Multistage gas liquefaction plant driven by loop multistage thermoacoustic engine

A thermoacoustic engine and liquefaction device technology, applied in the directions of liquefaction, refrigeration and liquefaction, gas cycle refrigerators, etc., can solve the problems of large heat transfer loss, low efficiency, inability to achieve gas cascade cooling, etc., and achieve large cooling capacity, energy The effect of high density and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

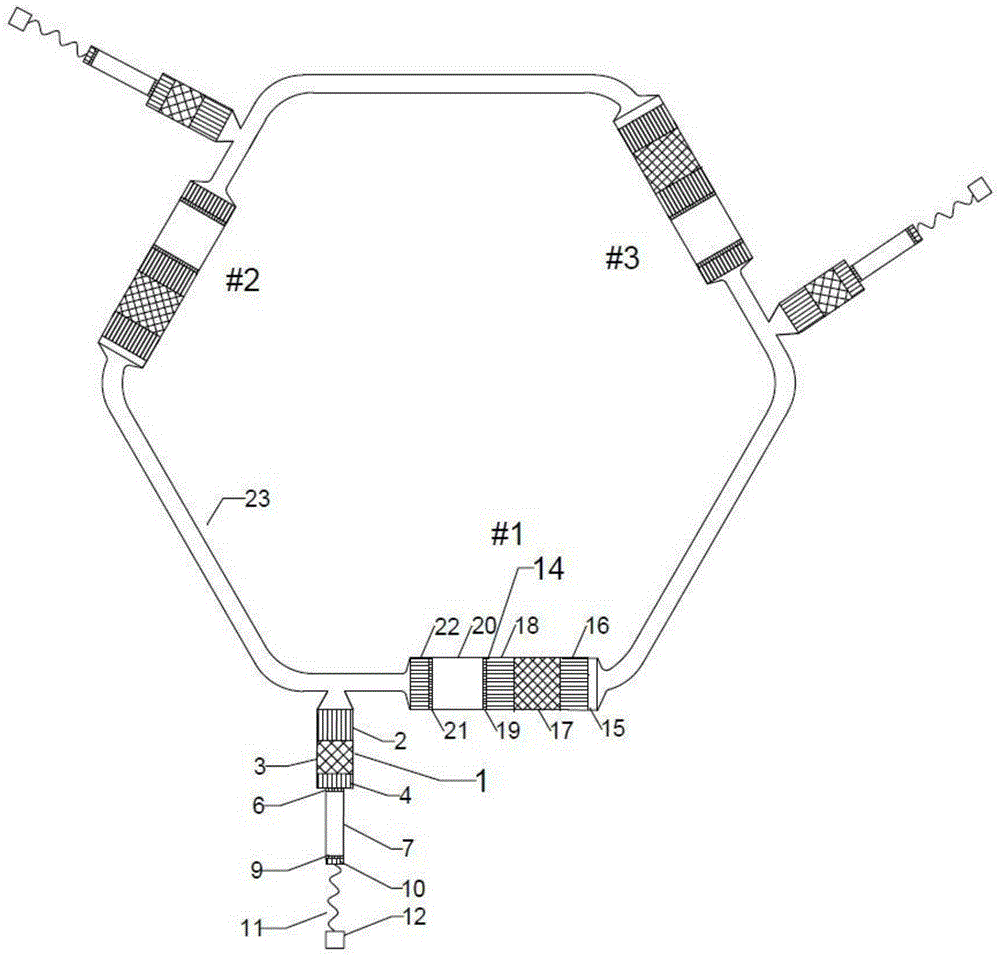

[0028] image 3 It is a structural schematic diagram of a loop multi-stage thermoacoustic engine-driven gas multi-stage (four-stage) liquefaction device (embodiment 1) of the present invention. It consists of 3 thermoacoustic engine units (1#, 2#, 3#) connected end-to-end through a resonance tube 23 to form a loop structure and 3 pulse tube refrigerator units 1; each thermoacoustic engine unit 14 is composed of DC Suppressor 15, engine main cooler 16, engine regenerator 17, heater 18, high temperature end laminar fluidization element 19, heat buffer pipe 20, engine room temperature end laminar fluidization element 21 and engine secondary cooler 22; A pulse tube refrigerator unit 1 is bypassed at the outlet of the engine subcooler 22 of a thermoacoustic engine unit 14;

