Double-crankshaft engine

An engine and double crankshaft technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of complex manufacturing process, low reliability, friction surface wear, etc. The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with embodiment the present invention is further described.

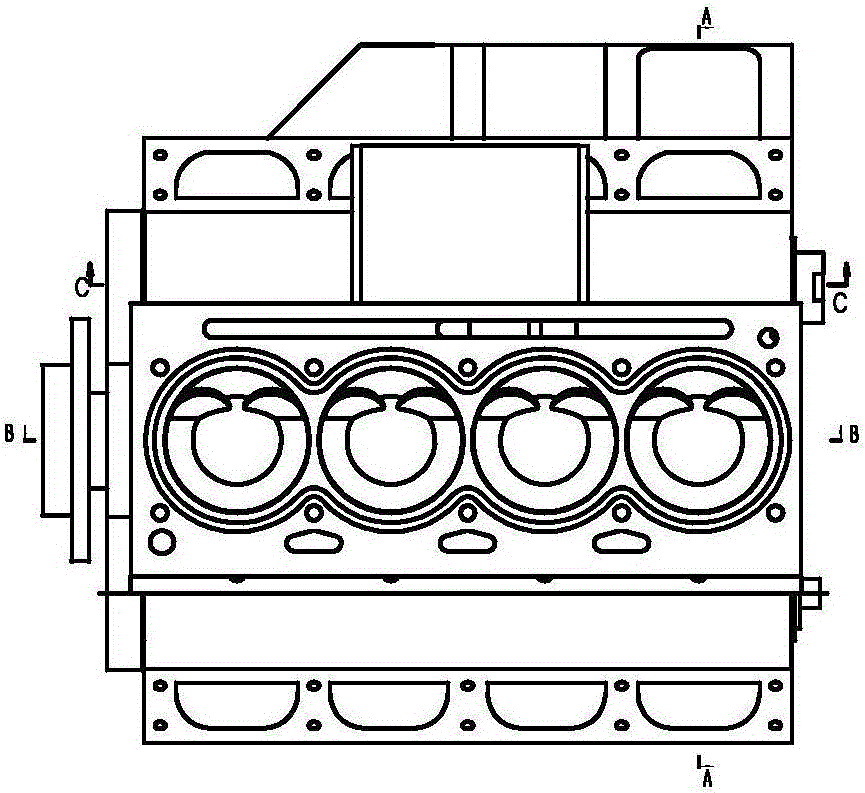

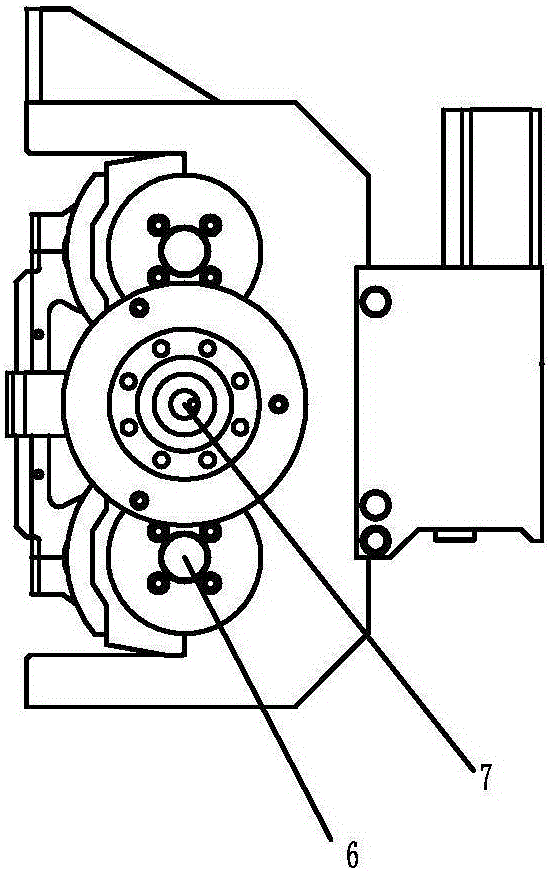

[0049] as attached Figure 1-Figure 10 A kind of double crankshaft engine, it comprises cylinder 2 and the piston 3 that can do linear reciprocating motion in cylinder,

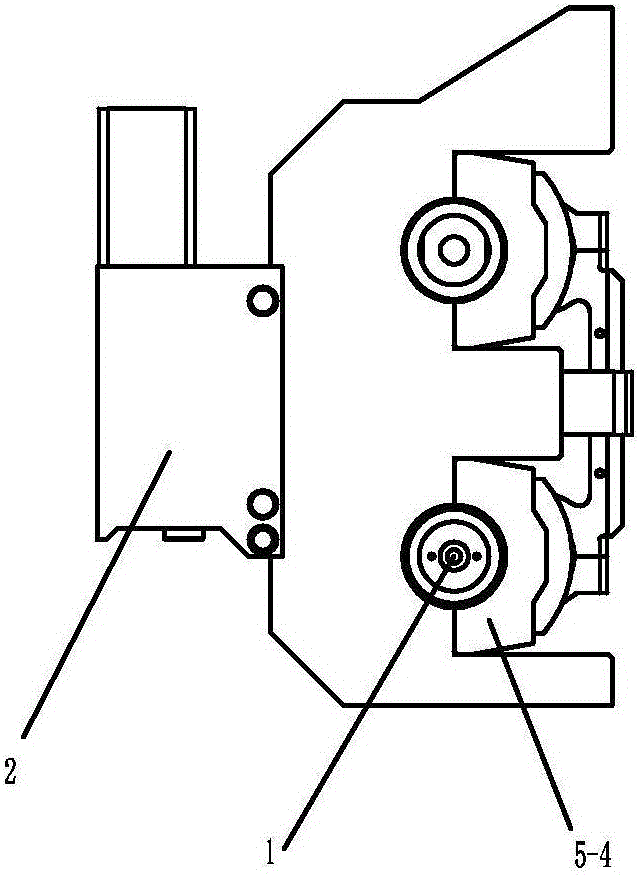

[0050] Two crankshafts 1 arranged in parallel are arranged on both sides of the cylinder 2, and a connecting rod 4 is hinged between the corresponding crank pins 1-1 of the two crankshafts 1, forming a double crank mechanism;

[0051] It also includes a cylinder block 5, which includes a cylinder body portion 5-1 forming the cylinder 2 and a crankshaft support portion 5-2 for accommodating and supporting the double crank mechanism;

[0052]The top of described piston 3 is piston head 3-1, and the lower end of piston head 3-1 is neck 3-2, and the lower end of neck 3-2 is cylindrical piston guide rod 3-5, and piston guide rod 3-5 A slot 3-4 is made on the top, and the connecting rod 4 is slidably inserted into the slot 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com