Patents

Literature

50results about How to "Improve combustion sufficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

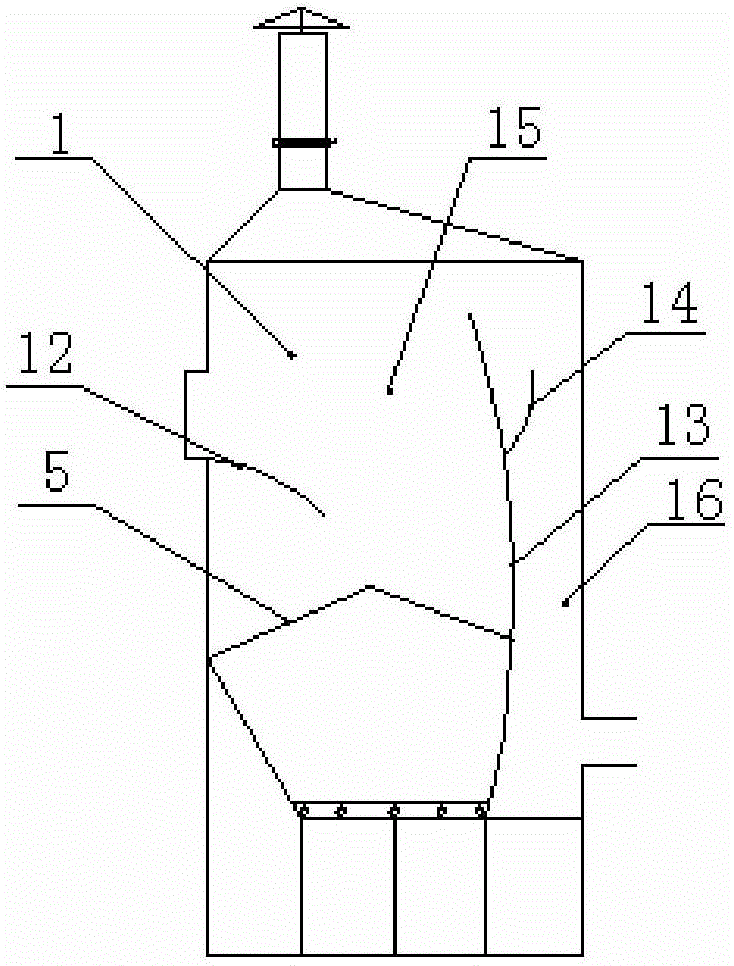

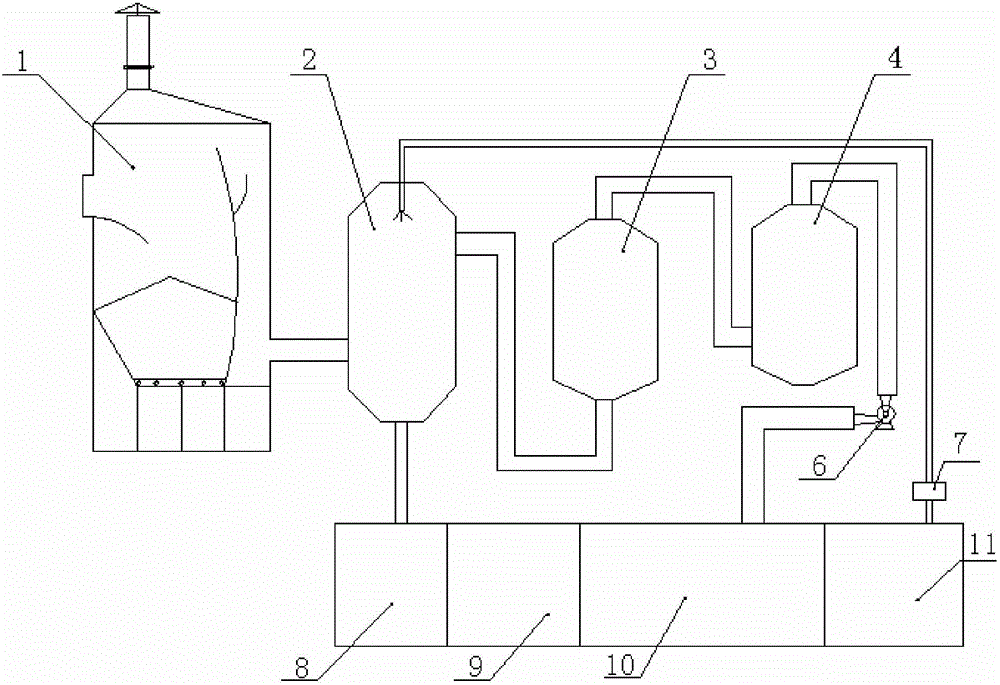

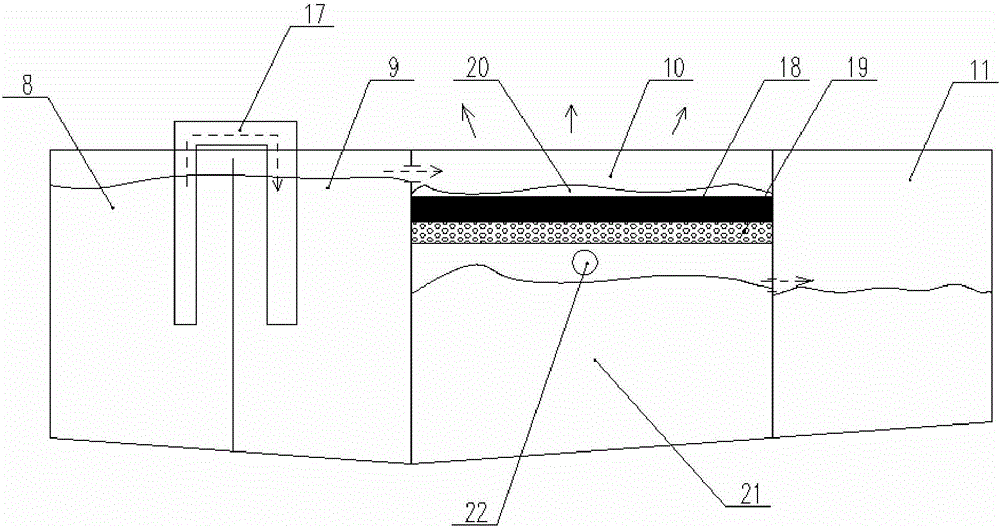

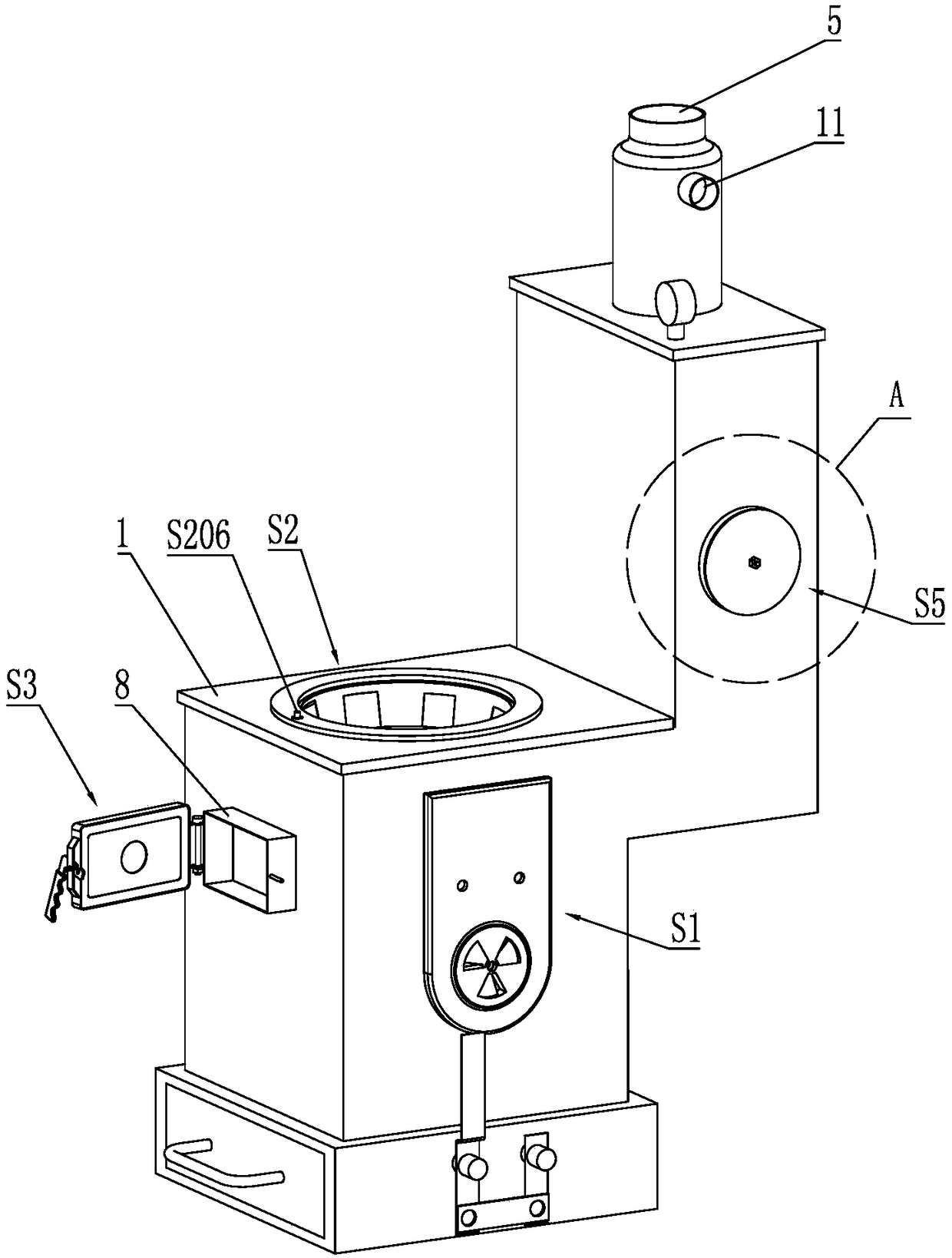

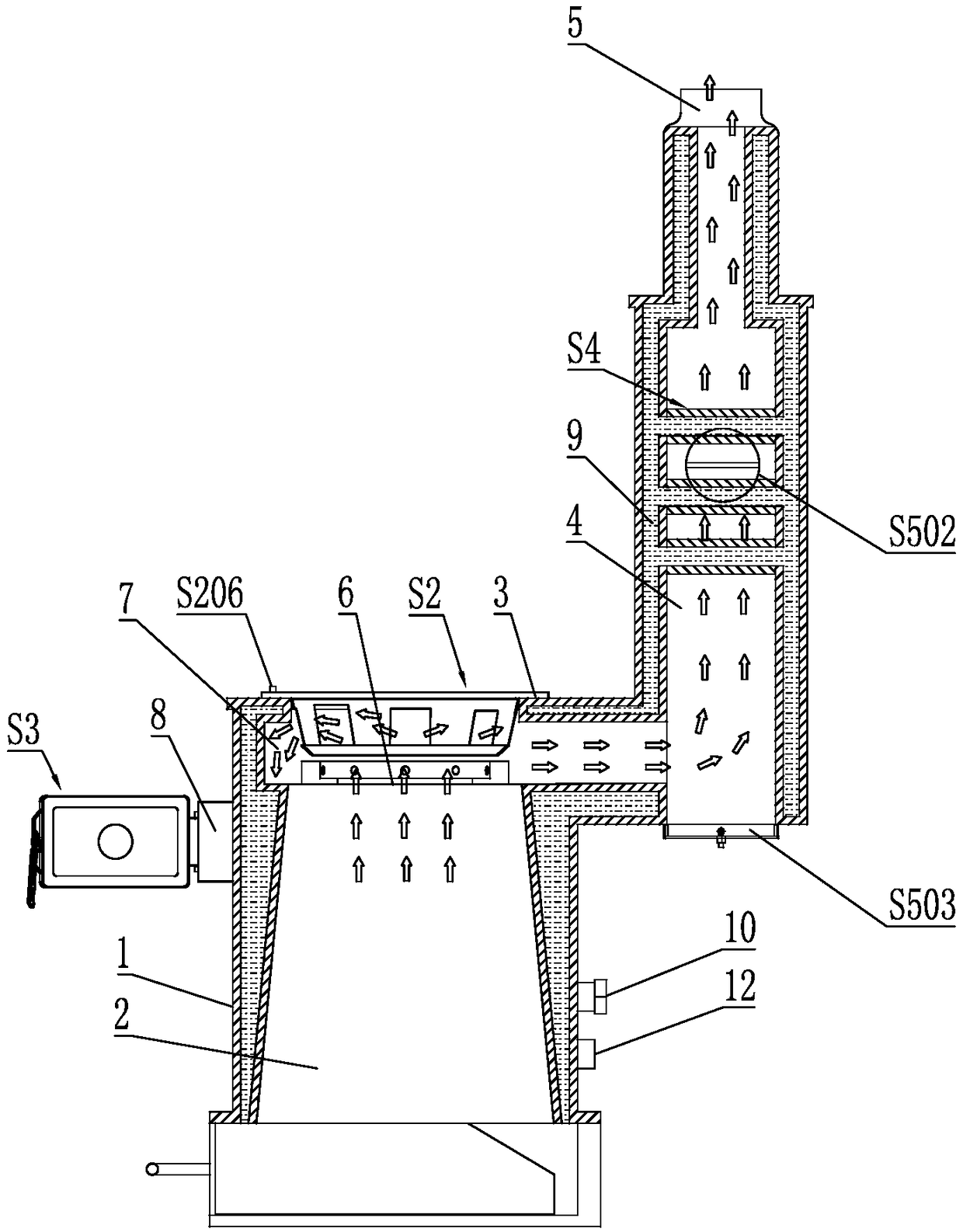

Garbage incinerator and whole-set garbage treatment system adopting same

ActiveCN106196087ATo dryFor the purpose of breaking upIncinerator apparatusNitrogen oxidesCombustion

