Gas multi-stage liquefying plant driven by acoustic resonance type thermo-acoustic engine

A thermoacoustic engine and acoustic resonance technology, which is applied in refrigeration and liquefaction, gas cycle refrigerators, refrigerators, etc., can solve problems such as the inability to realize the overall process of gas liquefaction, and achieve compact structure, good application prospects, and high energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

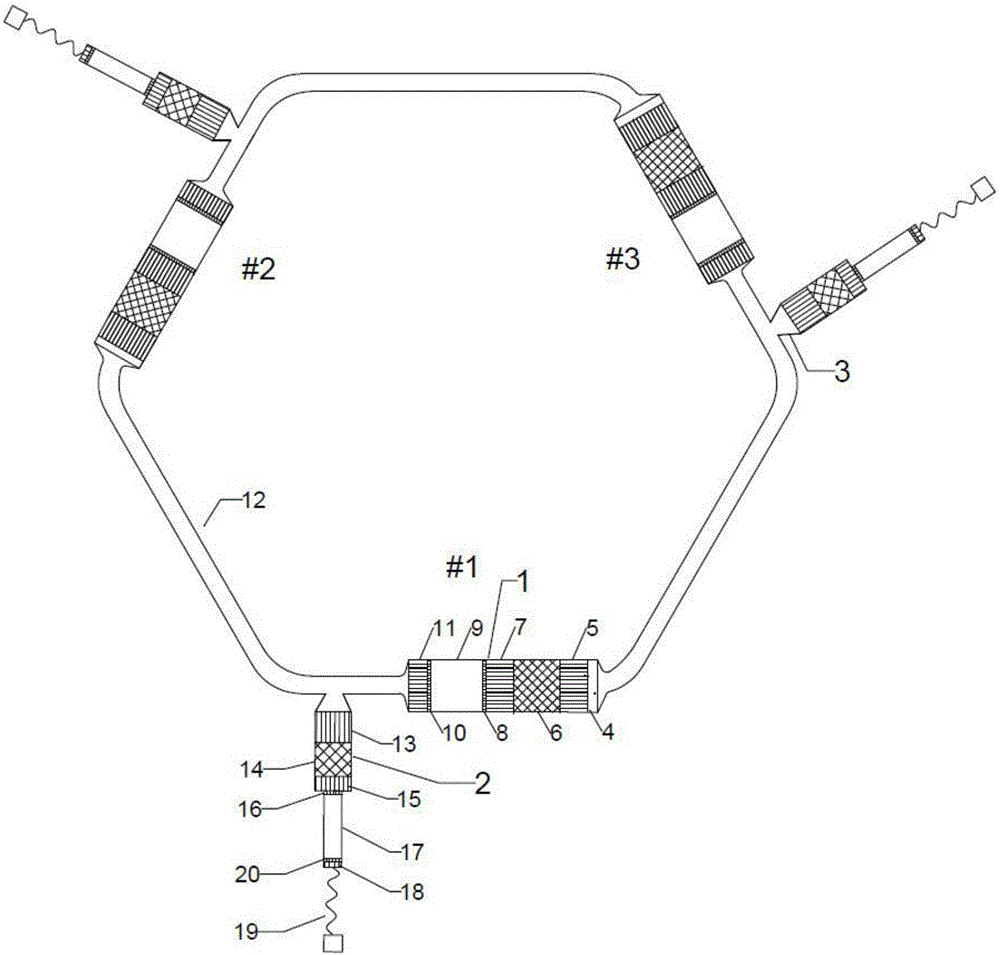

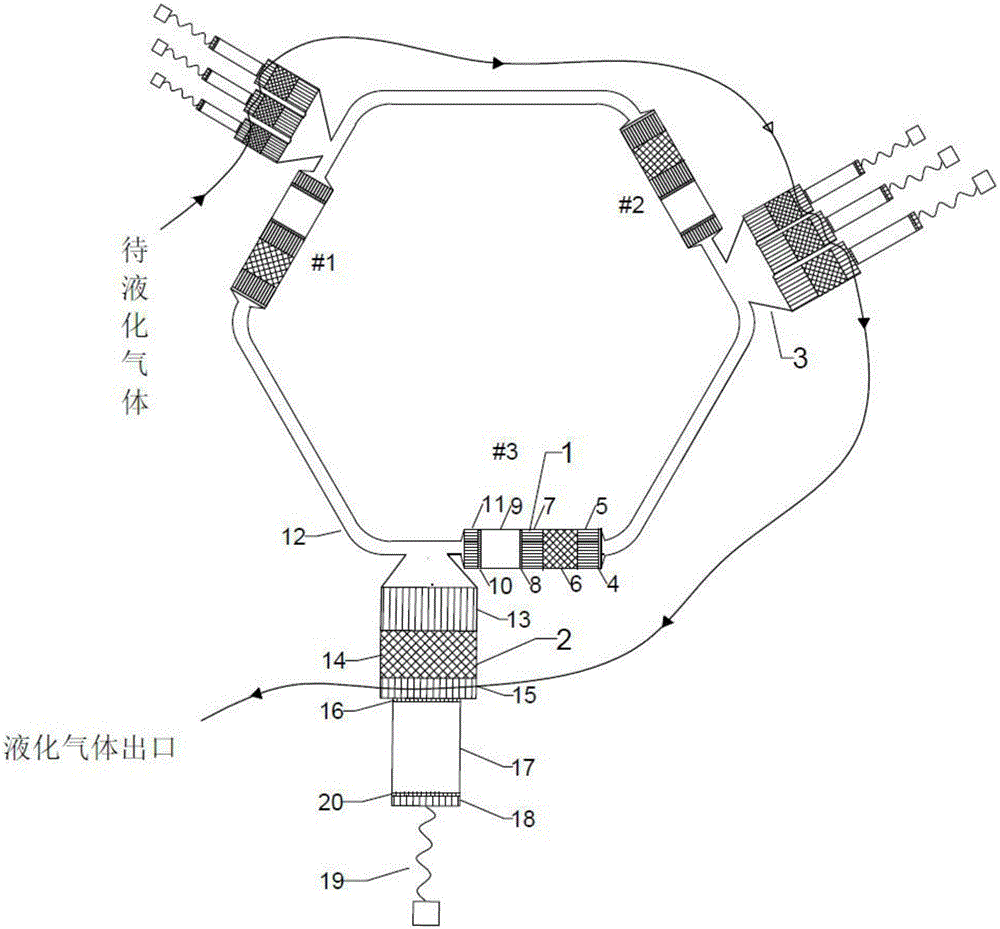

[0024] figure 2 It is a structural schematic diagram of an acoustic resonance thermoacoustic engine-driven gas multistage liquefaction device (Example 1) of the present invention. Such as figure 2 As shown, the gas multistage liquefaction device driven by acoustic resonance type thermoacoustic engine in Example 1 has 3 stages (#1 thermoacoustic engine unit, #2 thermoacoustic engine unit and #3 thermoacoustic engine unit) with heat equal in length. The acoustic engine unit 1 and the third-stage bypass 3; the thermoacoustic engine units at all levels are connected end-to-end through the resonant tube 12 to form a loop structure; each bypass 3 is connected to the pulse tube refrigerator unit 2, wherein the first stage and the first stage The second-stage bypasses