Minisize propeller with electrolyzing water function

A technology for electrolysis of water and thrusters, which is applied to electrolysis components, electrolysis processes, jet propulsion devices, etc., can solve the problems of limited technological means and material selection, incompatibility of enhanced heat exchange structure, increased resistance and substrate heat conduction, etc. The power supply system and drive circuit are simple, easy to miniaturize, and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention proposes a miniature electrolyzed water propeller. The basic working principle is:

[0039] 1) First, use the electrochemical principle to electrolyze pure water or water electrolyte solution into hydrogen and oxygen:

[0040] cathodic reaction

[0041] Anode reaction

[0042] overall response

[0043] 2) Ignite the electrolytic reaction product of the above hydrogen-oxygen mixed gas, deflagrate and release heat to form high-temperature and high-pressure water vapor, which is ejected from the micro nozzle to form thrust.

[0044] hydrogen-oxygen combustion reaction

[0045] Regardless of the intermediate links, the way of energy conversion is "electrical energy→thermal energy".

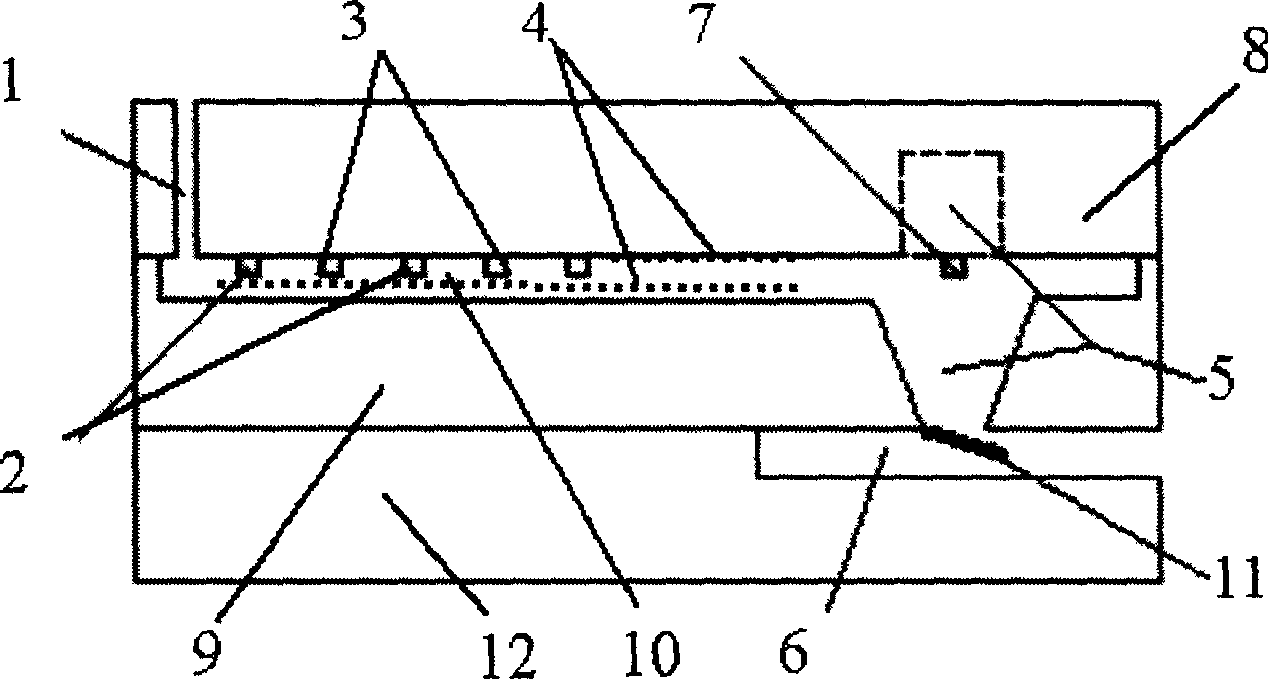

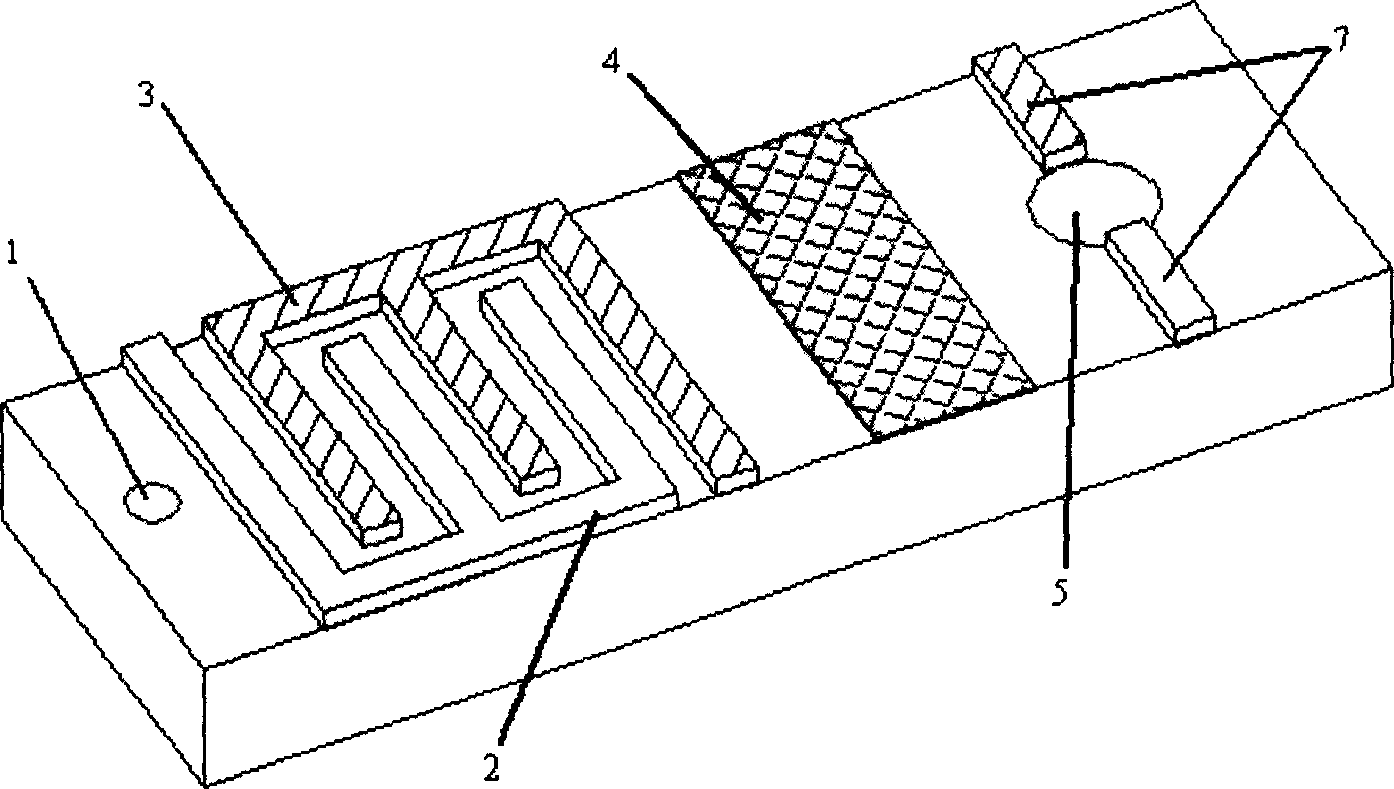

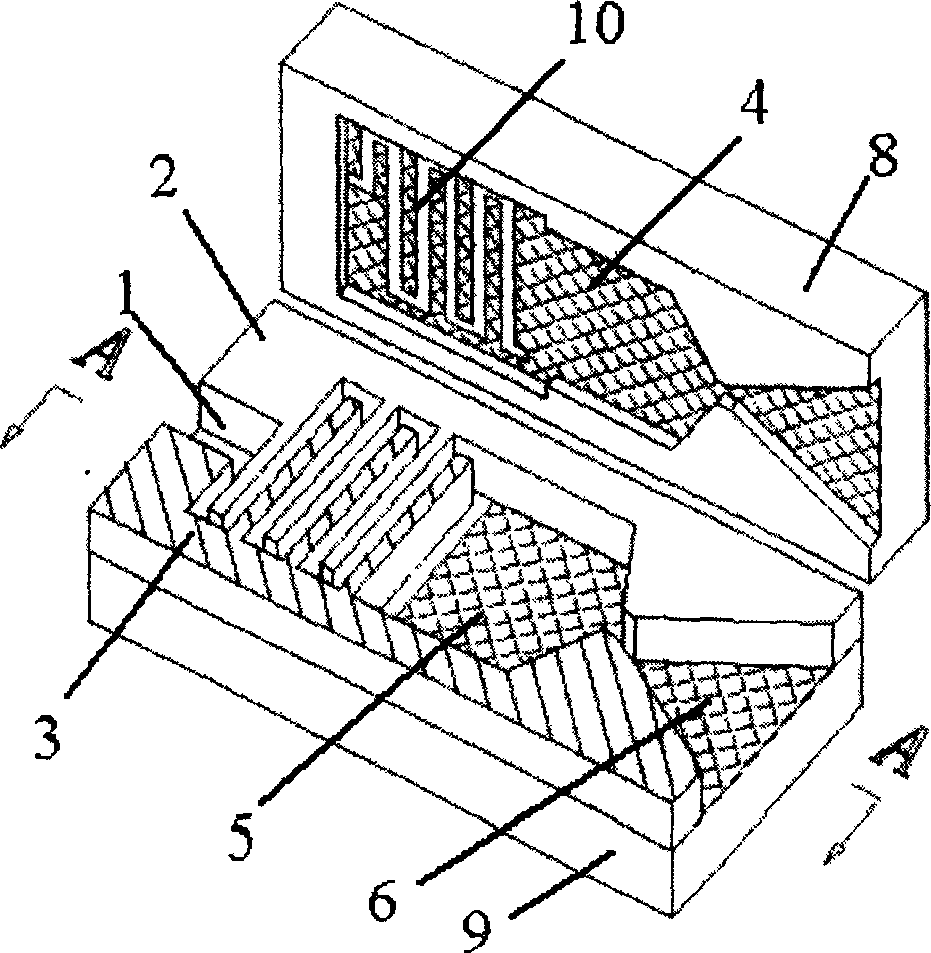

[0046] exist figure 1 In the structural schematic diagram of a miniature water electrolysis propeller using planar electrodes and one-way valves, in the working medium storage tank, a relatively low supply back pressure is maintained by using saturate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com