Adsorption forced methane steam reforming hydrogen manufacturing process and apparatus using circulating fluidized bed

A technology of methane water vapor and circulating fluidized bed, which is applied in the fields of hydrogen, chemical recovery, inorganic chemistry, etc., can solve the problems of heat transfer gradient, many catalysts, low hydrogen concentration, etc., and achieve stability and continuity, reduce Effect of absorbing heat loss and reducing heat transfer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

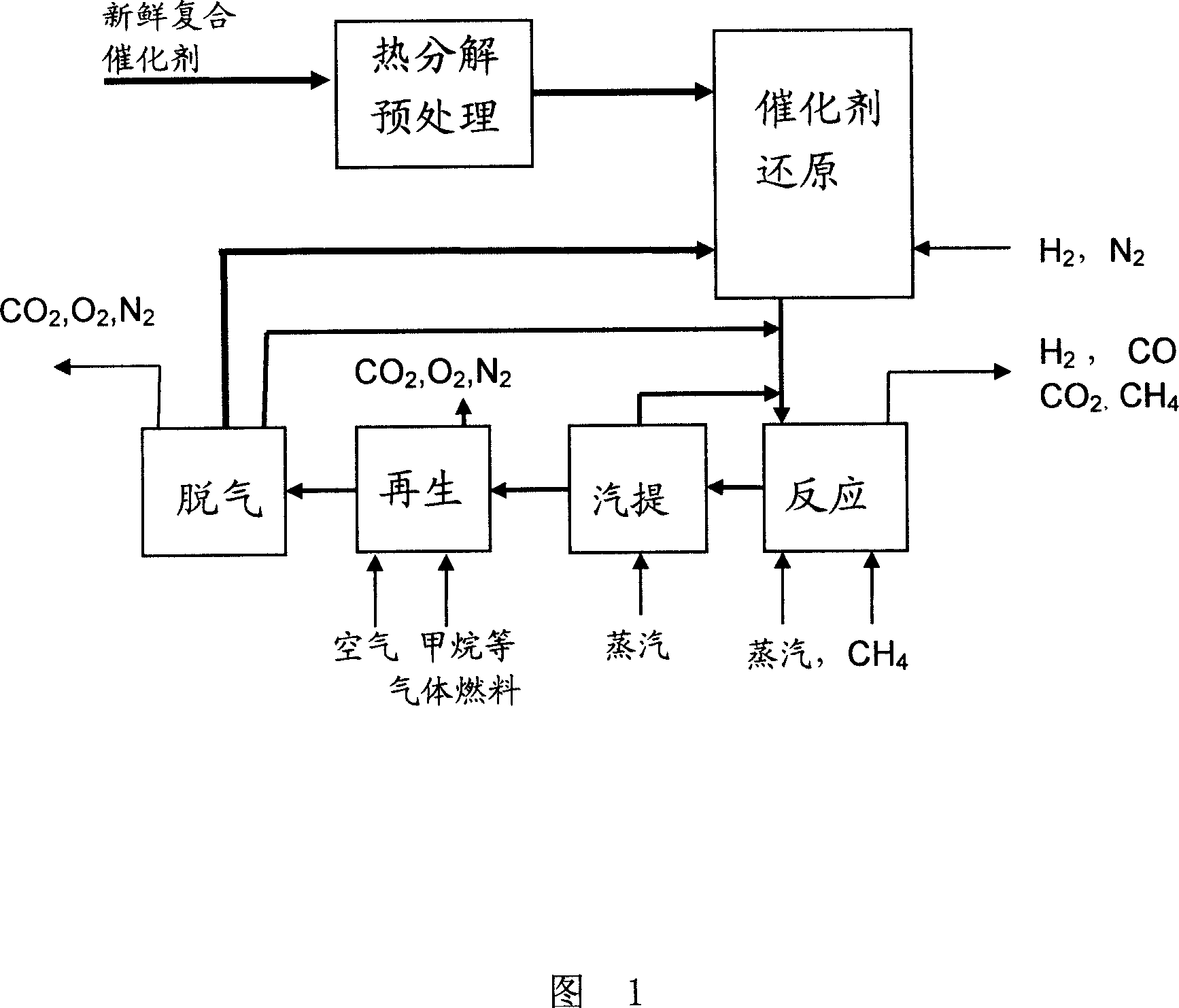

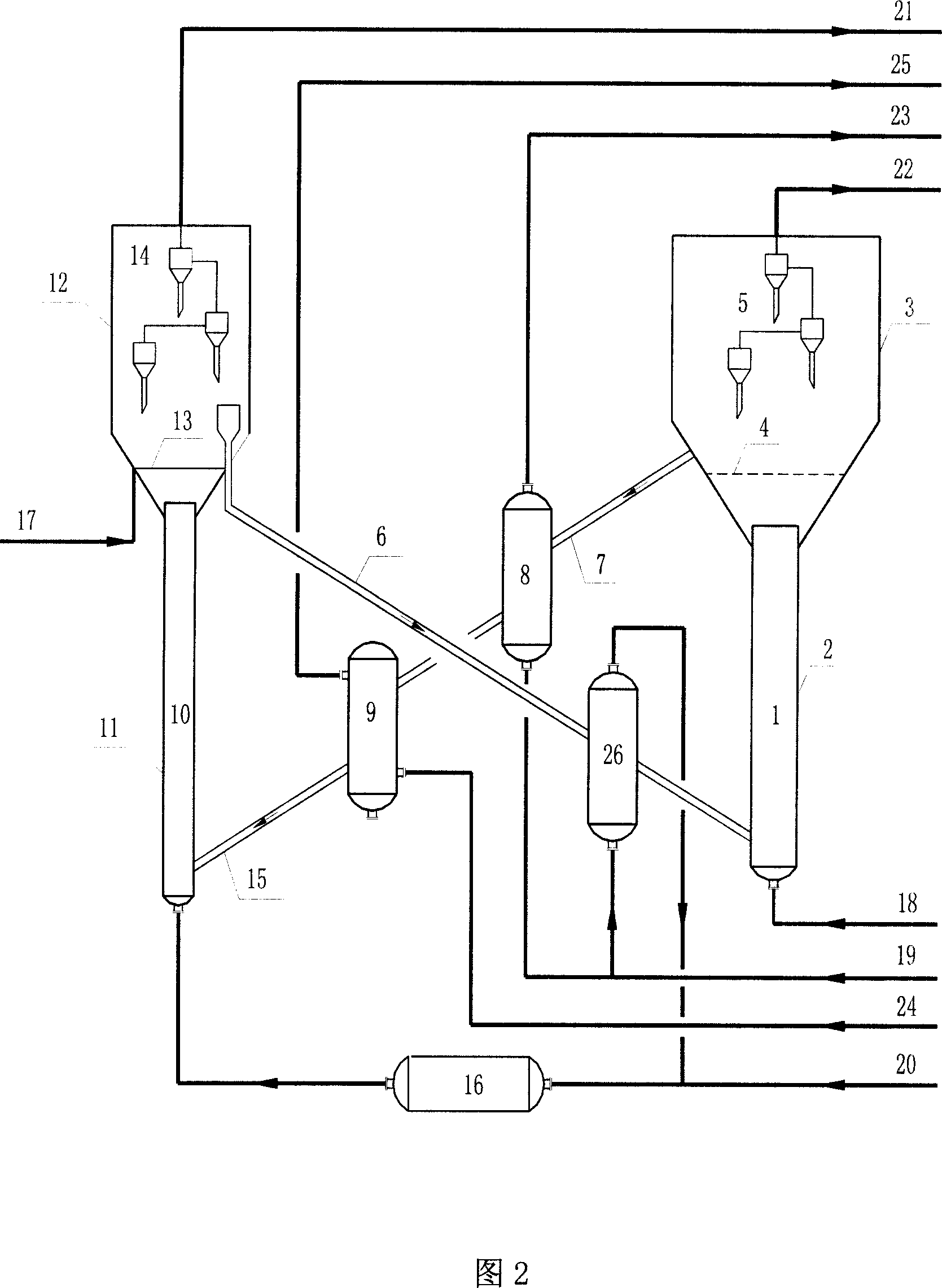

[0068] Referring to Fig. 1 and Fig. 2, when using a fresh composite catalyst, the composite catalyst is firstly subjected to thermal decomposition pretreatment and catalyst pre-reduction.

[0069] The composite catalyst is pretreated, and the microsphere composite catalyst is loaded into the fluidized bed regenerator 1. The lower part of the fluidized bed regenerator 1 is the regenerator conveying section. The regenerator conveying section used in this embodiment has a riser 2, The upper part of the fluidized bed regenerator 1 is a regenerator fluidized section 3 with a three-stage cyclone separator 5 inside, and a distribution plate 4 is arranged between the riser section 2 and the regenerator fluidized section 3 . From the gas nozzle at the bottom of the riser 2 of the regenerator, gas fuels such as air and methane are introduced through the pipeline 18, and the temperature is raised to the regeneration temperature. The composite catalyst is pretreated (or regenerated) in the...

Embodiment 2