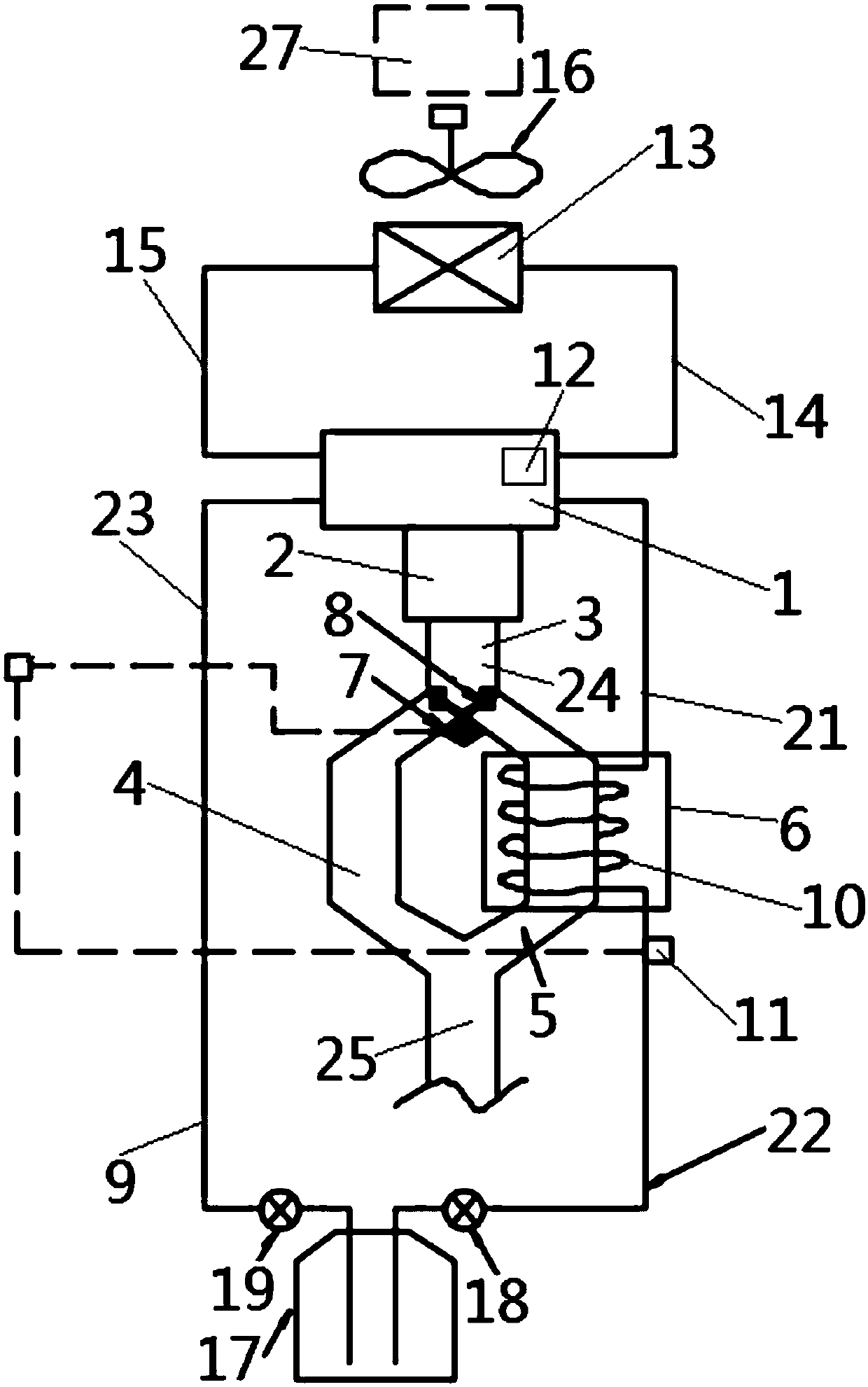

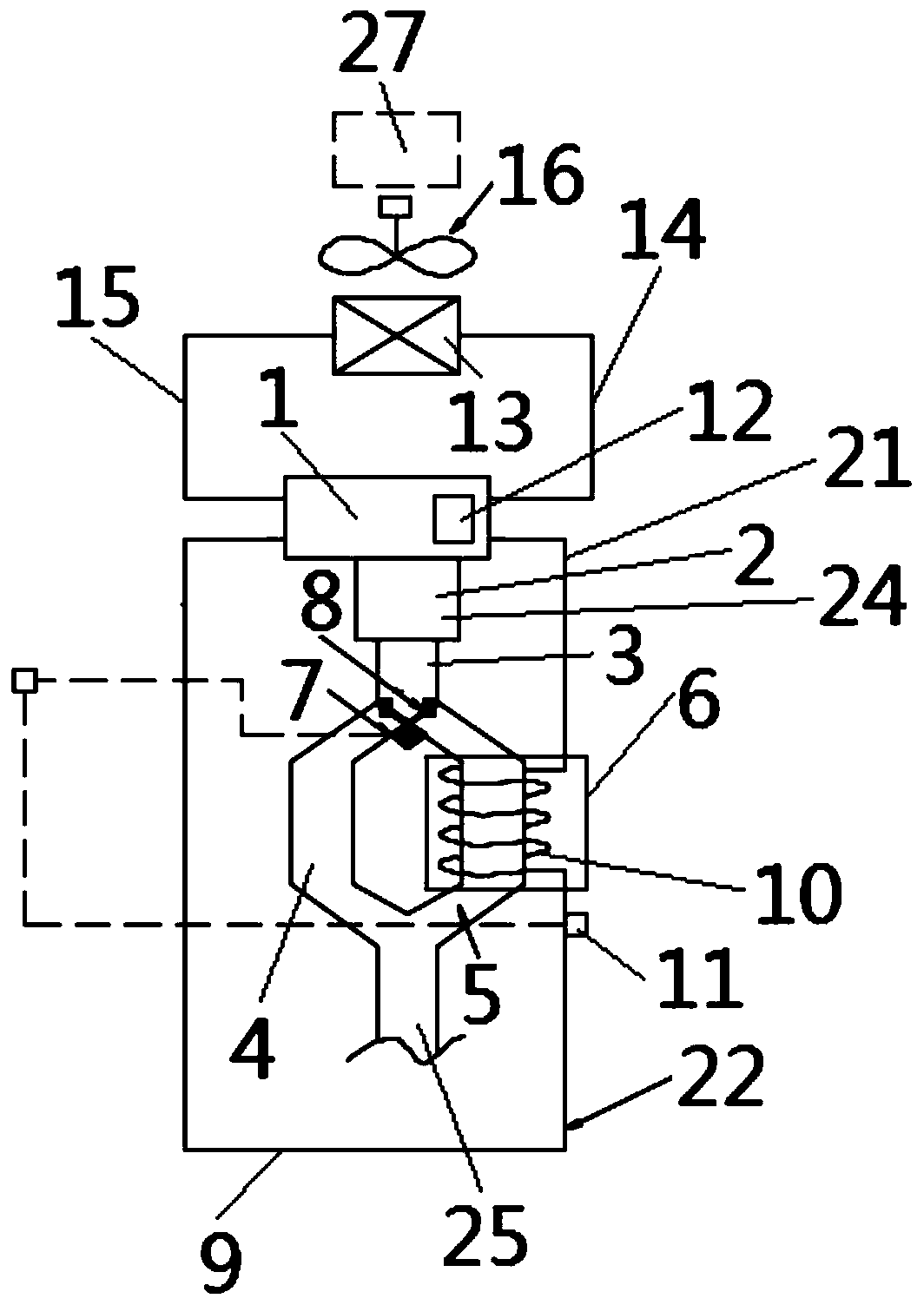

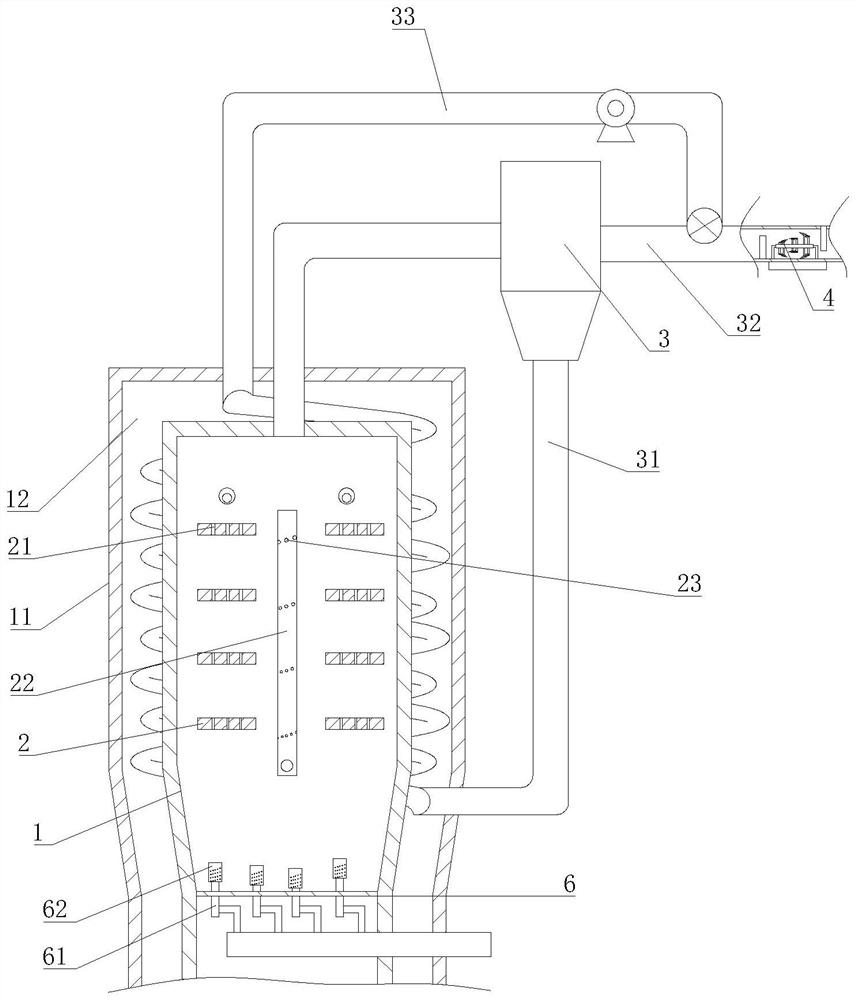

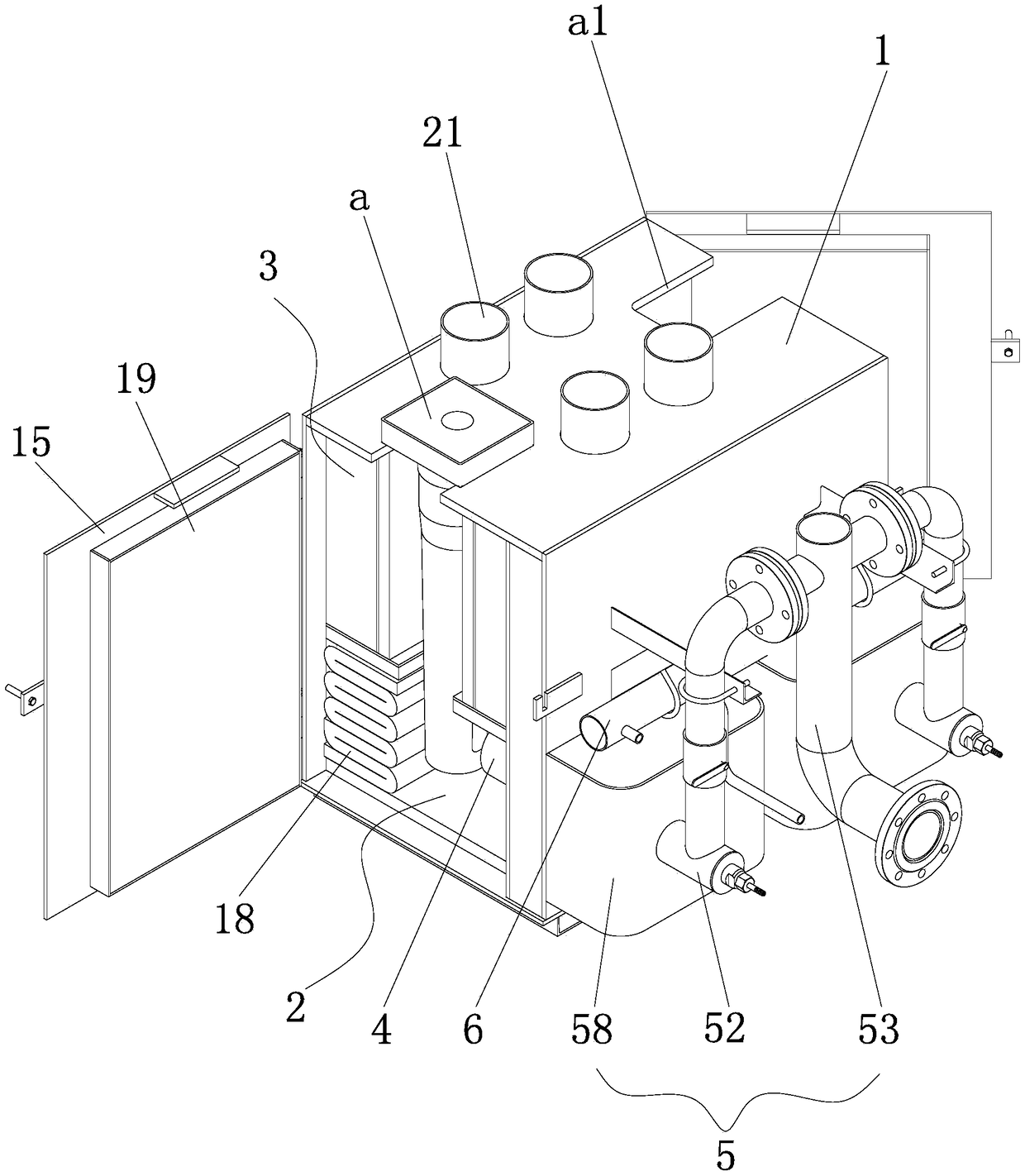

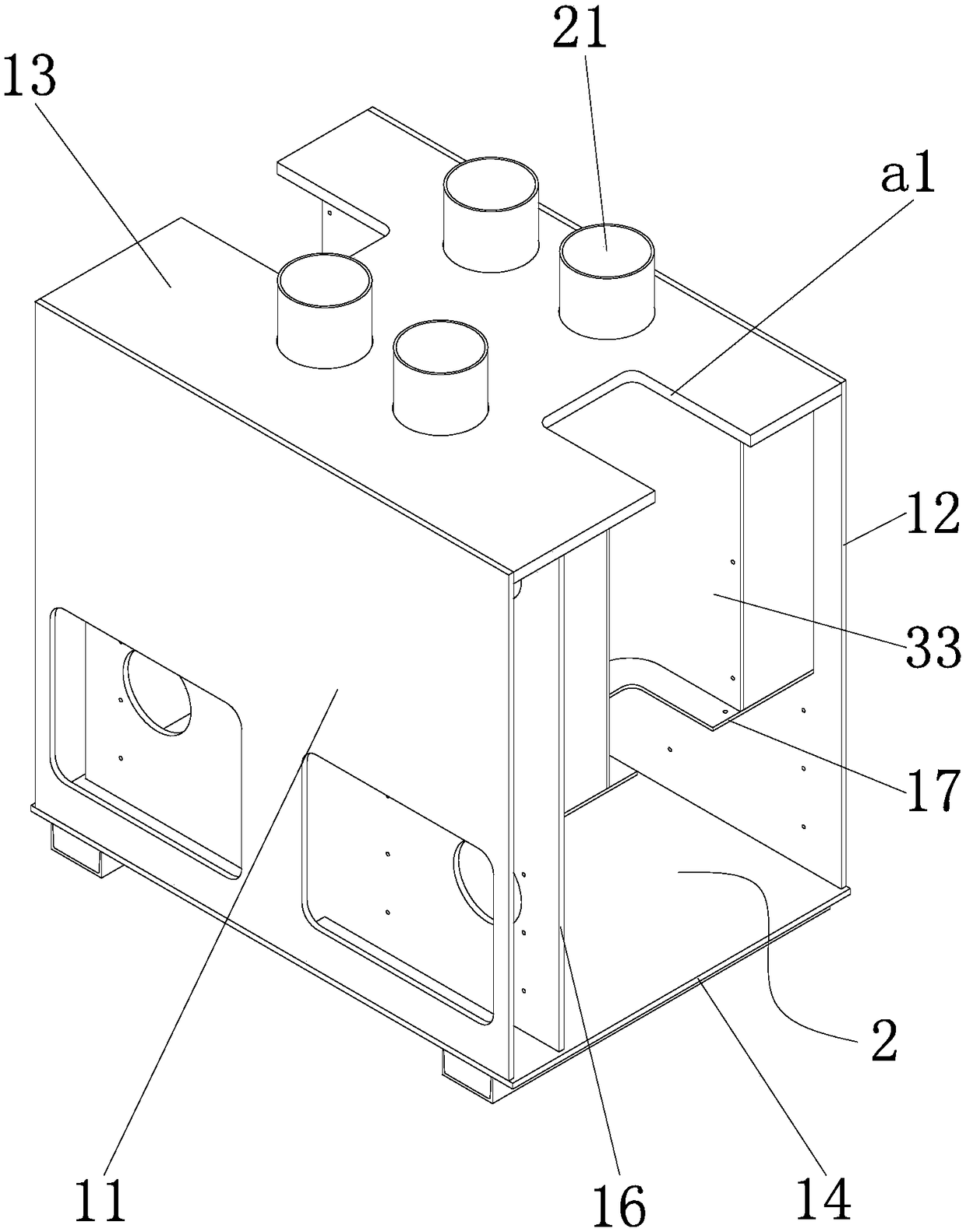

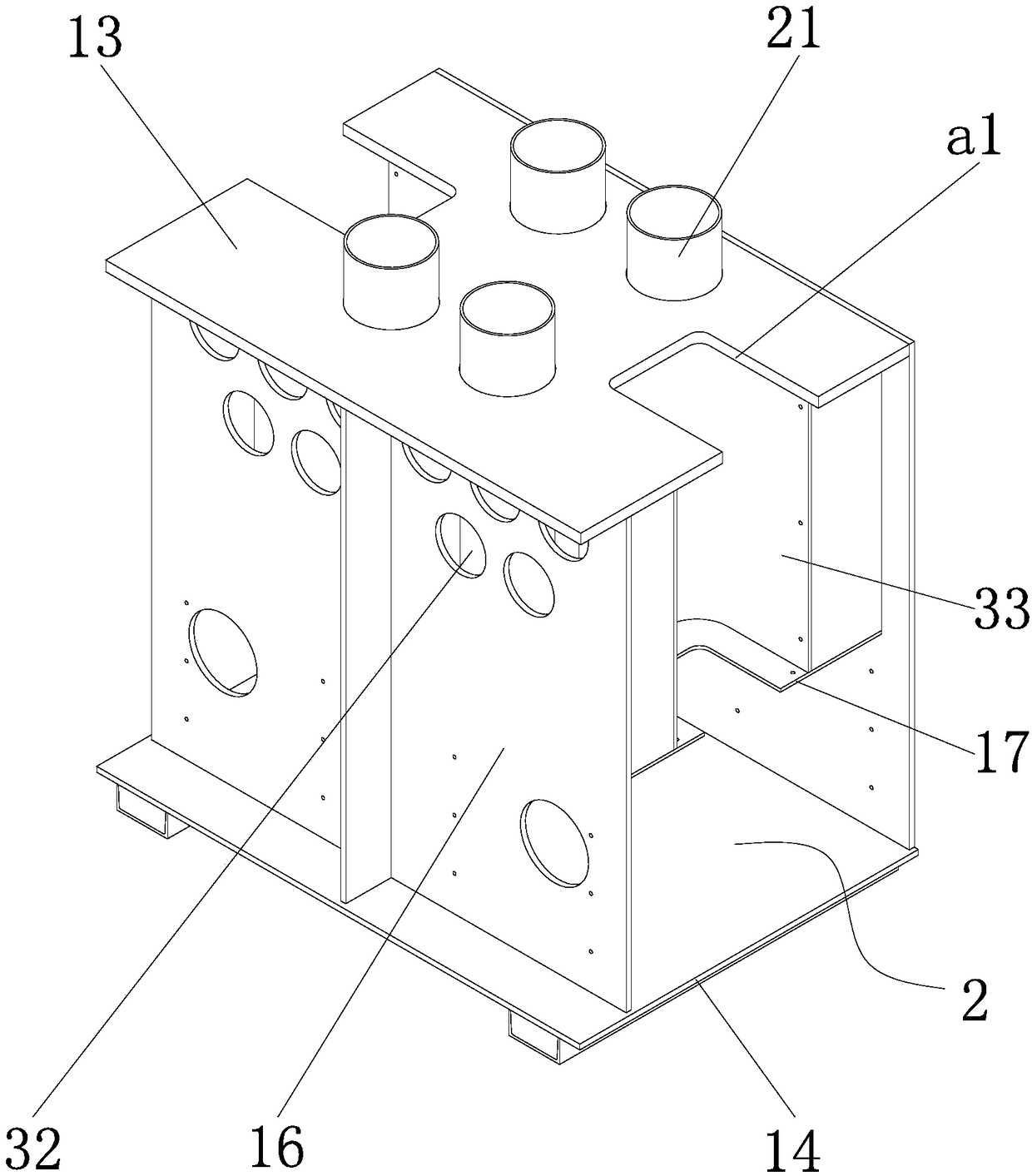

The invention discloses a garbage incinerator and a whole-set garbage treatment system adopting the same. The garbage incinerator is internally divided into a garbage combustion area and a smoke decomposition area through a partition plate. The garbage combustion area is communicated with a feeding opening and internally provided with a furnace arch and a furnace grate. A channel for smoke ventilation is formed between the smoke decomposition area and the garbage combustion area. A smoke outlet of the garbage incinerator is directly communicated with the smoke decomposition area. The smoke outlet of the garbage incinerator is sequentially connected with a deacidification tower, a demisting tower and a stink treatment device in series. An outlet of the stink treatment device is connected with a sand filter through a fan. Treated smoke is exhausted through the sand filter. According to the garbage incinerator, the combustion sufficiency of garbage in the incinerator is improved, the decomposition efficiency of harmful substances like dioxin in the smoke is improved, emissions of dioxin and the like are reduced, dust, sulfide and nitrogen oxide in the smoke are effectively eliminated, the smoke is filtered and exhausted by the adoption of the sand filter, water is utilized circularly, and cost of aspects such as investment, production machining and equipment installation of equipment is saved.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

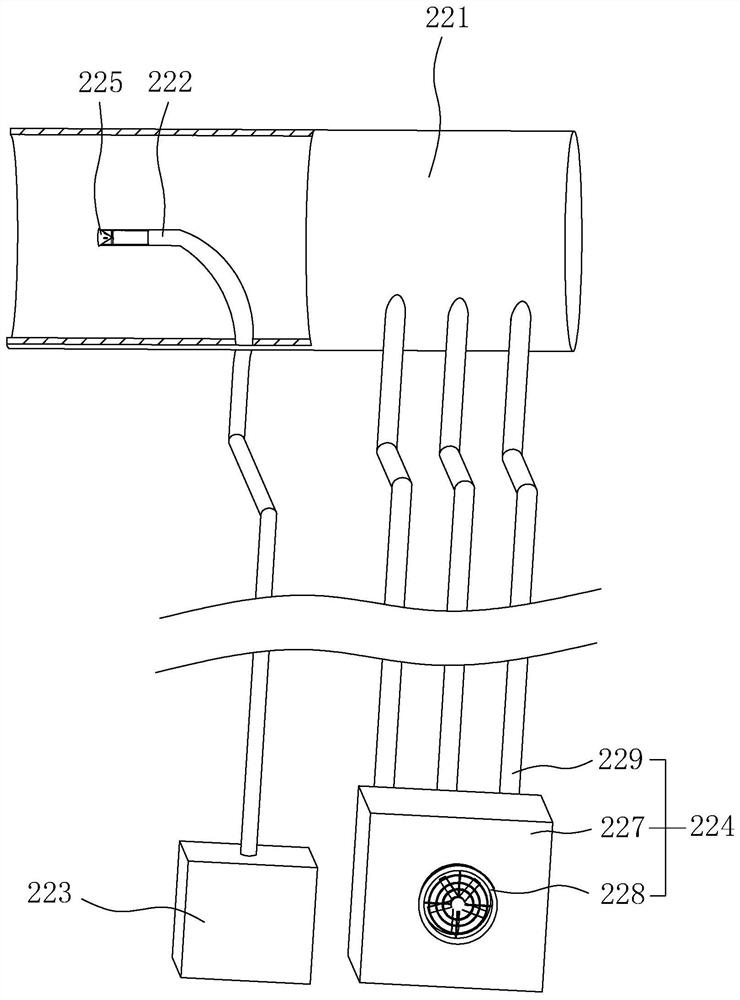

Automobile waste heat recovering and reusing system

InactiveCN109630246AShorten warm-up timeLow waste heat qualityInternal combustion piston enginesExhaust apparatusLiquid temperatureCombustion

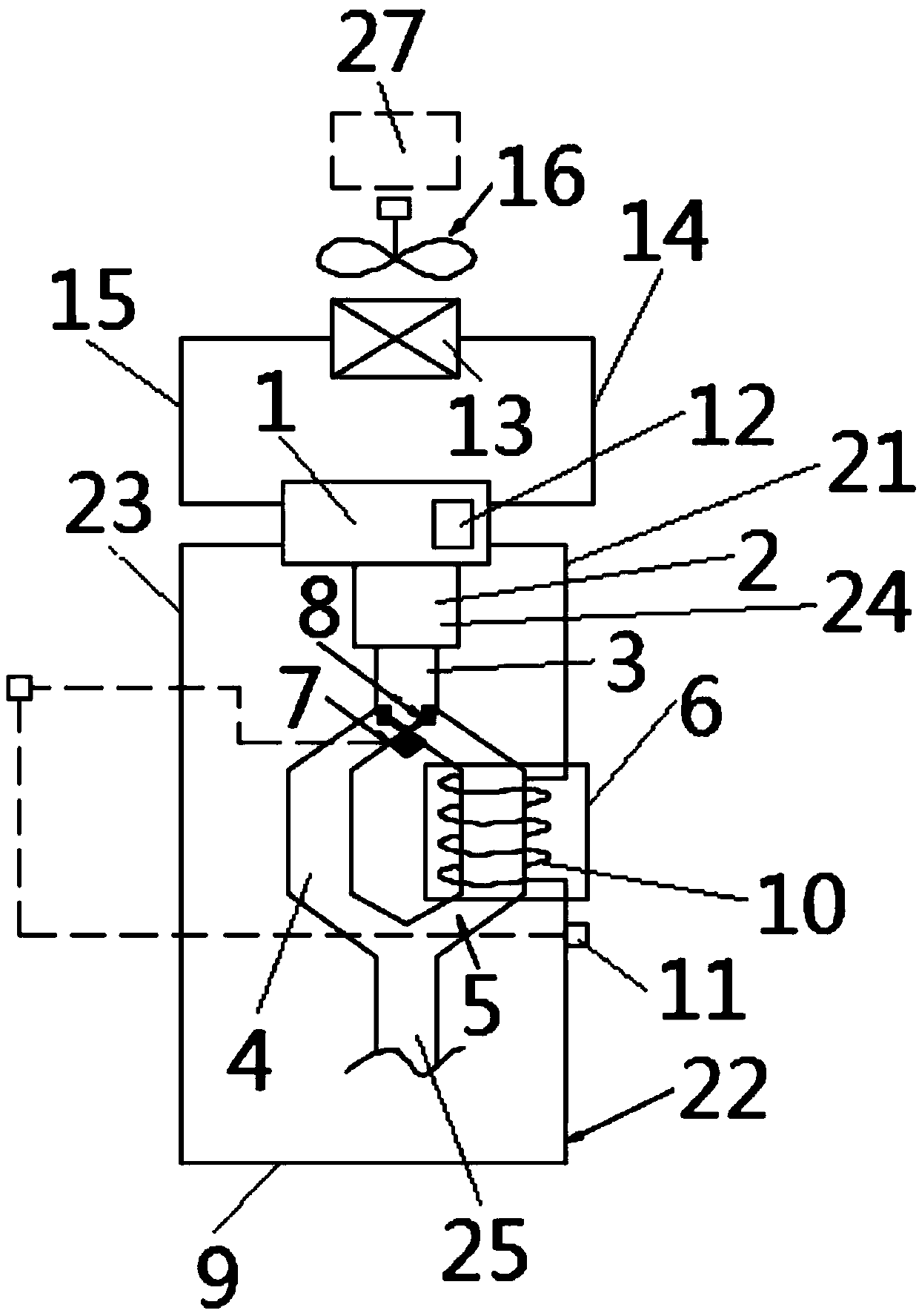

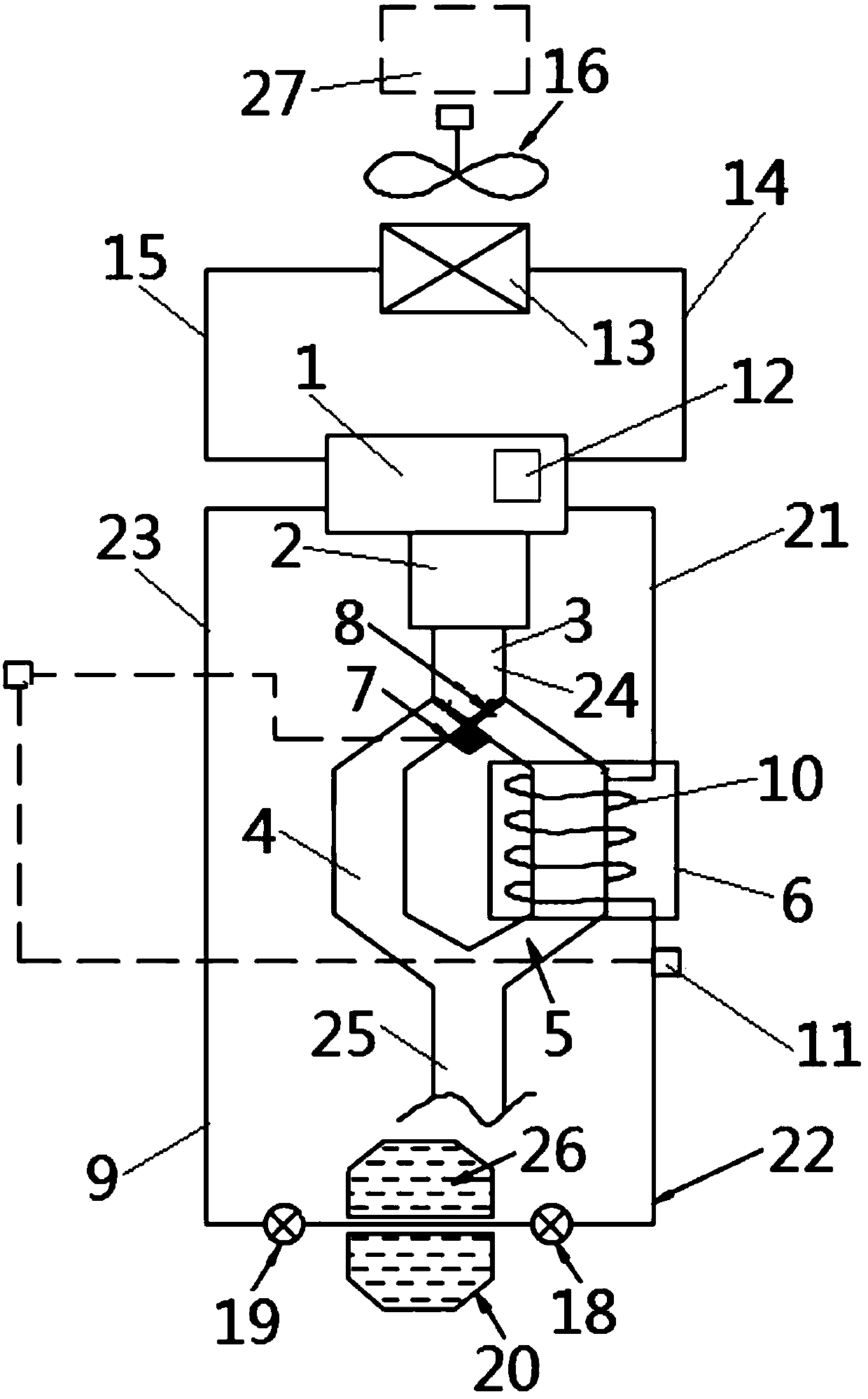

The invention provides an automobile waste heat recovering and reusing system applied to the technical field of automobile engines. An exhaust pipe (3) of the automobile waste heat recovering and reusing system comprises an exhaust pipe branch pipeline I (4) and an exhaust pipe branch pipeline II (5). A heat exchanger (6) is arranged on the exhaust pipe branch pipeline II (5). A bypass valve actuator (7) and a bypass valve (8) are arranged on the exhaust pipe (3). A spiral heat-exchange pipe part (10) is arranged on the portion, located in the heat exchanger (6), of a cooling liquid pipeline (9). A heat exchanger outlet cooling liquid temperature sensor (11) is arranged on the portion, stretching out of the heat exchanger (6), of the cooling liquid pipeline (9). According to the automobilewaste heat recovering and reusing system, the structure is simple; during cold starting of an automobile, part of heat in automobile exhaust can be recovered to be used for heating cooling liquid inan automobile engine cooling system, so that an engine is heated rapidly and reliably, the heat efficiency during cold starting of the engine is improved, and combustion in a cylinder is made more sufficient.

