Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of large heat transfer loss and achieve the effect of less heat transfer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

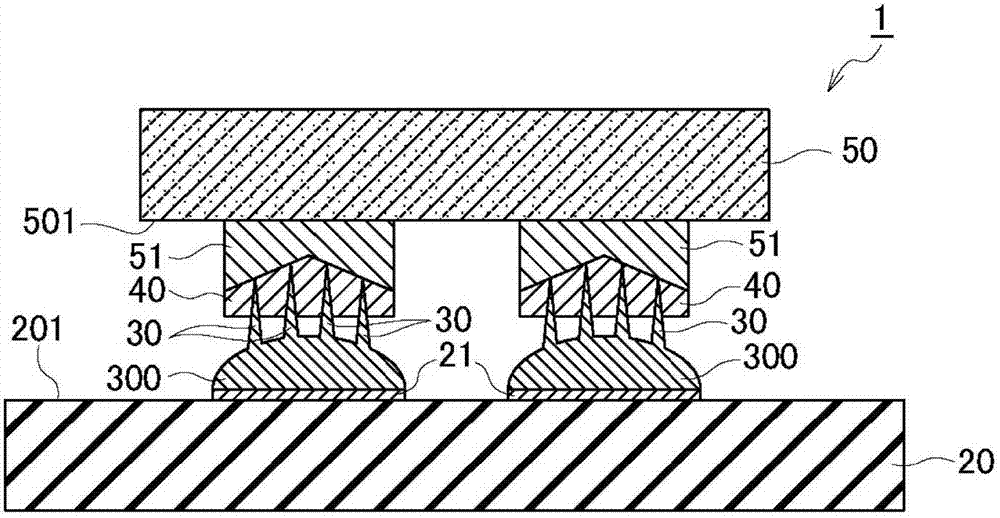

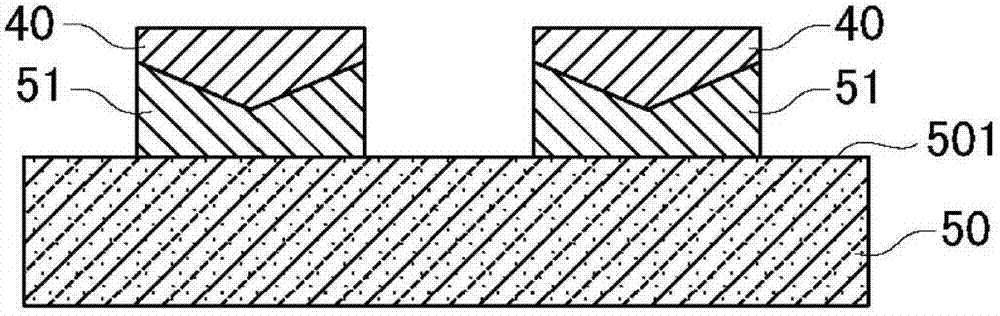

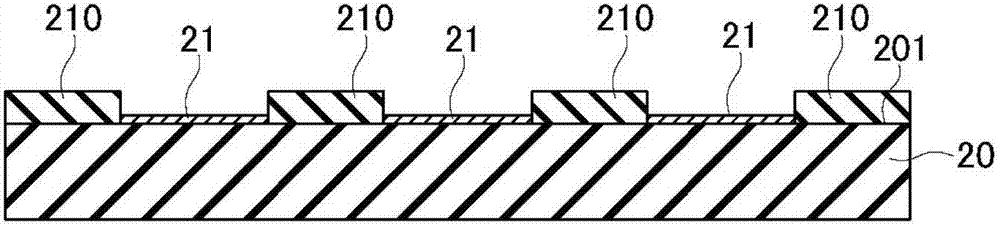

[0037] Next, embodiments of the present invention will be described with reference to the drawings. In the following description of the drawings, the same or similar symbols are attached to the same or similar parts. However, the drawings are schematic diagrams, and it should be noted that the ratio of the thickness of each part and the like are different from actual ones. Therefore, specific thicknesses and dimensions should be judged in consideration of the following descriptions. In addition, it is needless to say that between the drawings, parts where the relationship or ratio of dimensions are different from each other are included.

[0038] In addition, the embodiments shown below are examples of devices and methods for embodying the technical idea of the present invention. In the embodiments of the present invention, the materials, shapes, structures, arrangements, etc. of the constituent parts are not limited to the following . Various modifications can be made to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com