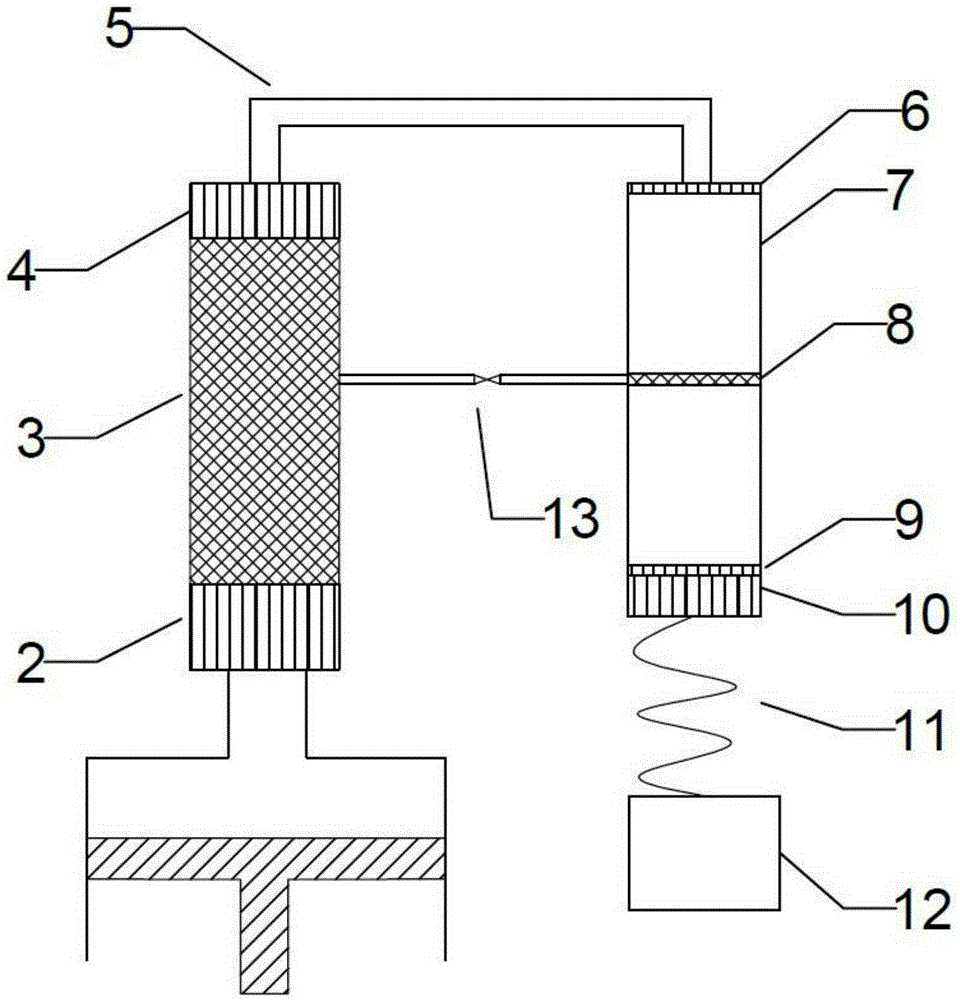

[0029] In this embodiment, each pulse tube refrigerator unit 1 is composed of the main water cooler 2 of the refrigerator, the 4-stage refrigeration unit connected in series, the connecting pipe 5, the pulse t...

