Preparation method of multi-stage pore type molecular sieve membrane

A technology of molecular sieves and channels, which is applied in the field of preparation of molecular sieve membrane materials, can solve the problems affecting the compactness of molecular sieve membranes and cracks, and achieve the effects of excellent hydrophobicity, high success rate, and good permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

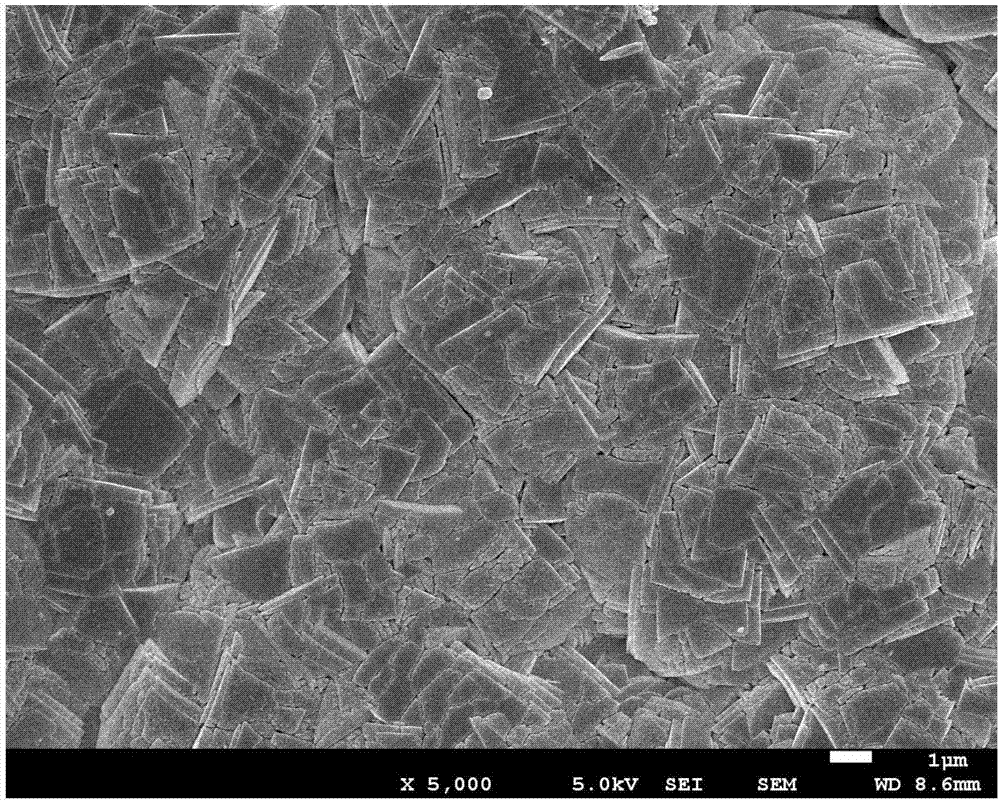

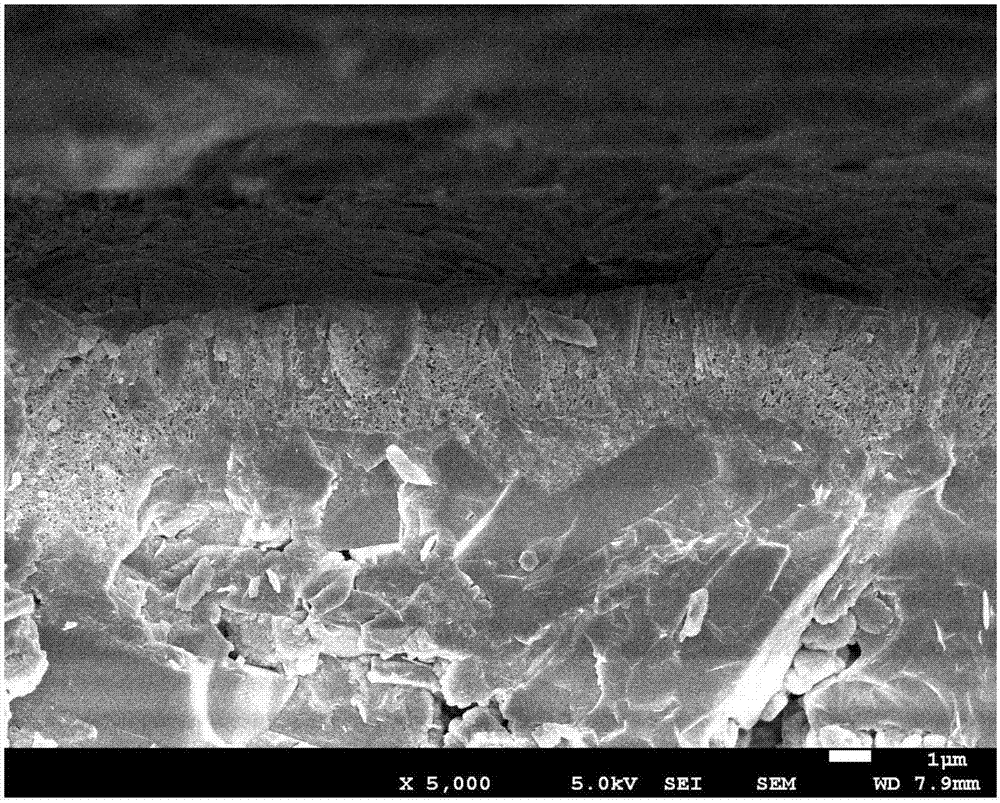

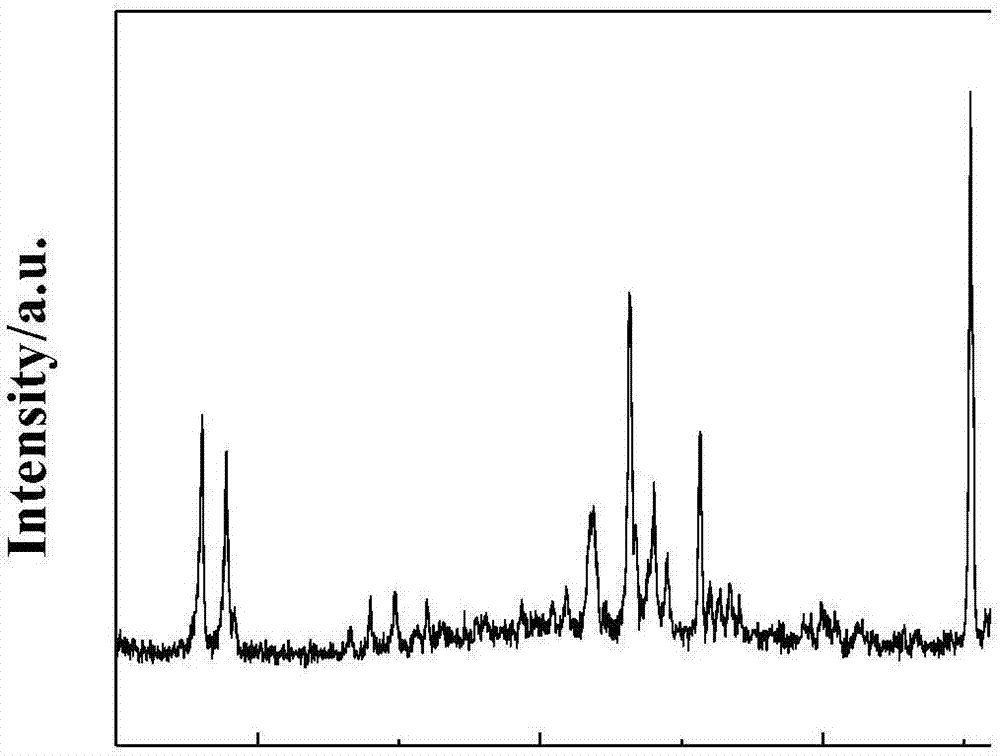

[0024] Embodiment 1: the preparation of MFI type titanium silicon molecular sieve (TS-1) type molecular sieve membrane

[0025] (1) Prepare an alkaline suspension containing molecular sieves:

[0026] Disperse 0.15g of TS-1 molecular sieve in a mixture of 0.75g of TPAOH (tetrapropylammonium hydroxide, 25wt.%) and 11.25g of ultrapure water, and ultrasonicate for 30min to obtain a molecular sieve-alkaline suspension;

[0027] (2) Erosion molecular sieve membrane:

[0028] The prepared TS-1 molecular sieve membrane is horizontally placed on the support, submerged with the molecular sieve-alkaline suspension obtained in step (1), with the membrane facing down, placed in a polytetrafluoroethylene-lined stainless steel crystallization kettle, and the The stainless steel crystallization kettle was placed in a constant temperature box, the temperature was raised to 160°C, and the constant temperature was dissolved for 48 hours; after the dissolution, the TS-1 molecular sieve membrane...