Owner:JAPHL POWERTRAIN SYST

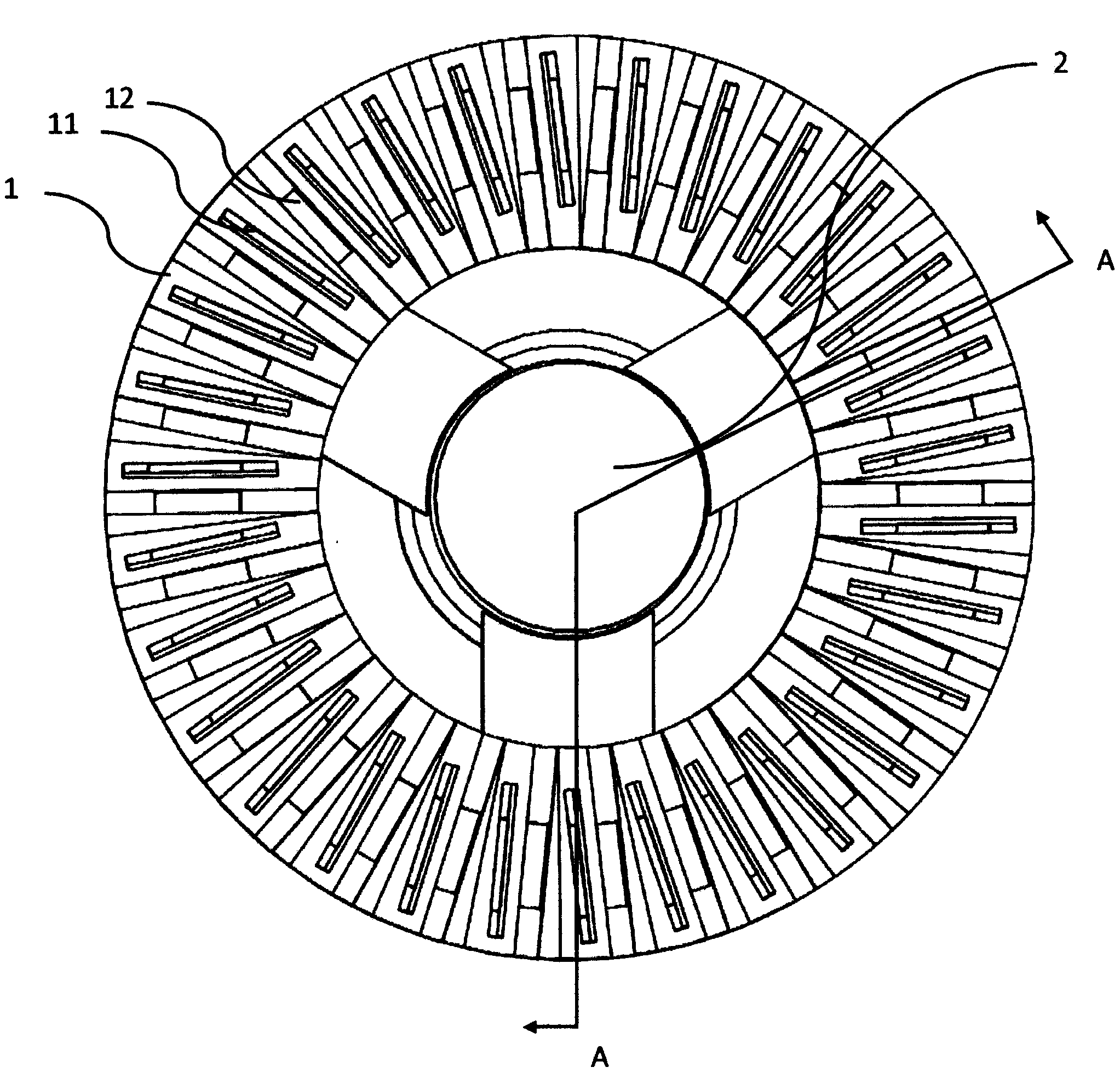

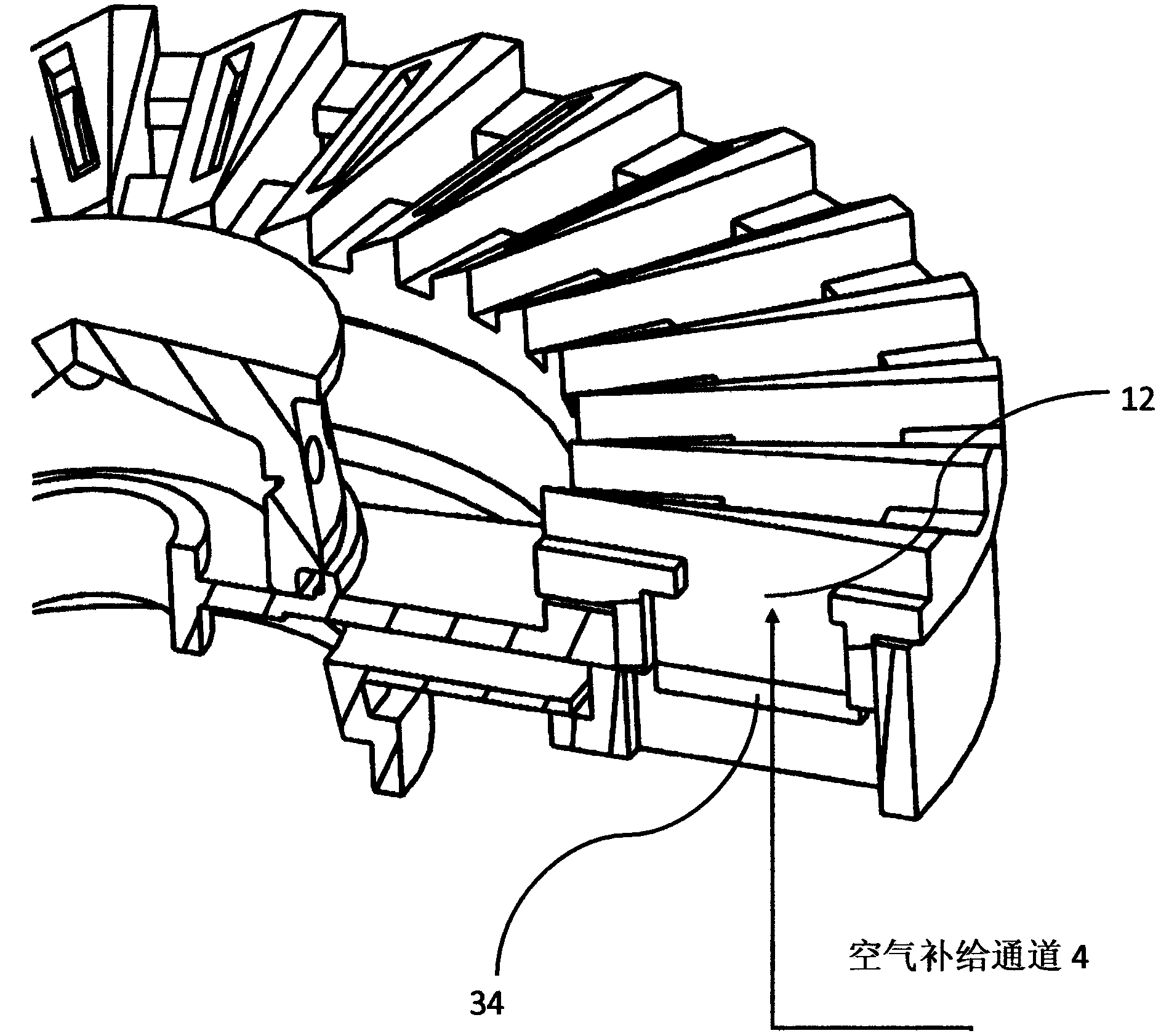

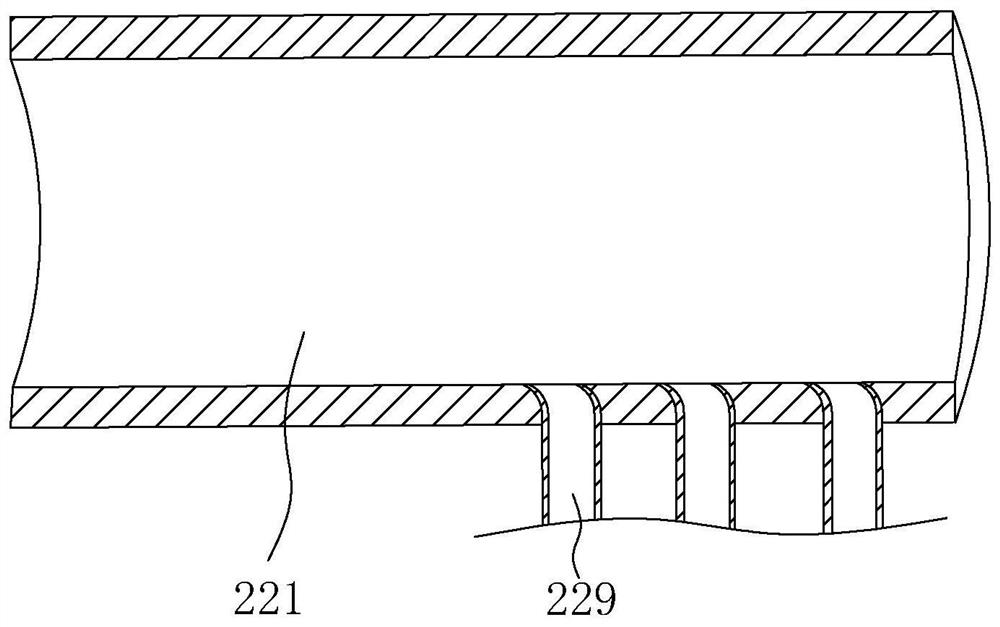

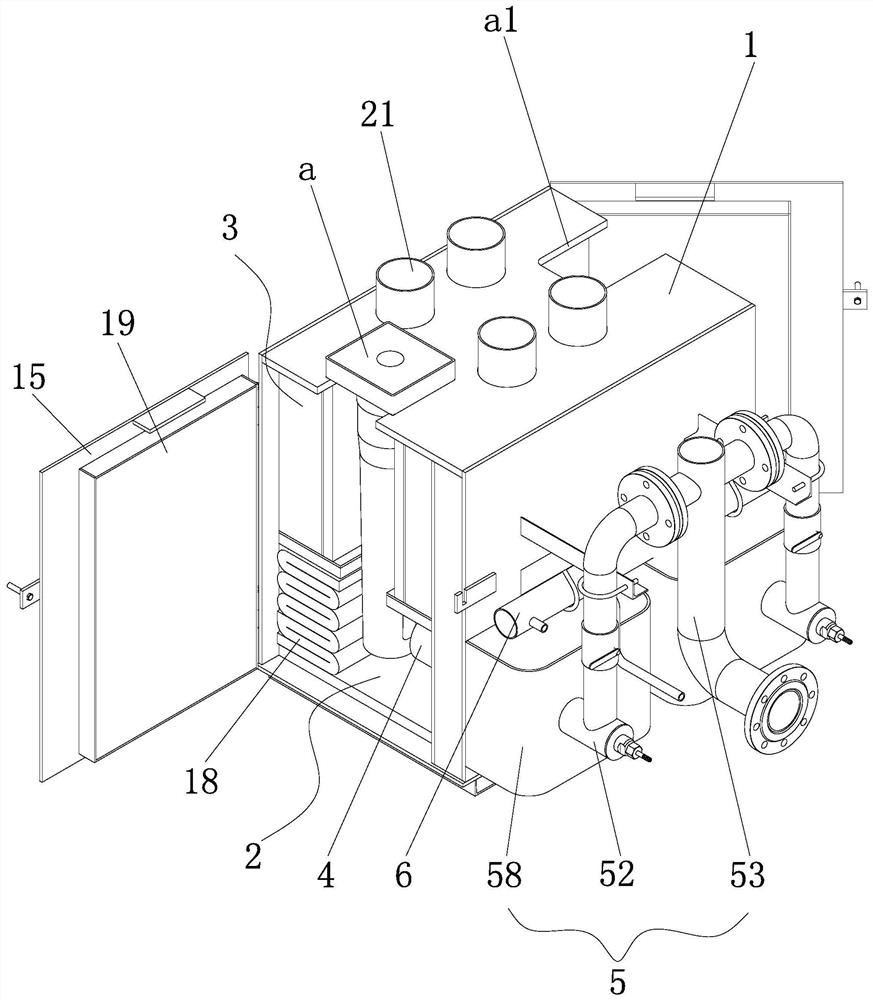

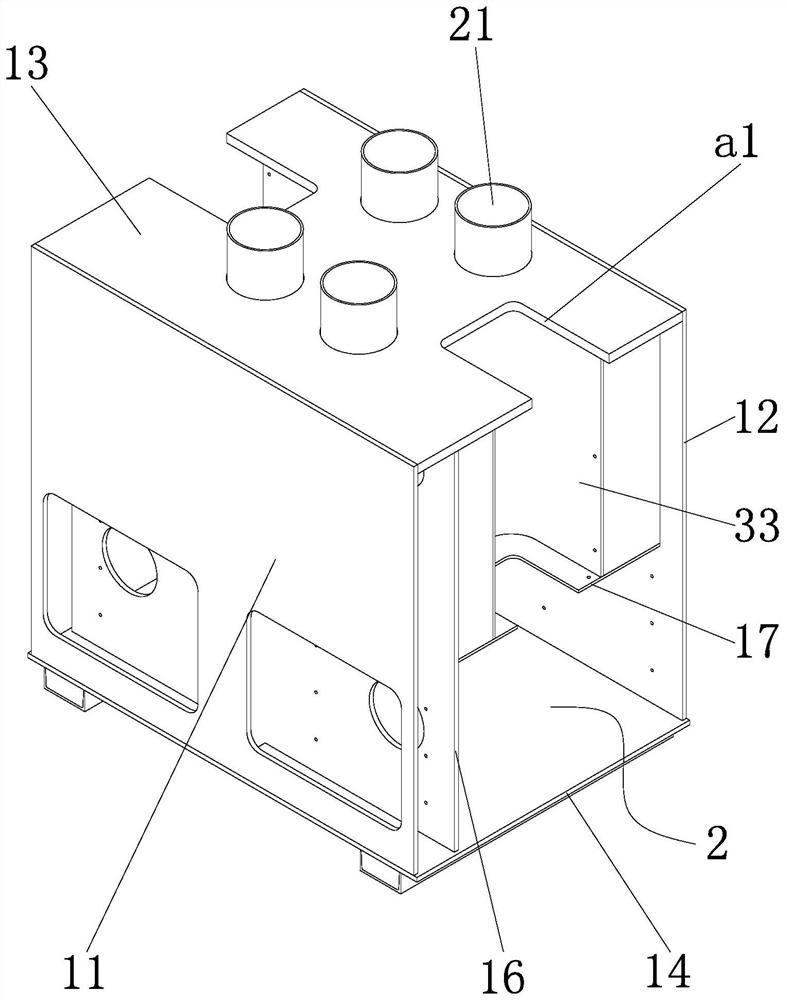

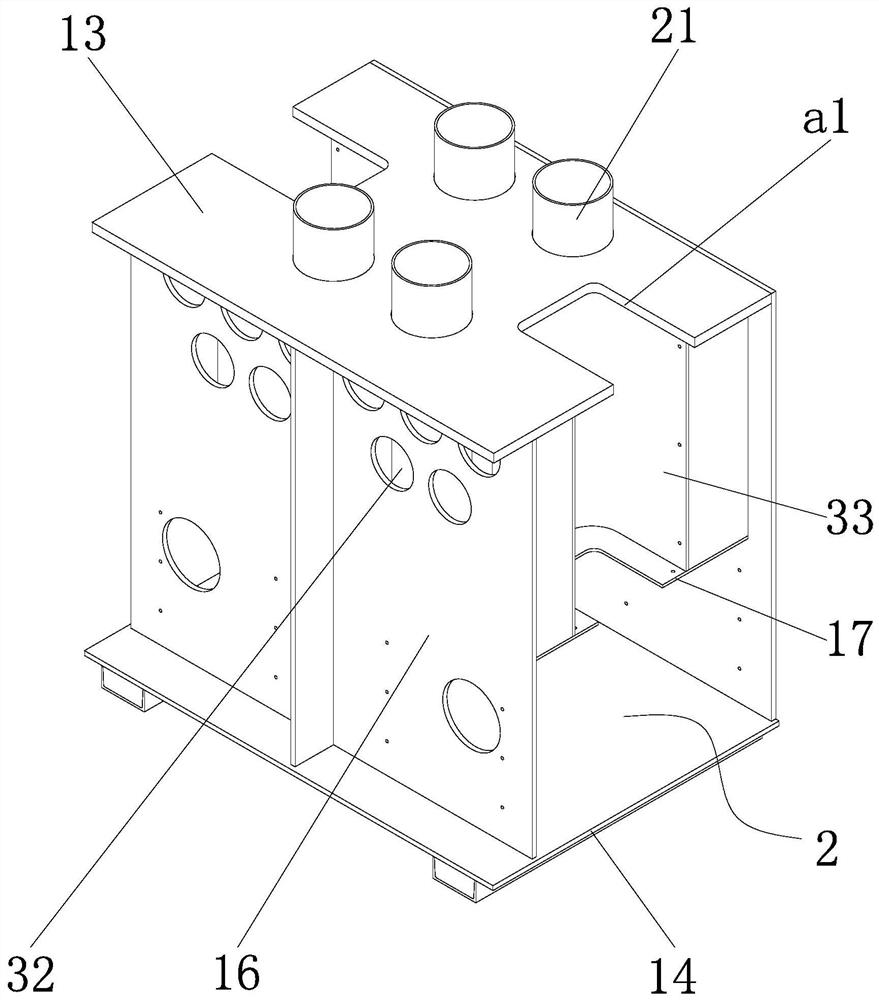

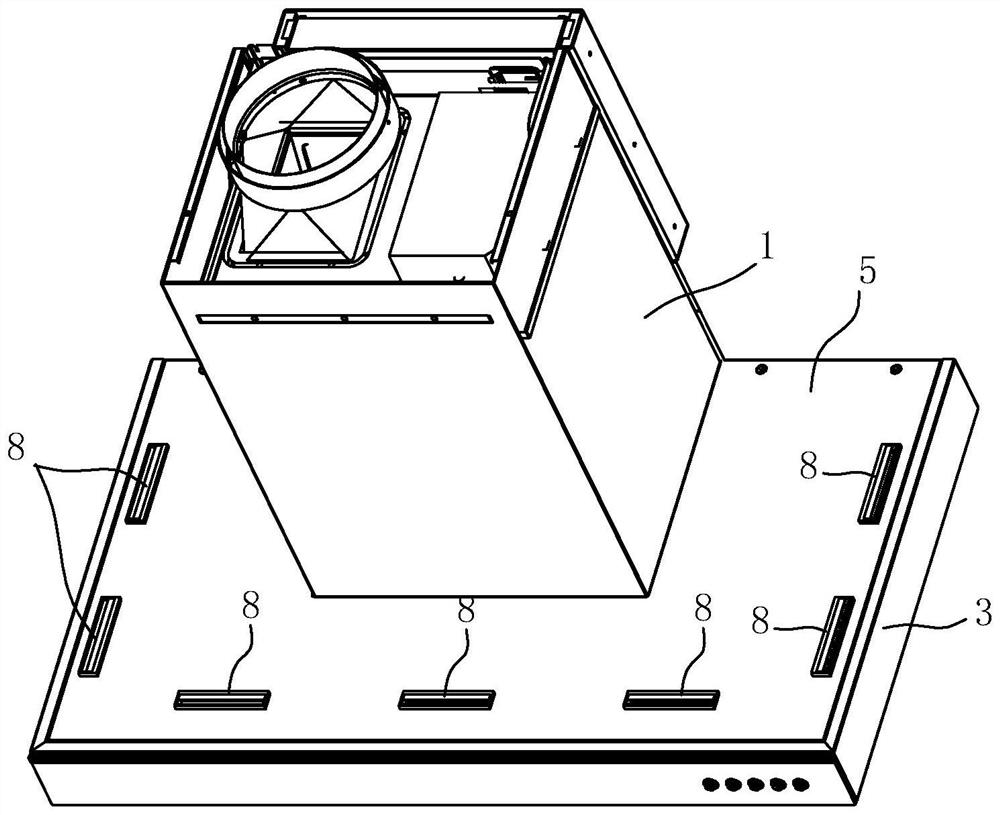

Indoor range hood and operation control method thereof

ActiveCN111520787AReduce the temperatureReduce distractionsDomestic stoves or rangesLighting and heating apparatusFresh airEngineering

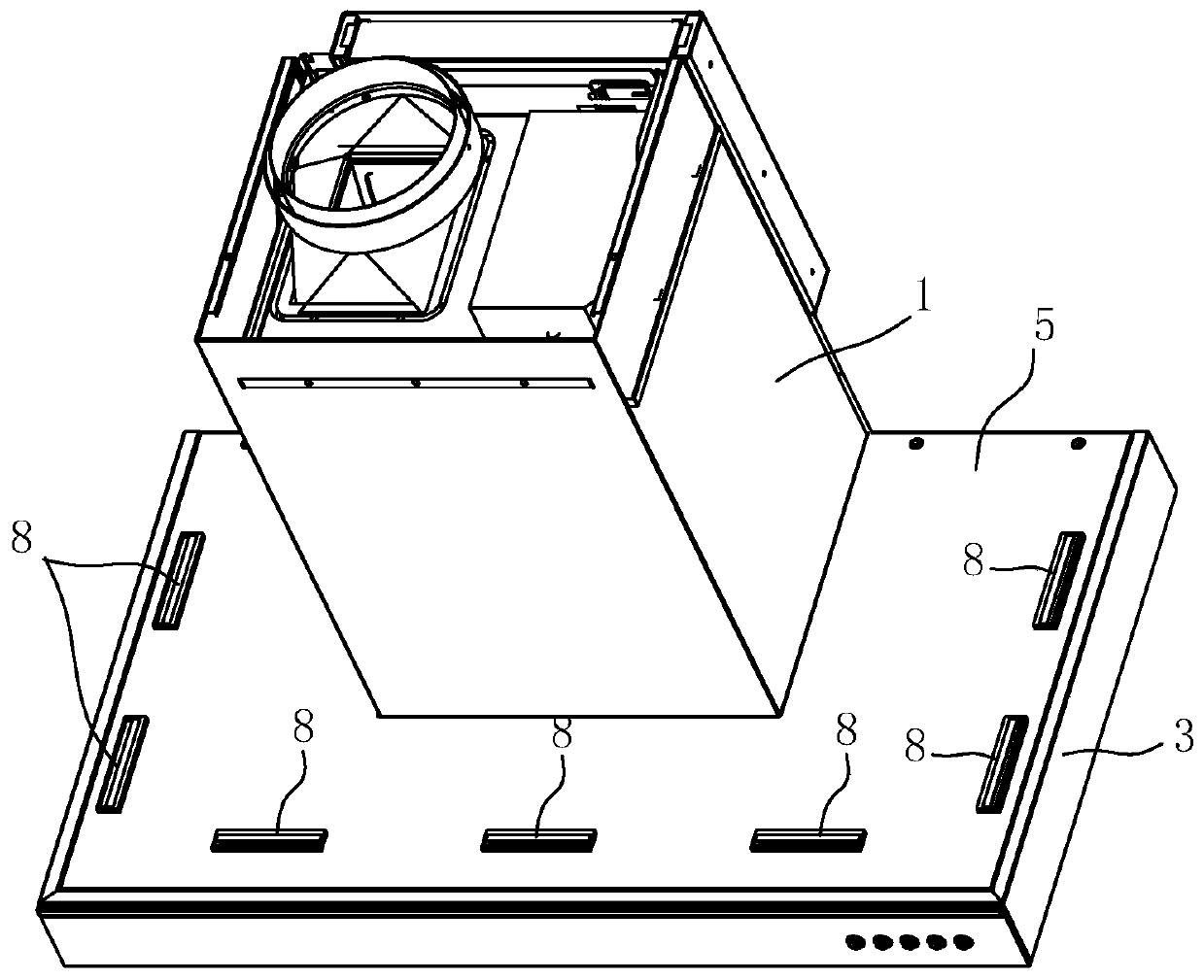

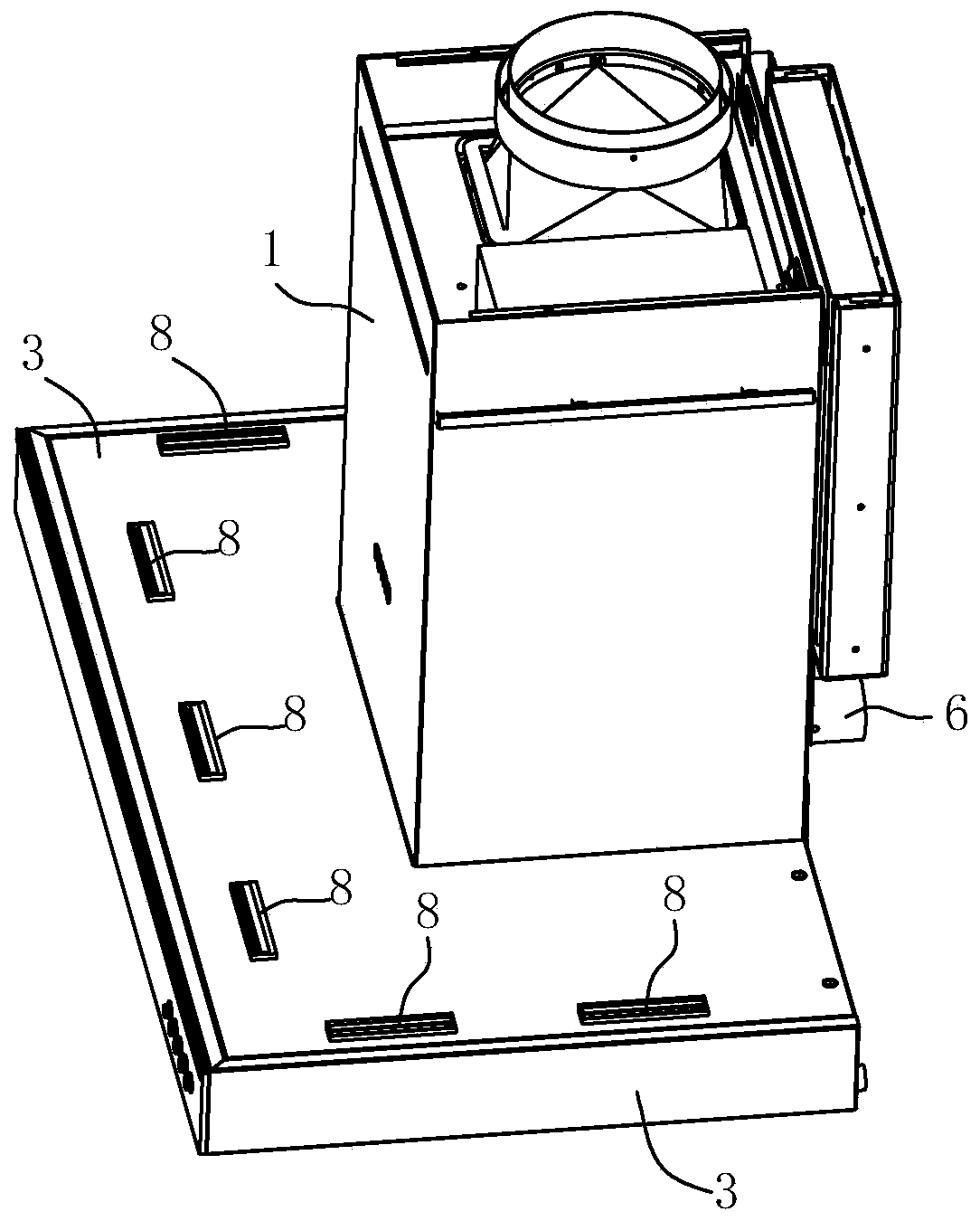

The invention relates to an indoor range hood and an operation control method thereof. The indoor range hood comprises an upper shell body, a fan system and a smoke collecting hood, a top plate is arranged above the smoke collecting hood, the top plate is connected below the upper shell body, a gap is formed between the top plate and the smoke collecting hood, and the indoor range hood is characterized in that the indoor range hood further comprises an air supplement pipe, an air supplement valve is arranged in the air supplement pipe, one end of the air supplement pipe communicates with the external space of a kitchen, the other end of the air supplement pipe communicates with the gap between the top plate and the smoke collecting hood, and the side face of the smoke collecting hood or / and the top plate is / are provided with an air outlet assembly which communicates with the gap. Compared with the prior art, the indoor range hood and the operation control method thereof have the advantages that fresh air can be actively introduced from the external space of the kitchen, and the fresh air and hot air near a stove easily form an outer surrounding flow field, so that the interferenceto the flow field near the range hood when doors and windows are opened and closed and other people walk is reduced, the face blowing effect can be provided for a user, and the use experience is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

