High-flow, low-parameter and high-backpressure expansion power energy-saving system

An energy-saving system and low-parameter technology, applied in heating systems, heat recovery systems, energy-saving heating/cooling, etc., can solve the problems of increased heat consumption, energy loss, and inability to achieve effective energy saving in power generation, and achieve heat transfer loss reduction small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

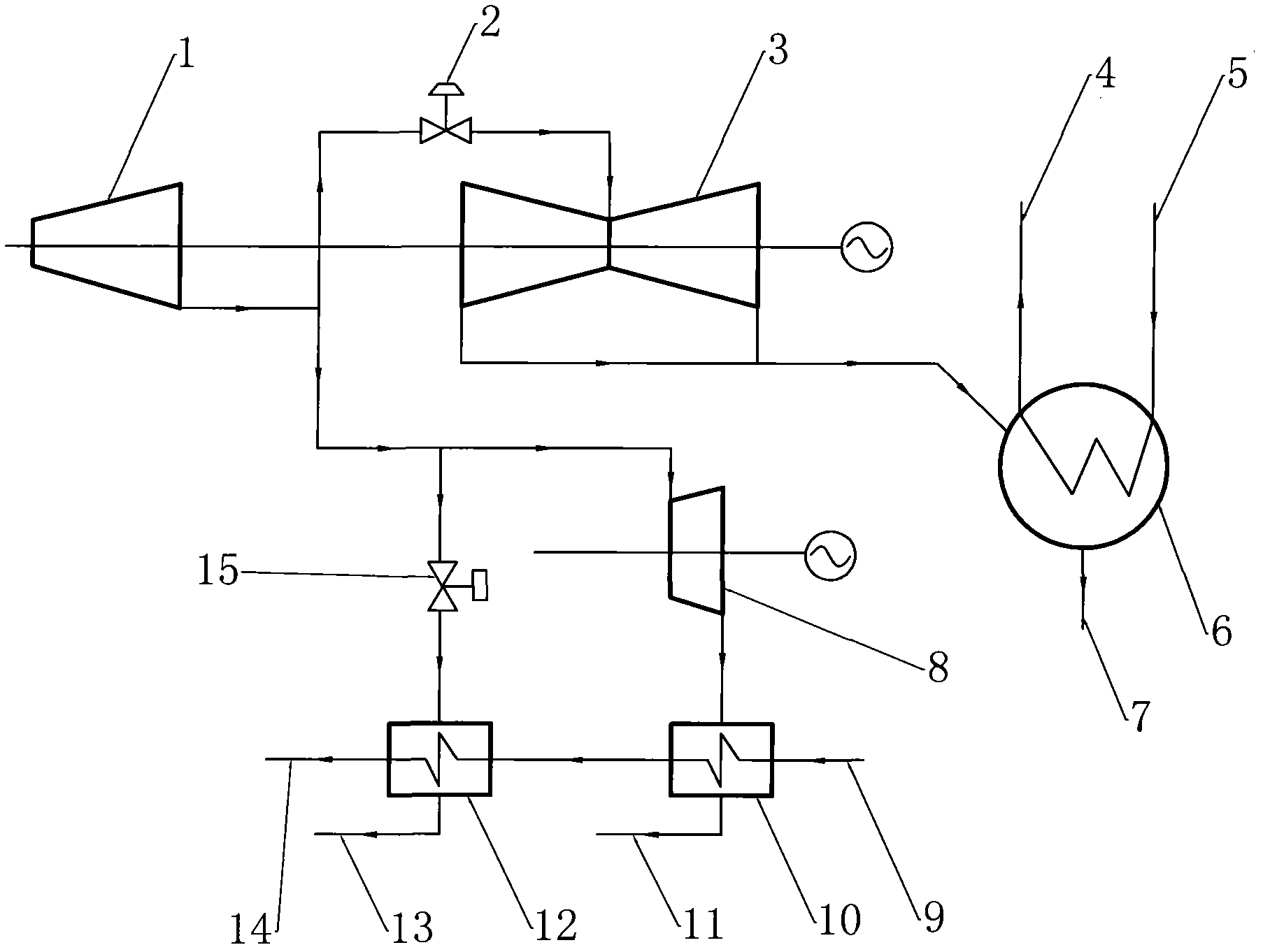

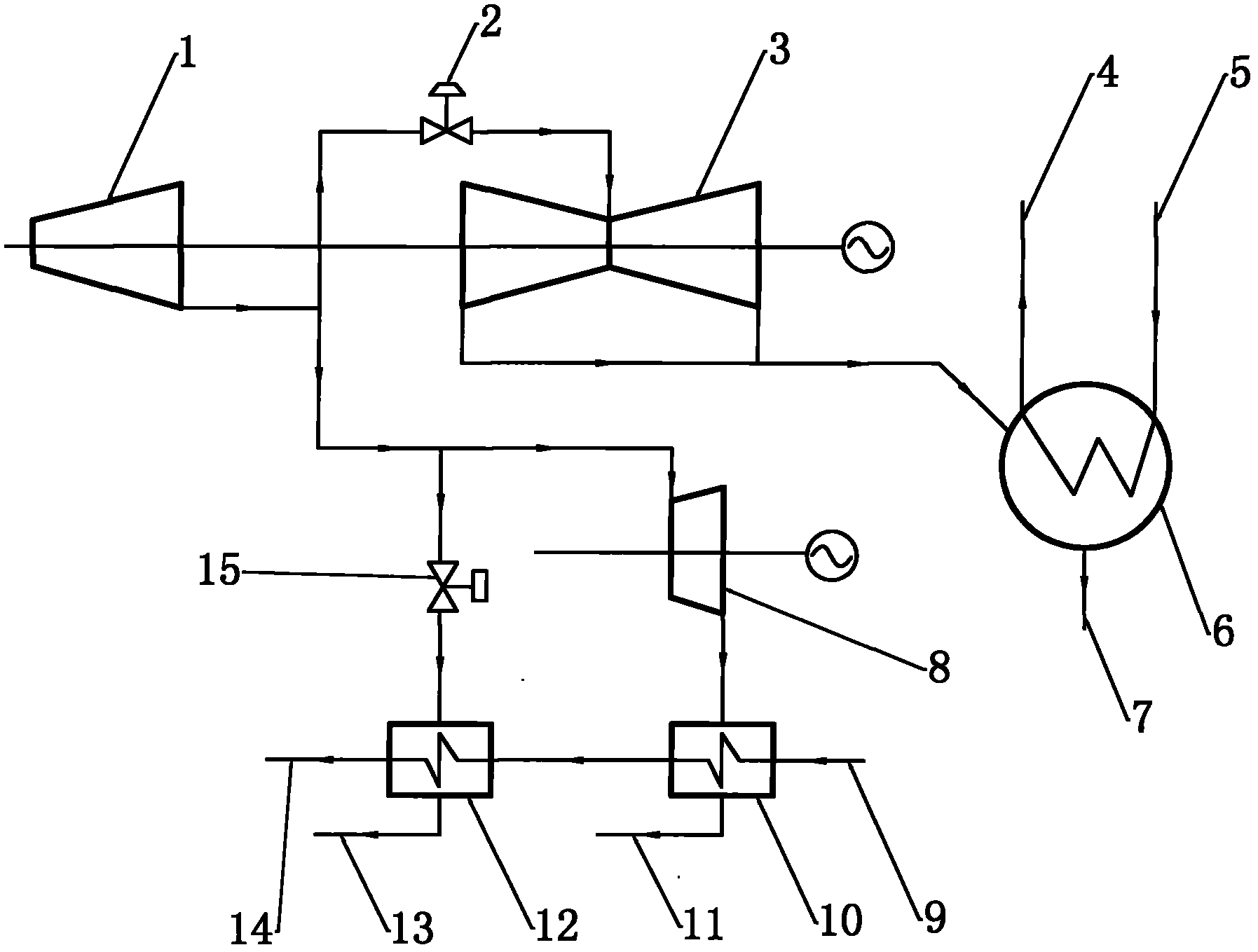

[0011] Accompanying drawing is a kind of specific embodiment of the present invention. The high-flow, low-parameter, high-backpressure expansion power energy-saving system includes a steam turbine medium-pressure cylinder 1 and a heat supply and return water heater 10 connected through pipelines, and the heat supply and return water heater 10 is connected to a heat supply and return water main pipe 9 And the drain pipe 11 of the heat supply and return water heater, the drain pipe 11 of the heat supply and return water heater is connected with the heat recovery heating system of the steam turbine, and its characteristic is: the pipeline between the medium pressure cylinder 1 of the steam turbine and the heat supply and return water heater 10 Expansion power machine 8 is installed on it. There is a fork in the pipeline between the medium-pressure cylinder 1 of the steam turbine and the expansion power machine 8. The fork is connected with the regulating butterfly valve 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com