Air treatment equipment

An air treatment and equipment technology, applied in the field of air treatment equipment, can solve the problems of low energy efficiency and complex system structure in the air treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

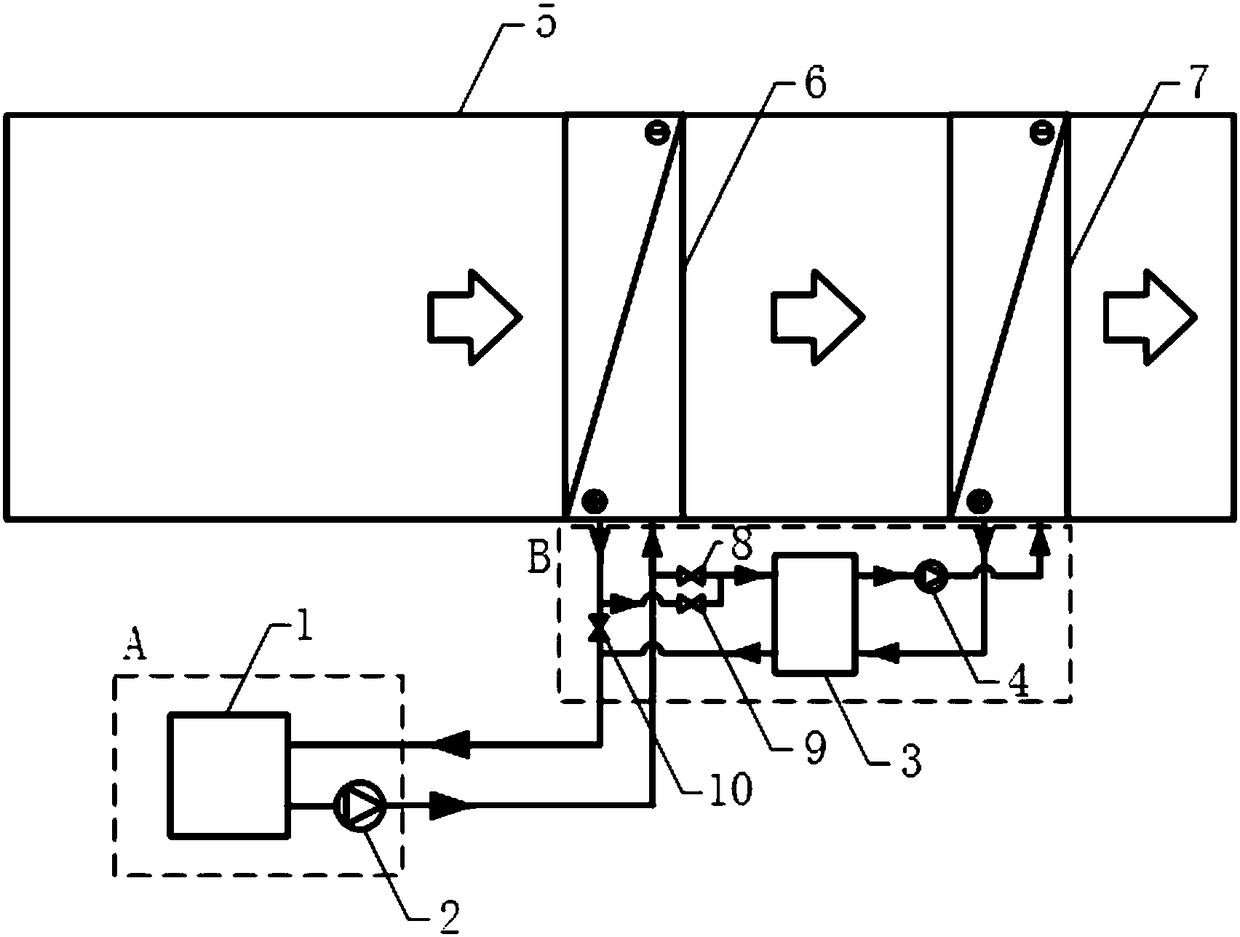

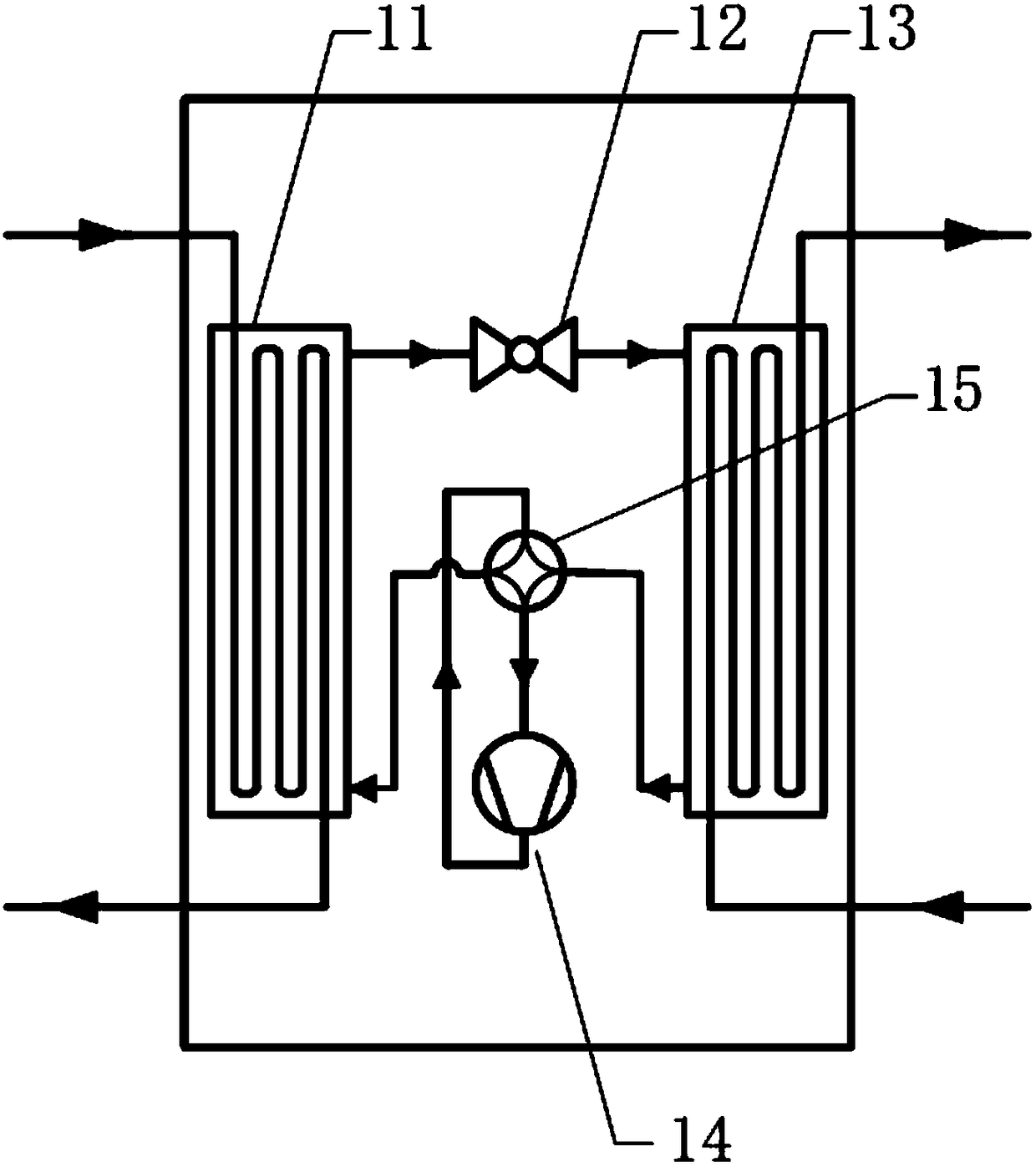

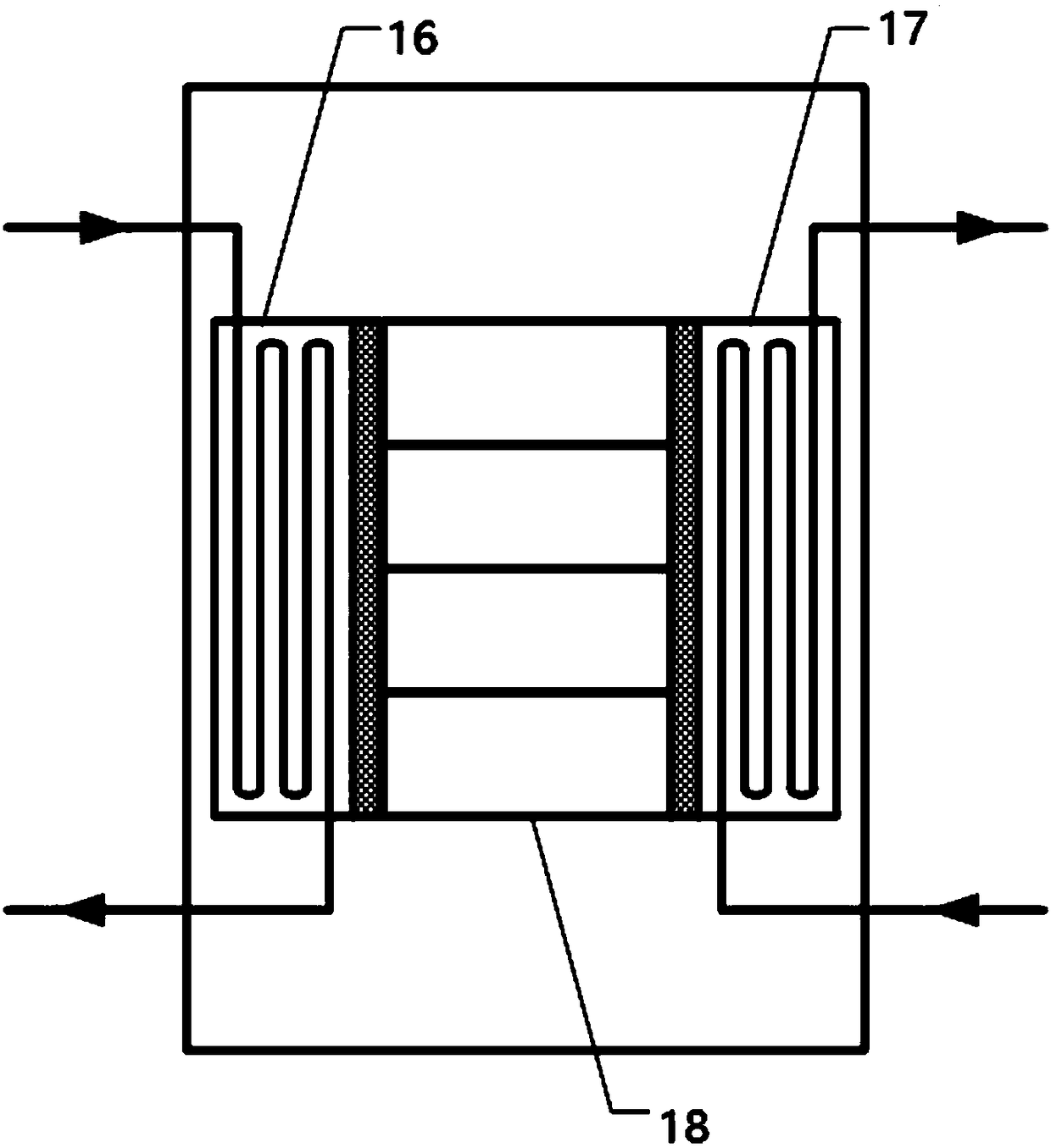

[0041] Such as figure 1 Shown is a specific implementation of an air treatment device, including an air conditioning box 5; two sets of heat exchangers that are sequentially arranged in the air conditioning box 5 as heat exchange devices, and the air passes through the air conditioning box 5 in the air conditioning box 5. The above-mentioned heat exchange device exchanges heat step by step, and the two sets of heat exchangers