Active coke modular bearing device, absorbing tower and flue gas purifying method

A carrier device and active coke technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of unspecified process layout, loose contact of hoppers, and large flue gas treatment capacity, etc., and achieve high utilization rate High, low airflow resistance, large flue gas treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

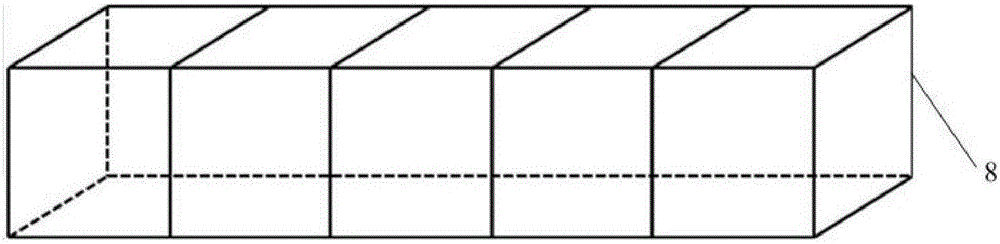

[0072] An active coke modular carrying device includes a plurality of active coke modules 8 and a transmission device.

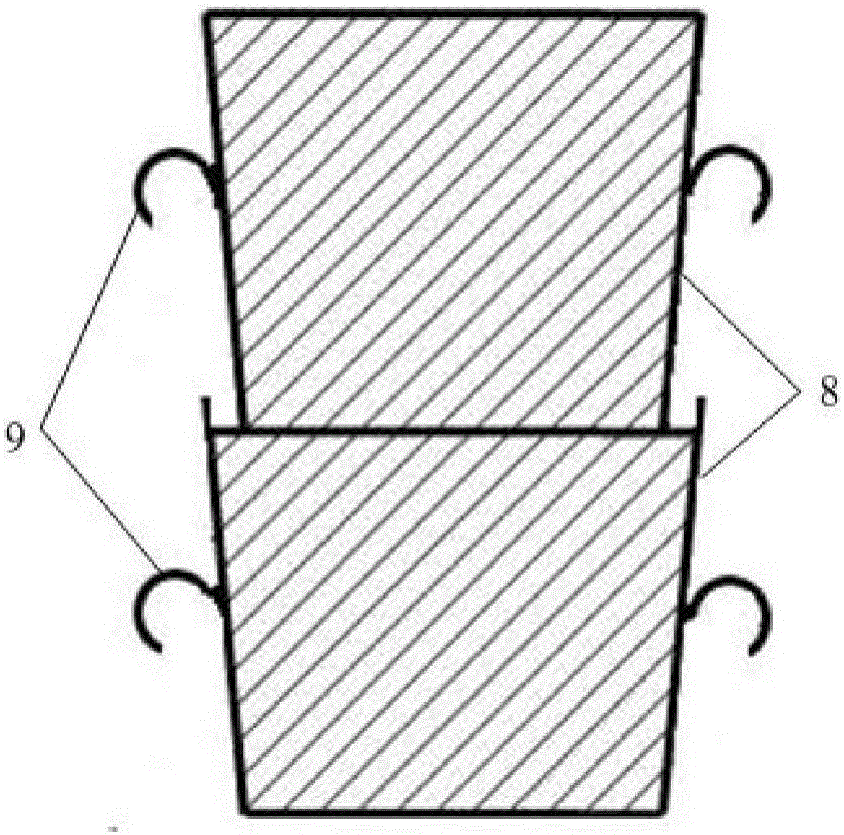

[0073] The active coke module 8 (such as figure 2 As shown) is used to place active coke, which is a mesh cube structure with reinforcing ribs on its side; its bottom width is 3-5cm smaller than the upper width, the top is open, and several partitions are arranged inside; its height and width are independently 50- 80cm, length is 80-120cm; Its both sides are provided with hook 9.

[0074] The transmission device includes a hollow channel steel, a power unit and a chain 7, and the chain 7 is placed in the hollow channel steel and connected with the power unit. The power unit is a speed-regulating motor, which is used to drive the chain 7 to move.

[0075] A plurality of active focus modules 8 are seamlessly stacked up and down (such as figure 1 Shown) after being hung on the chain 7 by hook 9, moves up and down along with chain 7.

