Connection structure of engine exhaust gas reclrculation pipe and plastic intake manifold

A technology of exhaust gas recirculation and intake manifold, which is applied in the direction of exhaust gas recirculation, engine components, combustion engines, etc., and can solve the problems of low reliability and melting of plastic intake manifolds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

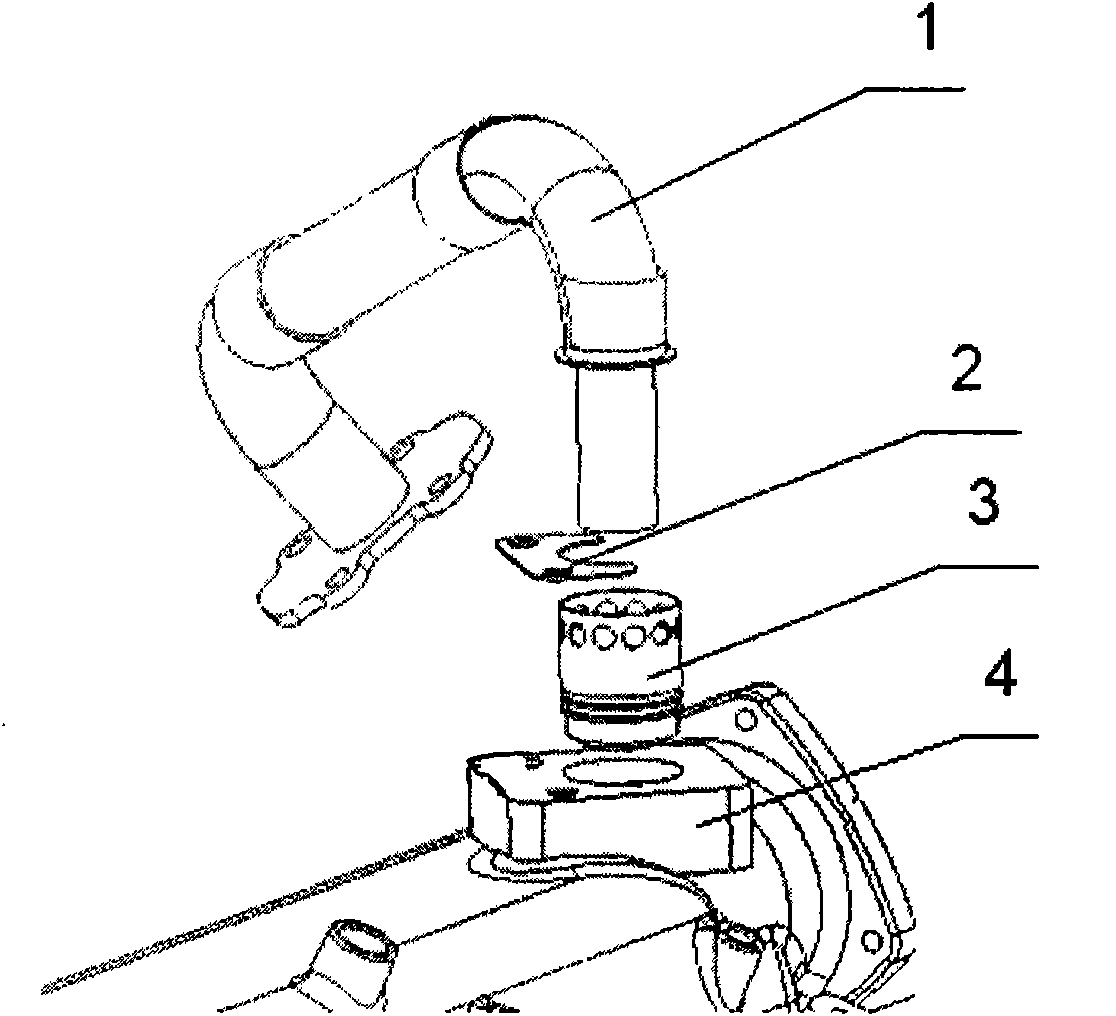

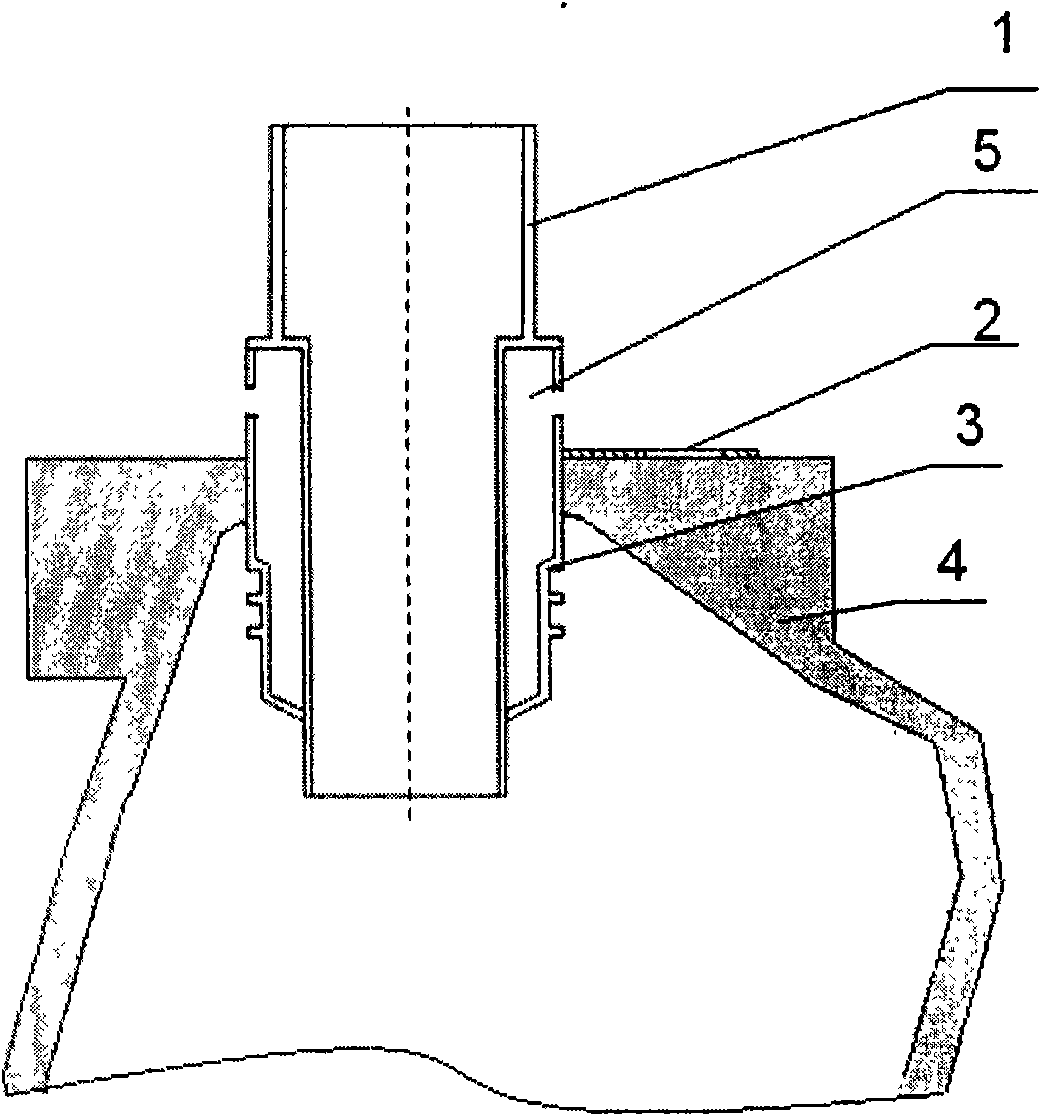

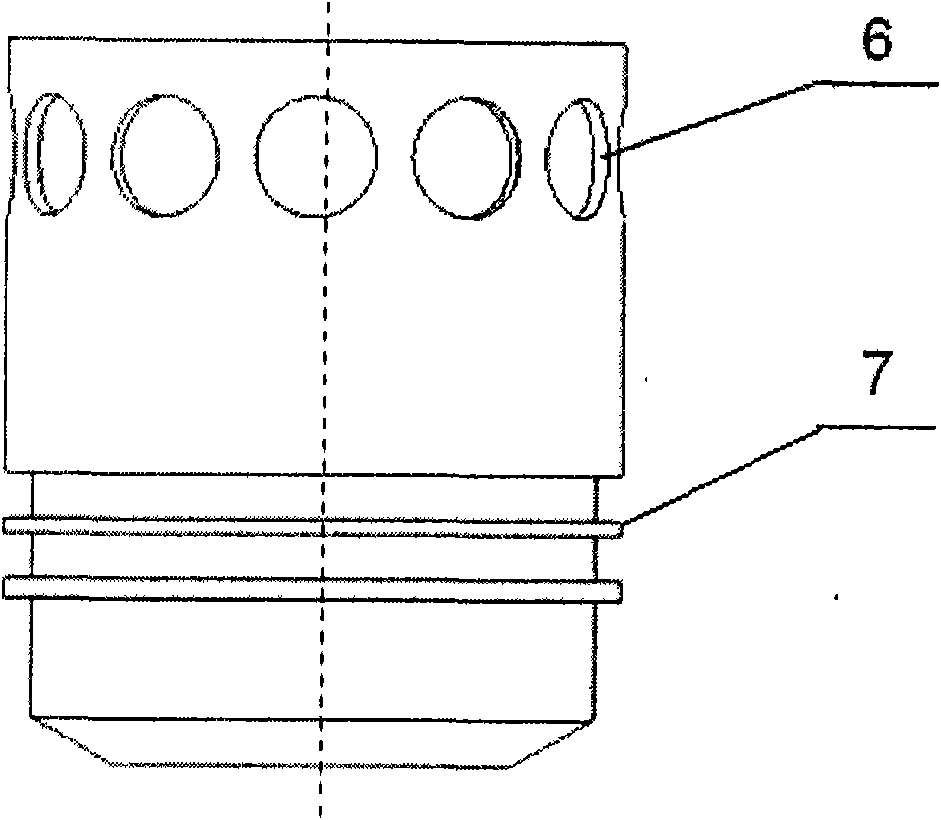

[0016] The connection structure is described in detail below in conjunction with the accompanying drawings:

[0017] see figure 1 and figure 2 , the connection structure includes the exhaust gas recirculation inlet pipe 1 and the plastic intake manifold 4, and a connecting boss is arranged at the entrance where the plastic inlet manifold 4 is connected to the exhaust gas recirculation inlet pipe 1, and there is a connecting boss on the boss Bolt hole.

[0018] A thermal insulation sleeve 3 is arranged between the connection part of the exhaust gas recirculation inlet pipe 1 and the plastic intake manifold 4, the material of the thermal insulation sleeve is stainless steel, and the wall thickness is not less than 2mm. The heat insulation sleeve 3 is installed in the inlet of the installation boss of the plastic intake manifold 4, and the connection head of the exhaust gas recirculation inlet pipe 1 is inserted into the heat insulation sleeve 3, and the two are connected thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com