PCD cutting drill bit and machining method with same applied

A processing method and drill bit technology, applied in the direction of stone processing equipment, stone processing tools, metal processing equipment, etc., can solve the problems of silicon carbide material damage, silicon carbide material loss, silicon carbide material collapse, etc., to achieve balanced strength, reduce Damage, reduce the effect of physical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

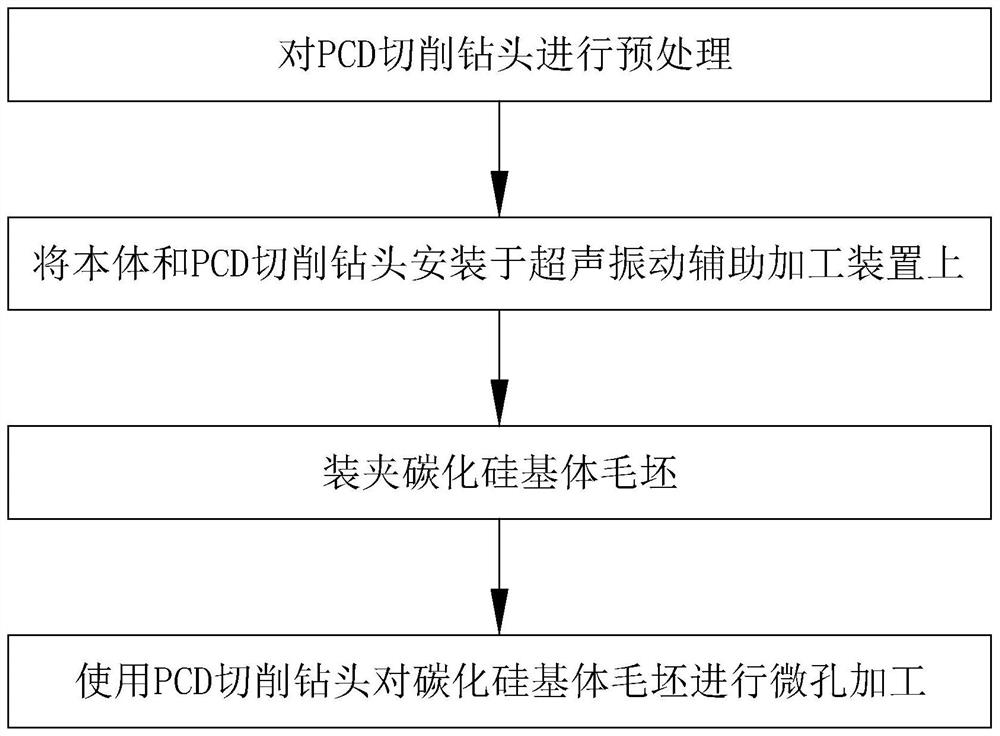

[0032] The following is attached Figure 1-3 The application is described in further detail.

[0033] The embodiment of the present application discloses a PCD cutting drill bit and a processing method using the same.

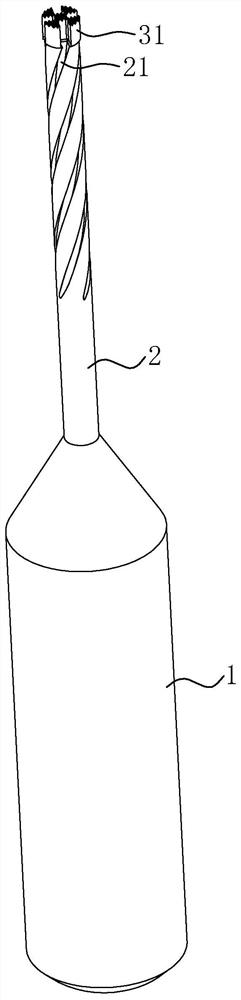

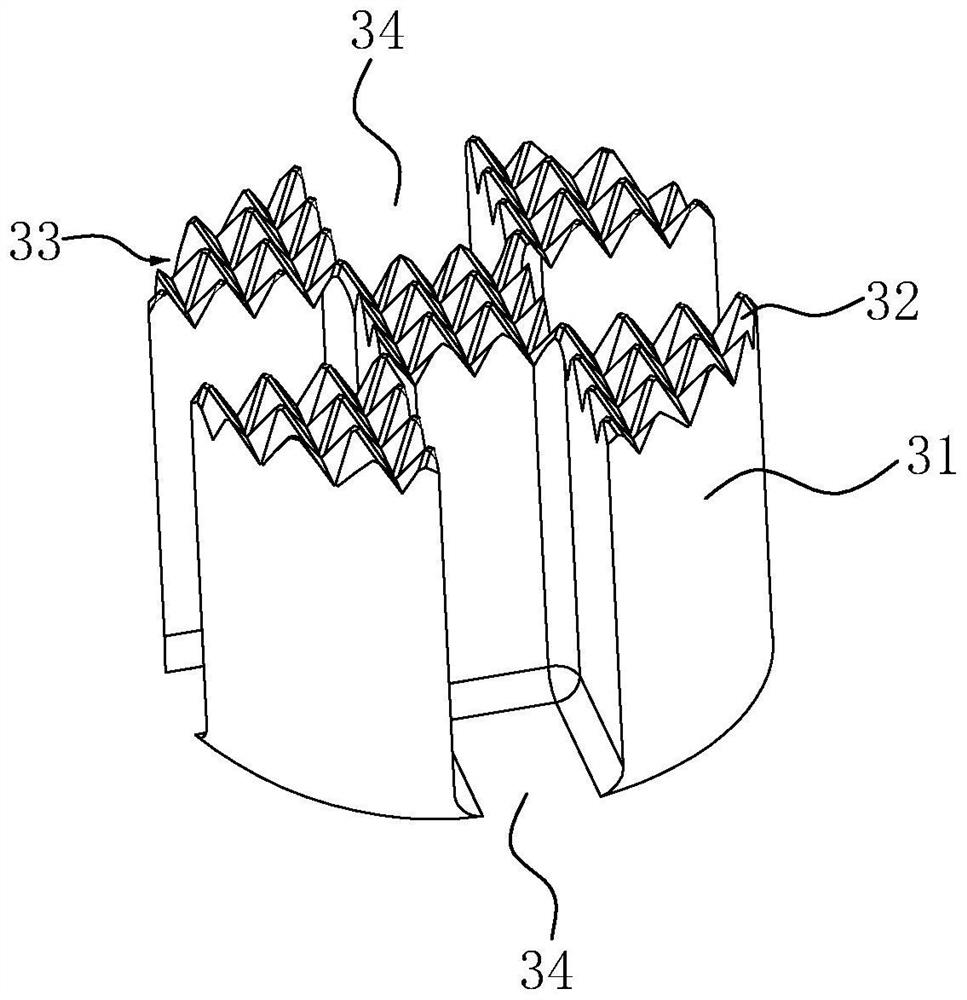

[0034] refer to figure 1 with figure 2 , a PCD cutting bit, which is fixedly connected to one end of the body 1 of the cutting tool, the PCD cutting bit includes a working part 2, one end of the working part 2 is fixedly connected to the body 1, and five cutting parts are arranged on the end surface of the other end 31, the five cutting parts 31, the working part 2 and the main body 1 are fixed by high-frequency welding.

[0035] The cutting part 31 is made of polycrystalline diamond, and the main body 1 is made of cemented carbide.

[0036] Four working chip removal grooves 21 are opened on the outer wall of the working part 2, and the four working chip removal grooves 21 are arranged obliquely.

[0037] A cutting portion 31 is positioned at the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com