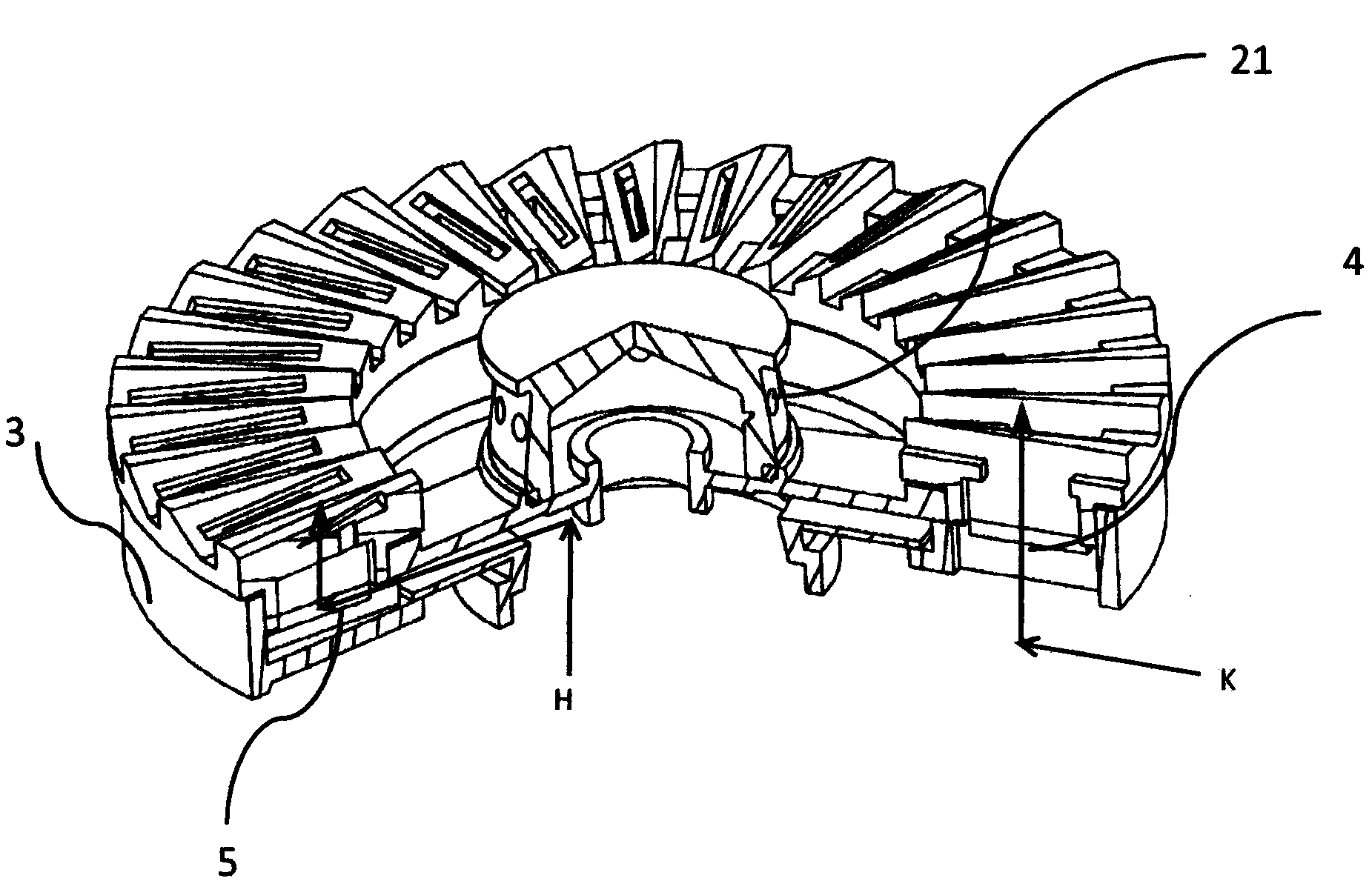

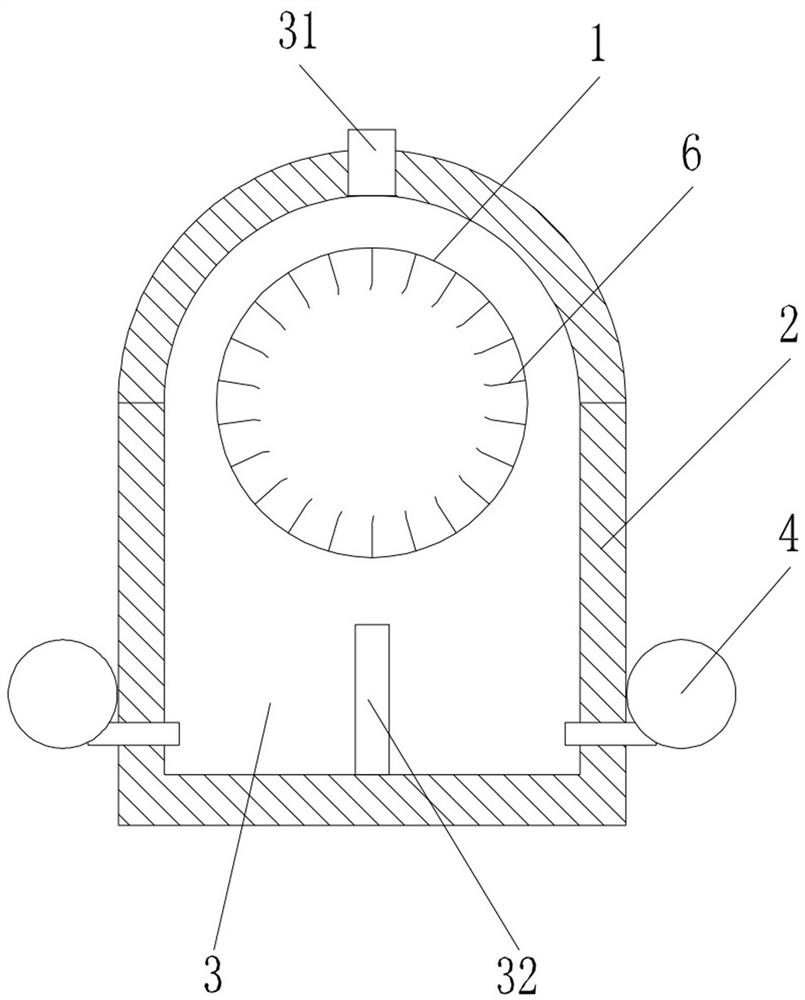

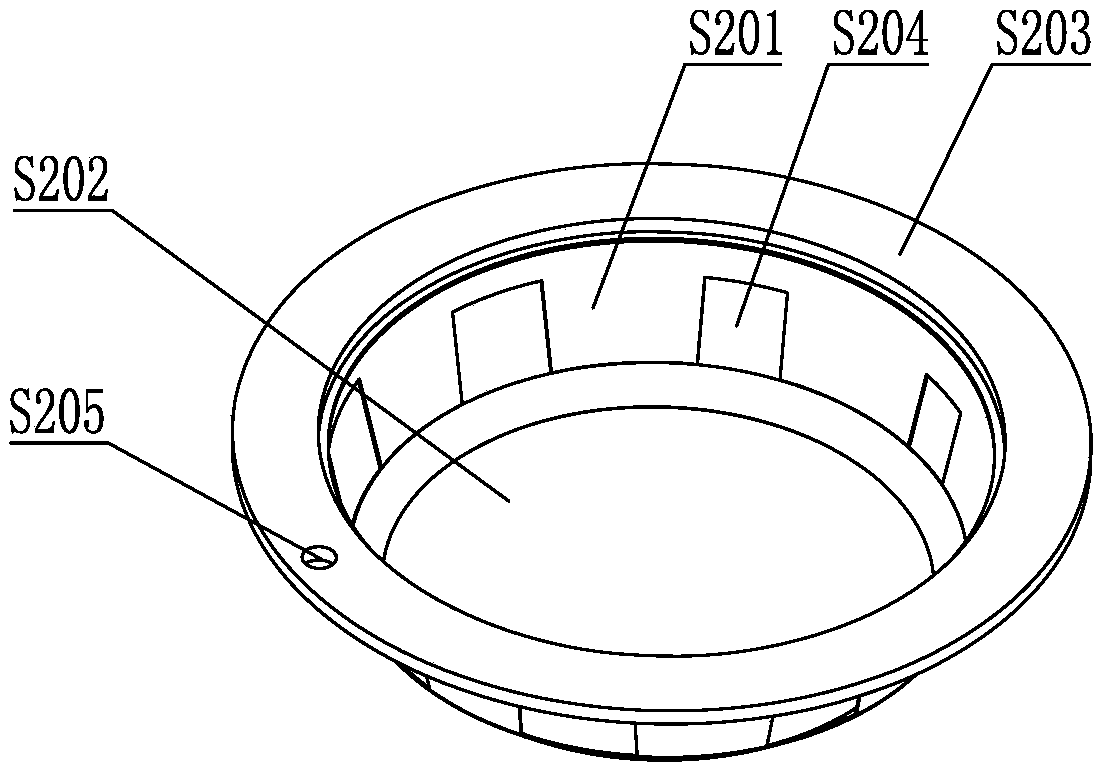

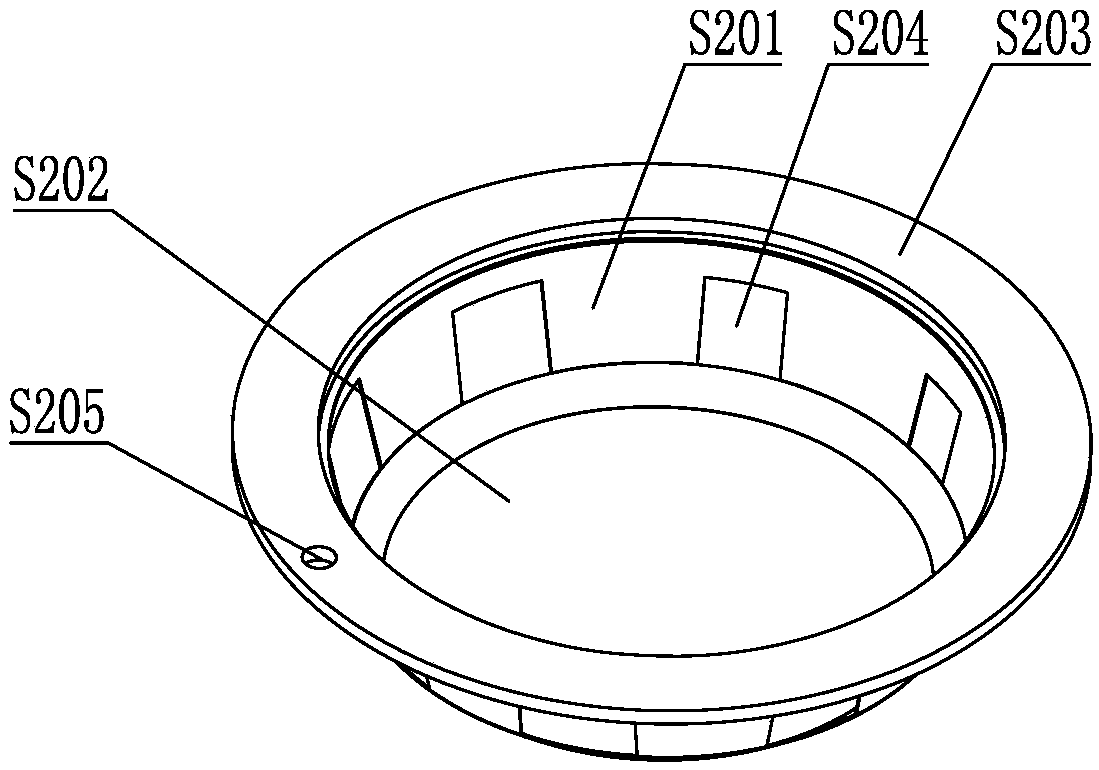

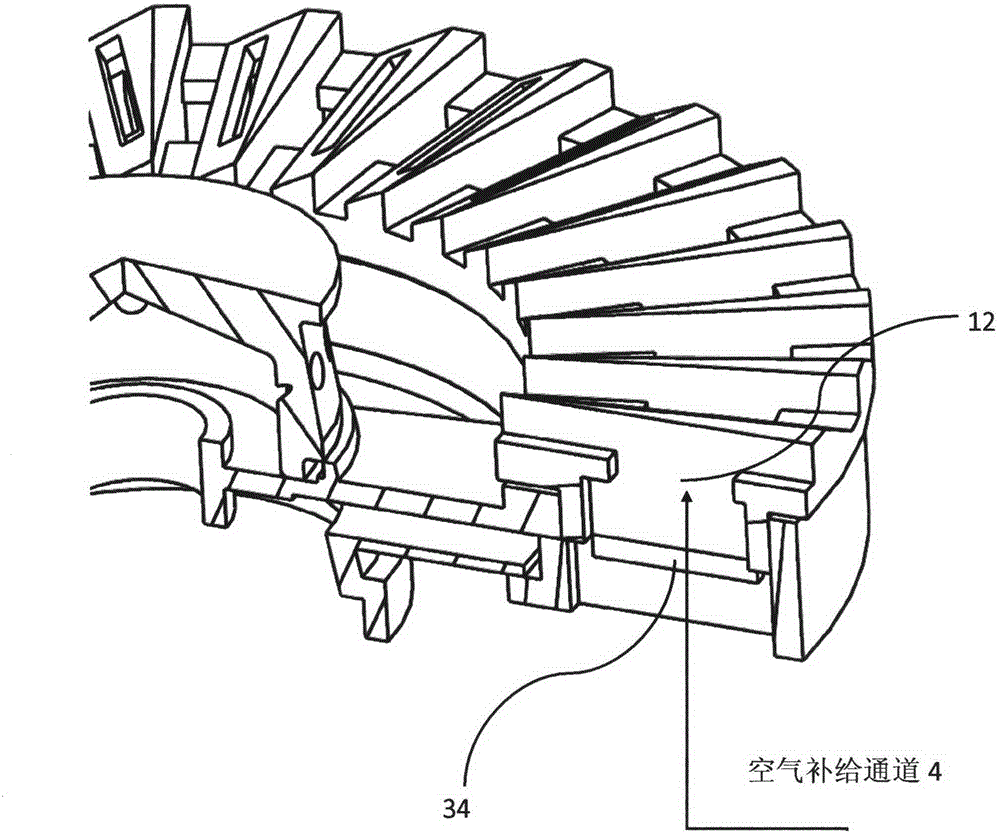

Combustor used for gas stove

ActiveCN103807855ASolve no hairReplenishment issues when resolvingGaseous fuel burnerHeat fluxProduct gas

The invention relates to a combustor used for a gas stove. The combustor comprises a big fire cover, a small fire cover and a base, and is characterized in that fire outlet holes, air supply passageways and gas mixing cavities are formed in the big fire cover, fire outlet holes are formed in the small fire cover, a base inner ring and a base outer ring are arranged on the base, and gas mixing cavities and air supply passageways are formed in the base outer ring. The air supply passageways of the big fire cover are matched with the air supply passageways in the base outer ring to form integral air supply passageways. The gas mixing cavities in the big fire cover are matched with the gas mixing cavities of the base to form integral gas mixing cavities. According to the combustor, mixed gas is mixed in the mixing cavities and combusted in the fire outlet holes of the fire covers, sufficient air supply is conducted through the air supply passageways, and therefore the mixed gas can be sufficiently combusted, and the technical effects of improving the heat flux and the heat efficiency of the combustor are achieved.

Owner:刘申昌

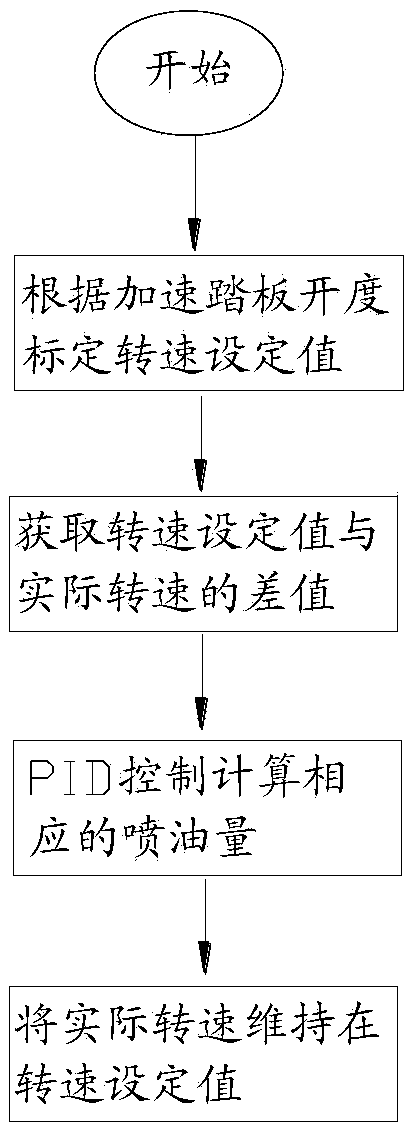

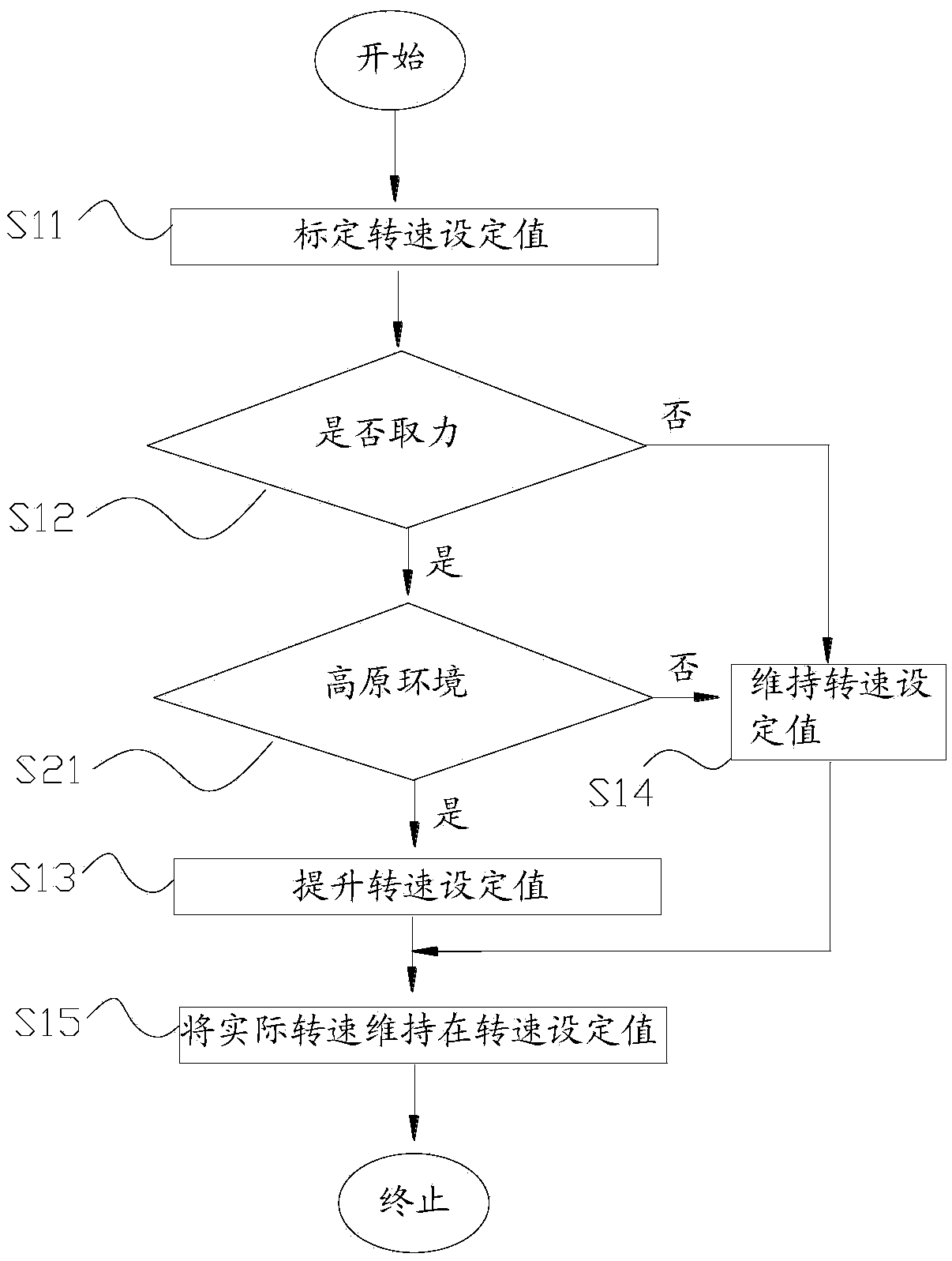

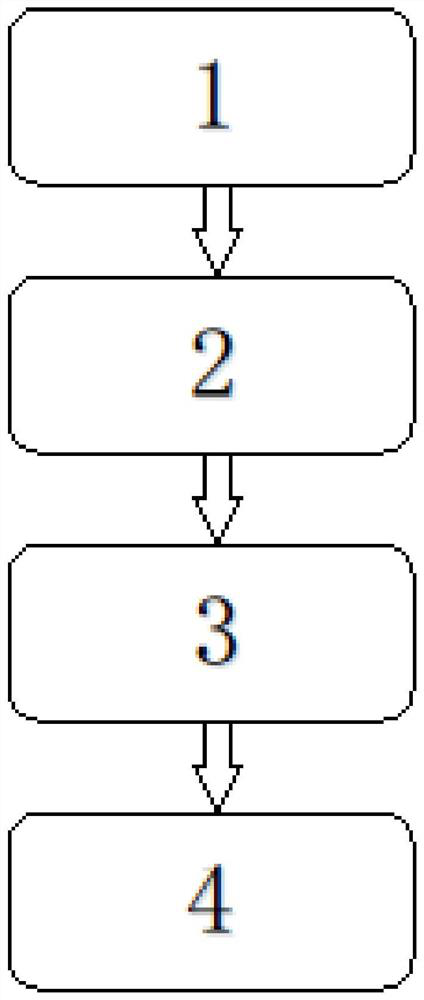

Method for improving economical efficiency of engineering mechanical fuel

InactiveCN105370420AImprove combustion sufficiencyImprove economyElectrical controlSpeed sensing governorsEconomic regionCombustion

The invention provides a method for improving the economical efficiency of engineering mechanical fuel. Under the condition that the configuration of an engine is not changed, the working condition of the engine is adjusted to a universal characteristic economic region, and the economical efficiency of the fuel is improved on the premise that the requirement for the output power is met. The method includes the steps that 11, whether force needs to be obtained or not is judged, if yes, the step 21 is executed, and if not, the step 31 is executed; 21, a rotation speed set value is increased; 31, the rotation speed set value is maintained or reduced to an idling set value of a fuel economic region; and 41, the actual rotation speed is maintained at the rotation speed set value. When force needs to be obtained, the rotation speed set value is increased so as to increase the air inflow, and therefore the combustion sufficiency of the fuel is improved; and when force is not needed, the rotation speed set value is maintained or reduced to the idling set value of the economic region, and fuel consumption is reduced. Therefore, the rotation speed set value is calibrated differentially according to the condition whether force is obtained or not, so that the rotation speed set value is better matched with the working condition, the fuel can be burnt sufficiently under various working conditions, and the economical efficiency of the fuel is improved.

Owner:WEICHAI POWER CO LTD

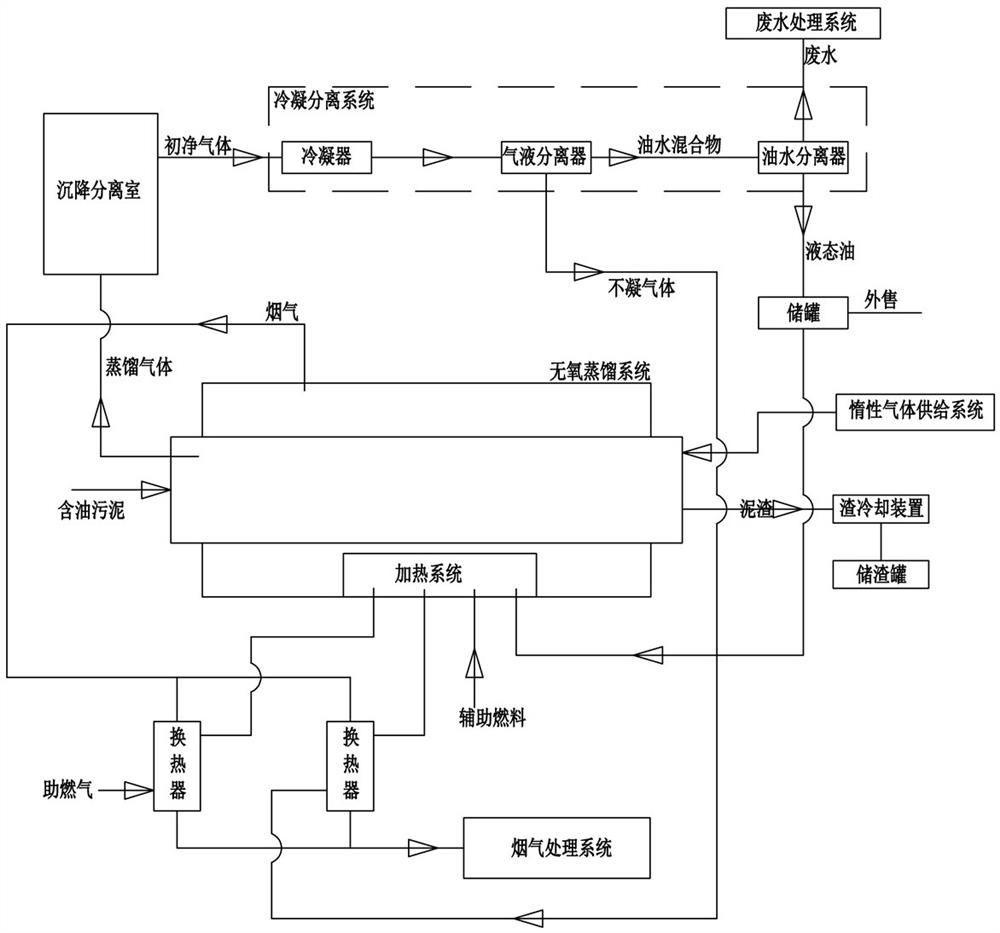

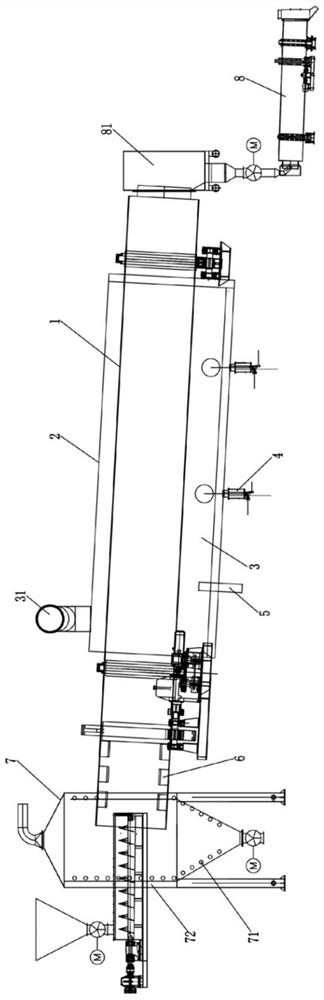

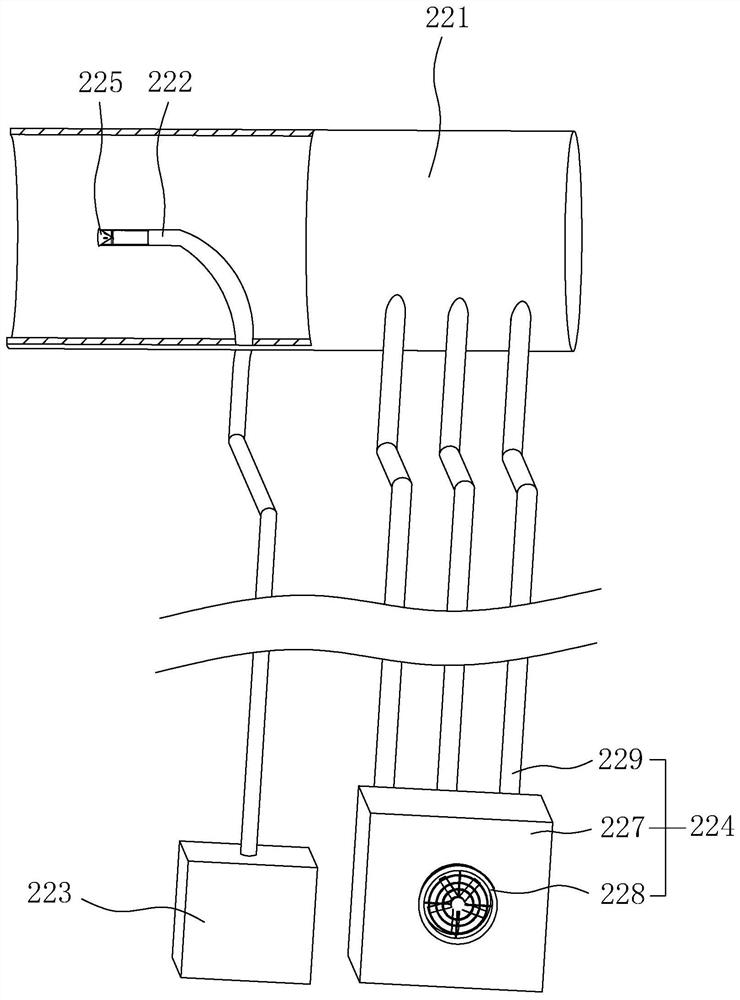

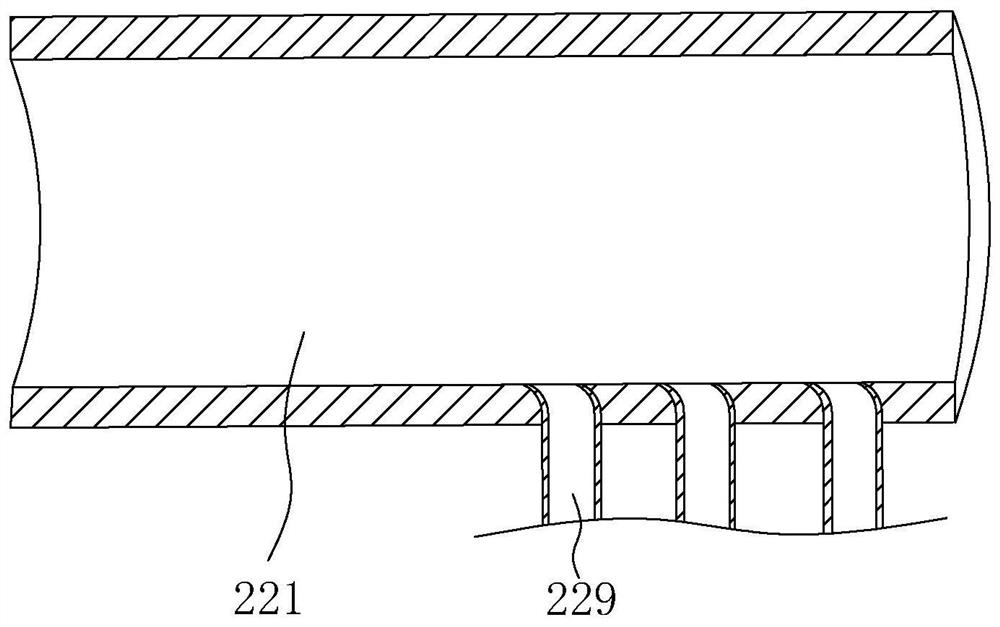

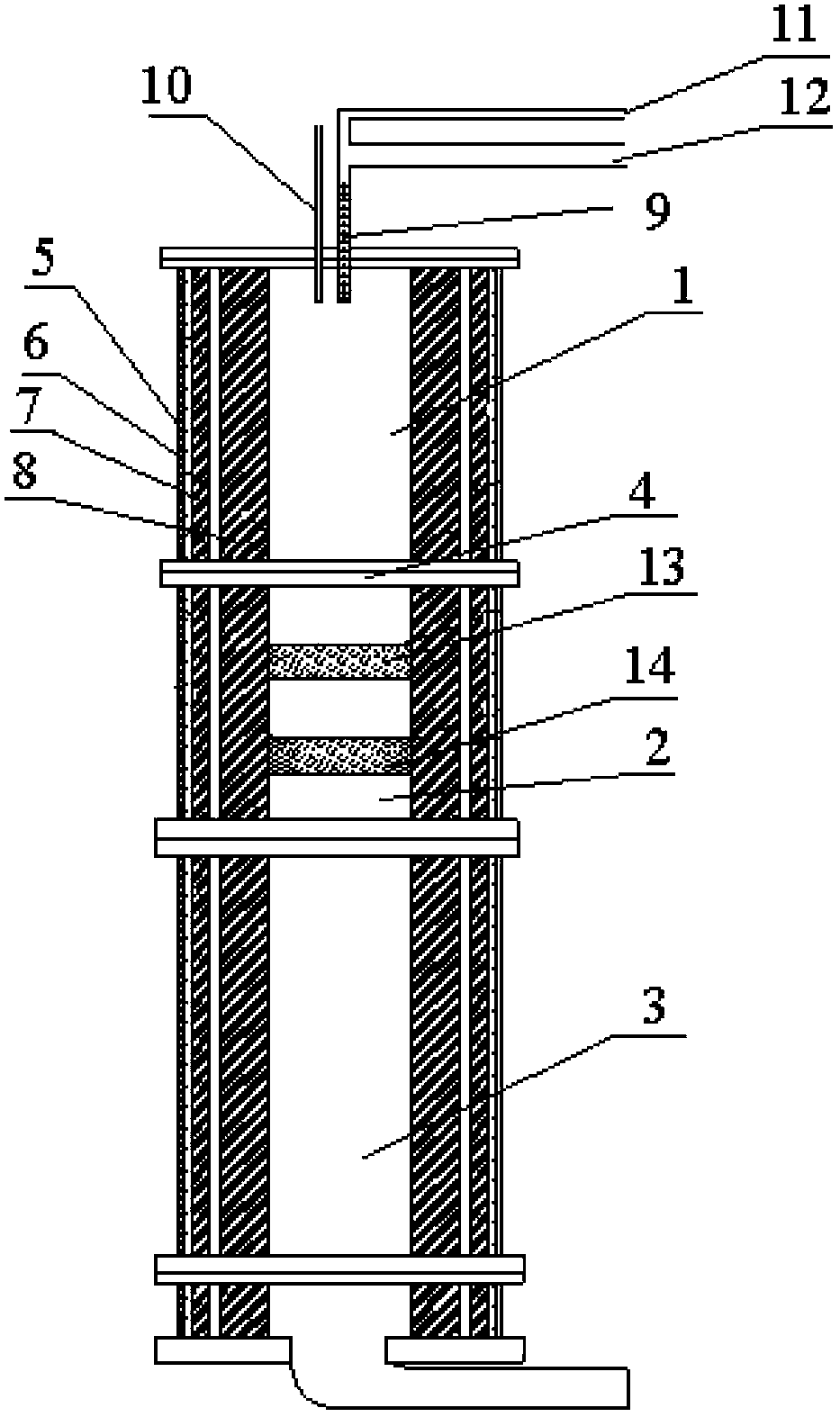

Oily sludge treatment system and method

PendingCN113149395AImprove use valueNo chemical changeSludge treatment by de-watering/drying/thickeningWater contaminantsSludgeDistillation

The invention discloses an oily sludge treatment system which comprises an anaerobic distillation system and a condensation separation system, the anaerobic distillation system comprises a rotary cylinder and a shell surrounding the circumferential periphery of the rotary cylinder, a heating cavity is formed between the shell and the rotary cylinder, a heating system is arranged on the heating cavity, oily sludge is heated in the rotary cylinder to be subjected to anaerobic distillation, distillation gas generated by anaerobic distillation is conveyed to a condensation separation system to be subjected to condensation separation to obtain non-condensable gas, liquid oil and waste water, the non-condensable gas and the liquid oil serve as fuel to be supplied to the heating system, and the non-condensable gas and combustion-supporting gas pass through a heat exchanger, are preheated by smoke generated by combustion and then are conveyed to the heating system. Water and petroleum hydrocarbons in the oily sludge are distilled and separated in an oxygen-free environment, substances only change physically and do not change chemically, heating power consumption is low, non-condensable gas and liquid oil are recycled as fuel to be utilized, self-sufficiency is achieved, the operation cost is low, secondary pollution is avoided, and harmless treatment is achieved.

