Lathe main shaft protruding edge circular disc speed changing device

A speed change device and machine tool spindle technology, which is applied in the direction of drive devices, metal processing machinery parts, metal processing equipment, etc., and can solve problems such as the need to adjust the output speed of the spindle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

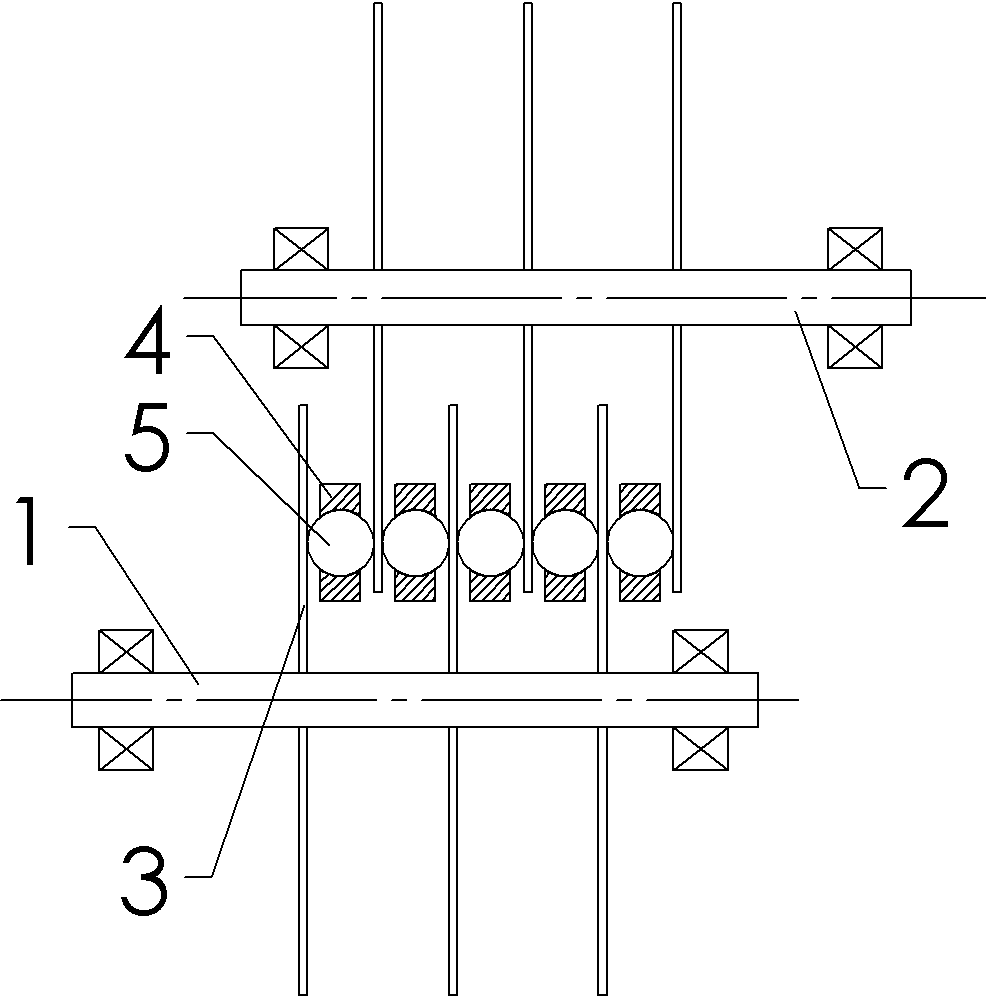

[0010] The reference numerals in the drawings of the description include: input shaft 1 , adjustment shaft 2 , driving conical disk 21 , output shaft 3 , driven flange disk 31 , belt 4 , and spring 5 .

[0011] basically as figure 1 Shown: In this embodiment, including the frame, the input shaft, the adjustment shaft and the output shaft, the input shaft, the adjustment shaft and the output shaft are all horizontally arranged in parallel, and the input shaft is connected with the pulley and the belt with the belt automatic tensioning device. The adjustment shaft is connected. Both the input shaft and the output shaft are connected to the frame through bearings. The adjustment shaft is also equipped with a rotating bearing. The rotating bearing is connected to the frame through a chute. There is also a screw to adjust the horizontal position of the rotating bearing. , to realize the radial horizontal position adjustment of the adjustment shaft. On the adjustment shaft and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com