GCr15 high carbon chromium bearing steel on-line rapid spheroidizing annealing technology

A high-carbon chromium bearing steel, spheroidizing annealing technology, applied in the field of steel rolling, can solve the problems of long processing time, uneven carbide particles, affecting the microstructure and performance of cold processing and heat treatment, and achieve low cost, low equipment requirements, and shortened Effect of spheroidizing annealing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

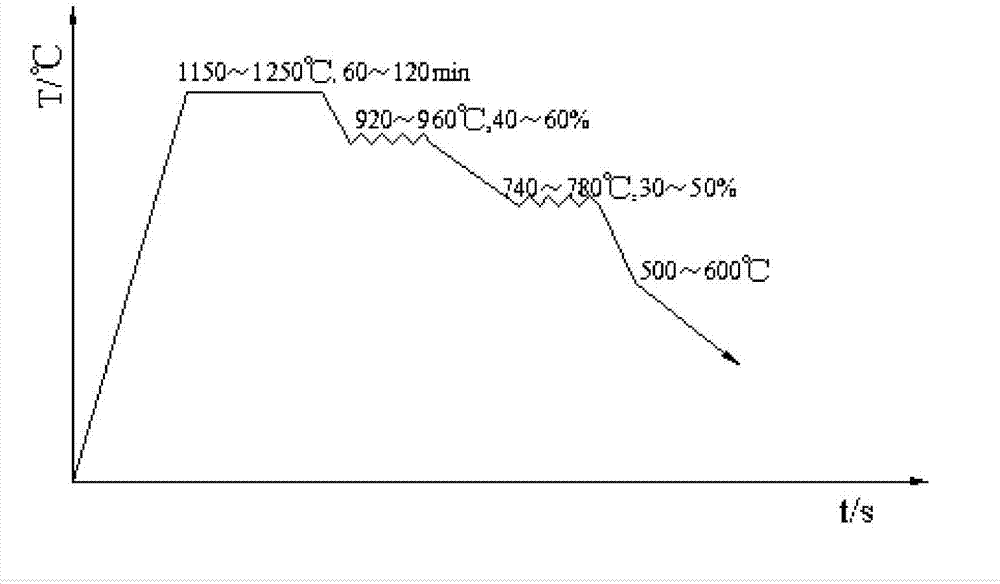

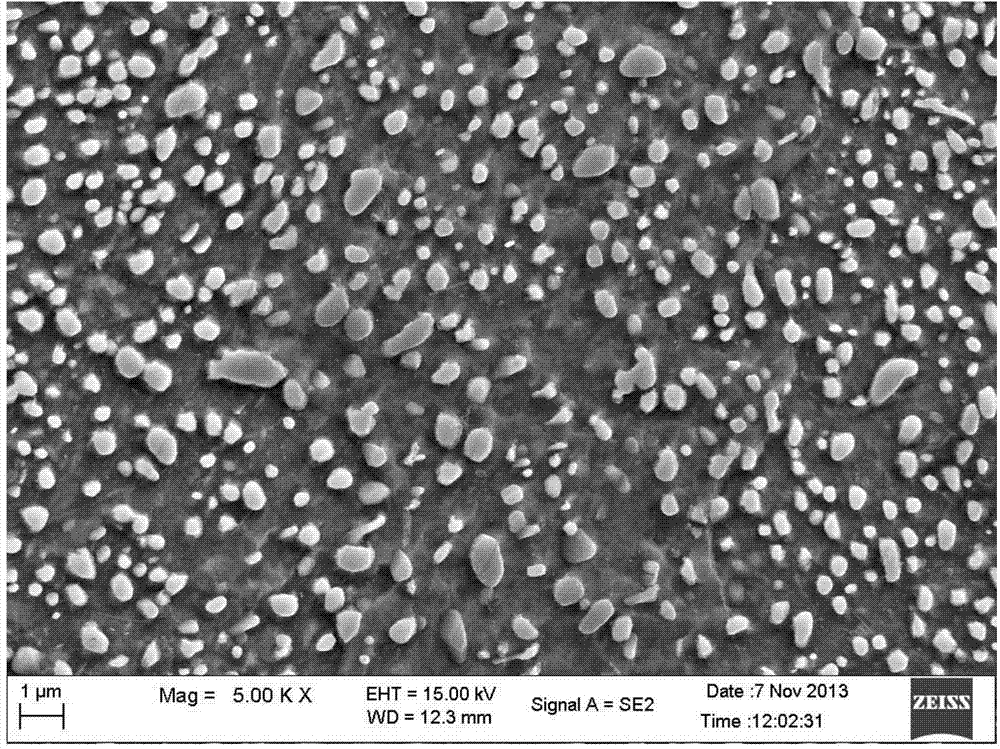

[0016] The content of the present invention will be further specifically described below through specific examples in conjunction with the accompanying drawings. Such as figure 1 An online rapid spheroidizing annealing process for GCr15 high-carbon chromium bearing steel is shown. The microstructure of the hot-rolled piece after treatment is fine and uniform spherical carbides dispersed on the ferrite matrix.

[0017] The GCr15 high-carbon chromium bearing steel is processed through an online rapid spheroidizing annealing process, which specifically includes the following steps of heating and heat preservation, two-step rapid cooling and deformation, slow cooling, and rapid cooling:

[0018] 1. Heat up and keep warm. The GCr15 high-carbon chromium bearing steel was heated up to 1170°C at a heating rate of 10°C / s, and held at this temperature for 80 minutes. GCr15 high-carbon chromium bearing steel at 1170°C for high temperature insulation can ensure the melting of carbides a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com