Hydrogen fuel cell tail gas aftertreatment device based on catalysis and micro-combustion

A tail gas post-treatment, fuel cell technology, applied in the direction of fuel cells, electrical components, circuits, etc., can solve the problems of not being utilized, increasing the complexity of the structure, increasing the cost, etc., to improve safety and stability, prevent gas Suck back and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

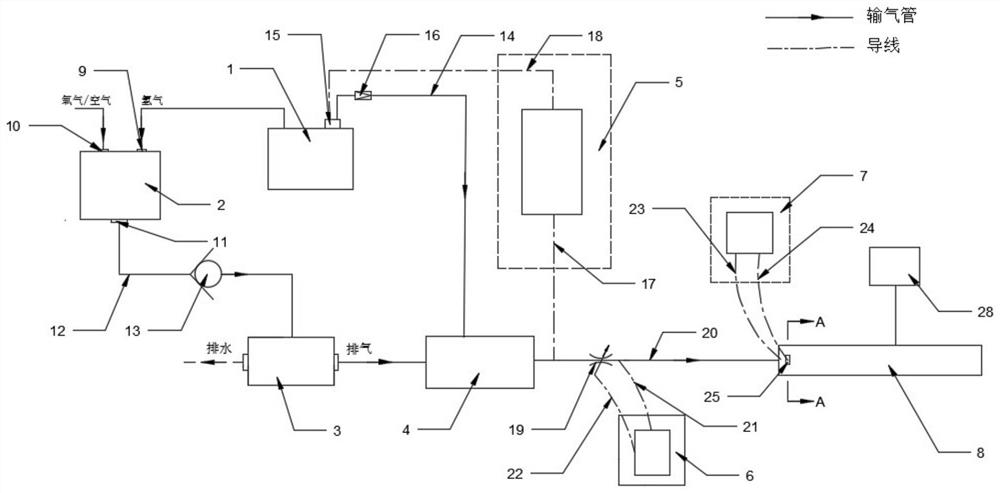

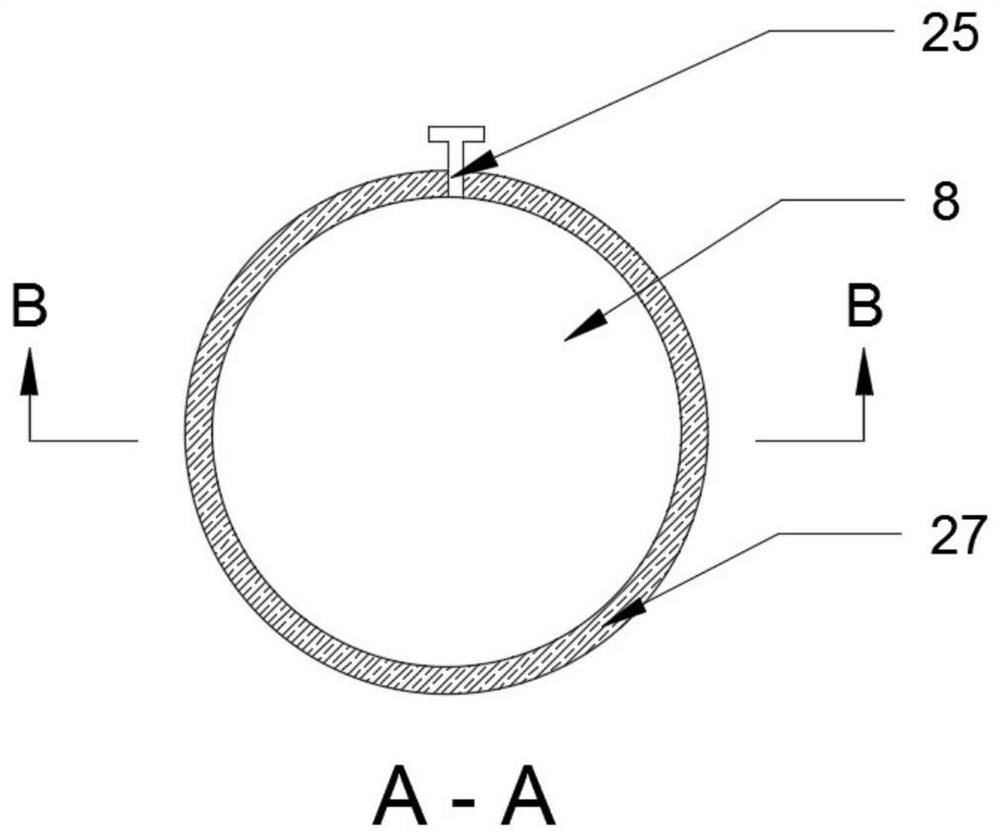

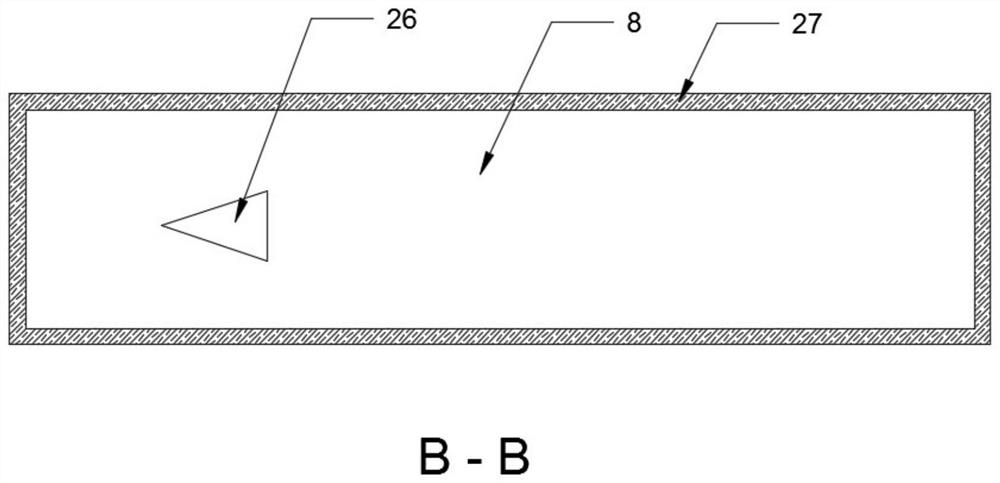

[0034] Such as figure 1As shown, the hydrogen fuel cell tail gas post-treatment device based on catalysis and micro-combustion according to the present invention, its working principle is to combine micro-combustion technology and catalytic technology, and apply it to the post-treatment of hydrogen fuel cell tail gas; the specific process is as follows , the hydrogen produced by the hydrogen production device 1 is passed into the anode inlet 9 of the hydrogen fuel cell 2, and the cathode inlet 10 is passed into oxygen or air, and these two gases undergo oxidation and reduction reactions at the anode and the cathode respectively. 2 The tail gas produced includes unreacted hydrogen, oxygen, product water and a lot of heat. The tail gas enters the tail gas filter device 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com