Sleeve-type electric heating device for high-temperature and high-pressure gas

A high-temperature and high-pressure gas and electric heating device technology, which is used in air heaters, fluid heaters, lighting and heating equipment, etc. The service life and thermal efficiency are improved, the consumption of precious metal materials is saved, and the effect of saving high-temperature precious metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

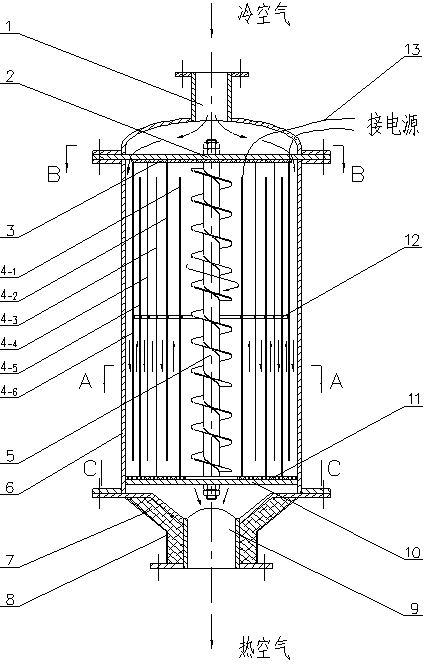

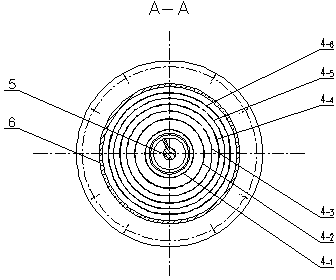

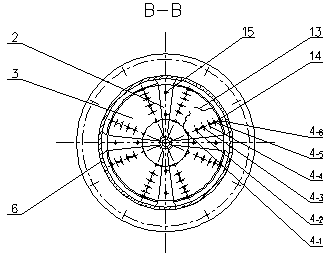

[0037] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

[0038] The gas electric heating device provided by the present invention is as Figure 1-10 As shown, the device includes a shell 6, a heating core, an inlet fixing plate 2, an outlet fixing plate 10, an inlet insulating sealing plate 3, an outlet insulating sealing plate 11, and inlet and outlet connecting pipes 1 and 9, among which the heating core The body includes parts such as an inner cylinder 4, a ceramic screw rod 5 and a ceramic fixing ring 12.

[0039] The shell 6 is a sealed shell, which bears the pressure difference between the heating gas and the outside. The material and wall thickness of the shell can be selected according to the pressure of the gas, and different material and wall thickness parameters can be selected. According to the heating power and the final temperature of gas heating, the inner surface of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com