[0077] Adsorption-enhanced methane steam reforming for hydrogen production was carried out according to the process flow in Example 1.

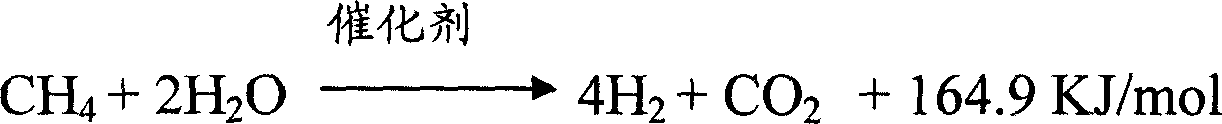

[0078] Among them, the composite catalyst CA-3 catalyst (refer to Example 1 for the preparation method) has an average particle size of 60 microns, and the hydrogen production reaction conditions: the water-to-carbon ratio is 4, the reaction temperature is 600°C, the gauge pressure is 0.2MPa, and the methane flow rate is 1m / s, the ratio of the amount of the composite catalyst of filling and the input amount of methane is 4: 1 (g: ml), residence time 20 seconds, hydrogen content 92.7% in the reaction product gas, carbon monoxide content 0.5%, carbon dioxide 2.9%, methane The conversion rate was 92.3%. The regeneration temperature is 750°C and the gauge pressure is 0.1MPa.

Embodiment 3

[0080] Adsorption-enhanced methane steam reforming for hydrogen production was carried out according to the process flow in Example 1.

[0081] Among them, the composite catalyst CA-3 catalyst (refer to Example 1 for the preparation method) has an average particle size of 80 microns, and the hydrogen production reaction conditions: the water-to-carbon ratio is 4, the reaction temperature is 600°C, the gauge pressure is 0.2MPa, and the methane flow rate is 1m / s, the ratio of the amount of the composite catalyst of packing and the input amount of methane is 0.01: 1 (g: ml), residence time 30 seconds, hydrogen content 91.6% in the reaction product gas, carbon monoxide content 0.9%, carbon dioxide 3.8%, methane The conversion rate was 91.9%. The regeneration temperature is 800°C and the gauge pressure is 0.1MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com