Cooling scheme for combustion chamber wall surface of aspirated type pulse detonation engine

A technology of pulse detonation and combustion chamber, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of insufficient cooling methods, achieve good cooling effect, improve safety, and increase thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

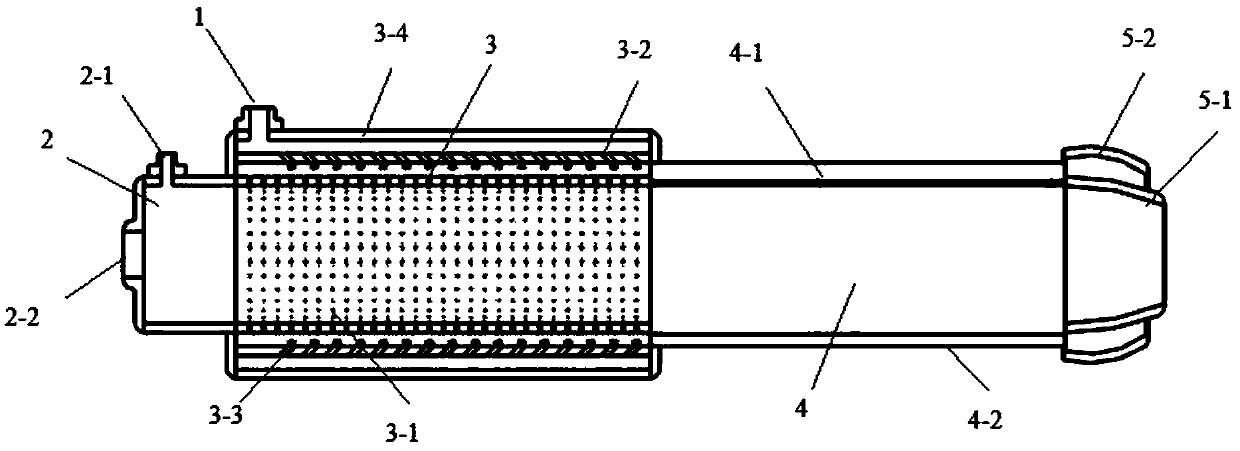

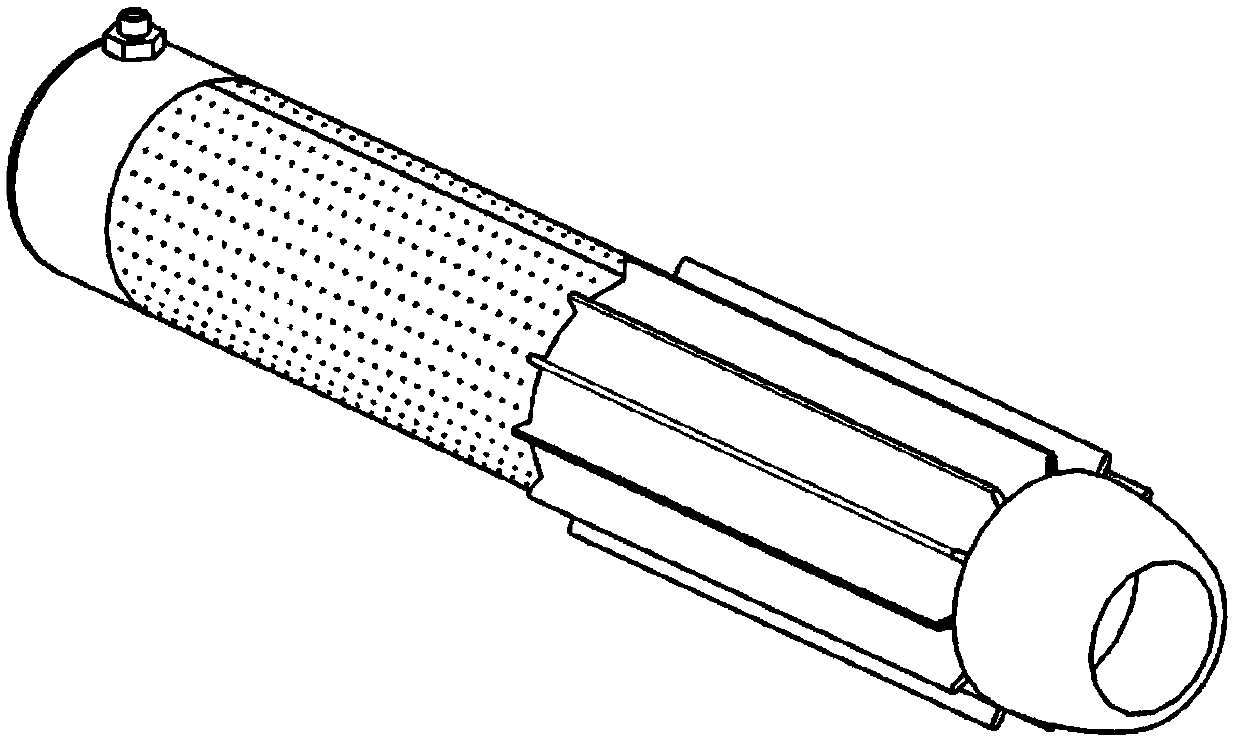

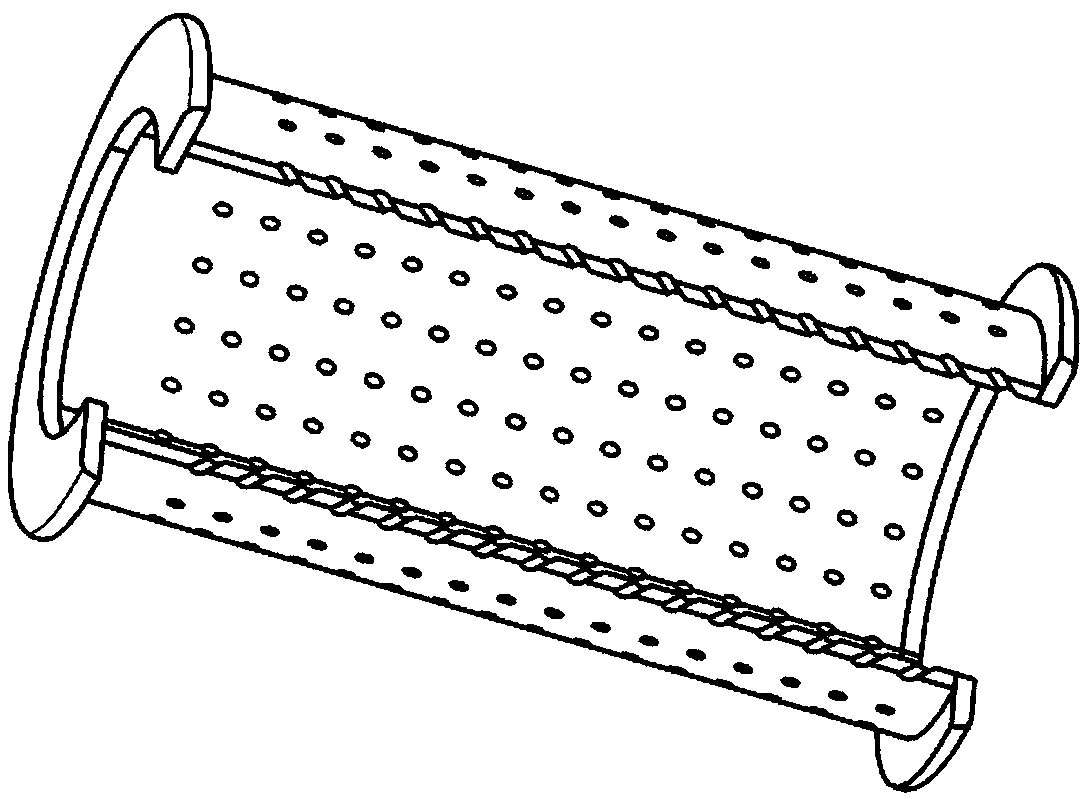

[0026] The present invention is a cooling solution for the combustion chamber wall of an air-breathing pulse detonation engine, such as figure 2 , image 3 and Figure 4 As shown, it includes: cooling gas inlet 1, detonation tube head 2, fuel inlet 2-1 in the head, combustion chamber air inlet 2-2, detonation tube DDT section 3, sweating hole 3-1 , partition plate with impact hole 3-2, impact hole 3-3, outer casing of the first stage cooling system 3-4, detonation propagation section 4 of the detonation tube, rib plate 4-1, detonation transmission section tube Wall 4-2, tail nozzle 5-1, cooling gas nozzle 5-2.

[0027] The above-mentioned cooling scheme for the combustion chamber wall of an air-breathing pulse detonation engine is characterized in that the present invention consists of a detonation tube, a first-stage cooling system, a second-stage coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com