Embodiment 2

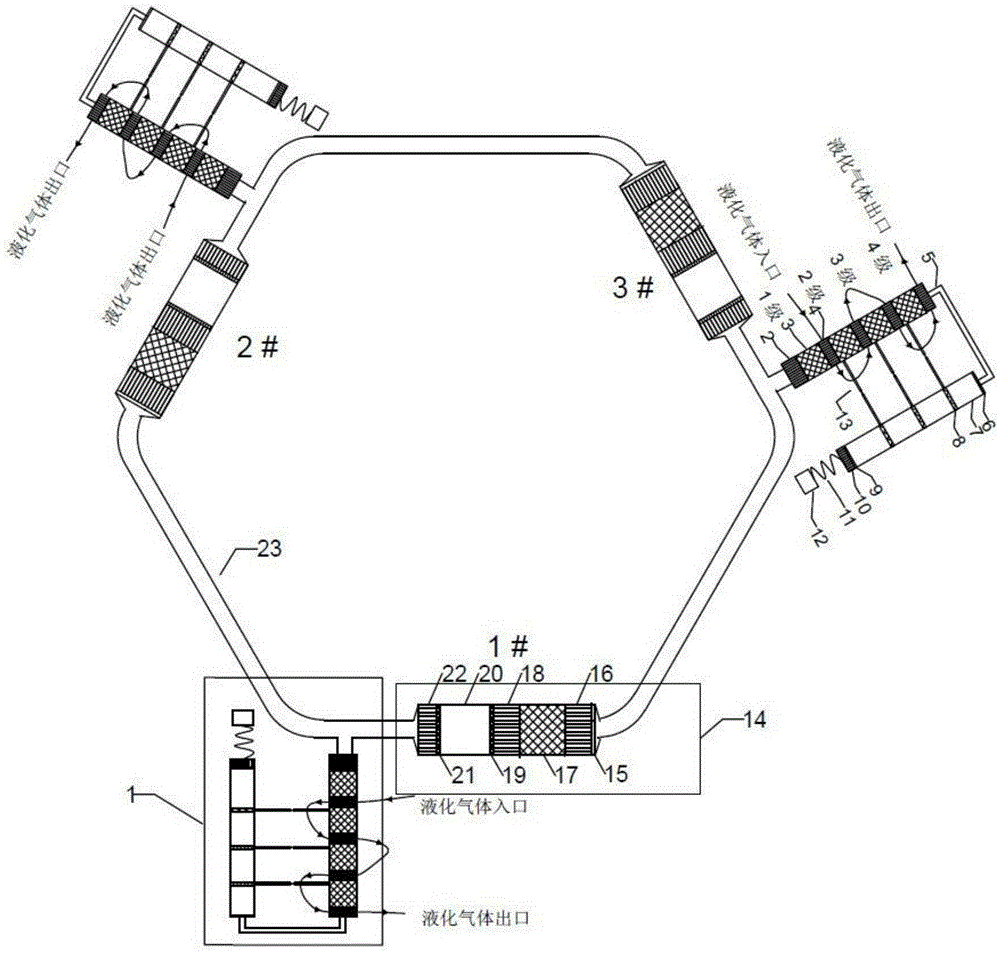

[0032] Figure 4 It is a schematic structural diagram of a gas multistage (4 stage) liquefaction device (embodiment 2) driven by a loop multistage thermoacoustic engine of the present invention; the device is passed by 3 thermoacoustic engine units (1#, 2#, 3#) The resonant tube 23 is connected end to end to form a loop structure and three pulse tube refrigerator units 1; each thermoacoustic engine unit 14 is composed of a DC suppressor 15, an engine main cooler 16, an engine regenerator 17, a heater 18, High-temperature end laminar fluidization element 19, heat buffer pipe 20, engine room temperature end laminar fluidization element 21 and engine sub-cooler 22; the exit of engine sub-cooler 22 of each thermoacoustic engine unit 14 is bypassed by a pulse tube refrigeration machine unit 1;

[0033] In each pulse tube refrigerator unit 1, a refrigerator regenerator 3 and a low-temperature end heat exchanger 4 connected in series form a first-stage refrigeration unit, and this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com