Owner:SICHUAN JUNHE ENVIRONMENTAL PROTECTION

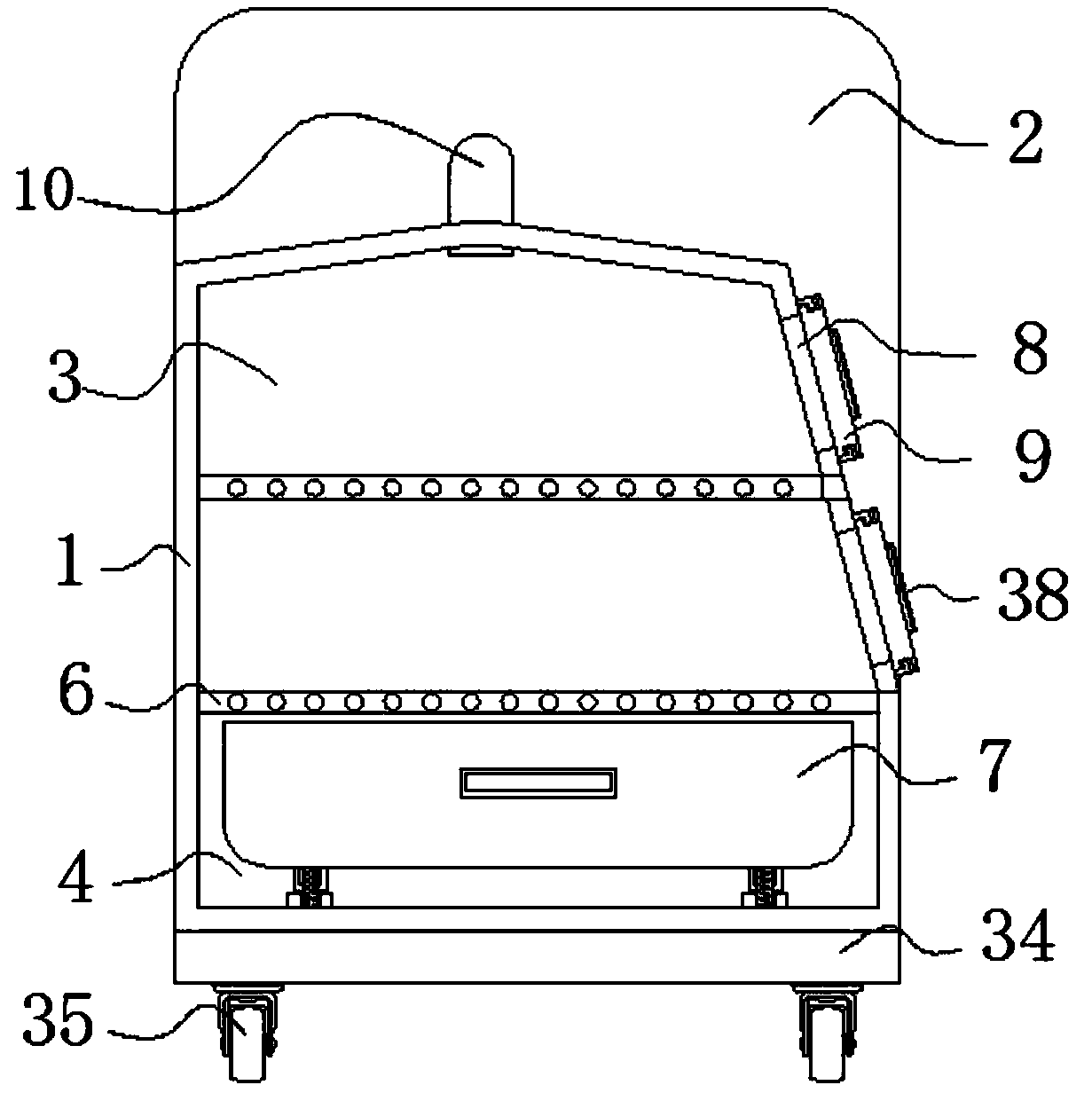

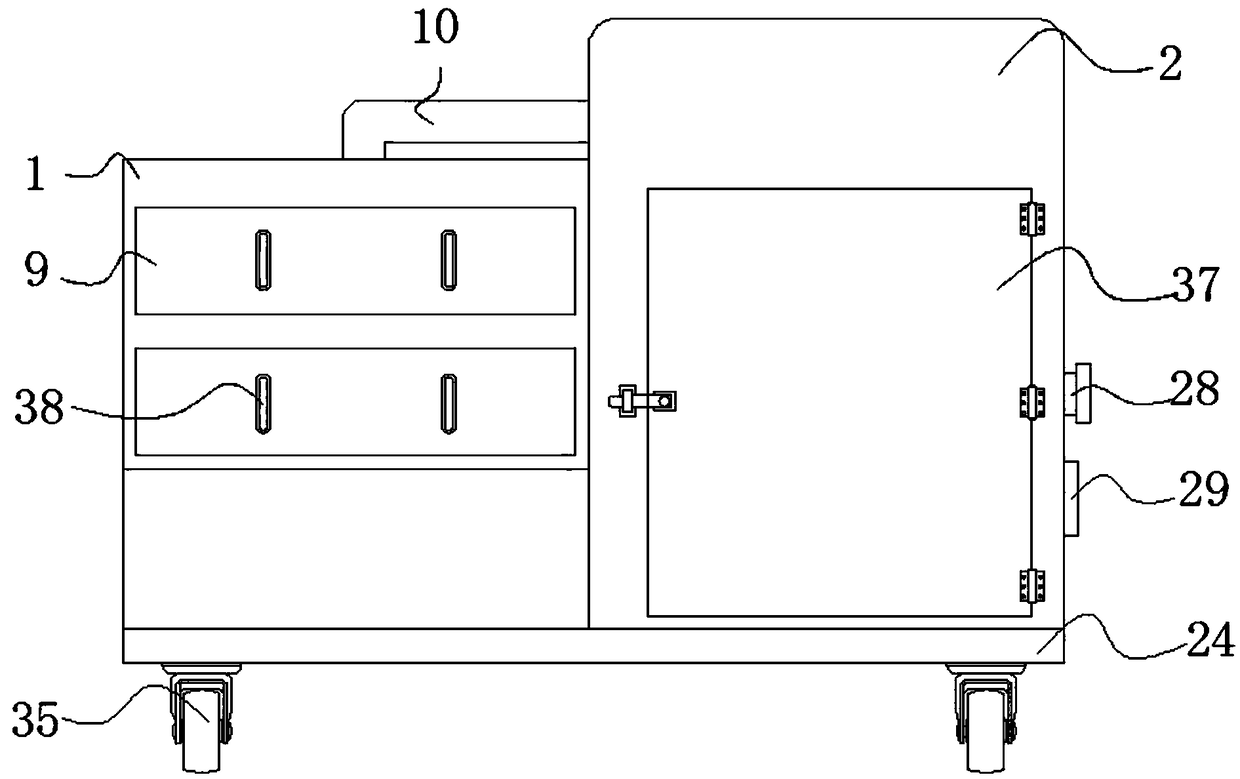

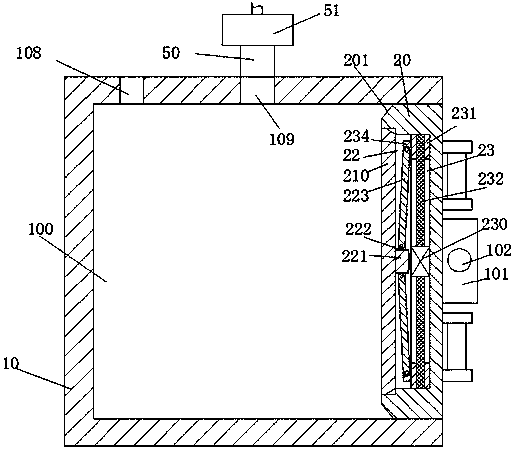

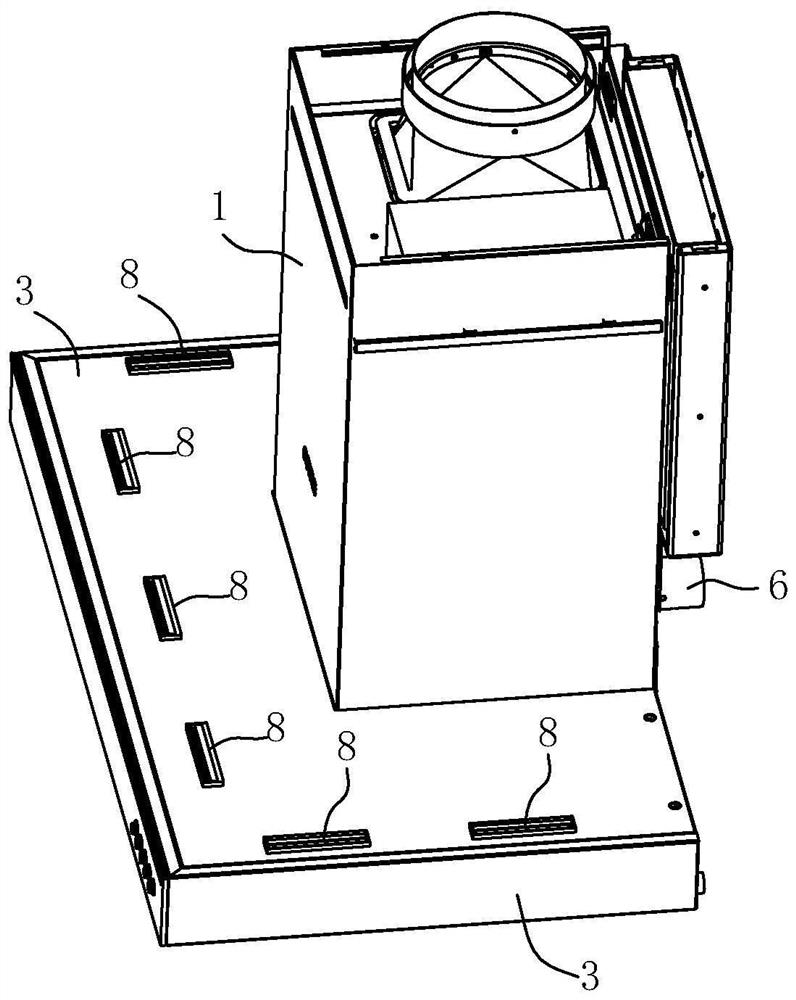

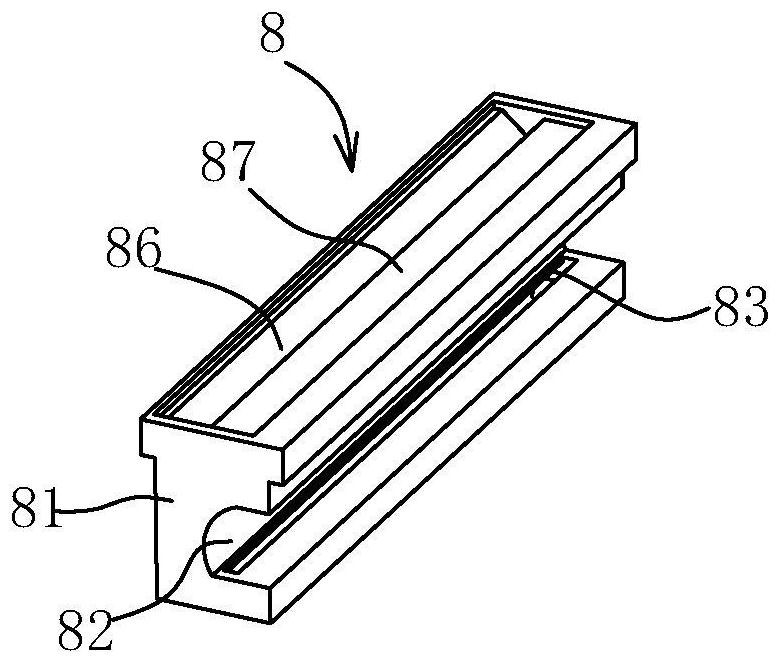

Energy-saving and environment-friendly waste incineration box

ActiveCN108826307AAvoid incomplete mixed combustionAvoid wasting energyIncinerator apparatusCombustion chamberEnvironmental engineering

The invention discloses an energy-saving and environment-friendly waste incineration box, and relates to the technical field of environment-friendly devices. The energy-saving and environment-friendlywaste incineration box comprises an incineration box and a purifying box, the incineration box is internally provided with a combustion chamber and an ash receiving chamber, a plurality of sliding rails are fixedly connected to the inner surface of the combustion chamber, flame bridges are arranged in the sliding rails in a sliding mode, and an ash receiving car matched with the combustion chamber and the flame bridges is connected to the position, corresponding to the combustion chamber and the flame bridges, of the inner surface of the ash receiving chamber in a sliding mode. The energy-saving and environment-friendly waste incineration box enables the waste incineration box to burn while dry damp waste, avoids the occurrence of waste of electric energy by incomplete mixed combustion ofdry and wet waste and needing combustion-supporting devices, further improves the combustion speed and combustion adequacy, performs multi-layer process and detection on the smoke after combustion, has a more thorough treatment of smoke after combustion and avoids the environmental pollution caused by smoke after combustion; and the ash receiving car collects ashes after combustion, centralized processing can be performed, and the secondary pollution is avoided.

Owner:YUNNAN BOXI ENVIRONMENTAL PROTECTION EQUIP CO LTD

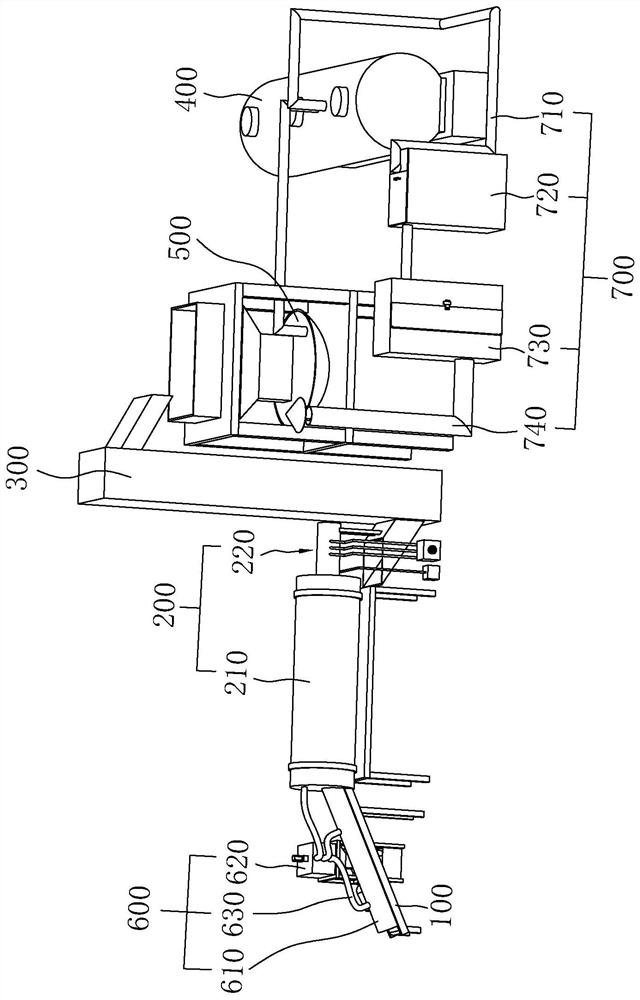

Energy-saving asphalt mixing station

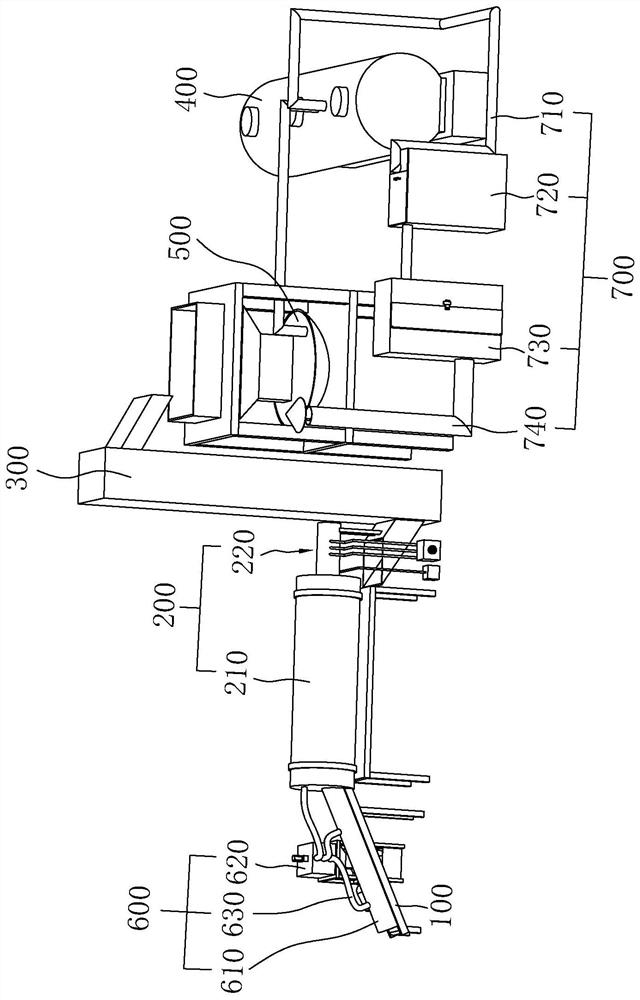

ActiveCN112211068AReduce turbulenceIncrease contact areaDirt cleaningRoads maintainenceFuel tankFuel oil

The invention relates to an energy-saving asphalt mixing station which comprises a feeding belt conveyor, a drying roller, a hot aggregate elevator, an asphalt tank and a stirring pot, the drying roller comprises a body and a heating mechanism, the heating mechanism comprises a combustion cylinder, an oil gun, an oil supply tank and an air supply assembly, the air outlet end of the combustion cylinder communicates with the body, and the oil gun is arranged in the combustion cylinder; an oil outlet of the oil gun faces the body, and the oil supply tank is communicated with the oil gun; the airsupply assembly comprises an air supply box, a draught fan and a plurality of air supply pipes, the draught fan is communicated with the air supply box, the air supply pipes are all communicated withthe combustion cylinder, the air supply pipes are tangent to the inner wall of the combustion cylinder, and the air supply pipes are sequentially arranged in the direction away from the body. Multiplelayers of spiral airflow can be formed in the combustion cylinder, the contact area of fuel oil and air is increased, the influence of turbulent flow of the air in the combustion cylinder on fuel oilcombustion is reduced, and finally the effect of improving the fuel oil combustion sufficiency is achieved.

Owner:山东省大通建设集团有限公司

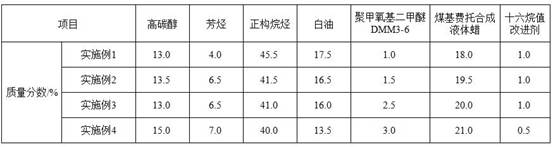

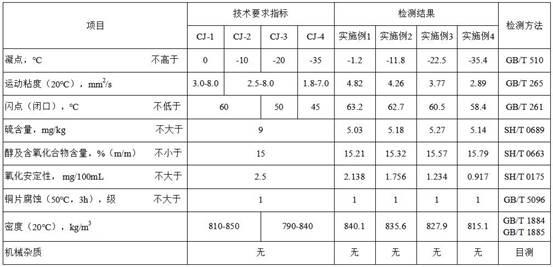

Alcohol-based fuel for compression ignition type internal combustion engine and preparation method of alcohol-based fuel

ActiveCN114369479AReduce manufacturing costReduce use costLiquid carbonaceous fuelsFuel additivesAlkaneInternal combustion engine

The invention discloses an alcohol-based fuel for a compression ignition type internal combustion engine and a preparation method of the alcohol-based fuel. The alcohol-based fuel is prepared from the following raw materials in percentage by mass: 40 to 45.5 percent of n-alkane, 13.5 to 17.5 percent of white oil, 13 to 15 percent of high alcohol, 4 to 7 percent of aromatic hydrocarbon, 1 to 3 percent of polyoxymethylene dimethyl ether DMM3-6, 18 to 21 percent of coal-based Fischer-Tropsch synthesis liquid wax and 0.5 to 1 percent of cetane number improver. The main raw materials are derived from a coal-to-oil process and value-added utilization of oxygen-containing oil (heavy), the raw materials are convenient to obtain and low in price, the production cost of enterprises and the use cost of terminal users are reduced, compared with diesel oil, the product has the advantages that the emission of carbon, sulfur and oxynitride is reduced, the heat efficiency is improved, and in the preparation process, besides the treatment of high-carbon alcohol and the earlier-stage process, the production cost is reduced. Core preparation sections of the alcohol-based fuel all adopt continuous physical embedding reaction at normal temperature and pressure, so that the energy consumption and the safety risk are reduced.

Owner:玉门祥天新能源产业发展有限公司

Dual-mode flue gas emission secondary combustion heating furnace

InactiveCN109404975AImprove combustion sufficiencyHigh thermal efficiencyDomestic stoves or rangesLighting and heating apparatusCombustionExhaust valve

The invention discloses a dual-mode flue gas emission secondary combustion heating furnace. The heating furnace comprises a furnace body, a furnace hearth and a smoke exhaust pipe communicating with the furnace hearth; the smoke exhaust pipe is provided with a smoke exhaust port; a smoke exhaust valve is arranged at the smoke exhaust port; a kang connection port is formed in the part, located on the rear portion of the furnace hearth, of the furnace body; a kang connection valve is arranged at the kang connection port; a fire outlet is formed in the top of the furnace hearth; a secondary combustion air supply system is arranged at the fire outlet; a flue gas guide fire-distributing device is mounted on a furnace mouth; the flue gas guide fire-distributing device is arranged above the secondary combustion air supply system; a coal charging port is formed in the front portion of the furnace body; a coal charging smoke reversing prevention sealing device is mounted correspondingly on theouter portion of the coal charging port in a hinged mode; a communicating heat exchange water jacket is arranged on the furnace hearth and the smoke exhaust pipe; a high-efficiency heat collecting system communicating with the heat exchange water jacket is arranged in the smoke exhaust pipe; and flue deashing device corresponding to the high-efficiency heat collecting system is arranged on the outer wall of the smoke exhaust pipe. The structure is simple, design is reasonable, the heating furnace can be used for being connected with a kang or a heater, and the thermal efficiency of the heatingfurnace is improved.

Owner:潍坊中远天成采暖设备制造有限公司

Automobile exhaust waste heat recycling system

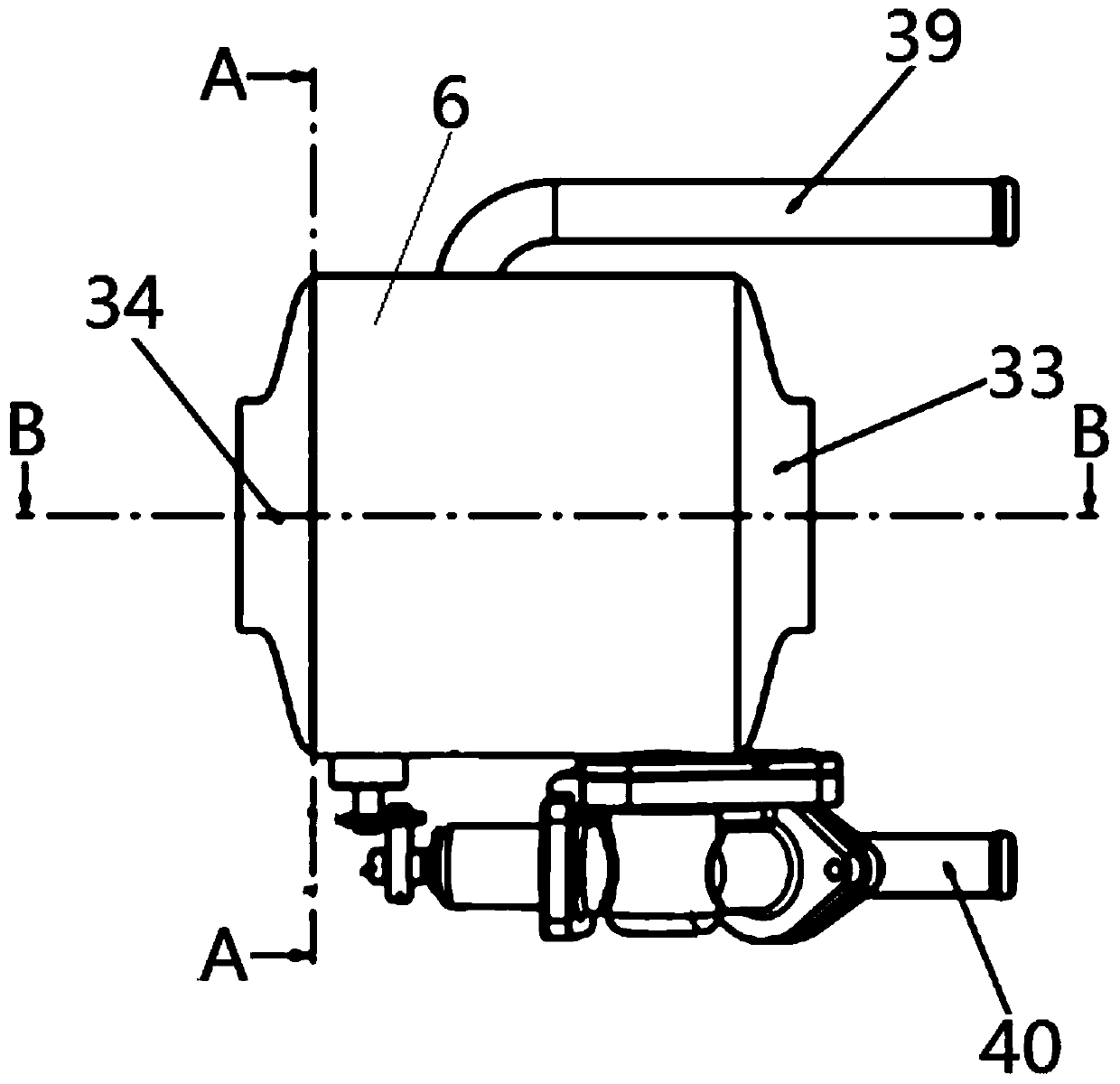

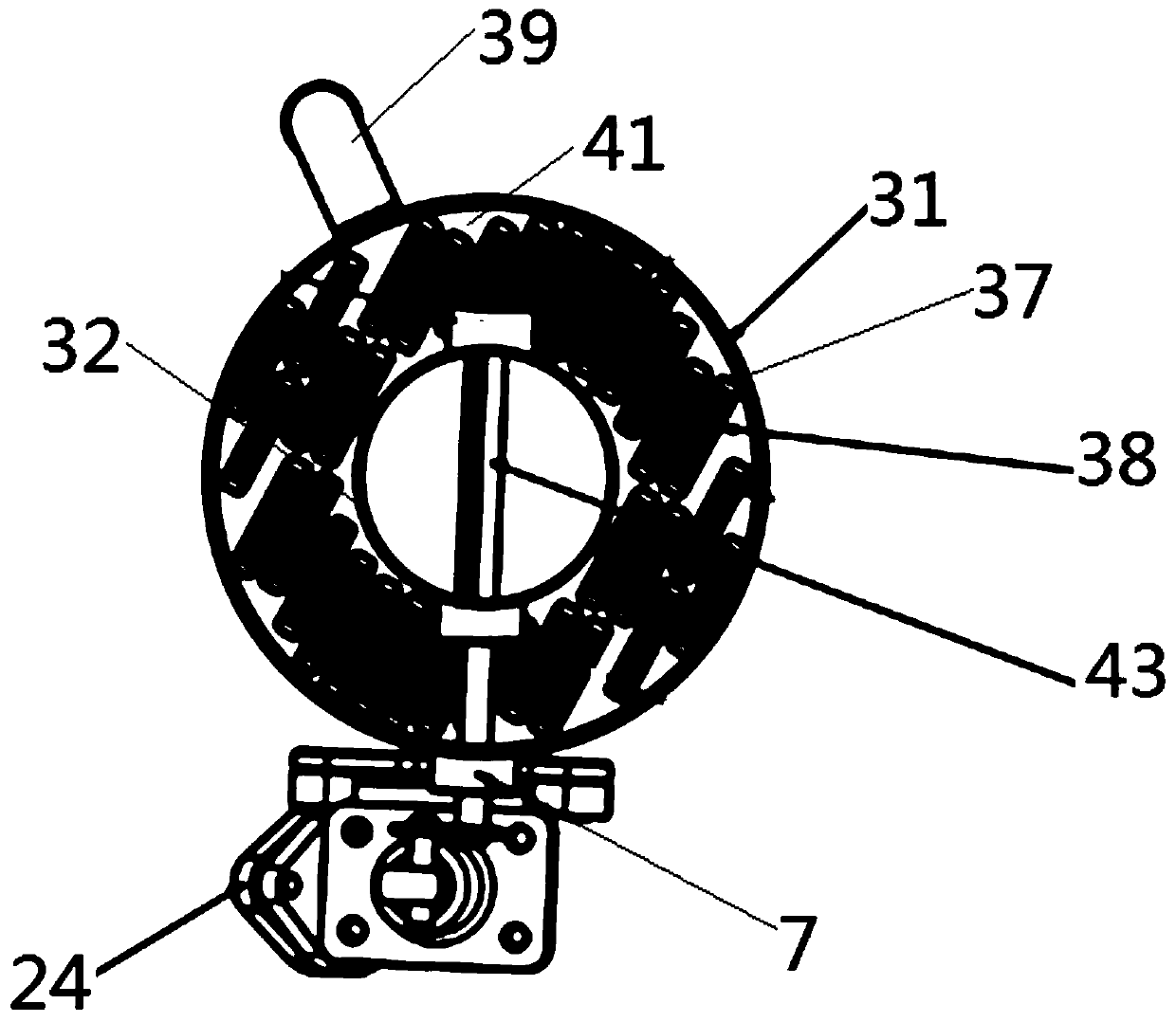

PendingCN110030066AShorten warm-up timeHigh thermal efficiencyOperating means/releasing devices for valvesInternal combustion piston enginesCooling fluidThermal efficiency

The invention provides an automobile exhaust waste heat recycling system applied in the technical field of automobile engines. A front end plate (35) is arranged at the position, close to an inlet cone end (33), between an outer layer shell (31) and an inner layer shell (32) of a heat exchanger (6) of the automobile exhaust waste heat recycling system; a rear end plate (36) is arranged at the position, close to an outlet cone end (34), between the outer layer shell (31) and the inner layer shell (32); a plurality of flat tubes (37) are inserted between the front end plate (35) and the rear endplate (36); fins (38) are inserted in each flat tube (37) separately; and a gap part is formed between each flat tube (37) and the fin (38) inserted in the flat tube (37). The automobile exhaust heatrecycling system can recover part of the heat from automobile exhaust when an automobile is cold-started, and then utilize the heat to heat a coolant in an automobile engine cooling system so as to quickly and reliably warm an engine and improve the thermal efficiency of the engine during cold-start.

