Air-cooled grading cylinder type permanent magnet eddy current descent control device

A technology of permanent magnet eddy current and slow descender, which is applied in the direction of permanent magnet clutch/brake, cooling/ventilation device, electric brake/clutch, etc. The problem of high failure rate of the device, to achieve the effect of accelerating heat dissipation efficiency, increasing stability, and reducing physical wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

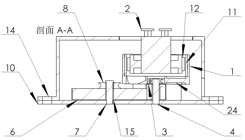

[0025] Below in conjunction with accompanying drawing, the present invention will be further described

[0026] The graded cylinder type permanent magnet eddy current slow down device of the present invention adopts the braking slow down device composed of permanent magnets and conductors to replace the traditional friction mechanism slow down device.

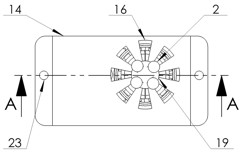

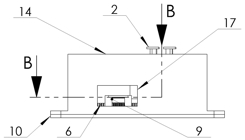

[0027] Such as figure 1 , Figure 5 As shown, a preferred embodiment of the present invention relates to a graded cylinder type coupling mechanism, the cylinder type slow descender includes a casing 14, a bottom plate 10, a graded slowing device and a speed increasing device; the casing 14 covers the bottom plate 10, the grading retarder and the speed-up device are arranged in the cavity formed by the shell body 14 and the bottom plate 10; the front of the shell 14 has a fan-shaped cooling hole 16, the top is provided with an upper air inlet hole 21, and the side is provided with a side air inlet. Hole 22.

[0028] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com