Embodiment 2

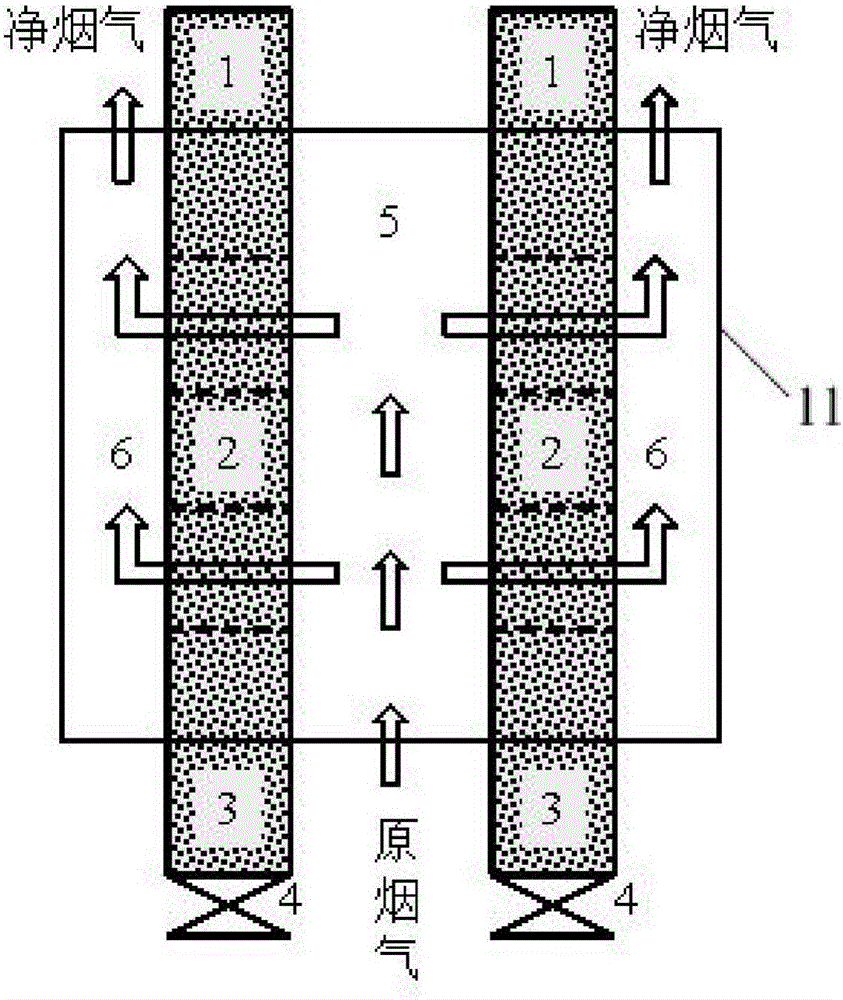

[0077] A kind of absorption tower 11, its structural diagram is as image 3 shown. The bottom of the side of the absorption tower 11 is provided with an air inlet flue, and a deflector is arranged in the air inlet flue, and an outlet flue is arranged at the top of the absorption tower 11; the inside of the absorption tower 11 is provided with an inlet chamber 5, an outlet chamber 6 and two active coke module groups 2. The active coke module group 2 is seamlessly connected to the inner wall of the absorption tower 11 through a U-shaped groove, and the length of the side wall of the U-shaped groove is 10-30cm. The active coke module group 2 includes a plurality of active coke modular carrier devices described in Embodiment 1, and the plurality of active coke modular carrier devices are stacked up and down and front and back to form the active coke module group 2 .

[0078] The inlet flue is connected to the inlet chamber 5, and the outlet flue is connected to the outlet chamber...

Embodiment 3

[0085] An absorption tower combination, which is composed of three parallel absorption towers described in Embodiment 2.

[0086] Utilize the method for purifying flue gas of above-mentioned absorption tower combination, comprise the steps:

[0087] (1) The flue gas to be purified enters the intake chamber of each parallel absorption tower through the intake flue;

[0088] (2) The active coke module moves from top to bottom in the absorption tower, and the flue gas in the air inlet chamber enters the air outlet chamber after passing through the active coke module group;

[0089] (3) The purified flue gas in the outlet chamber is discharged through the outlet flue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com