Owner:JAPHL POWERTRAIN SYST

An energy-saving asphalt mixing plant

ActiveCN112211068BReduce turbulenceIncrease contact areaDirt cleaningRoads maintainenceThermodynamicsFuel tank

This application relates to an energy-saving asphalt mixing plant, which includes a feeding belt conveyor, a drying drum, a hot aggregate hoist, an asphalt tank and a mixing pot. The drying drum includes a body and a heating mechanism. The heating mechanism includes a combustion cylinder and an oil gun. , Fuel supply tank and air supply assembly, the gas outlet end of the combustion tube is connected to the body, the oil gun is set in the combustion tube, and the oil outlet of the oil gun is set towards the body, the fuel supply tank is connected to the oil gun, and the air supply assembly includes a supply Air box, fan and multiple air supply pipes, the fan is connected to the air supply box, and the multiple air supply pipes are connected to the combustion cylinder and arranged tangentially to the inner wall of the combustion cylinder, and the multiple air supply pipes are arranged along the direction away from the body Arranged sequentially. In this application, a multi-layer spiral airflow will be formed in the combustion tube, thereby increasing the contact area between fuel and air, reducing the influence of turbulent air flow in the combustion tube on fuel combustion, and finally achieving the effect of increasing fuel combustion sufficiency.

Owner:山东省大通建设集团有限公司

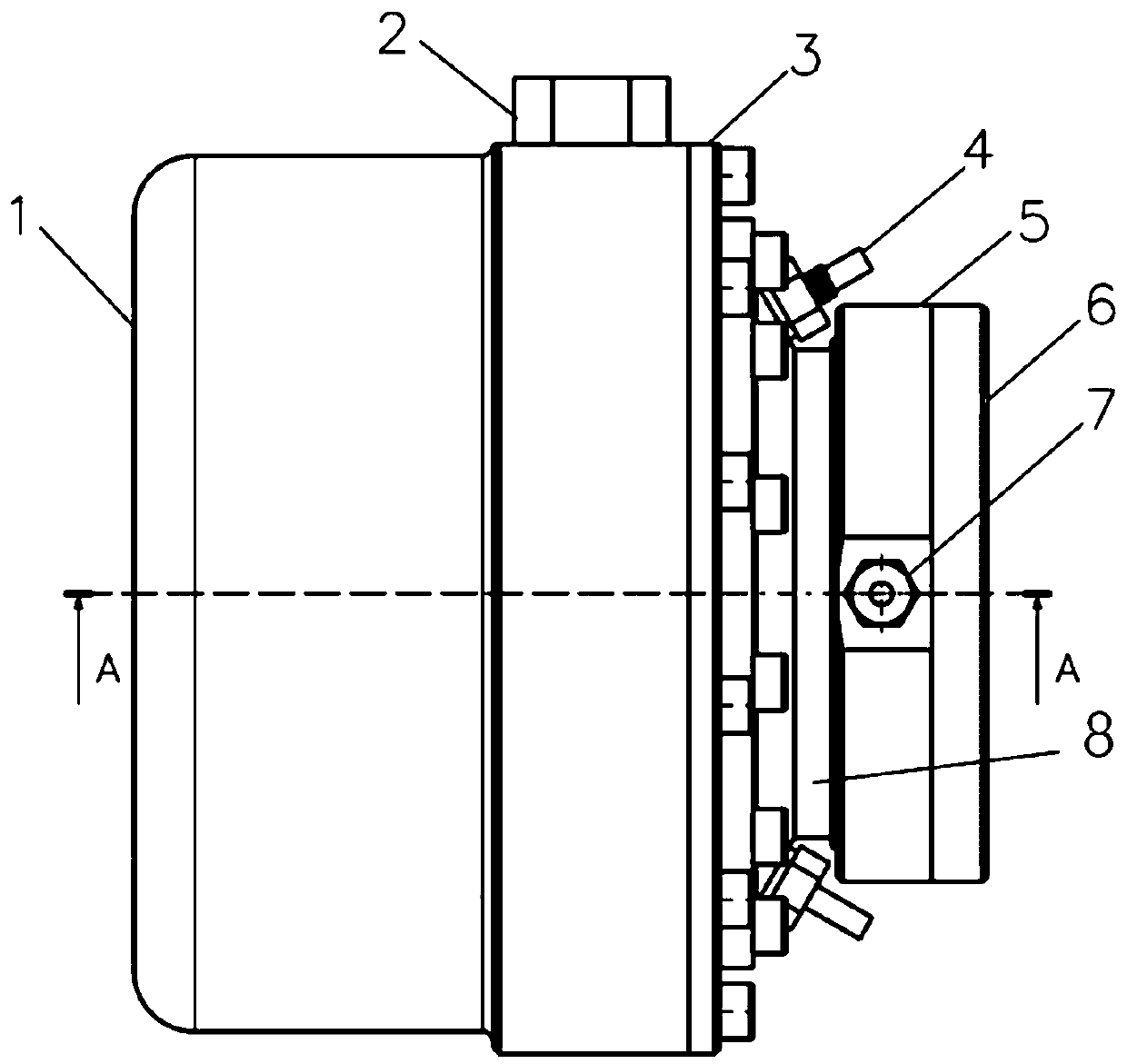

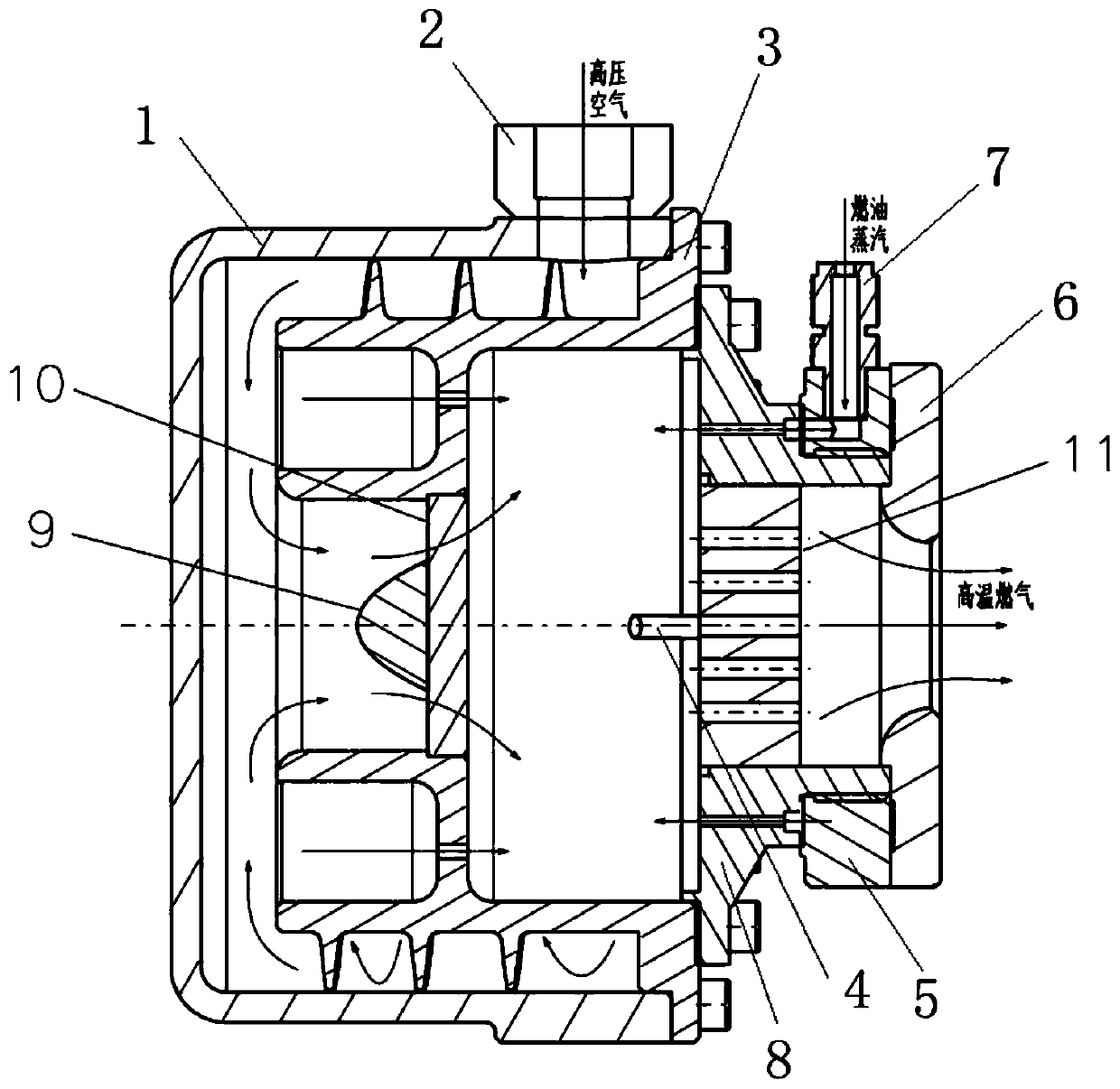

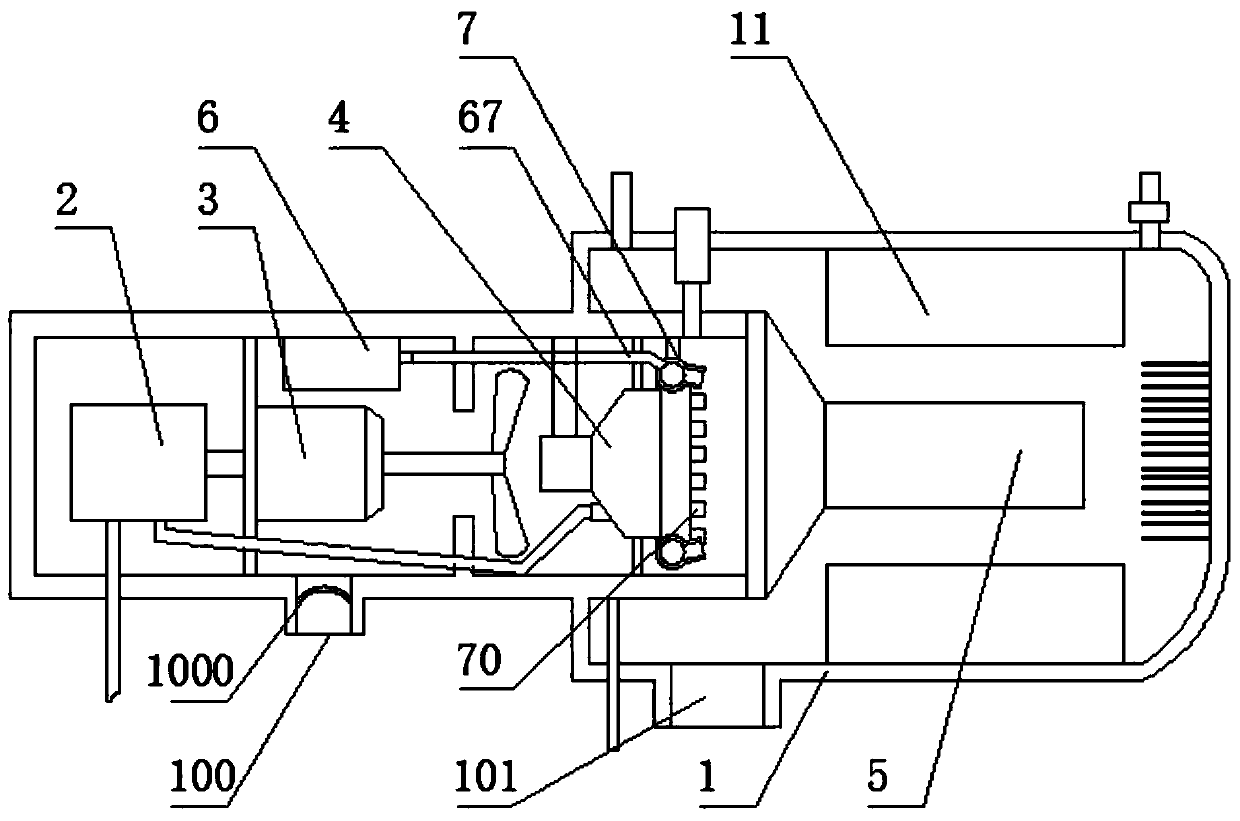

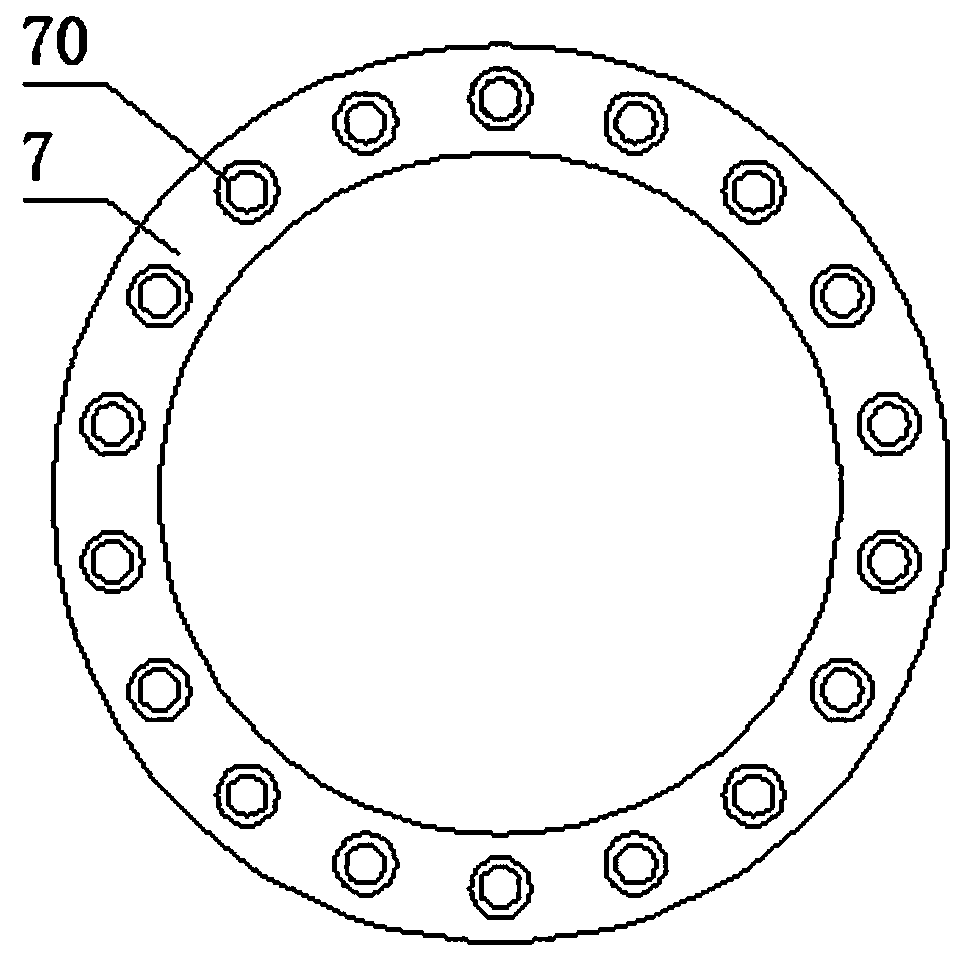

Low-cost trapped vortex combustor

ActiveCN109780573AIncrease profitReduce consumptionContinuous combustion chamberCombustion chamberCombustor

The invention discloses a low-cost trapped vortex combustor, and belongs to the technical field of combustor structures. The low-cost trapped vortex combustor comprises an air inlet cavity, an air inlet valve, a combustion chamber front section, a glow plug, a fuel vapor inlet cavity, an exhaust flange, a fuel vapor inlet valve and a combustion chamber rear section; the combustion chamber front section is installed in the air inlet cavity in a sleeved mode; a spiral cavity is formed between the inner circumferential surface of the air inlet cavity and a spiral groove in the combustion chamberfront section, the large diameter end of the combustion chamber rear section is coaxially and fixedly connected with the open end of the combustion chamber front section in a butting mode, and the fuel vapor inlet cavity is formed in the outer part of the small diameter end of the combustion chamber rear section in a sleeved mode; the air inlet valve is installed in an air inlet of the air inlet cavity; the fuel vapor inlet valve is installed in a fuel vapor inlet port of the fuel vapor inlet cavity; the exhaust flange is installed on the end surface of the small diameter end of the combustionchamber rear section; and the glow plug is fixed to the combustion chamber rear section. The low-cost trapped vortex combustor has the characteristics of sufficient combustion, simple structure, compactness, wide stable working range, less pollution divergence and low cost.

Owner:李杰 +1

Secondary combustion high-efficiency heating furnace

InactiveCN109404973AHigh thermal efficiencyImprove combustion sufficiencyDomestic stoves or rangesLighting and heating apparatusCombustion chamberFlue gas

The invention discloses a secondary combustion high-efficiency heating furnace. The secondary combustion high-efficiency heating furnace includes a furnace body, a combustion chamber, a furnace mouth,a furnace grate, an ash storage chamber, and a fume exhaust pipeline communicating with the combustion chamber, wherein the top of the combustion chamber is provided with a fire outlet; a secondary combustion air supply system is arranged at the fire outlet; a flue-gas-guide fire distributing device is arranged on the furnace mouth and above the secondary combustion air supply system; a coal inlet is arranged at the front portion of the furnace body; a coal adding reverse smoke preventing sealing device is arranged outside the coal inlet in a hinge mode; a communicating heat exchange water jacket is arranged on the combustion chamber and the fume exhaust pipeline; the fume exhaust pipeline is provided with a high-efficiency heat collecting system communicating with the heat exchange waterjacket; the outer wall of the fume exhaust pipeline is provided with a flue ash cleaning device corresponding to the high-efficiency heat collecting system; the lower portion of the rear part of thefurnace body is provided with an explosion-proof valve communicating with the heat transfer water jacket; and the heat transfer water jacket is connected with a heat supply terminal. The secondary combustion high-efficiency heating furnace has the advantages of simple structure and reasonable design, and the utilization rate of heat and the thermal efficiency of the heating furnace are improved.

Owner:潍坊中远天成采暖设备制造有限公司

A mounting structure that contributes to increasing the air gain of the engine

InactiveCN105041456BMinor changesQuick installationInternal combustion piston enginesAir cleaners for fuelCombustion chamberAir filter

Owner:广州市恒影汽车服务有限公司

Crystalline jelly wax and its production process

The crystalline jelly candle is compounded with white oil and thermoplastic styrene-butadiene rubber mixed fully and added myristic acid, and the styrene-butadiene rubber is compounded with styrene in 70wt% and butadiene in 30wt%. The addition of proper amount of myristic acid makes the jelly candle generate crystalline matter possessing excellent artistic effect of representing snowflake and being beautiful.

