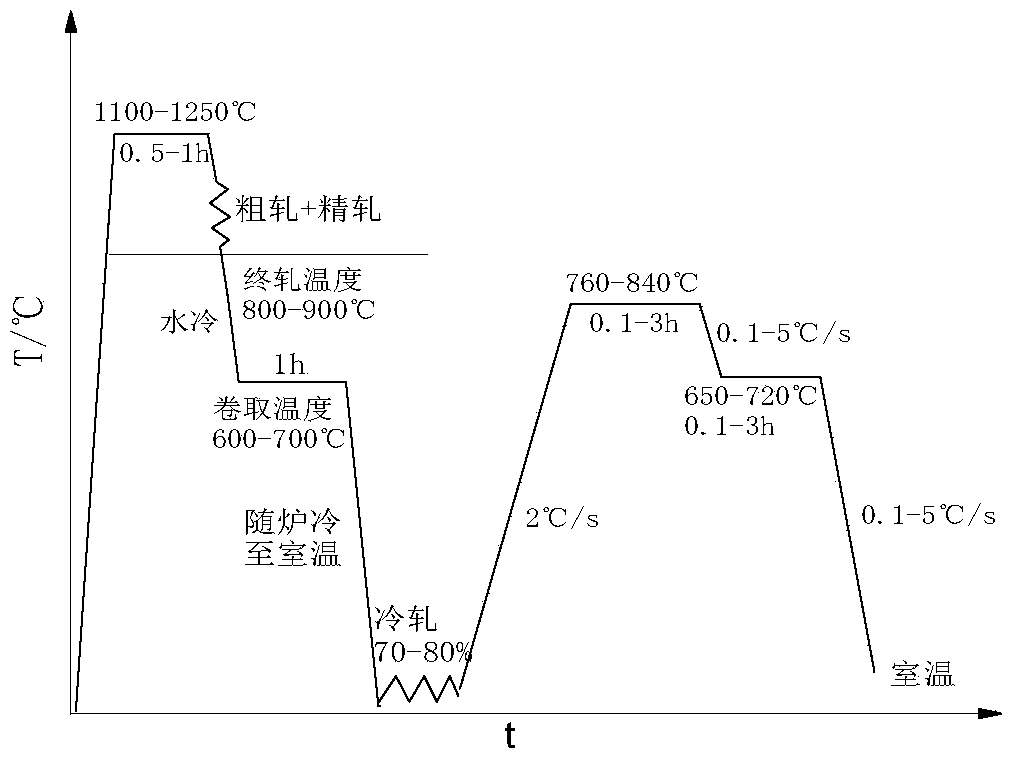

Method used

Image

Examples

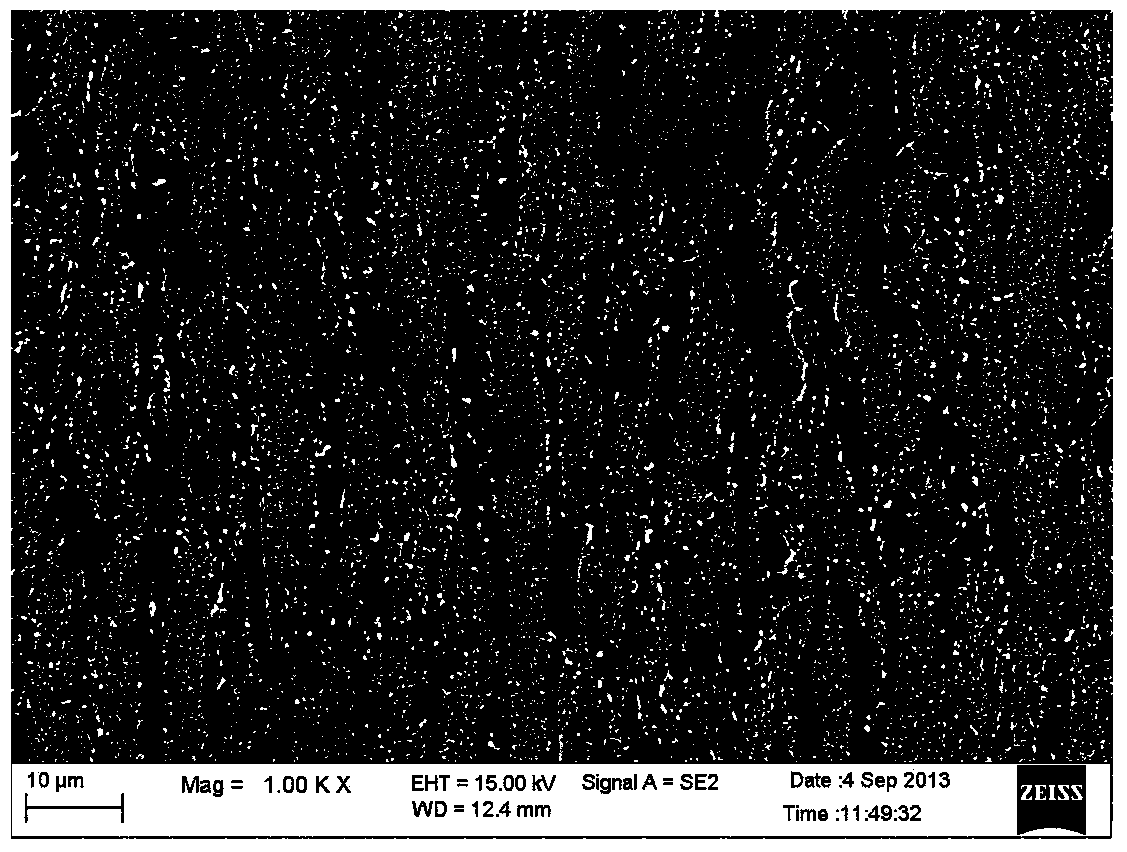

Embodiment 1

[0023] Heat the cold-rolled steel plate to 780°C, hold it for 10 minutes, then cool it to 700°C at a cooling rate of 1°C / s, hold it for 1 hour, and finally cool it to room temperature at a cooling rate of 1°C / s. The microstructure after annealing is ferrite + granular carbide, the recrystallization of ferrite is not complete, and the fiber structure of the cold-rolled state is still retained, and the distribution of granular carbide is uneven.

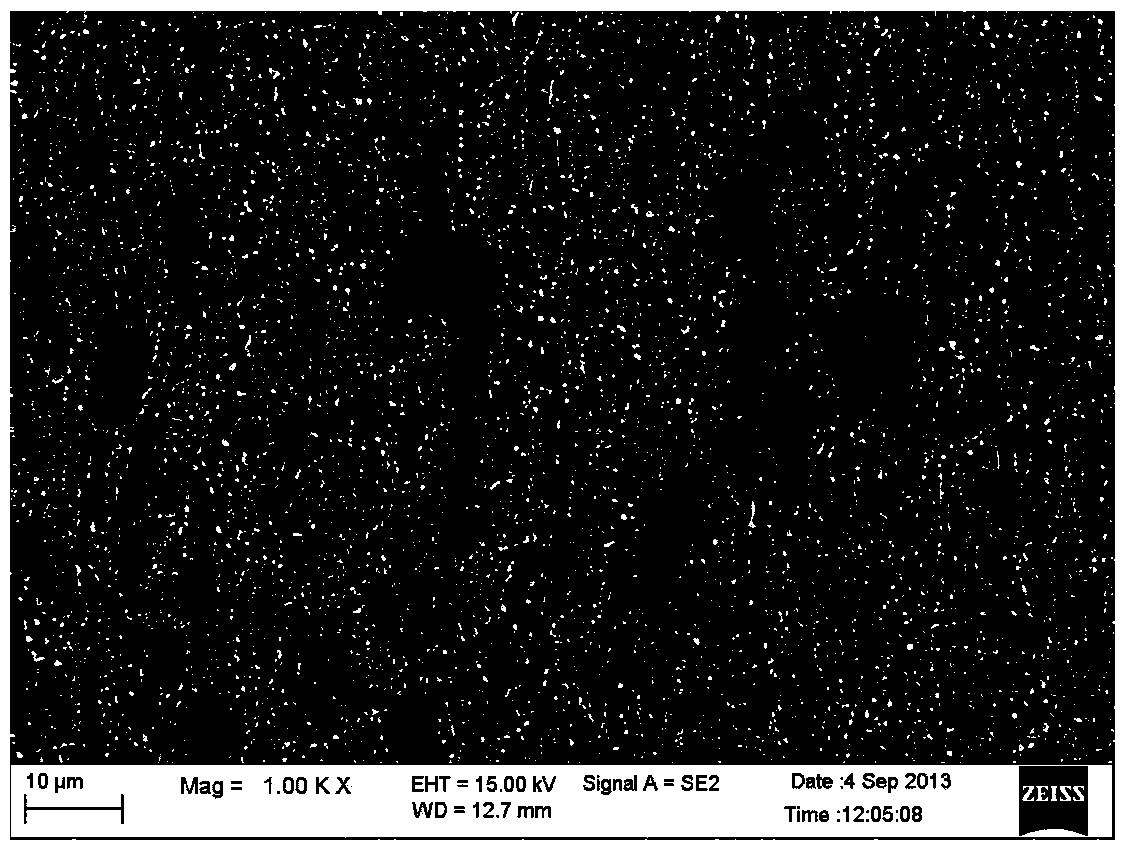

Embodiment 2

[0025] Heat the cold-rolled steel plate to 780°C, hold it for 0.5h, then cool it to 700°C at a cooling rate of 1°C / s, hold it for 1h, and finally cool it to room temperature at a cooling rate of 1°C / s. The microstructure after annealing is ferrite + granular carbide, the recrystallization of ferrite is basically completed, and the granular carbide is dispersedly distributed on the ferrite matrix. Embodiment three

Embodiment 3

[0026] Heat the cold-rolled steel plate to 780°C, hold it for 1 hour, then cool it to 700°C at a cooling rate of 1°C / s, hold it for 1 hour, and finally cool it to room temperature at a cooling rate of 1°C / s. The microstructure after annealing is ferrite + granular carbide, the recrystallization of ferrite is completed, and the granular carbide is dispersed on the ferrite matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com