Coal-fired hot blast furnace with pre-combustion hearth and smoke circulating device

A flue gas circulation and hot blast stove technology, which is applied to heating devices, lighting and heating equipment, dryers, etc., can solve the problems of low thermal efficiency, short service life of coal-fired hot blast stoves, and adaptability to polluted coal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

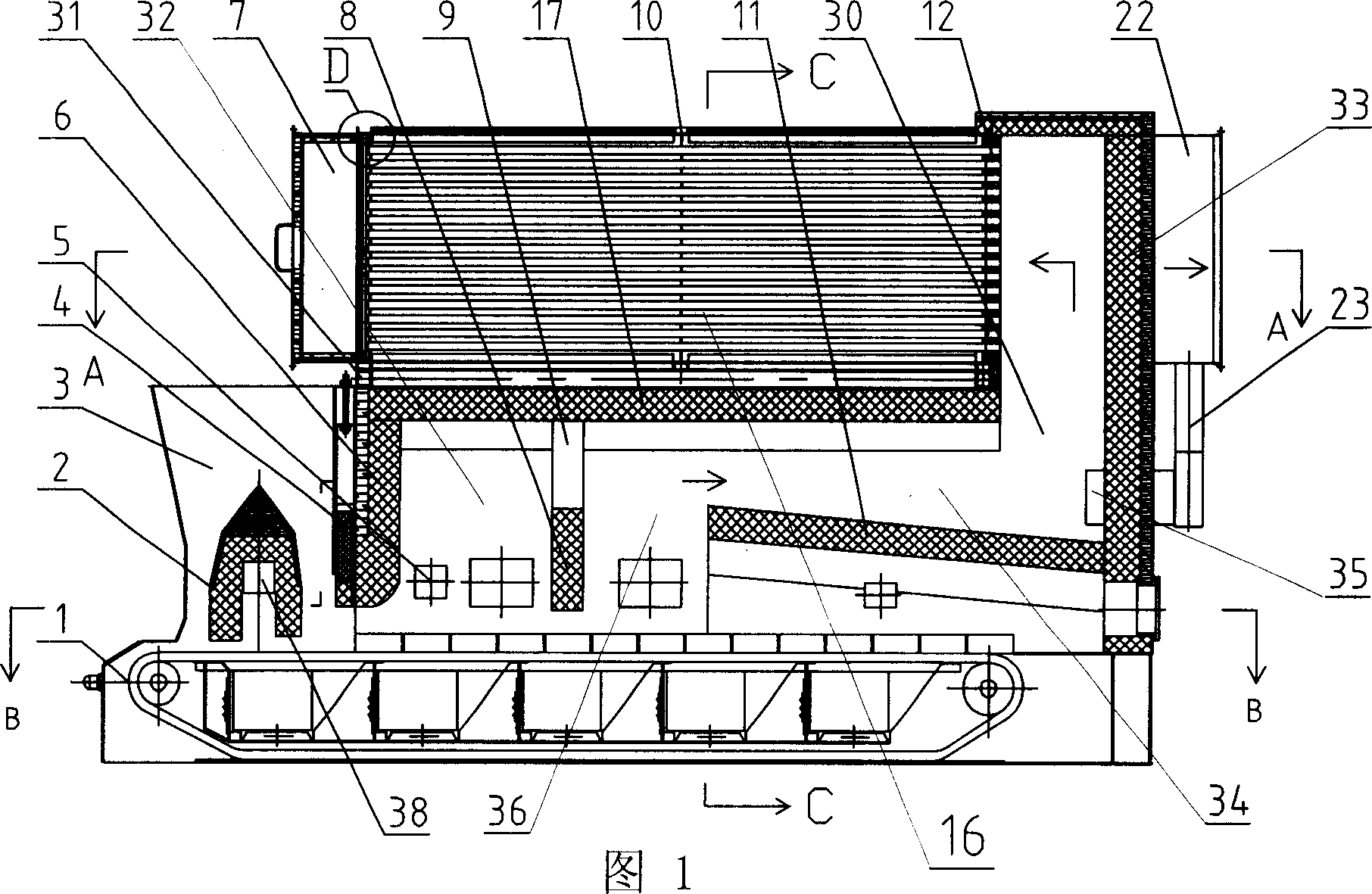

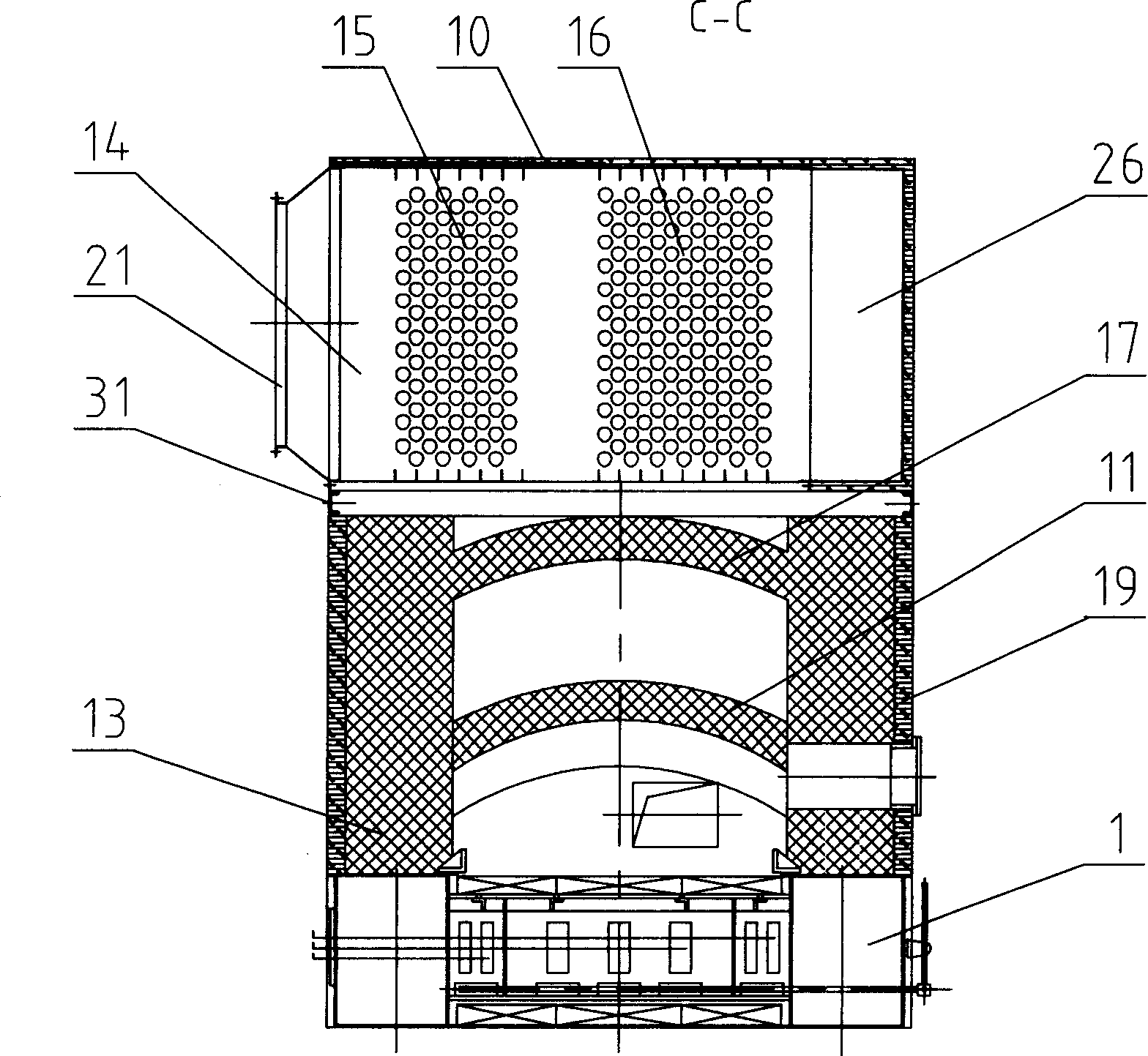

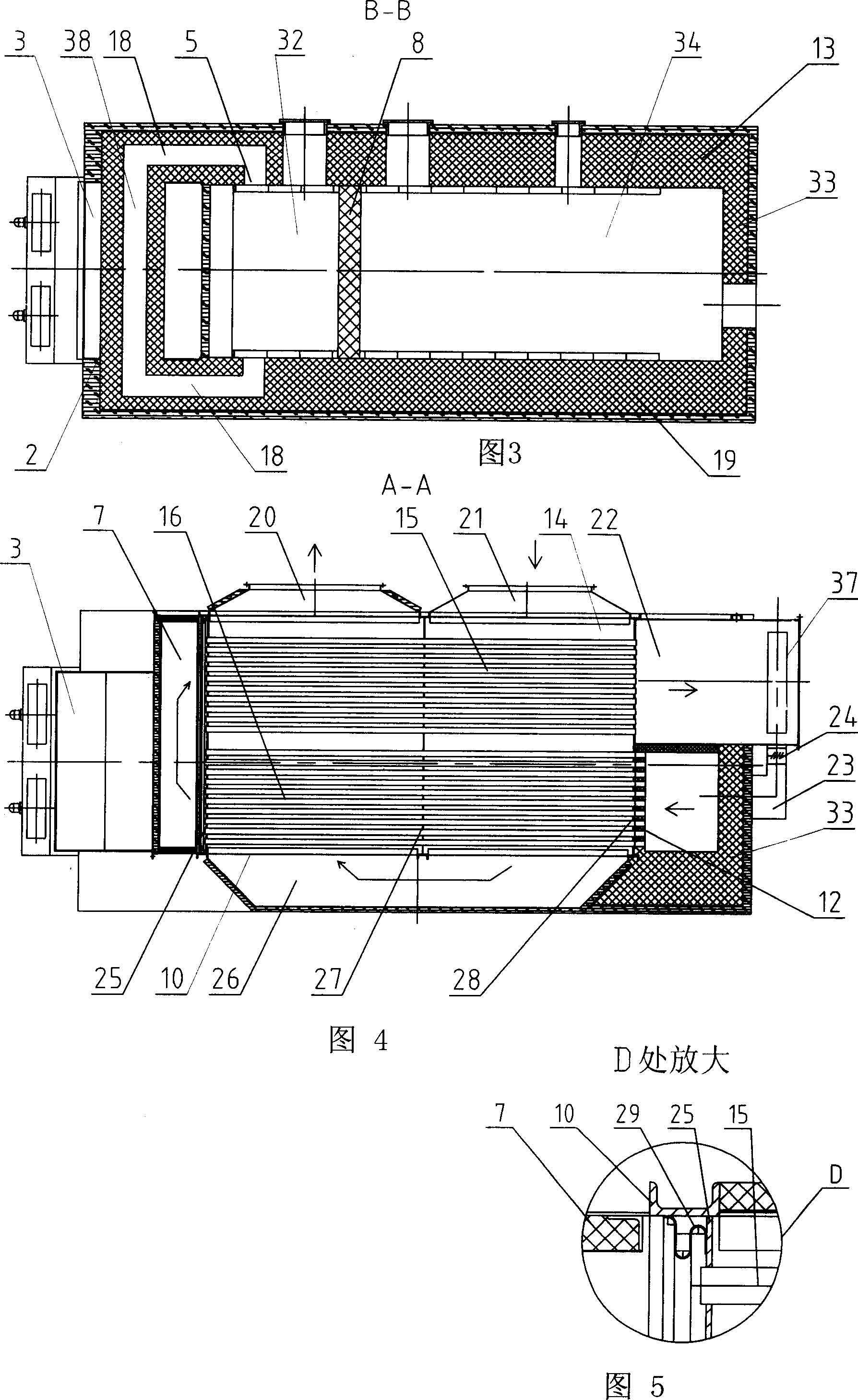

[0005] Specific embodiment one: (referring to Fig. 1~Fig. 4) this embodiment consists of chain grate 1, coal bucket 3, coal gate 4, front arch 6, middle arch 8, rear arch 11, left side wall 13, heat exchange device 14, top arch 17, right side wall 19, flue exhaust duct 22, steel frame 31, back wall 33, pre-combustion furnace 2, circulating flue 23 and circulating fan 24, left side wall 13 and right side wall 19 respectively It is fixed on the left and right sides of the chain grate 1, the front arch 6 is fixed