Owner:QINGDAO KINGKING APPL CHEM CO LTD

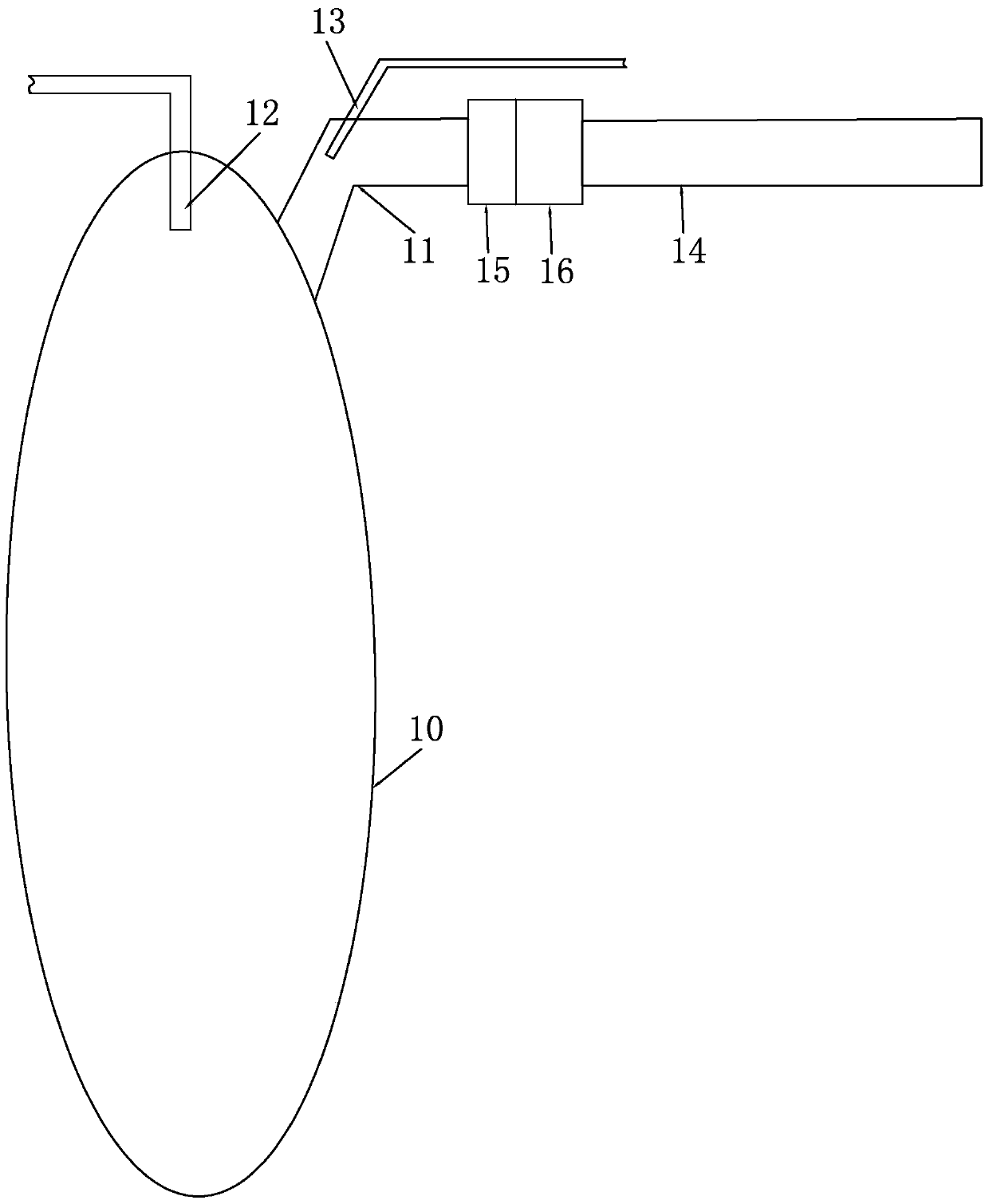

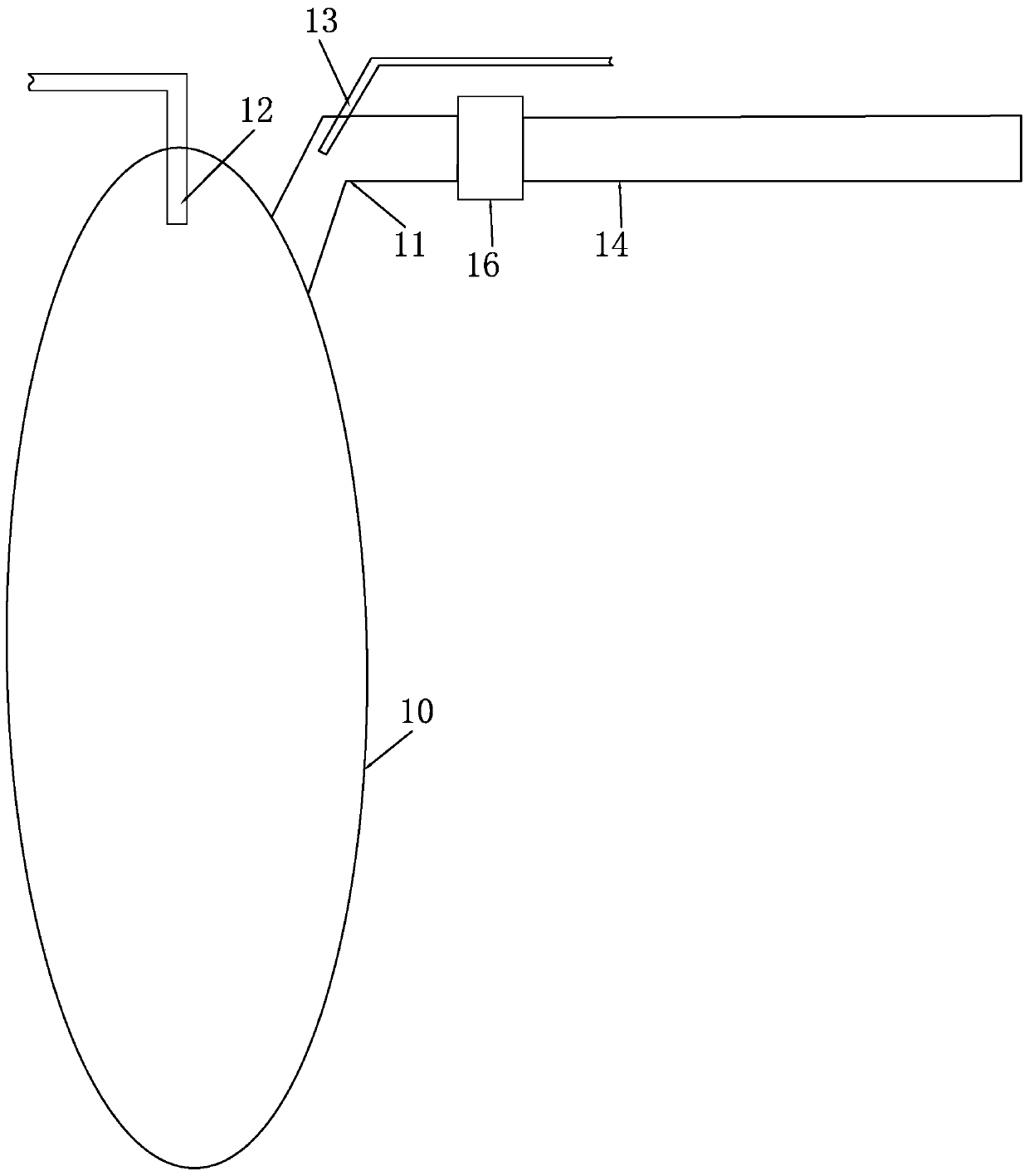

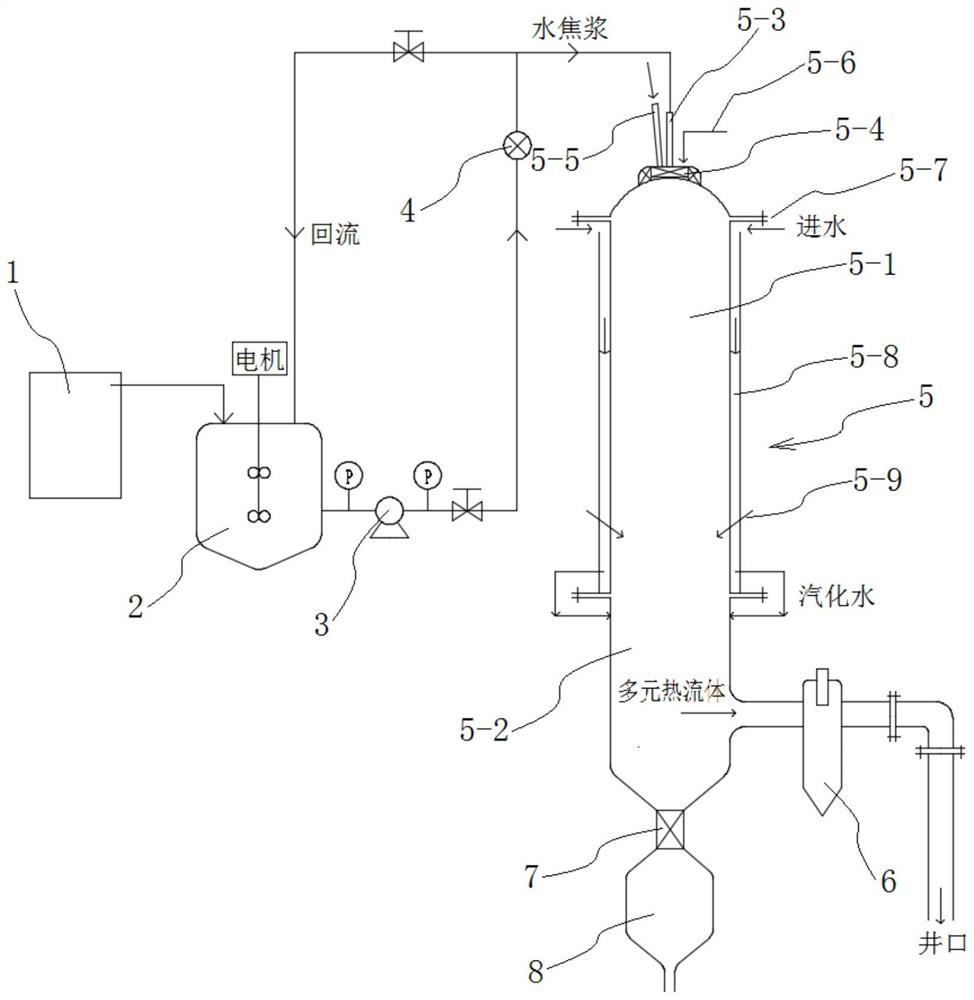

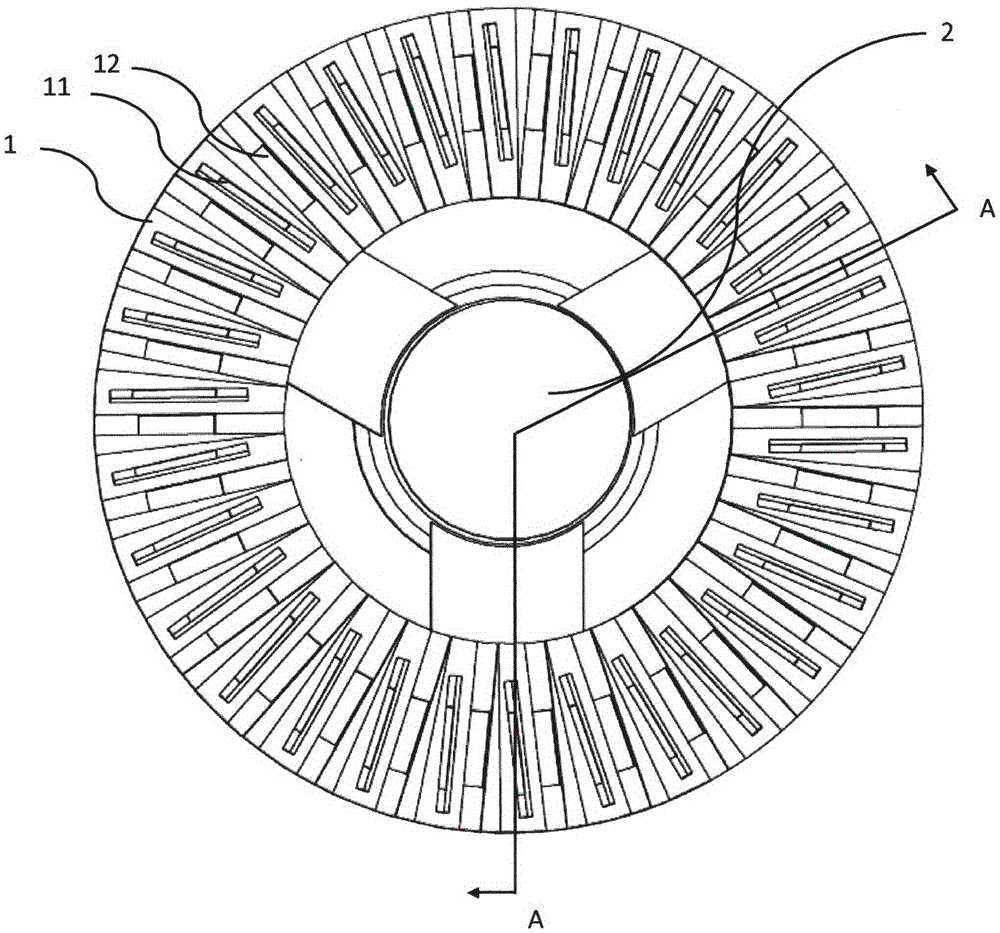

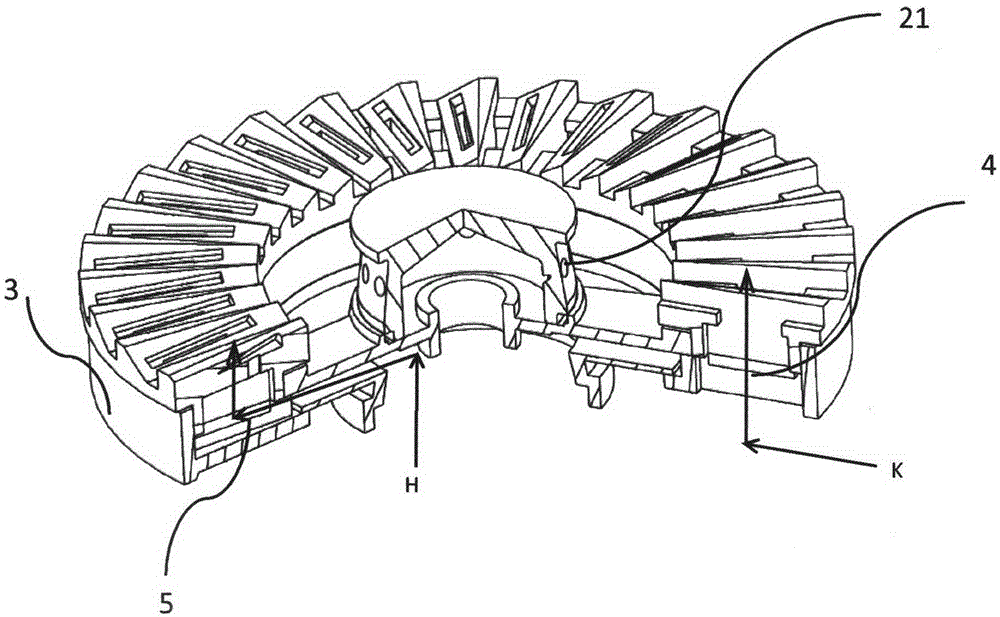

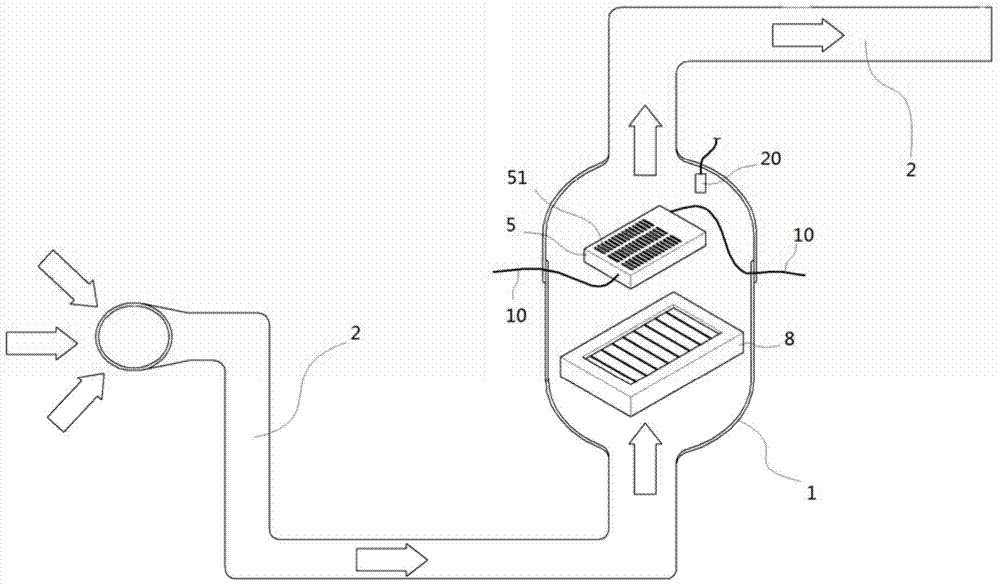

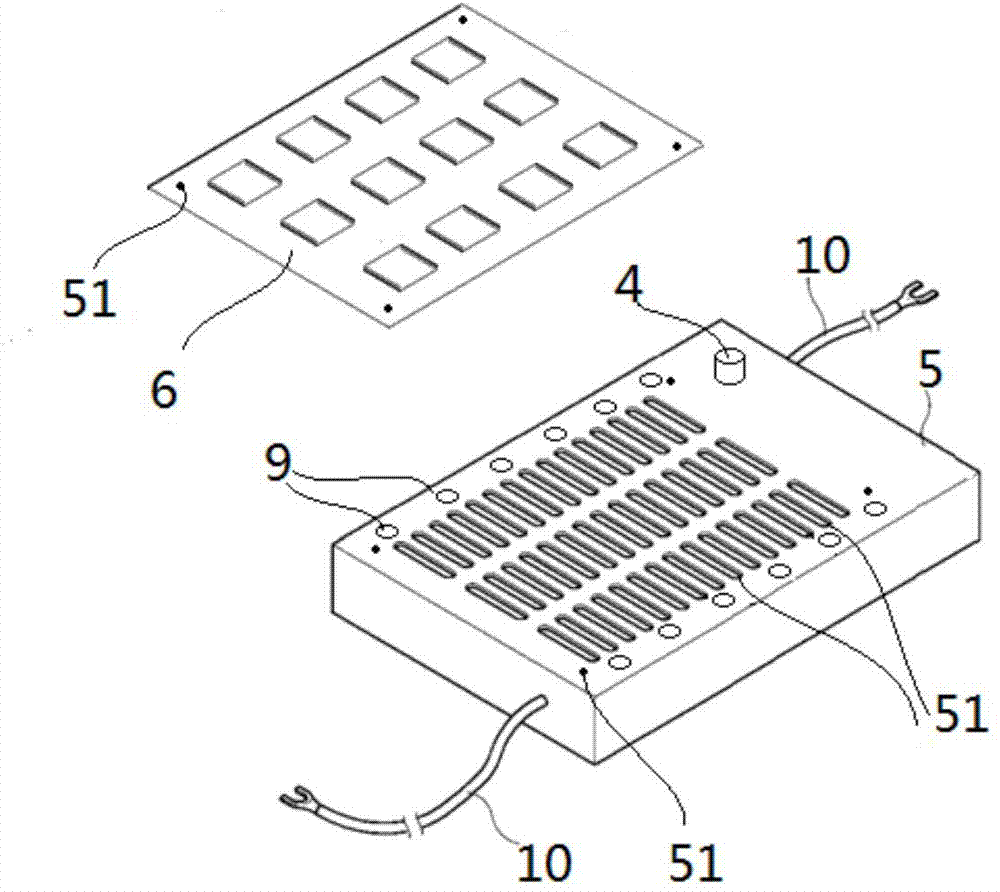

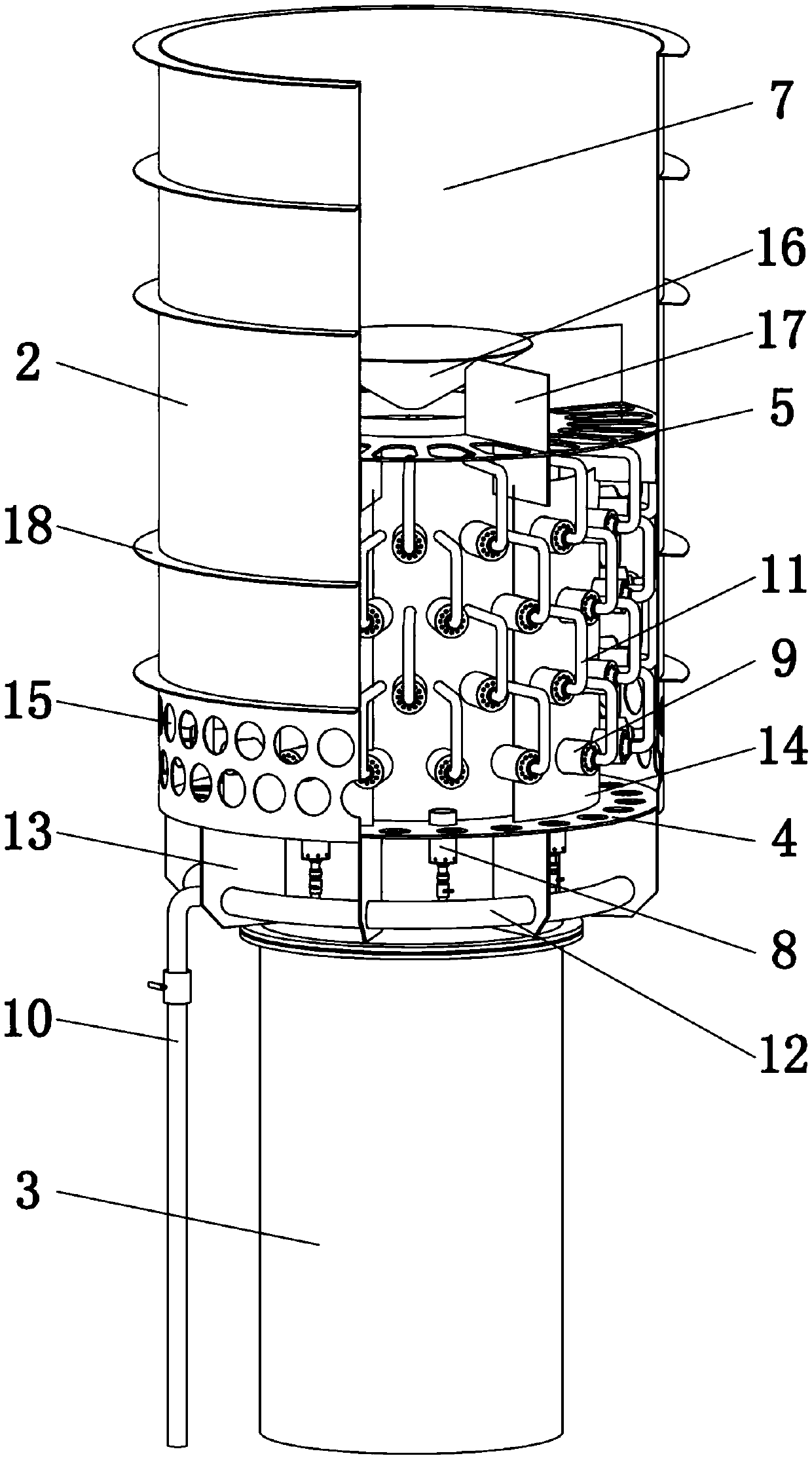

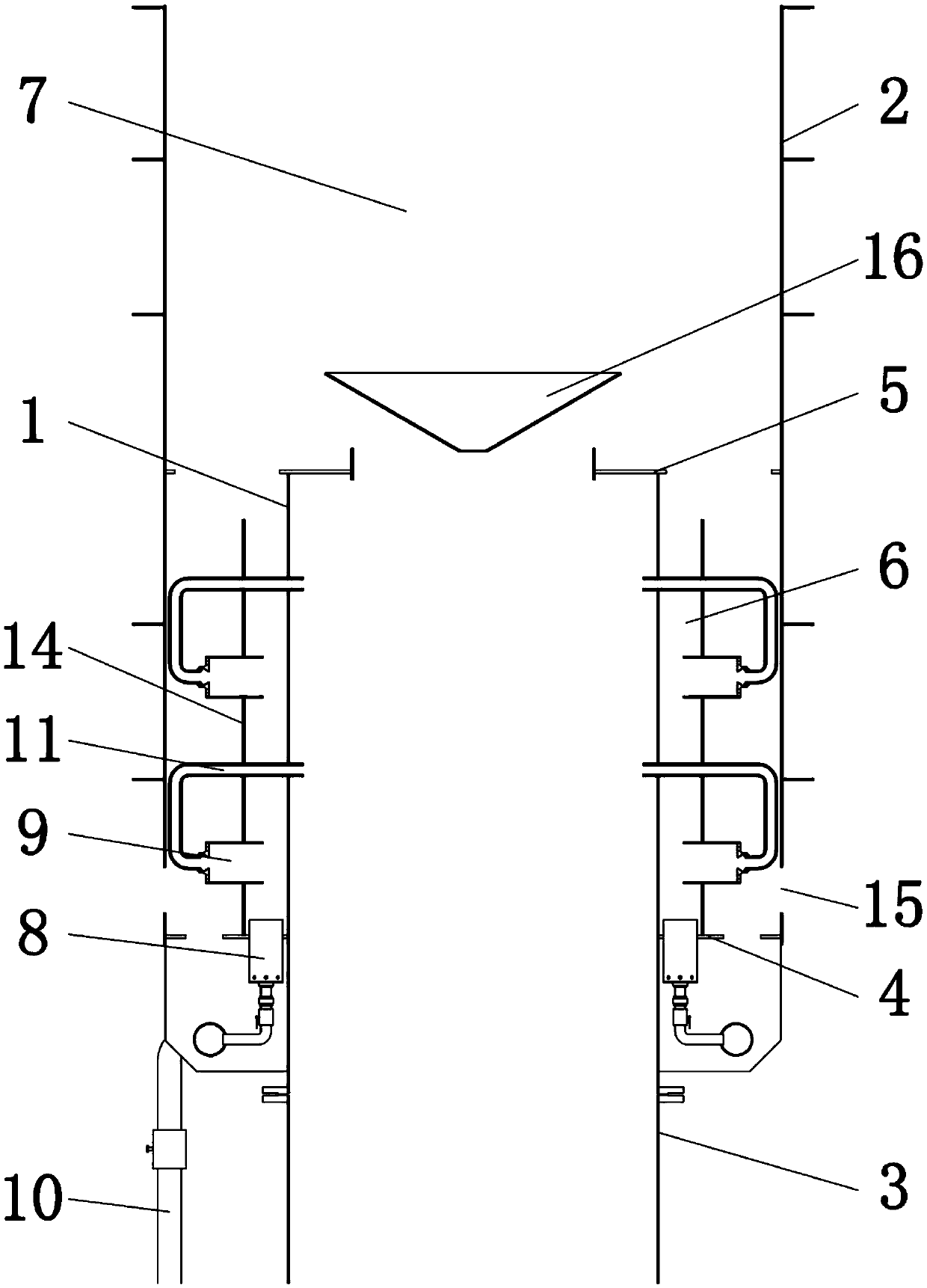

A multi-component thermal fluid generation system for petroleum thermal recovery using petroleum coke as fuel

ActiveCN111536504BExtended burn timeEasy to separateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHomogeneous charge compression ignitionCombustor

The invention discloses a petroleum heat extraction multiple thermal fluid generation system adopting petroleum coke as fuel, and belongs to the technical field of petroleum heat extraction. The petroleum heat extraction multiple thermal fluid generation system comprises a slurrying device, a stirring tank, a high-pressure pump, a combustor, a high-temperature separator and a slag storage tank, and the combustor is overall vertically arranged, comprises a combusting chamber and a vaporizing chamber formed in the lower part of the combusting chamber, and further comprises an atomization spray gun, a cyclone and an auxiliary ignition device which are arranged at the top of the combusting chamber. The top swirling combustor cooperates with the auxiliary ignition device, thus water-coke slurryand a combustion improver are mixed and then subjected to high-pressure swirling spray combustion, it is ensured that the water-coke slurry and the combustion improver are sufficiently mixed and atomized, swirl combustion is formed by the cyclone to enhance homogeneous charge compression ignition of the water-coke slurry, the homogeneous charge compression ignition time is prolonged, sufficient combustion of the water-coke slurry is ensured, coke embers and the carbon content of fly ash are reduced, thus the petroleum coke becomes possible for serving as the fuel of a multiple thermal fluid generator, and the cost of multiple thermal fluid thickened oil miming is lowered.

Owner:江苏亦通石油科技有限公司

burner for gas stove

ActiveCN103807855BAvoid uneven mixingSolve technical bottlenecksGaseous fuel burnerHeat fluxThermal efficiency

The invention relates to a combustor used for a gas stove. The combustor comprises a big fire cover, a small fire cover and a base, and is characterized in that fire outlet holes, air supply passageways and gas mixing cavities are formed in the big fire cover, fire outlet holes are formed in the small fire cover, a base inner ring and a base outer ring are arranged on the base, and gas mixing cavities and air supply passageways are formed in the base outer ring. The air supply passageways of the big fire cover are matched with the air supply passageways in the base outer ring to form integral air supply passageways. The gas mixing cavities in the big fire cover are matched with the gas mixing cavities of the base to form integral gas mixing cavities. According to the combustor, mixed gas is mixed in the mixing cavities and combusted in the fire outlet holes of the fire covers, sufficient air supply is conducted through the air supply passageways, and therefore the mixed gas can be sufficiently combusted, and the technical effects of improving the heat flux and the heat efficiency of the combustor are achieved.