are respectively the first heat exchanger 6 and the second heat exchanger 7 according to the order in which the air passes through; the cold / heat source unit A outputs cold water or hot water to the outside Water-water heat pump machine 3, the first pipeline that connects the outflow port of the cold / heat source unit A with the inflow port of the first heat exchanger 6, connects the outflow port of the first heat exchanger 6 The second pipeline communicating with the inlet of the cold / heat source unit A, the third pipeline connecting the inlet of the firs...

Embodiment 2

[0051] Such as Figure 4 As shown, the difference between this embodiment and the above embodiment is that it also includes a third regulating valve 19 arranged between the outlet of the circulating water pump 4 on the sixth pipeline and the inlet of the second heat exchanger 7, and the The sixth pipeline, the eighth pipeline located in the downstream part of the third regulating valve 19 communicated with the first pipeline, the fourth regulating valve 20 located in the eighth pipeline, and the seventh The pipeline communicates with the ninth pipeline located downstream of the fifth regulating valve 10 in the second pipeline. When the water-water heat pump 3 is selected to run, the third regulating valve 19 is opened and the fourth regulating valve is closed. Valve 20; when choosing to stop running the water-water heat pump machine 3, close the first regulating valve 8, close the second regulating valve 9, close the third regulating valve 19, open the fourth regulating valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com