on the front part between the left wall 13 and the right wall 19, and the middle arch 8 is fixed on the middle part between the left wall 13 and the right wall 19 , the two ends of rear wall 33 are fixedly connected with the rear ends of left side wall 13 and right side wall 19 respectively, top arch 17 is fixed on the top between left side wall 13 and right side wall 19, the front end of top arch 17 is connected with front The front end of the arch 6 is flush, a flue 30...

specific Embodiment approach 2

[0006] Specific implementation mode two: (referring to Fig. 1, figure 2 and Fig. 4) the heat exchanger 14 of the present embodiment is made of smoke box 7, frame 10, heat-resistant insulation layer 12, second smoke tube bundle 15, first smoke tube bundle 16, hot air outlet 20, cold air inlet 21, front tube plate 25 , turning bellows 26, middle tube plate 27 and rear tube plate 28, the rear end of smoke box 7 is fixedly connected to the front end of frame 10, the left end of turning bellows 26 is fixedly connected to the right end of frame 10, and middle tube plate 27 is fixed In the middle part of the frame 10, the rear tube plate 28 is fixed on the rear part in the frame 10, the front tube plate 25 is arranged on the front part in the frame 10, and the two ends of the second smoke tube bundle 15 are respectively fixed on the front tube plate 25 and the rear tube plate 25. On the left side of the tube plate 28, the middle part of the second smoke tube bundle 15 is fixed on the...

specific Embodiment approach 3

[0007] Embodiment 3: (see FIG. 1 and FIG. 5 ) The difference between this embodiment and Embodiment 2 is that an expansion joint 29 is provided between the front tube plate 25 of the heat exchanger 14 and the inner wall of the frame 10 . Other compositions and connections are the same as those in the second embodiment. The heat exchanger uses expansion joints to compensate for the expansion of the heated components, which avoids damage to the heat exchanger device due to thermal stress caused by thermal expansion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com