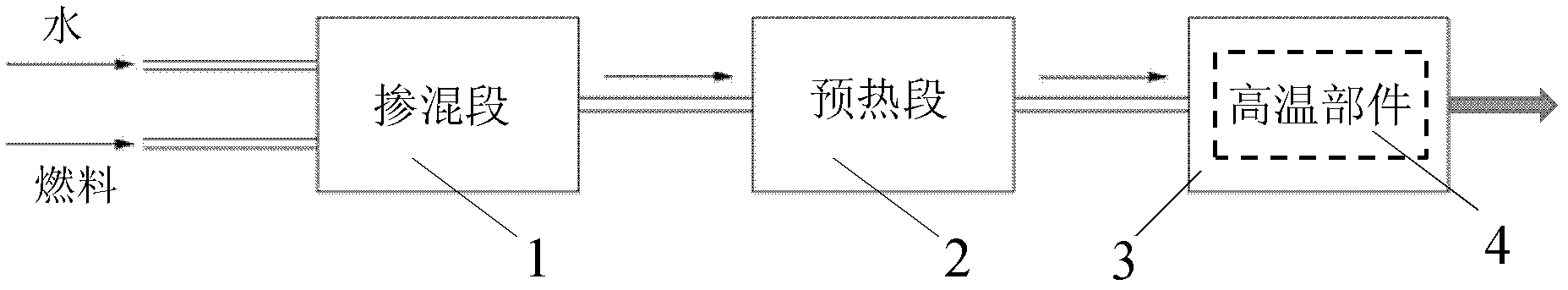

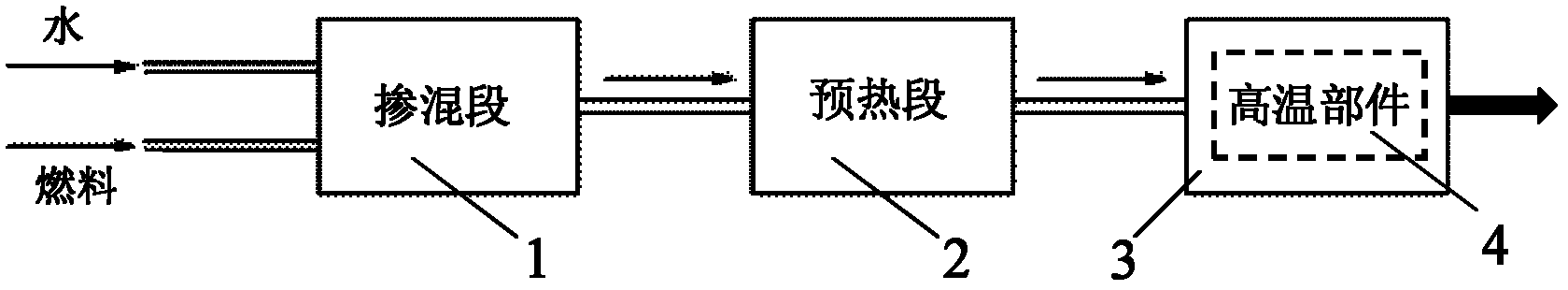

Method for cooling high temperature parts through catalytic reforming of liquid hydrocarbon fuel

A technology of hydrocarbon fuels and high-temperature components, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as insufficient cooling capacity, achieve fast flame propagation speed, low ignition energy, and reduce coking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

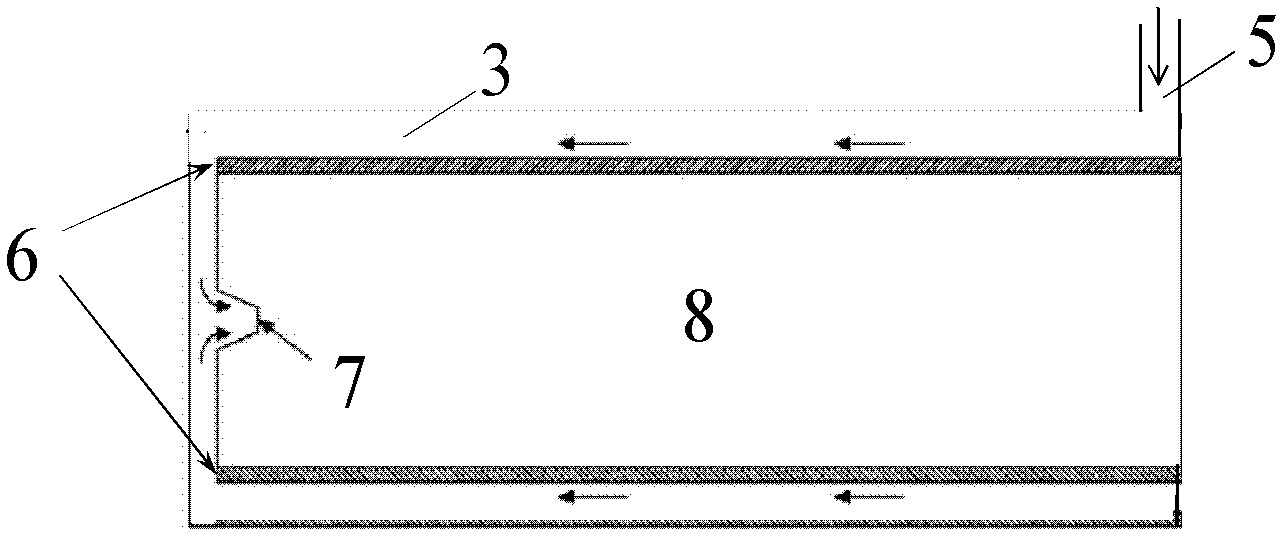

Method used

Image

Examples

Embodiment 1

[0024] Using kerosene as hydrocarbon fuel, under the condition of 3MPa pressure and water mixing ratio of 30%, the total heat sink (heat absorption) is 2.2MJ / kg when the wall temperature is 400°C, compared with the total heat of pure kerosene without catalytic reforming reaction The weight increases by 1MJ / kg; the volume content of hydrogen in the catalyzed reaction product reaches 80% when the wall temperature is 400°C, and reaches 20% when the wall temperature is 800°C.

Embodiment 2

[0026] Using dodecane as hydrocarbon fuel, under the conditions of 8MPa pressure and 50% water mixing ratio, the total heat sink reaches 4.5MJ / kg when the wall temperature is 800°C, and the hydrogen volume content in the catalyzed reaction product reaches 15%. Under the same wall heat flux condition, the surface temperature of the high-temperature parts with the catalytic section decreases by 200°C.

Embodiment 3

[0028] Using diesel oil as hydrocarbon fuel, under the conditions of 0.2MPa and 5% water, the total heat sink is 2MJ / kg when the wall temperature is 420°C, and the hydrogen volume content in the catalyzed reaction product reaches 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com