Stage regulating method of gas amount in single-screw compressor with plunger solenoid valve

A single-screw compressor, step-by-step adjustment technology, applied in the direction of rotary piston machinery, mechanical equipment, machines/engines, etc., can solve the adverse effects of power consumption and exhaust temperature increase, compressor cost increase, motor life and energy consumption and other issues to achieve high efficiency and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

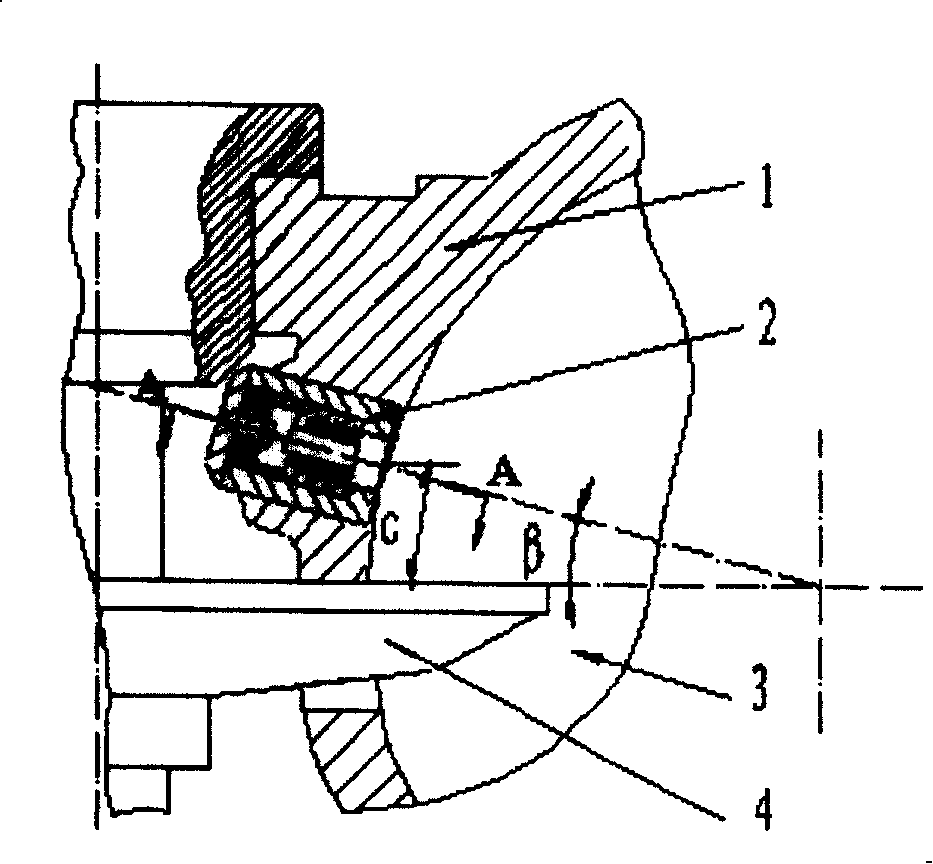

[0013] See attached picture, figure 1 The middle represents the installation position of the plunger solenoid valve 2 on the compressor body 1, and the β angle representing its circumferential position depends on the specific structure of the compressor body; the C value representing its circumference in the figure is as follows The formula (2) is determined.

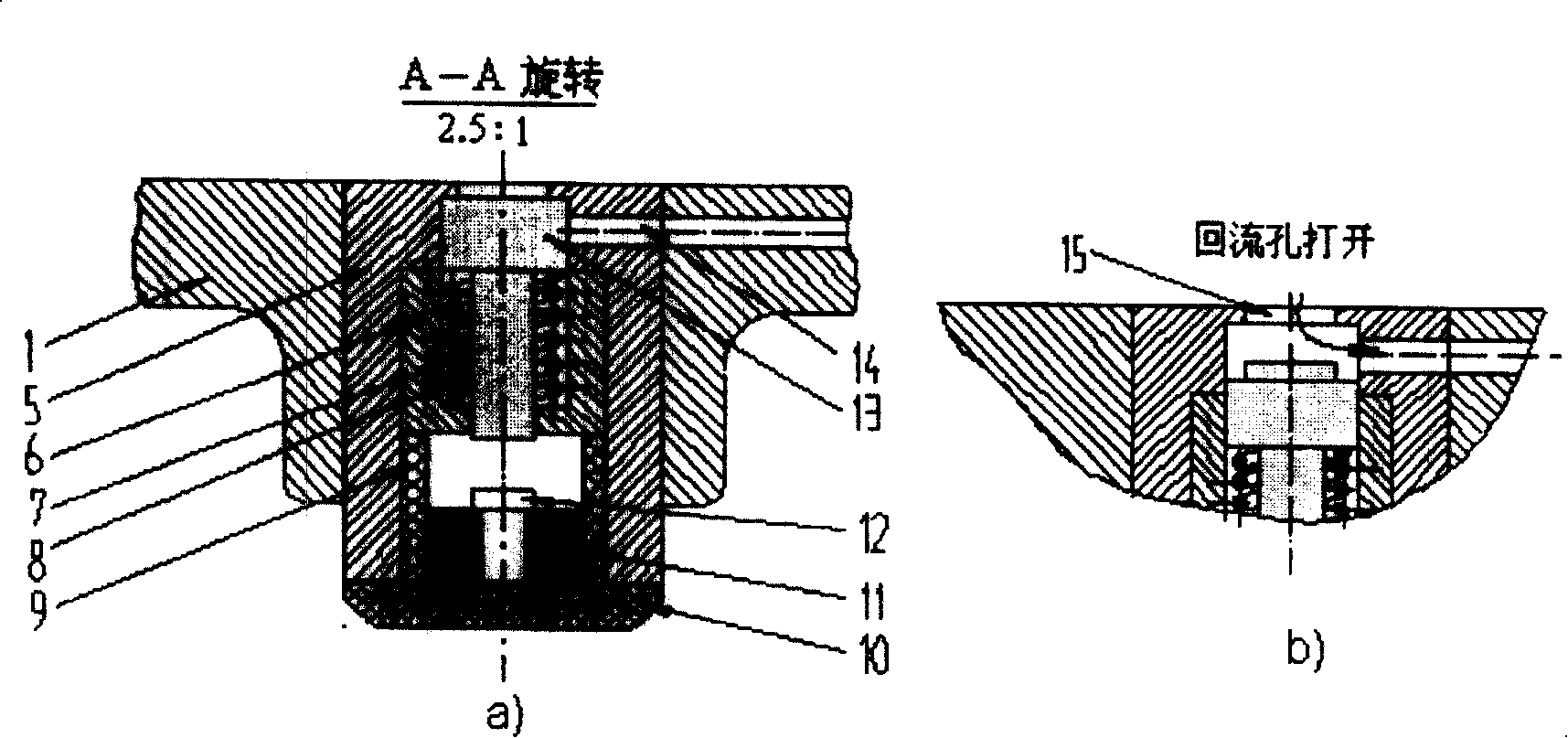

[0014] figure 2 Represent the working principle and structure of the normally closed plunger solenoid valve used in the present invention, the plunger solenoid valve 2 includes a base plate 10, the base plate 10 is connected with a housing 5 with a return passage 14, the lower part in the housing 5 There is an iron core 12, an electromagnetic coil 11 and a ferrule 9 are arranged around the iron core 12, a spring support body 6 is arranged above the ferrule 9, and a spring 8 is placed in the cavity of the spring support body 6, and an armature 7 is arranged in the middle of the spring 8, on which the armature 7 A retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com