Preparation method for microporous membrane with structural self-regulating characteristics for membrane distillation

A membrane distillation, microporous membrane technology, applied in chemical instruments and methods, pervaporation, membrane technology, etc., can solve problems such as fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

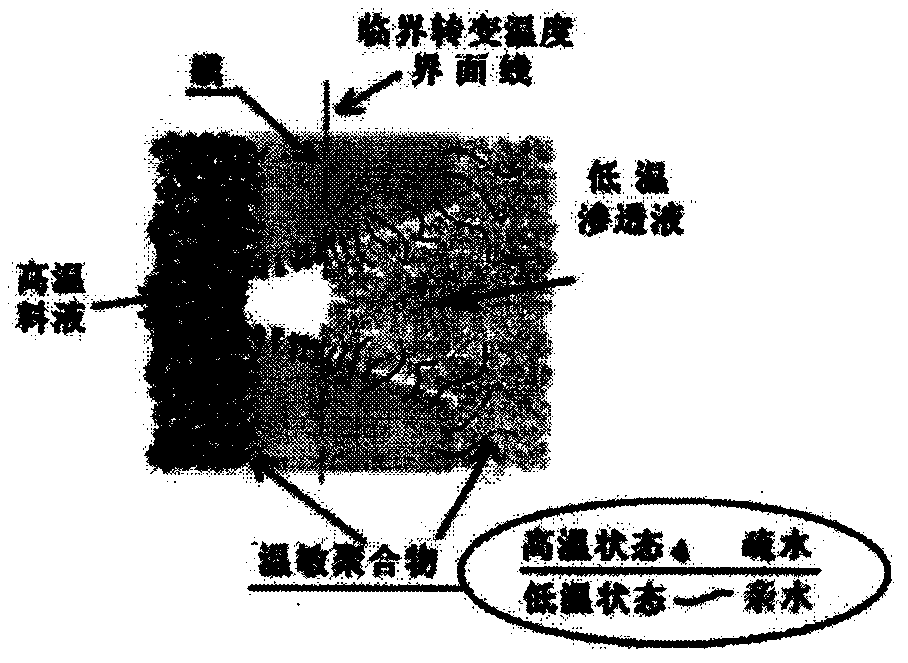

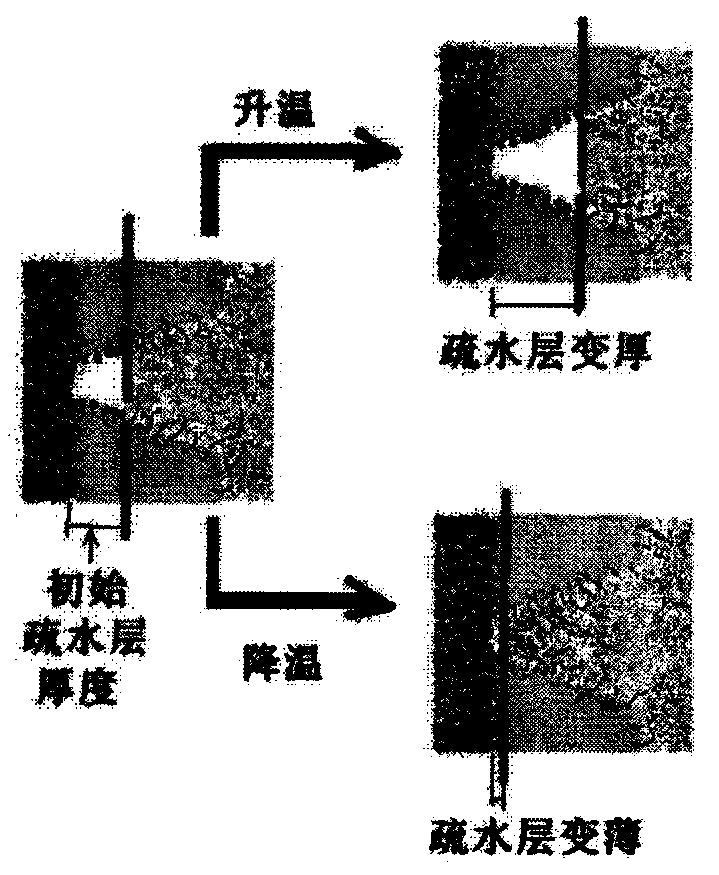

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using N-isopropylacrylamide (NIPAAM) and polyethylene glycol methacrylate (MAPEG) as monomers, copolymerize to obtain a temperature-sensitive polymer with an LCST of 45°C - Poly(NIPAAM-MAPEG). Poly(NIPAAM-MAPEG) and polyvinylidene fluoride (PVDF) are blended, PVDF is 15% by mass percentage, Poly(NIPAAM-MAPEG) is 3.5%, and caprolactam is 81.5%, configures casting liquid, mixes Poly (NIPAAM-MAPEG) and PVDF were added to the molten diluent caprolactam, stirred and dissolved at a constant temperature of 140°C for 4 hours under the protection of nitrogen, and then left for defoaming under heat preservation to obtain a homogeneous casting solution. Pour it on a glass plate, scrape it into a nascent eco-film with a film scraper, put it in water, and solidify into a film through a phase separation process combining non-solvent-induced phase separation and thermal-induced phase separation. The solvent is completely dissolved, and then freeze-dried at -50°C to obtain a dry microp...

Embodiment 2

[0026] Using NIPAAM as a monomer, polymerize to obtain a temperature-sensitive polymer material with a LCST of about 31°C——Poly(NIPAAM). Blend Poly(NIPAAM) with PVDF, PVDF is 12% by mass, Poly(NIPAAM) is 2.4%, dimethylacetamide is 70.6%, polyethylene glycol-1000 is 15%, and cast film is configured solution, Poly(NIPAAM) and PVDF, porogen polyethylene glycol-1000 were added to the solvent dimethylacetamide, stirred and dissolved at a constant temperature of 80°C for 3 hours under the protection of nitrogen, kept for heat preservation and defoaming, and a homogeneous cast film was obtained liquid. Pour it on a glass plate, scrape it with a scraper to form a nascent film, put it in water, solidify into a film through a non-solvent-induced phase separation process, replace the water to completely dissolve the solvent in the film, and then freeze it at -50°C Dried to obtain a dry microporous membrane, the measured thickness of the dry membrane is 100 μm, the average pore diameter ...

Embodiment 3

[0029] Using NIPAAM and polyethylene glycol methacrylate (MAPEG) as monomers, adjust the ratio of monomers, and copolymerize to obtain a temperature-sensitive polymer with an LCST of 55°C—Poly(NIPAAM-MAPEG). Blend Poly(NIPAAM-MAPEG) with polyvinylidene fluoride-hexafluoropropylene, the content of polyvinylidene fluoride-hexafluoropropylene is 20% by mass, Poly(NIPAAM-MAPEG) is 5%, caprolactam is 75% , configure the casting solution, add Poly(NIPAAM-MAPEG) and polyvinylidene fluoride-hexafluoropropylene into the melted diluent caprolactam, stir and dissolve at a constant temperature of 150°C for 4 hours under the protection of nitrogen, keep warm and stand for defoaming, and obtain a homogeneous Casting solution. Pour it on a glass plate, scrape it into a nascent eco-film with a film scraper, put it in water, and solidify into a film through a phase separation process combining non-solvent-induced phase separation and thermal-induced phase separation. The solvent is completely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com