Homogeneity improving method and device for hydride gaseous epitaxially groven GaN material

A hydride gas phase, uniform technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as not meeting the needs of practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

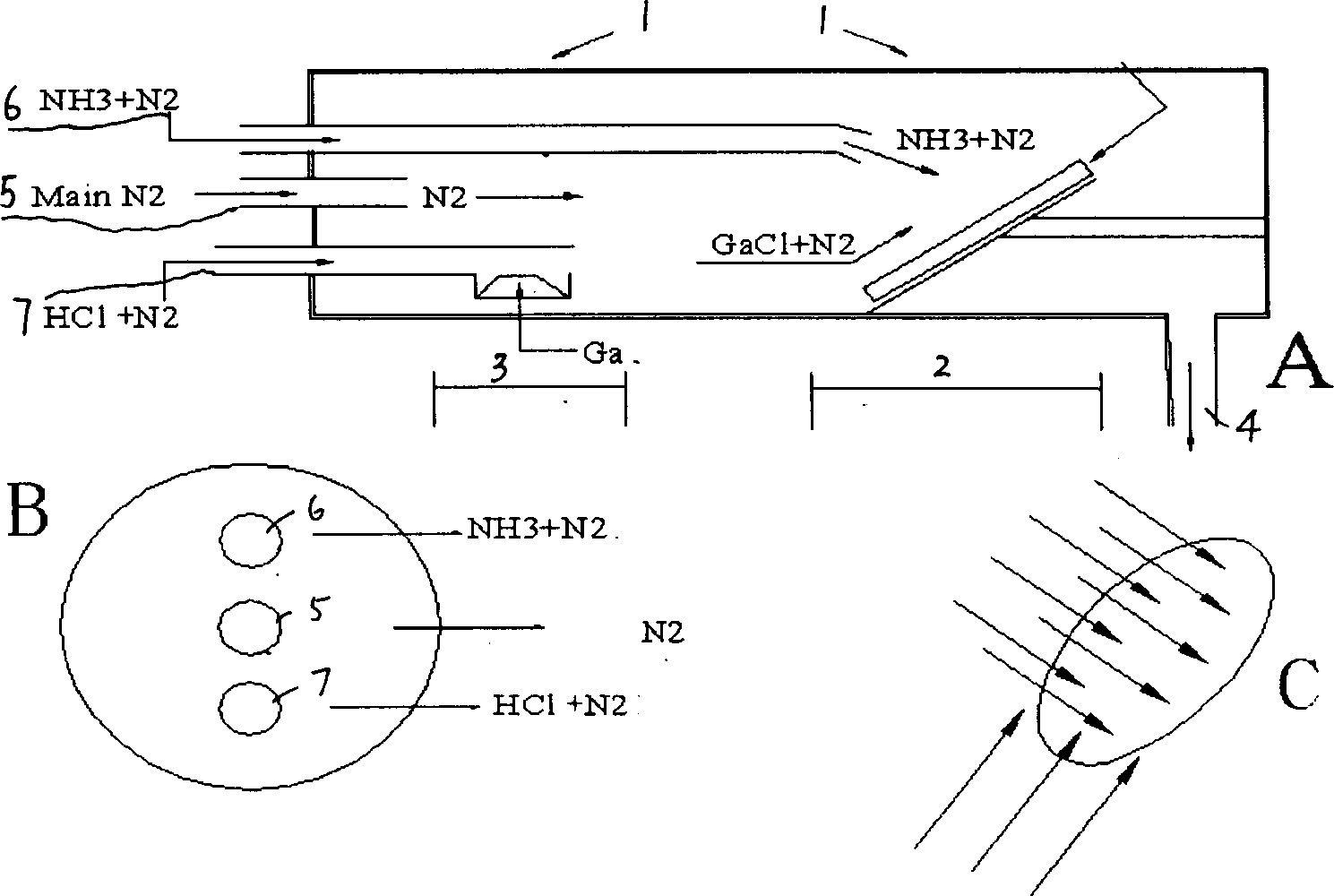

[0013] figure 1 Due to the limitations of the diameter of the gas path and the inner diameter of the electric furnace, the size of the obtained film material and the uniformity of the film are limited. The effective area of the GaN thin film is approximately 2 cm x 1.5 cm in a nearly elliptical area, while the effective area with a uniform thickness is only in a 1 cm x 1 cm near circular area. The dual-temperature-zone resistance furnace 1 has a high-temperature deposition zone 2, a low-temperature zone 3, a vent pipe 4, and a N 2 Pipeline 5 and NH 3 Pipeline 6, HCl-N with metal gallium source 2 pipeline7.