Embodiment 2

[0036] The specific steps are the same as in Example 1, except that the molecular sieve membrane used is a ZSM-5 molecular sieve membrane. In this example, the method of alkali treatment and erosion is used to obtain the multi-stage channel type ZSM-5 molecular sieve membrane.

[0037] (1) Prepare an alkaline suspension containing molecular sieves:

[0038] Disperse 0.15g of ZSM-5 molecular sieve in a mixture of 0.75g of TPAOH (tetrapropylammonium hydroxide, 25wt.%) and 10g of ultrapure water, and ultrasonicate for 30min to obtain a molecular sieve-alkaline suspension;

[0039] (2) Erosion molecular sieve membrane:

[0040] The prepared ZSM-5 molecular sieve membrane is horizontally placed on the support, submerged with the molecular sieve-alkaline suspension obtained in step (1), with the membrane facing down, placed in a stainless steel crystallization kettle lined with polytetrafluoroethylene, and the The stainless steel crystallization kettle was placed in a constant tem...

Embodiment 3

[0043] The specific steps are the same as in Example 2, except that the alkali in the molecular sieve-alkaline suspension is sodium hydroxide. Step (1), preparation of an alkaline suspension containing molecular sieves: disperse 0.50 g of ZSM-5 molecular sieves in a mixture of 1.00 g of NaOH and 15.00 g of ultrapure water, and sonicate for 30 minutes to prepare a molecular sieve-alkaline suspension. In step (2), the dissolution temperature is 120° C., and the treatment time is 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com