are respectively connected (parallel) to three pulse tube refrigerator units 2, and the third-stage bypass is connected to one pulse-tube refrigerator unit 2, and the size (length and cross-sectional area) of each ref...

Embodiment 2

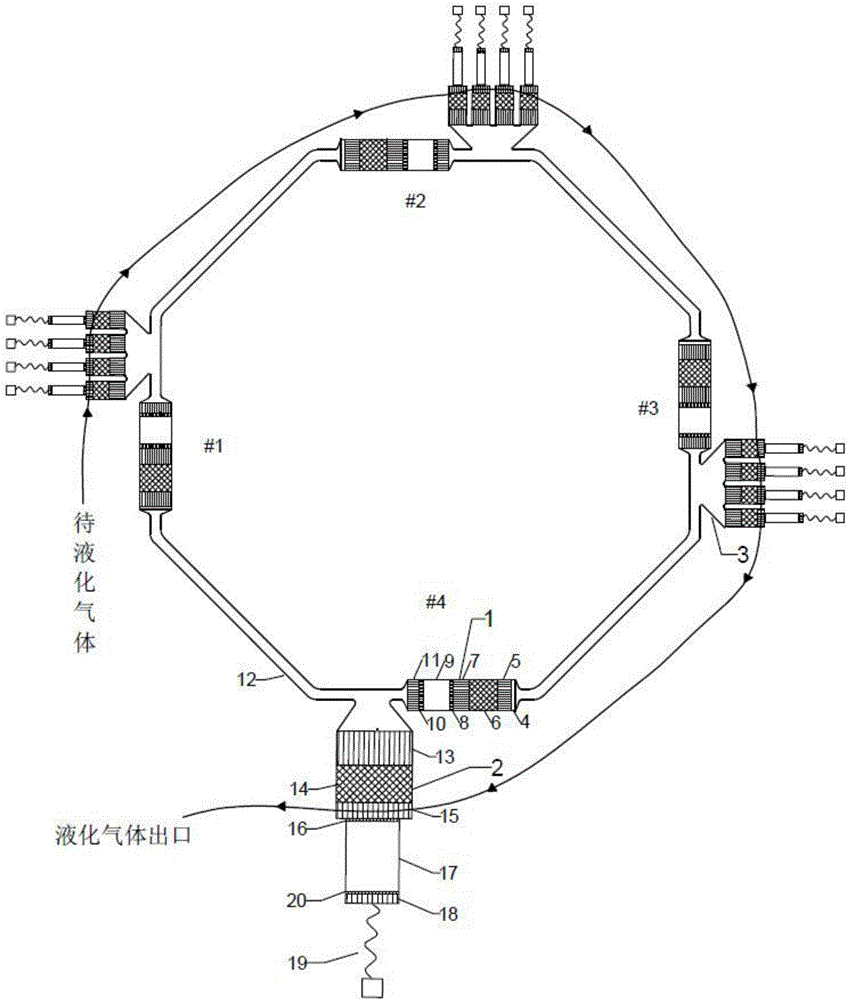

[0029] image 3 It is a structural schematic diagram of the gas multistage liquefaction device (embodiment 2) driven by an acoustic resonance type thermoacoustic engine of the present invention; image 3 As shown, the gas multistage liquefaction device of the present embodiment 2 has 4 stages (#1 thermoacoustic engine unit, #2 thermoacoustic engine unit, #3 thermoacoustic engine unit and #4 thermoacoustic engine unit) with equal dimensions (length and cross-sectional area) thermoacoustic engine unit and 4 bypasses; the thermoacoustic engine units at all levels are connected end-to-end through resonant tubes 12 of the same size to form a loop structure; each bypass 3 is connected to a pulse tube refrigerator unit 2 , wherein, except that the bypass connected to the #4 (4th stage) thermoacoustic engine unit is connected with a pulse tube refrigerator unit, the other bypasses are connected (parallel) with 4 pulse tube refrigerator units; and the size of each refrigerator unit (l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com