Piston intake two-stroke linear generating system

A technology of power generation system and linear generator, which is applied to internal combustion piston engines, electromechanical devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

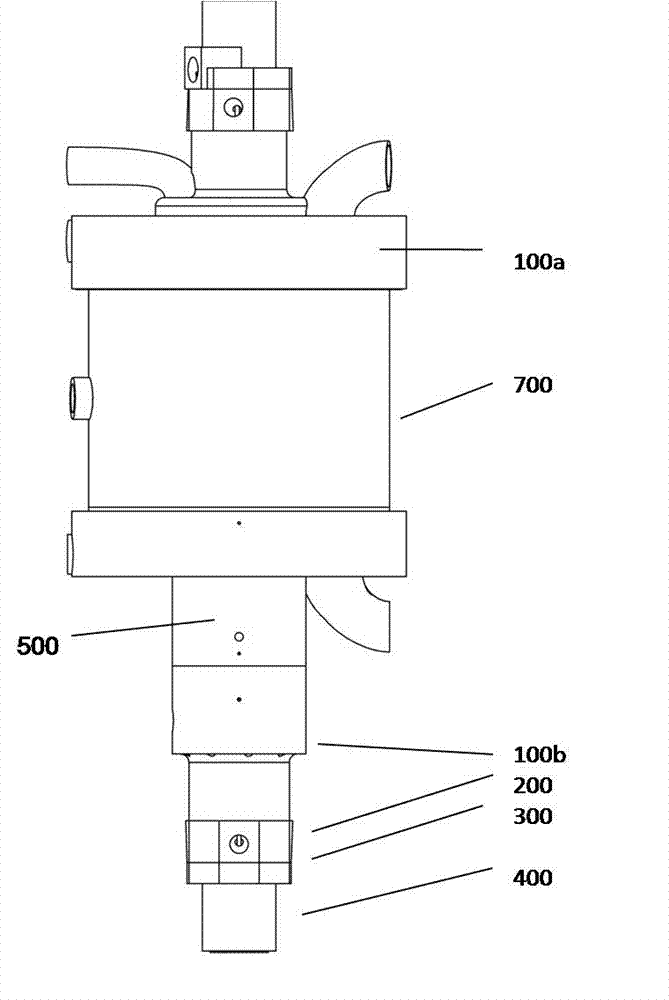

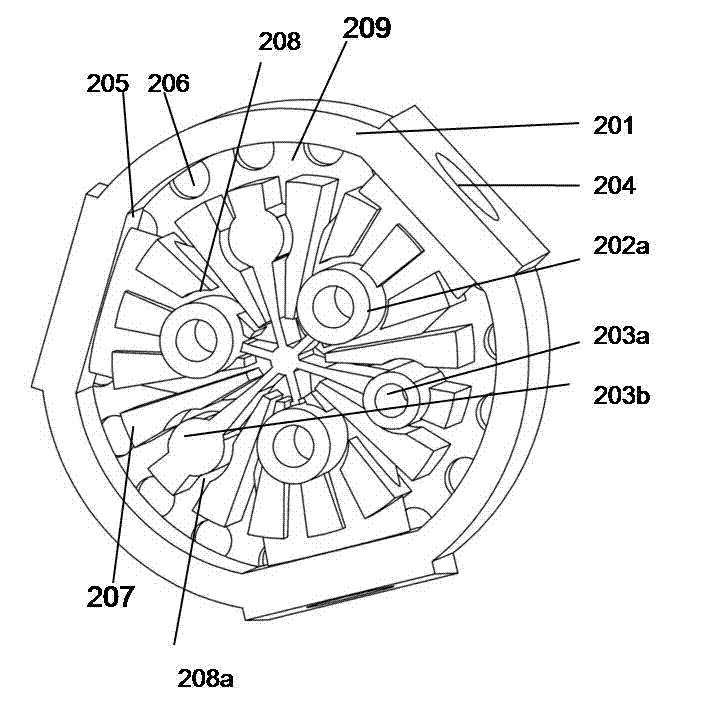

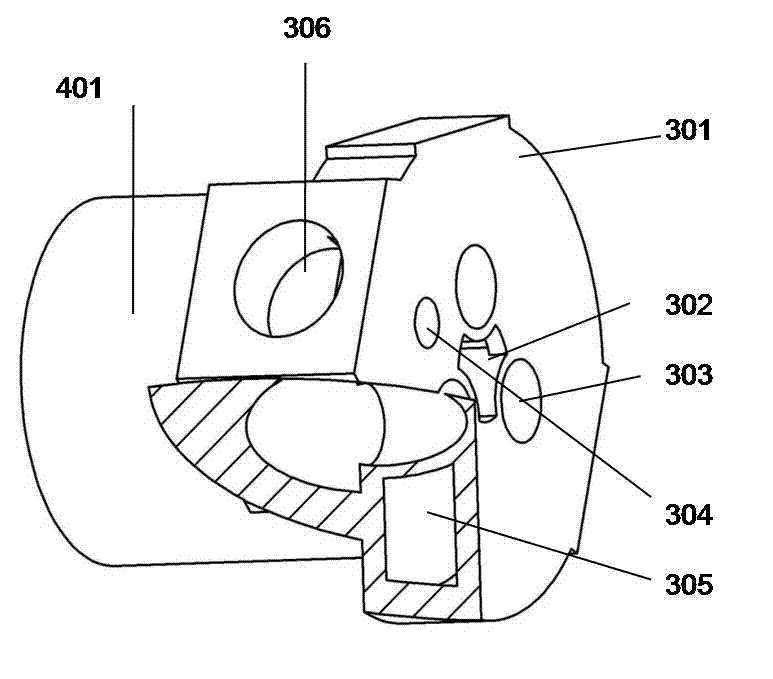

[0017] Figure 1~Figure 3 The overall structure of the linear power generation system is illustrated, the linear generator (700) is in the middle, the direct-connected motor cylinder assembly (100a), the lower cylinder head (200), the upper water channel section (300) and the valve driving section (400) are in sequence on one side, and the other On one side are the auxiliary cylinder assembly (500), the cylinder assembly with auxiliary cylinder (100b), the lower cylinder head (200), the upper water channel section (300) and the valve driving section (400); two engine pistons (800), linear motor motor The rotor (1000) and the auxiliary piston assembly (900) are fixed together with a linear hollow transmission shaft, and are coaxially slidably installed with the cylinder body assembly, auxiliary cylinder assembly, and linear motor stator. The linear motor mover (1000) is in the (700) internal axial movement, auxiliary piston assembly (900) axial movement within auxiliary cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com