Mini reforming hydrogen-preparation reactor

A technology of hydrogen production reactor and micro-reforming, which is applied in the field of hydrogen source system to achieve the effects of small pressure drop, uniform temperature distribution and uniform gas flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

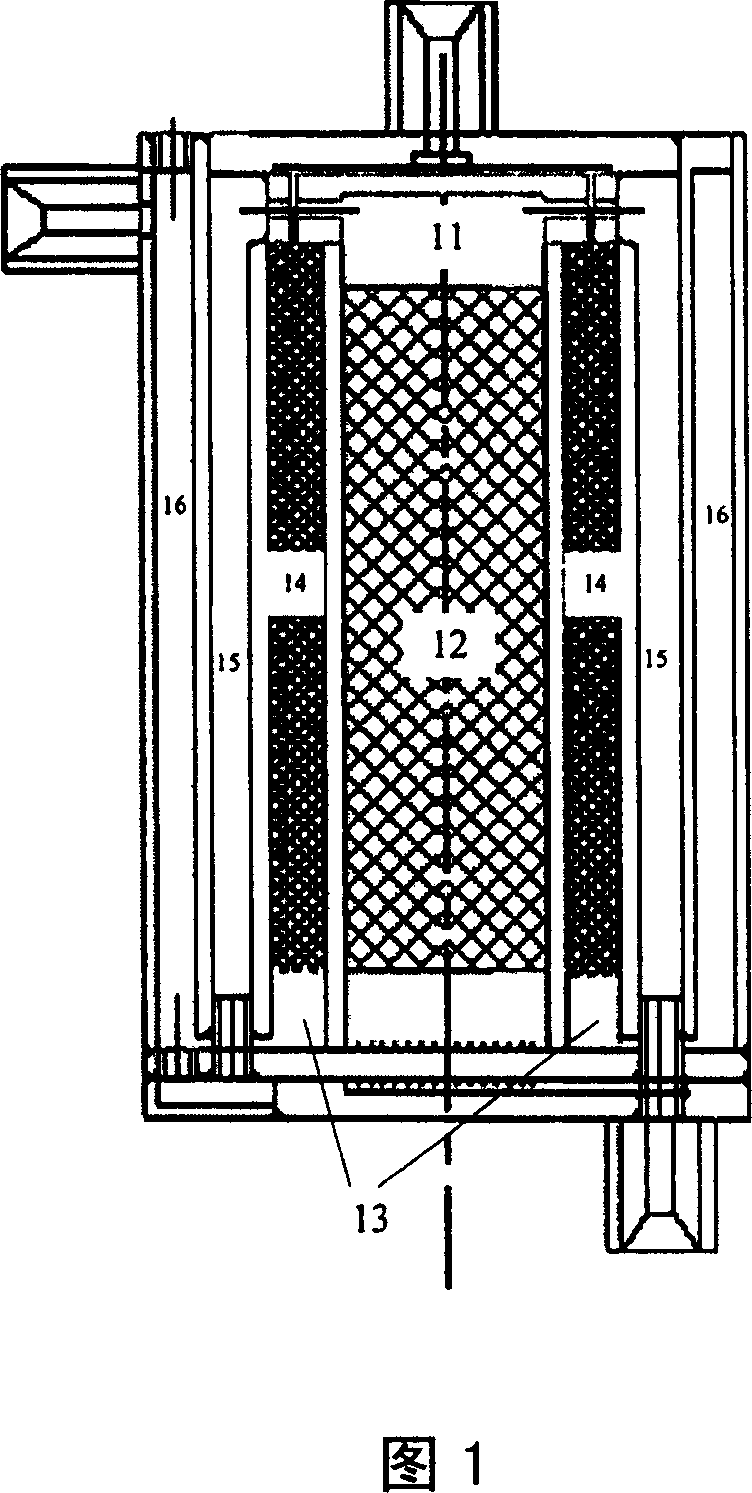

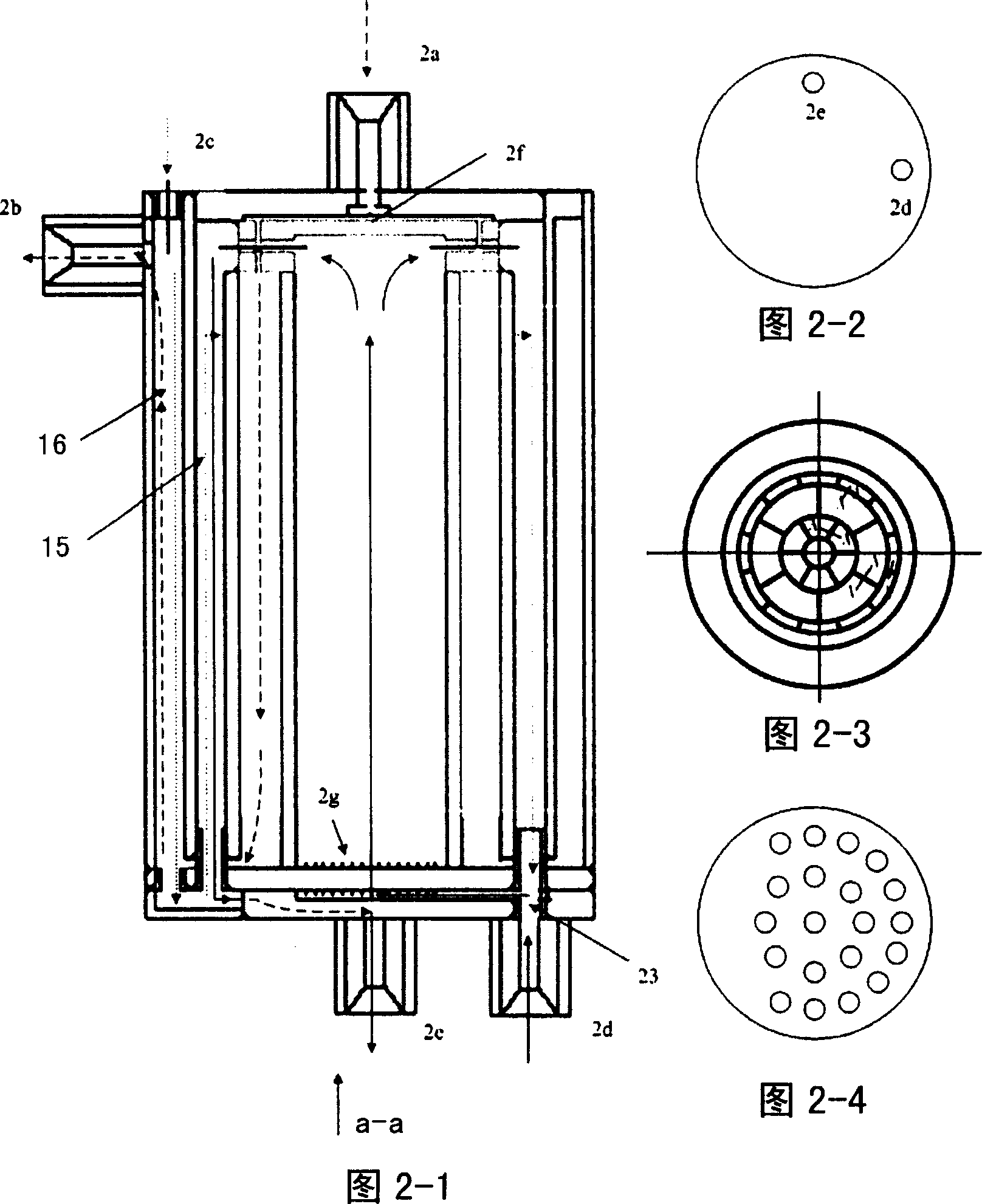

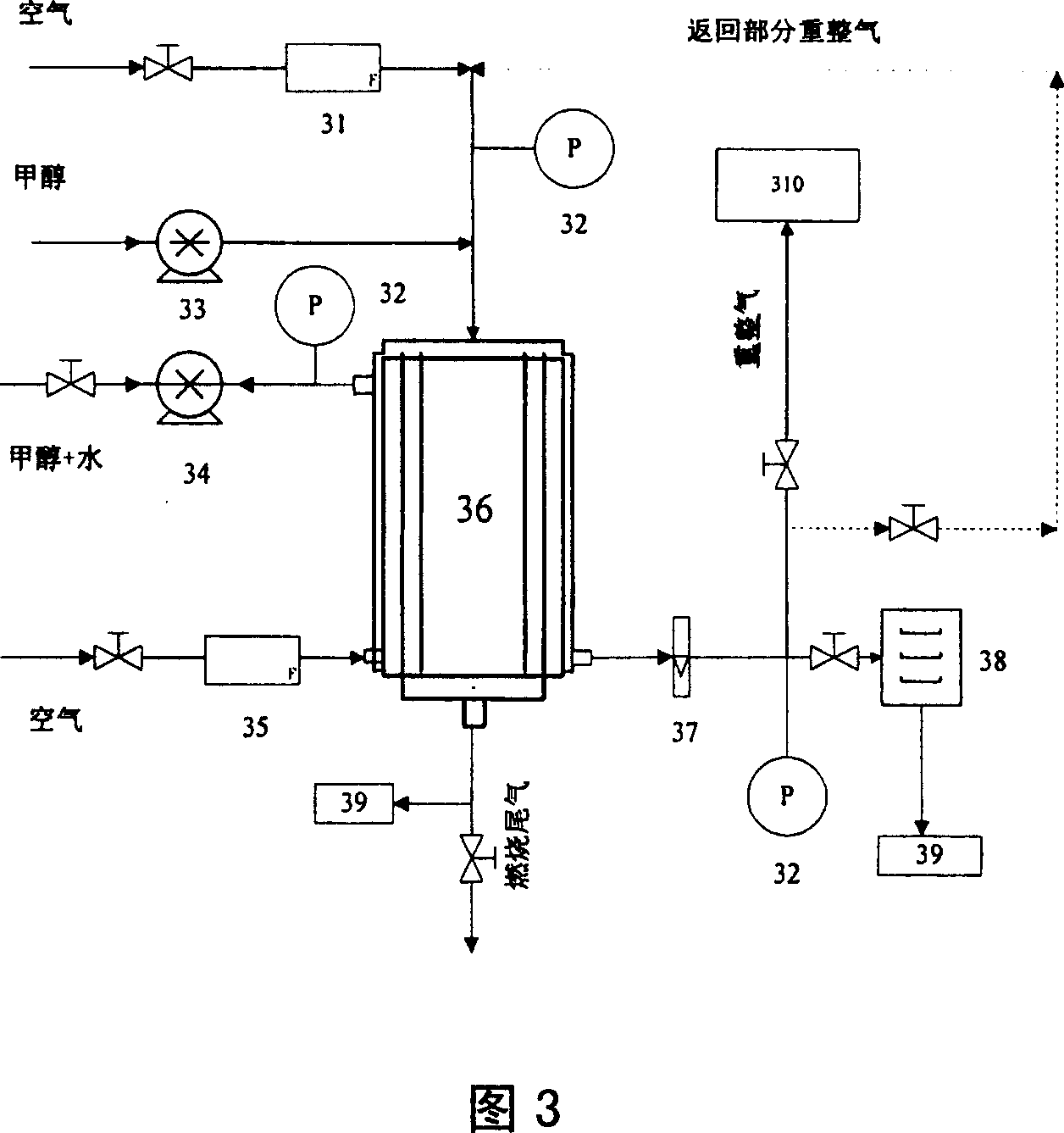

[0032] The micro-reforming hydrogen production reactor (Fig. 1) of the present invention can use natural gas, alcohols such as methanol, and hydrocarbons such as gasoline as raw materials. In order to briefly explain some situations in the actual implementation process, methanol and water are selected as raw materials to illustrate. The chemical reaction is mainly carried out in the combustion chamber and the reforming chamber, and the combustion zone mainly carries out the combustion reaction:

[0033] CH 3 Oh (g) +1.5O 2(g) →CO 2(g) +2H 2 o (g)

[0034] When the whole reaction system is running stably, the raw material of the combustion chamber can come from part of the reformed gas produced by the reforming chamber, and when integrated with the fuel cell system, use its anode tail gas as the fuel gas. Its main reaction is:

[0035] h 2 +1 / 2O 2 →H 2 o

[0036] When the present invention operates in conjunction with a fuel cell, the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com