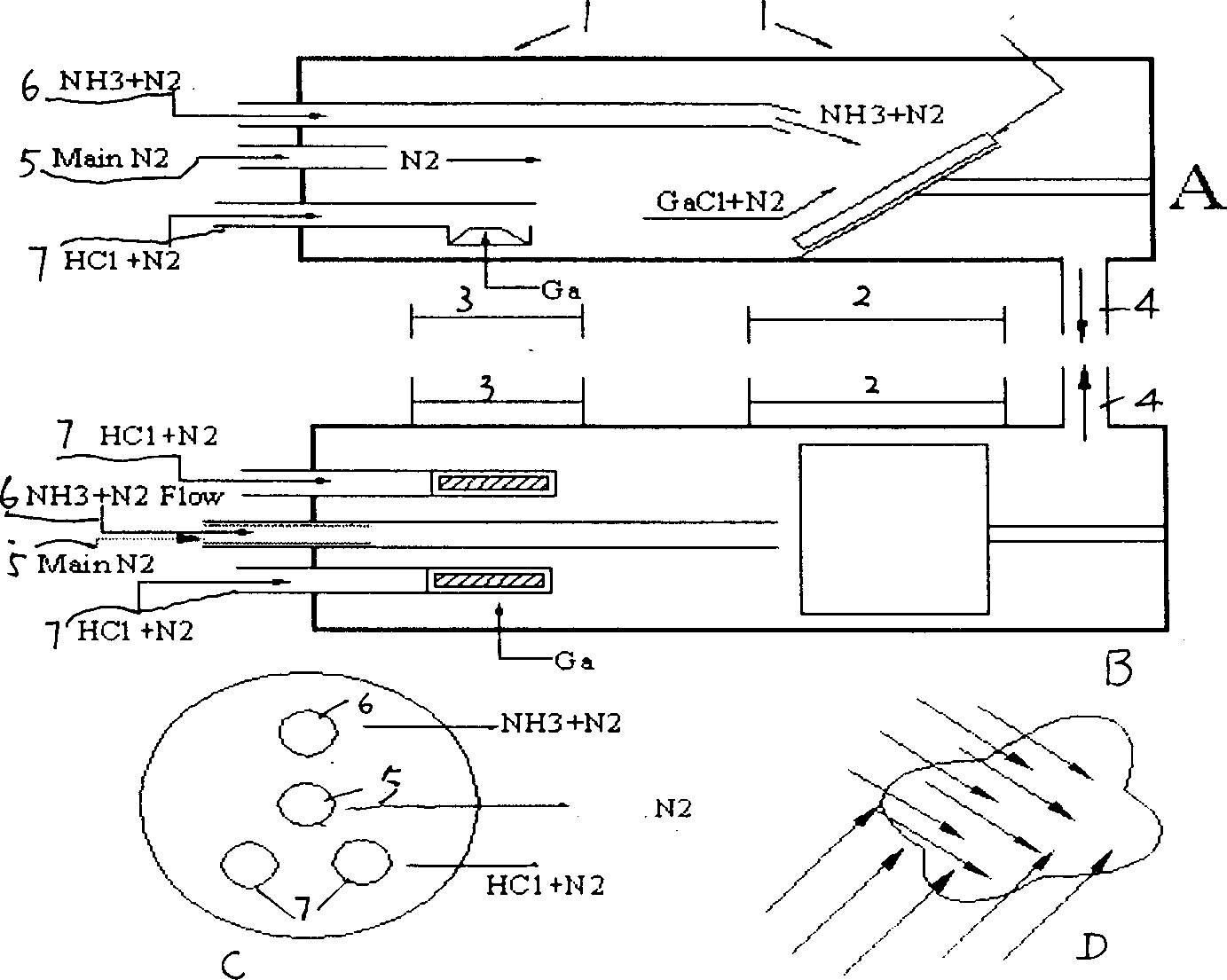

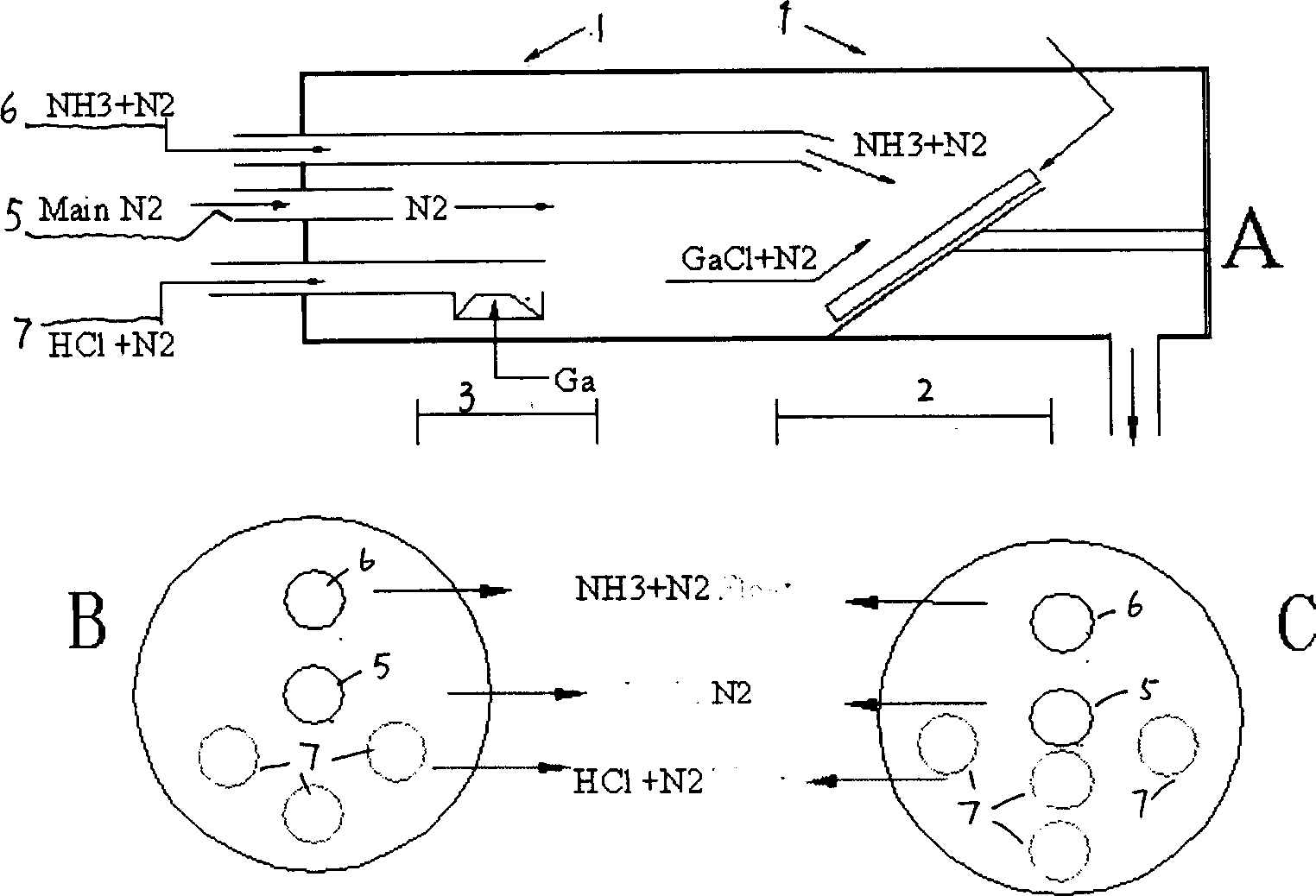

[0014] Such as figure 2 , 3 Shown: without changing the inner diameter of the electric furnace, two-way (or multi-way, image 3 ) Gallium source transmission pipeline. figure 2 C is a simple schematic diagram of the airflow distribution inside the improved system. It can be seen from the figure that the area of the film deposited after the improvement is incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com