A rotary pump for petrochemical industry

A technology of petrochemical and rotor pumps, which is applied in the direction of rotary piston pumps, pumps, rotary piston/swing piston pump components, etc., and can solve problems such as ineffective adjustment and technical solution limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

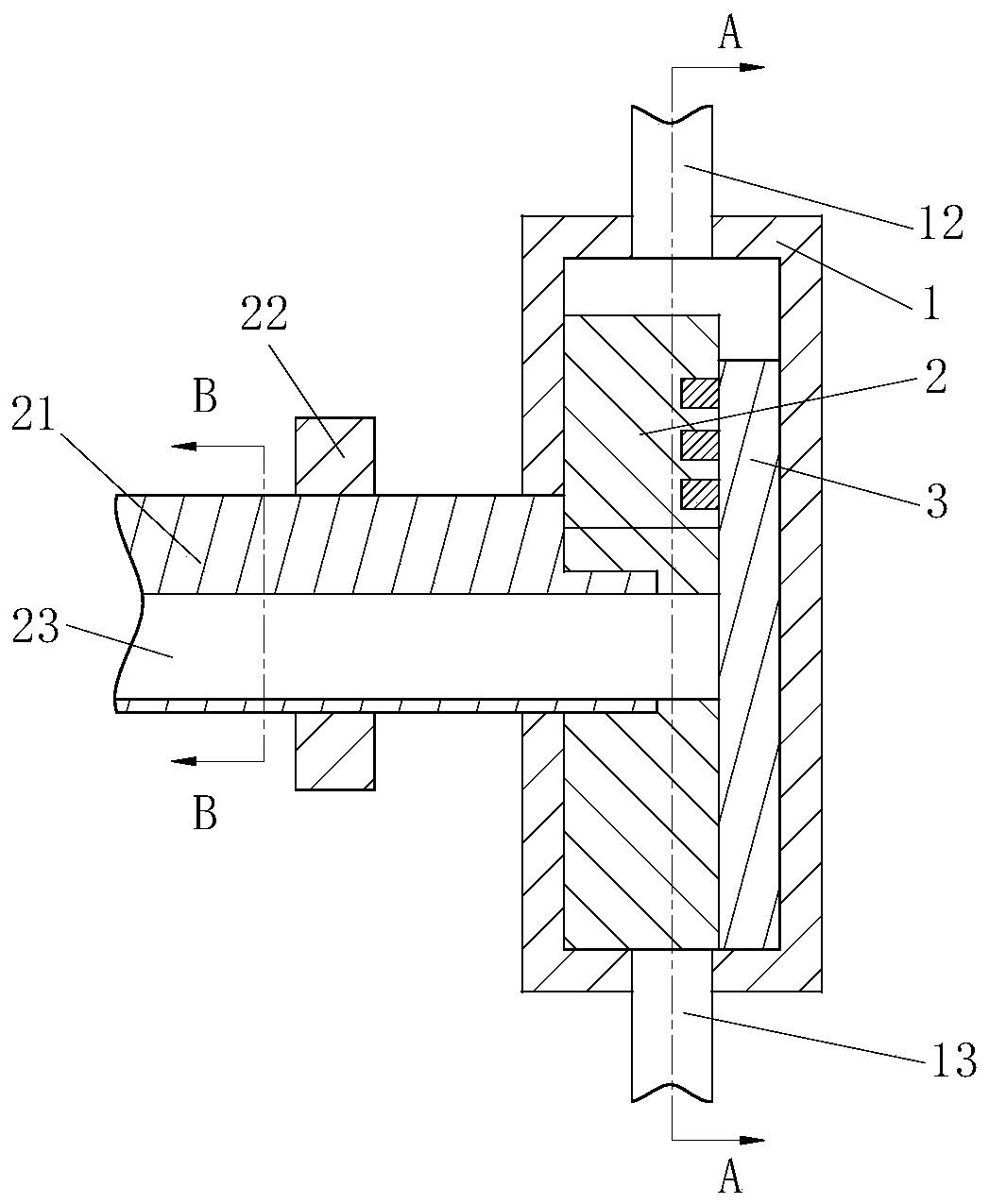

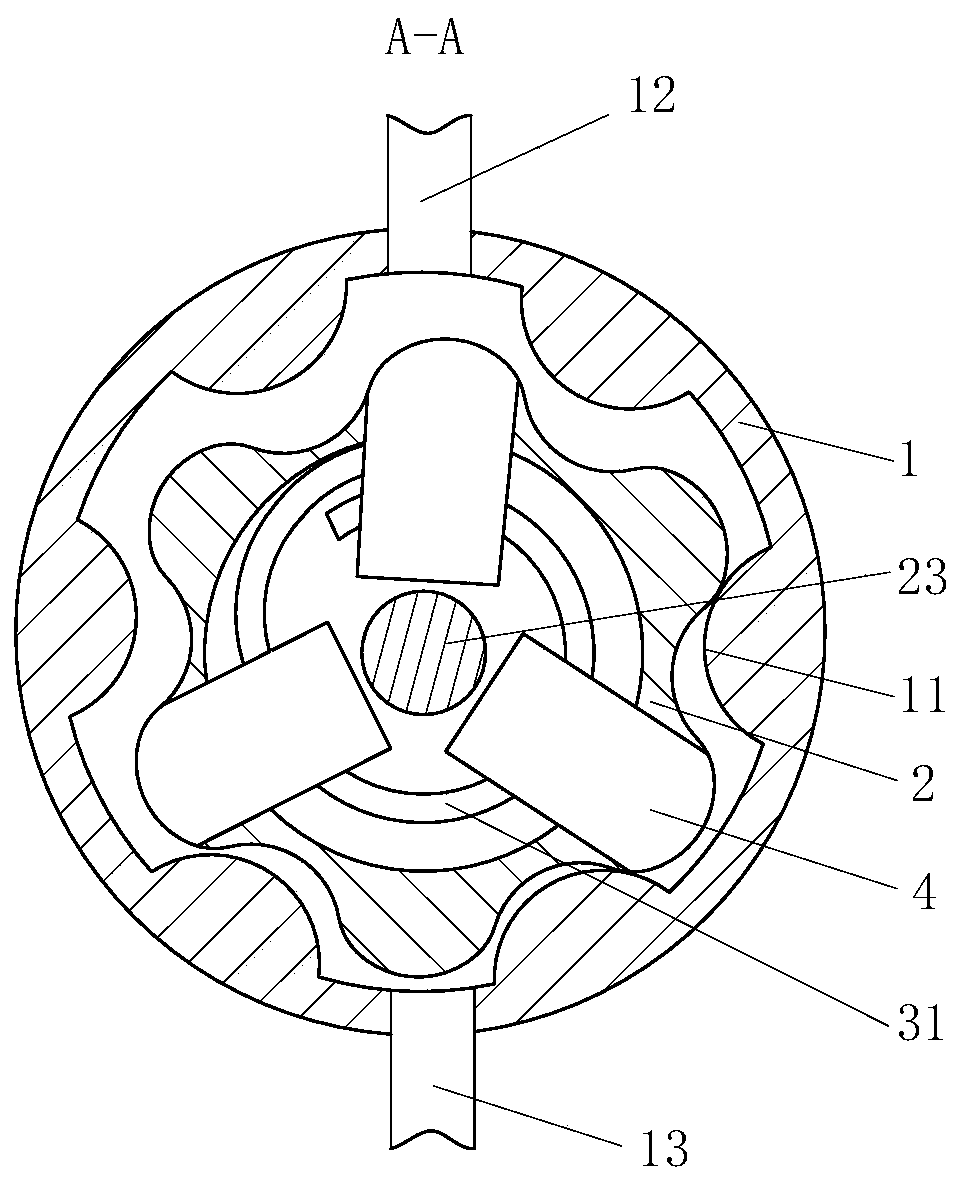

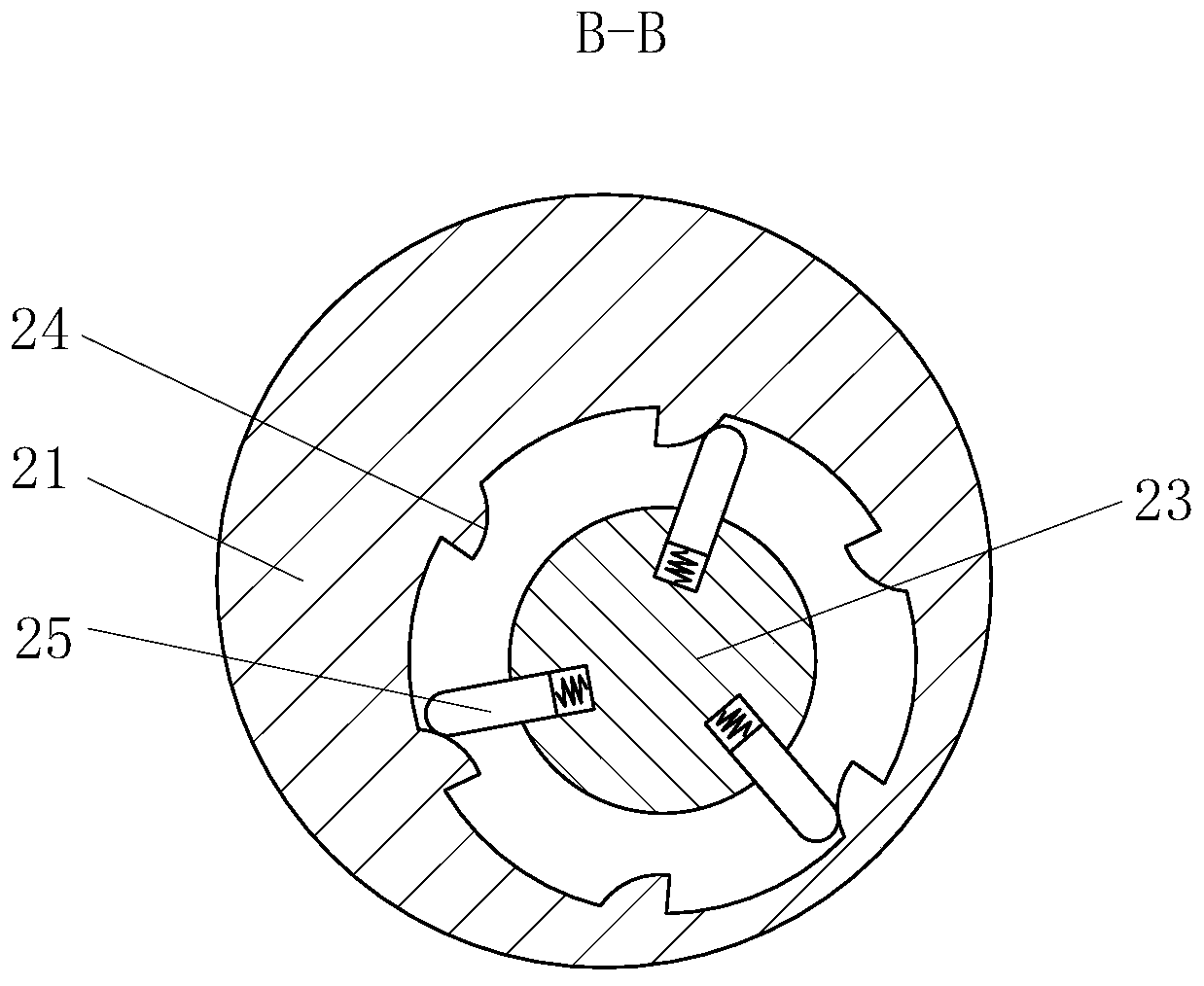

[0026] As an embodiment of the present invention, the second shaft 23 is a hollow shaft, the inner ring of the second shaft 23 is provided with a third shaft 26, and a group of guide rods 5 are arranged inside the second shaft 23; the third shaft 26 The outer ring is provided with an arc groove 27; the end of the guide rod 5 is arc-shaped, one end of the guide rod 5 is in contact with the No. 3 shaft 26, and the other end of the guide rod 5 is in contact with the No. 1 shaft 21; The shaft 26 is used for locking the second shaft 23 after the second shaft 23 adjusts the guide rod 5 . During work, rotate No. 2 shaft 23, under the drive of No. 2 shaft 23, guide rod 5 rotates, when guide rod 5 turns to certain position, rotate No. 3 shaft 26, No. 3 shaft 26 carries out to No. 2 shaft 23 lock tight.

[0027] As an embodiment of the present invention, the second shaft 23 is a hollow shaft, one end of the inner wall of the second shaft 23 is fixedly connected with the third shaft 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com