Owner:刘申昌

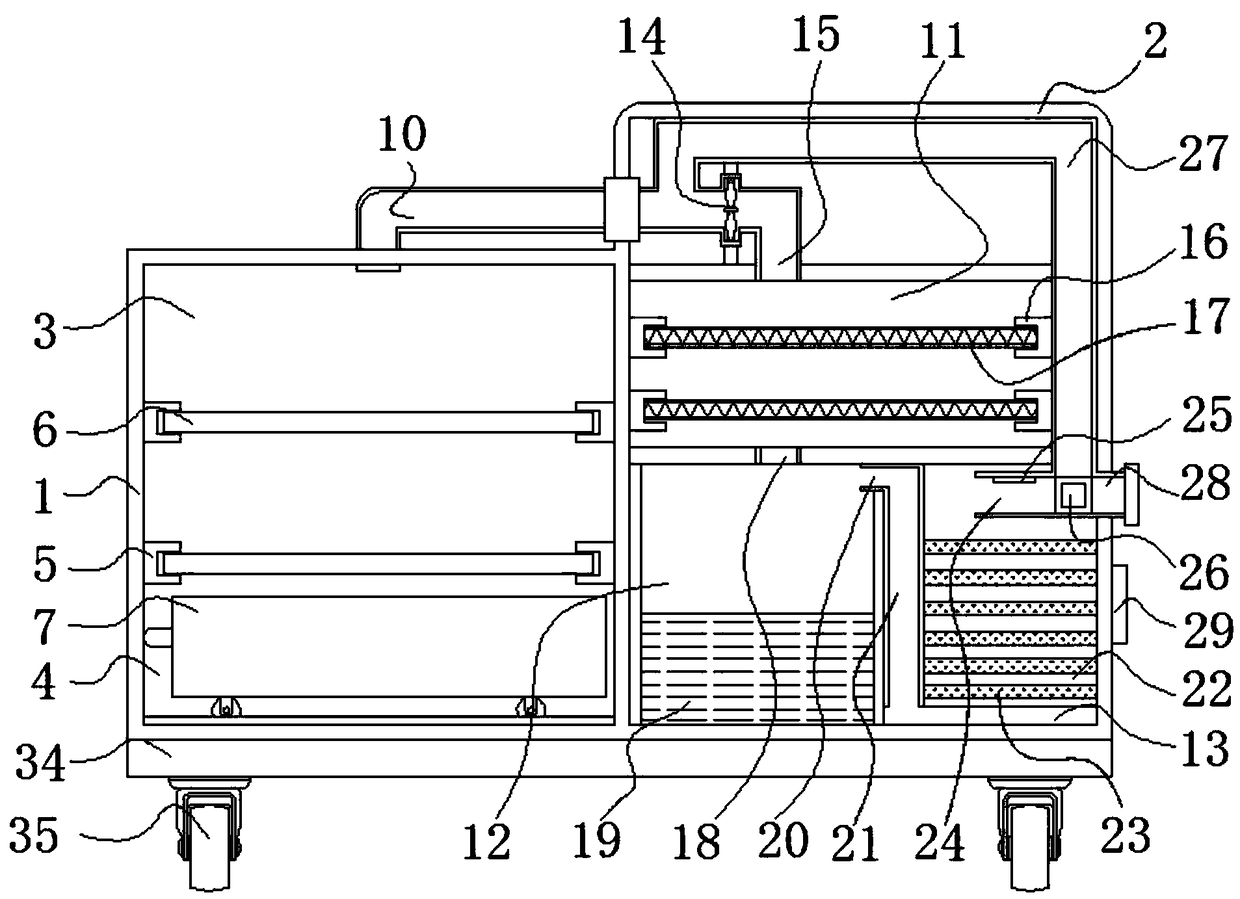

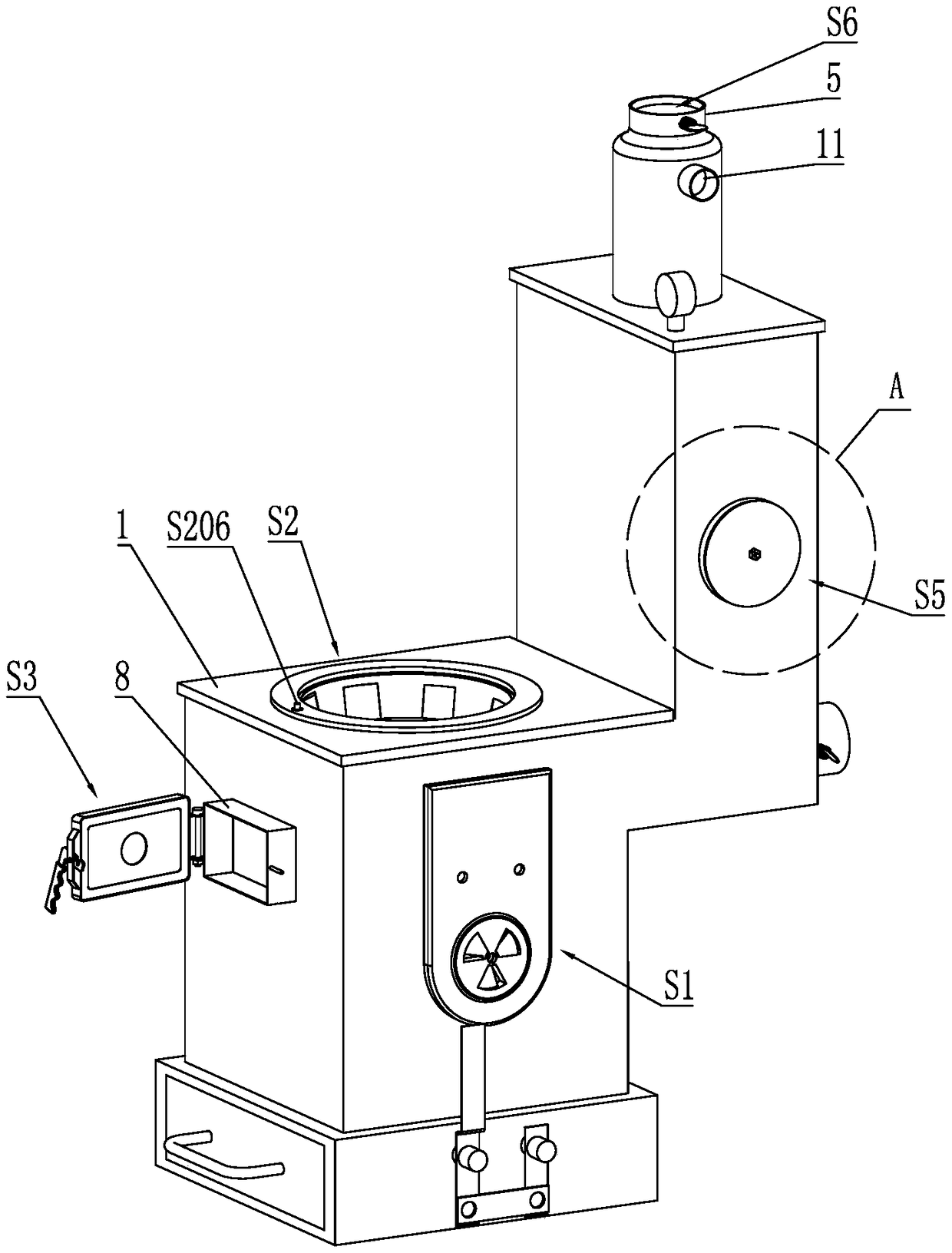

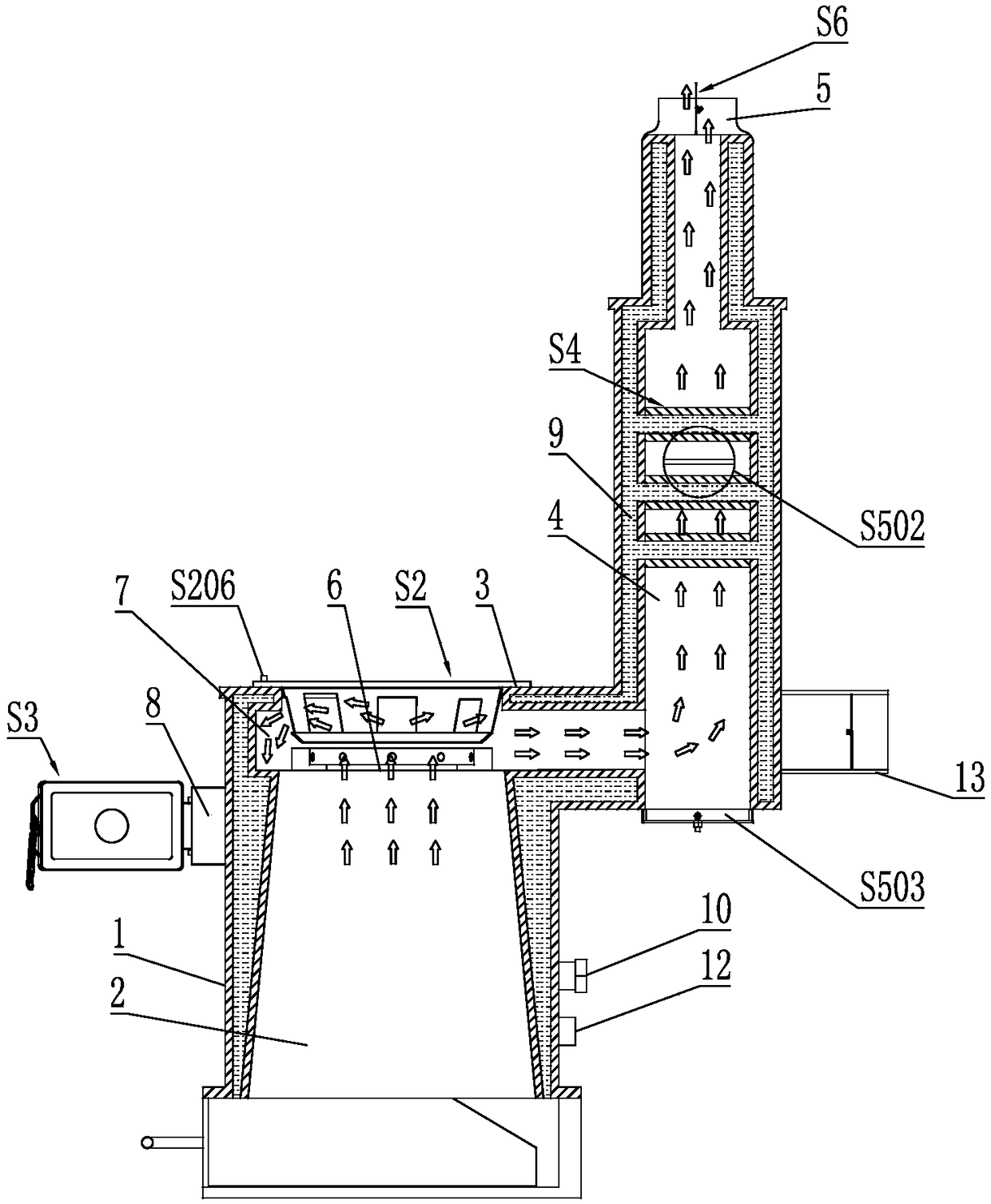

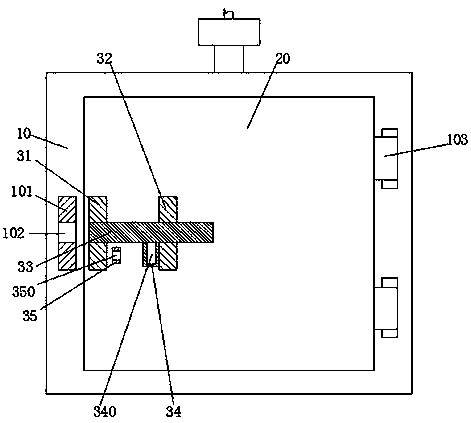

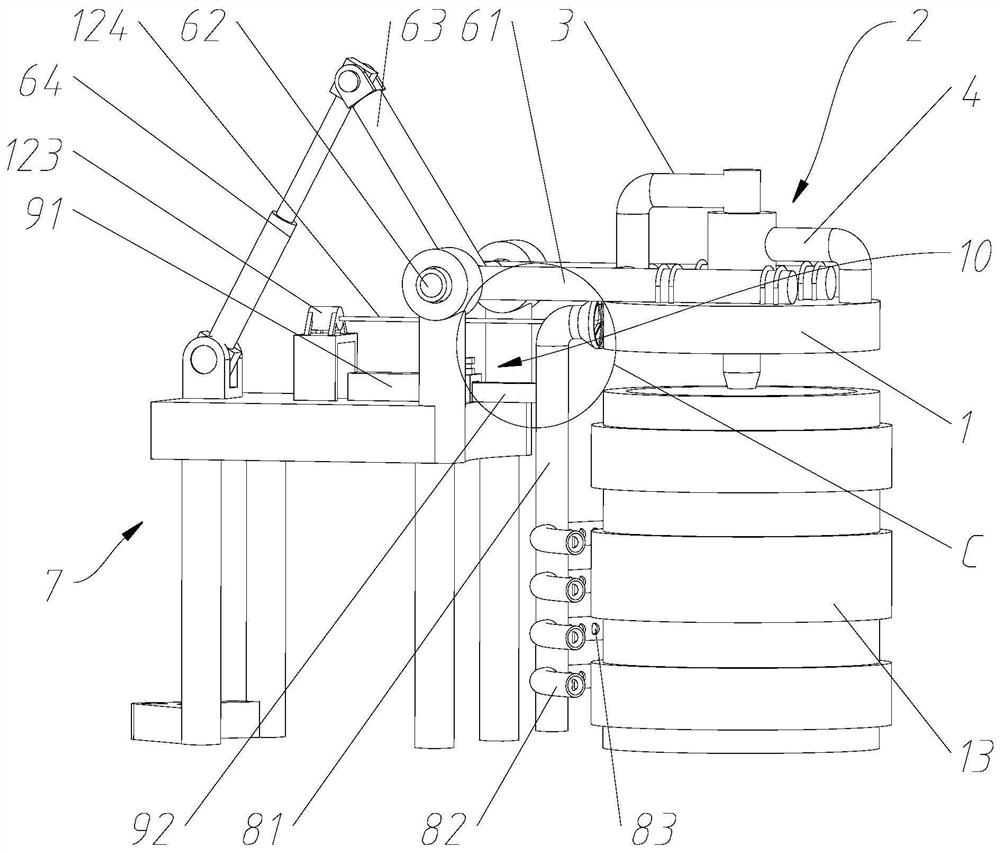

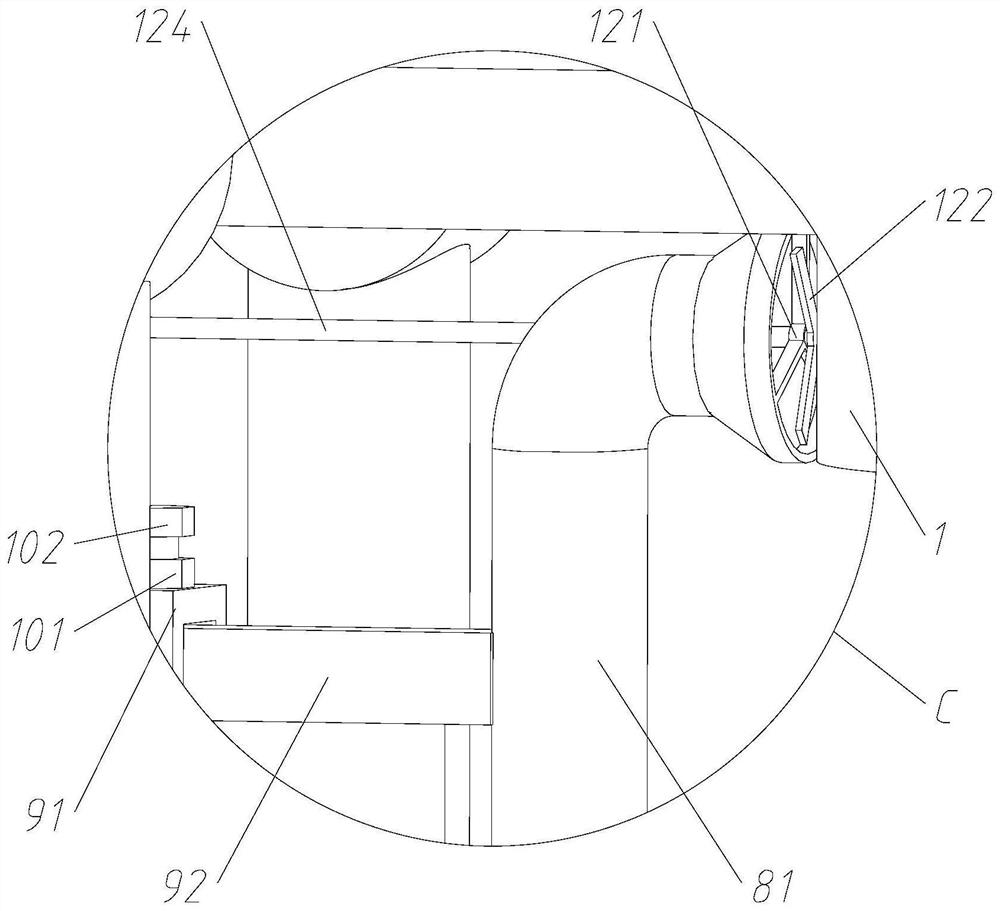

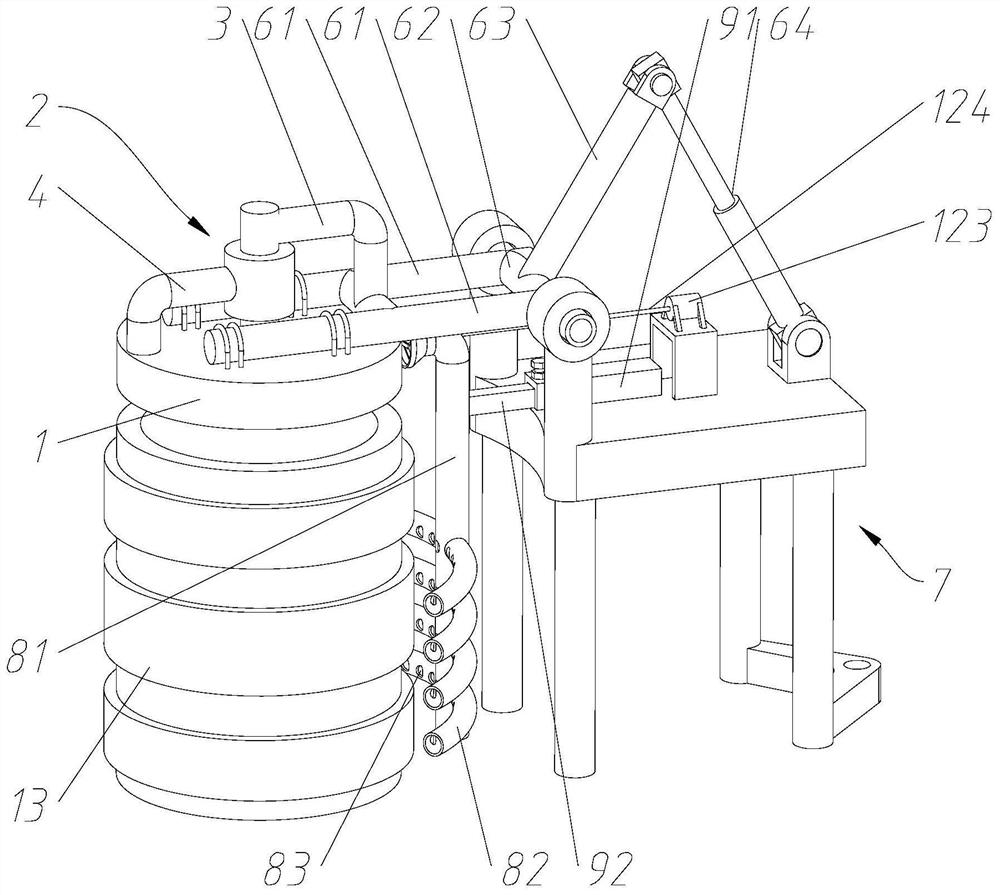

A spout baking equipment

ActiveCN109175344BIncrease profitImprove combustion sufficiencyMelt-holding vesselsCombustorProcess engineering

The invention discloses water gap baking equipment. The water gap baking equipment comprises a furnace body, and the furnace body is provided with a baking chamber for baking a water gap. A combustorfor providing fuel gas through a fuel gas supply pipeline assembly is arranged on the baking chamber, and a smoke exhaust pipe is arranged at the top of the baking chamber. The furnace body further comprises a combustion aiding air preheating chamber which is located at the top of the baking chamber and wrap the circumferential direction of the smoke exhaust pipe, and an air inlet and an air outlet are formed in the combustion aiding air preheating chamber. The air outlet communicates with the combustor, and the fuel gas supply pipeline assembly is connected with a gas pressurizing assembly for increasing the flowing speed of the fuel gas. According to the water gap baking equipment, combustion aiding air is preheated through smoke generated by fuel gas combustion, and meanwhile the flowing speed of the fuel gas is increased through the gas pressurizing assembly. More combustion aiding air can be driven to get into combustion, the combustion sufficiency is improved effectively, and thebaking temperature is improved; and the energy utilization rate is increased, it is ensured that the baking temperature of the water gap meets the needs, and the continuous casting quality is guaranteed.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

A medical waste incinerator

The invention provides a medical waste incinerator. The medical waste incinerator comprises an incineration tank, an incineration cavity and a door body used for closing the incineration cavity, wherein the incineration cavity is formed in the incineration tank, and an opening of the incineration cavity faces rightwards; the door body is rotatably mounted at the rear end of the right end wall of the incineration tank through hinge shafts; a pushing structure is arranged in the door body and comprises a sliding groove formed in the door body and extending up and down; a sliding block arranged up and down equally is slidably mounted in the sliding groove; an electric rotating motor is fixedly mounted in the middle position of the sliding groove. The sliding block is provided with a screw hole. A screw rod is mounted in the screw hole in a matched mode. One end of the screw rod is rotatably mounted in the end wall of the sliding groove, and the other end of the screw rod is connected withthe electric rotating motor. The left end of the sliding groove is provided with a mounting cavity communicating with the sliding groove. The left end of the mounting groove is provided with a sunkengroove.

Owner:浦江净新环保科技有限公司

Pellet roasting device

ActiveCN102808078BImprove combustion sufficiencyReduce heat dissipationCombustion chamberEdge effects

The invention discloses a pellet roasting device, which comprises an upper combustion chamber, a lower combustion chamber and a roasting beaker, wherein the upper combustion chamber, the lower combustion chamber and the roasting cup are connected sequentially from top to bottom and are in a cylindrical shape integrally. According to the provided pellet roasting device, a structure is improved, so that the combustion sufficiency of gas is improved, the radiating and edge effects of the roasting beaker are reduced, energy is saved, the problem of large quality difference of pellets on upper side, lower side, edges and central position of the roasting beaker caused by non-uniform flame and large edge effect during roasting tests of the pellets is solved, and the stable and effective condition is created for the roasting tests and study of the pellets.

Owner:SHOUGANG CORPORATION

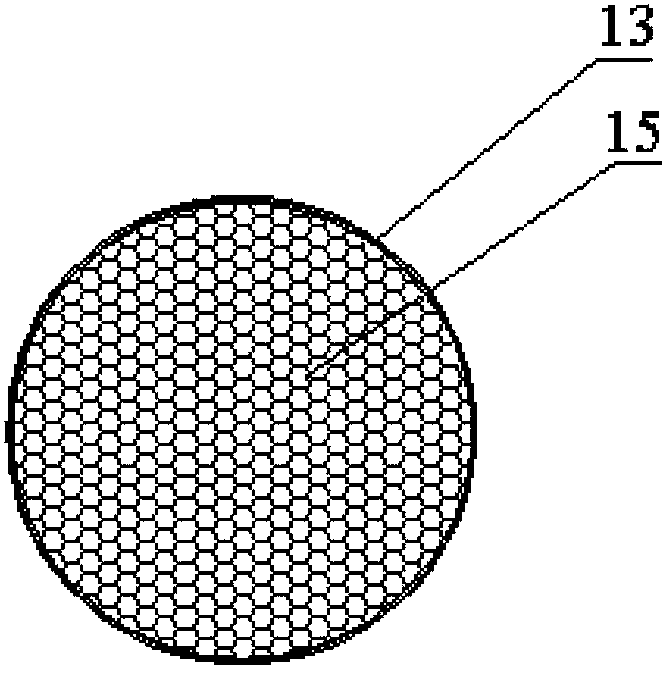

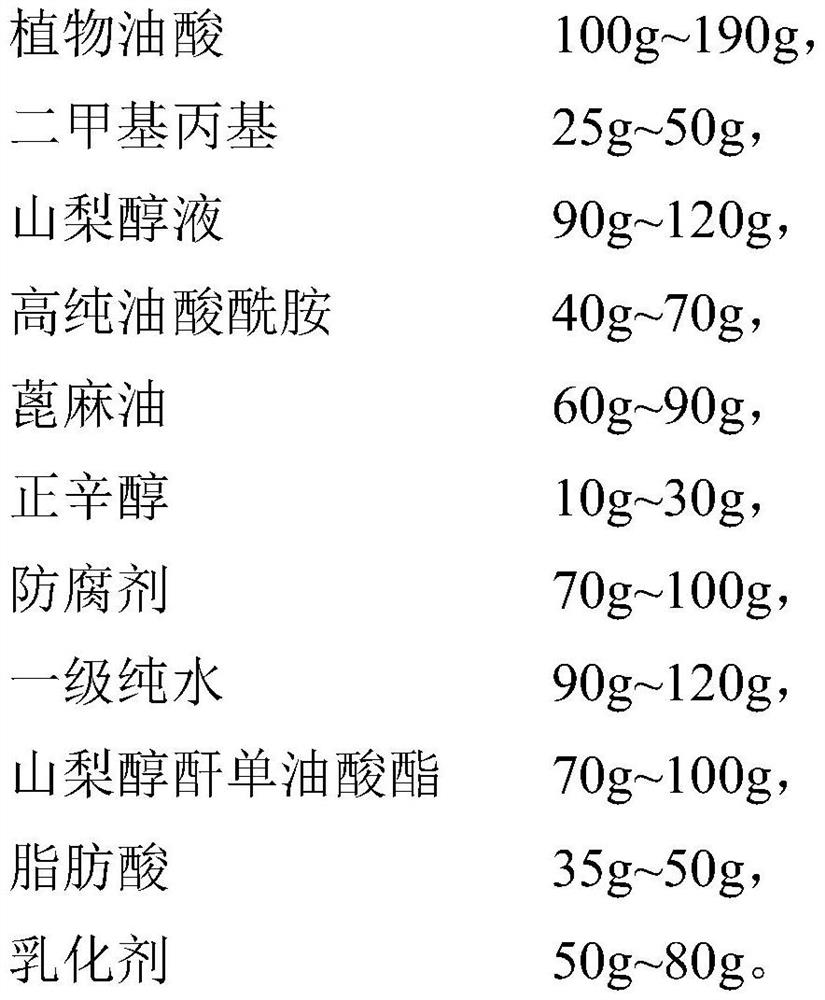

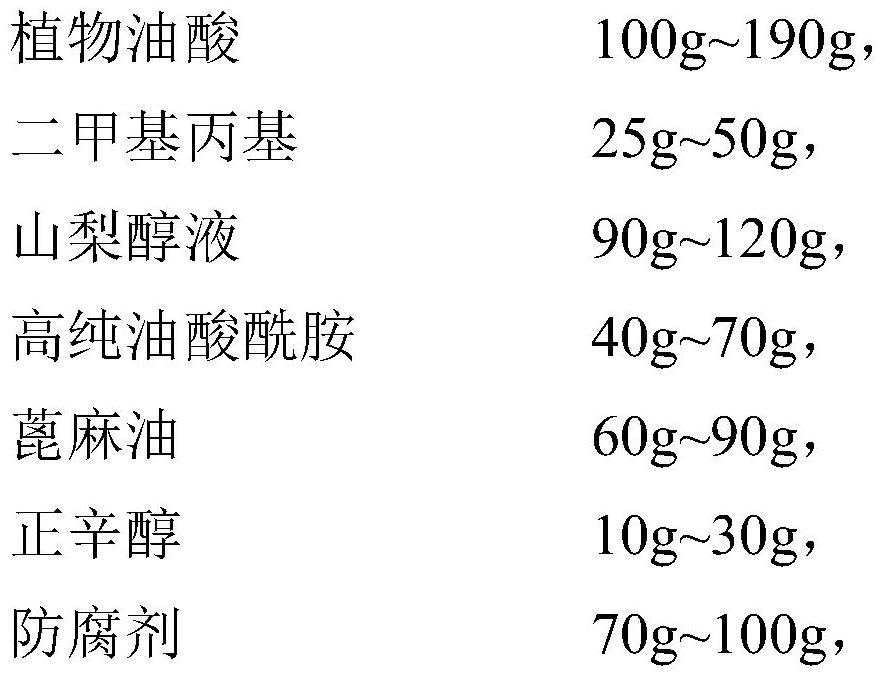

Additive for improving fuel efficiency and preparation method thereof

PendingCN113430020AImprove combustion sufficiencyImprove the safety of useLiquid carbonaceous fuelsFuel additivesFuel oilOleanolate

The invention relates to the technical field of fuel oil additives, in particular to an additive for improving fuel efficiency and a preparation method thereof. The additive for improving the fuel efficiency is prepared from the following components in percentage by weight: 100 g to 190 g of vegetable oleic acid, 25 g to 50 g of dimethyl propyl, 90 g to 120 g of sorbitol liquid, 40 g to 70 g of high-purity oleamide, 60 g to 90 g of castor oil, 10 g to 30 g of n-caprylic alcohol, 70 g to 100 g of a preservative, 90 g to 120 g of first-grade pure water, 70-100 g of sorbitan monooleate, 35-50 g of fatty acid and 50-80 g of an emulsifying agent. According to the invention, oil dirt in an oil path is automatically cleaned by fuel oil, the combustion sufficiency is improved, the components are non-toxic and harmless and are not flammable and explosive, and the additive has high use safety and reduces the emission of automobile exhaust pollutants.

Owner:上海吉油环保科技有限公司

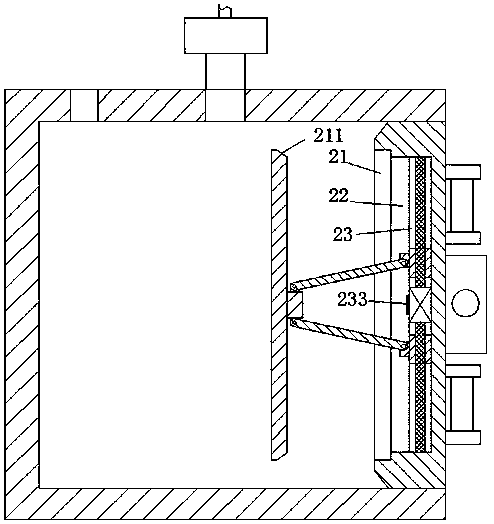

Efficient ladle cover and ladle baking device

ActiveCN111922327ASolve the problem of relatively low heating efficiencyImprove combustion sufficiencyMelt-holding vesselsProcess efficiency improvementThermodynamicsIndustrial engineering

The invention belongs to the technical field of ladle baking devices, and provides an efficient ladle cover and a ladle baking device. The efficient ladle cover comprise a cover body, a burner, a gaspipeline, an air pipeline and heat conduction blocks, the burner is arranged on the cover body, the gas pipeline is arranged on the cover body, one end of the gas pipeline is in communication with a gas inlet of the burner, one end of the air pipeline is in communication with an air inlet in the burner, the other end of the air pipeline is in communication with the outside, an annular cavity is formed in the cover body, an air vent is formed in the cover body and communicates with the annular cavity, the end, away from the burner, of the air pipeline communicates with the annular cavity, the communicating position between the air pipeline and the annular cavity is away from the air vent, a plurality of heat conduction blocks are arranged at the bottom in the annular cavity, and a pluralityof heat exchange holes are formed in the heat conduction blocks. By means of the technical scheme, the problem that in the prior art, the ladle baking device is relatively low in heating efficiency is solved.

Owner:河北煜剑节能技术有限公司

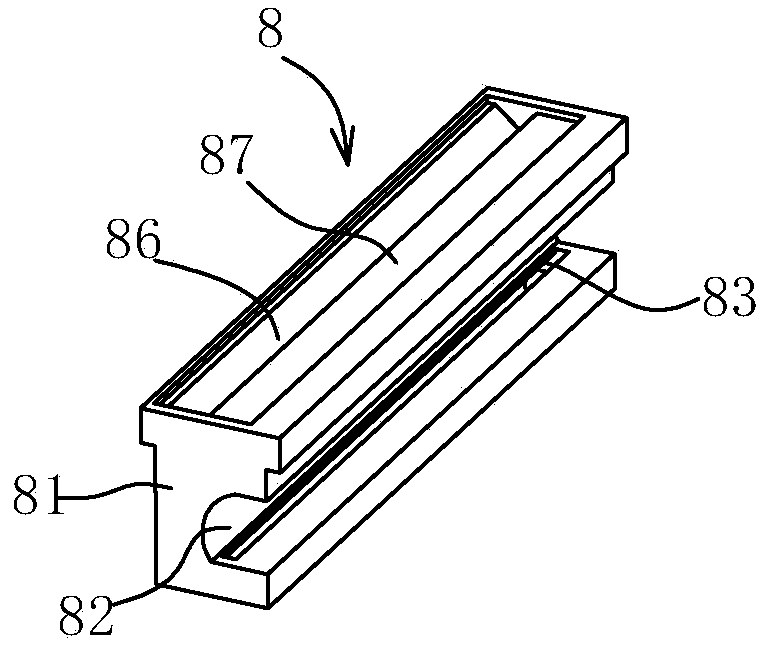

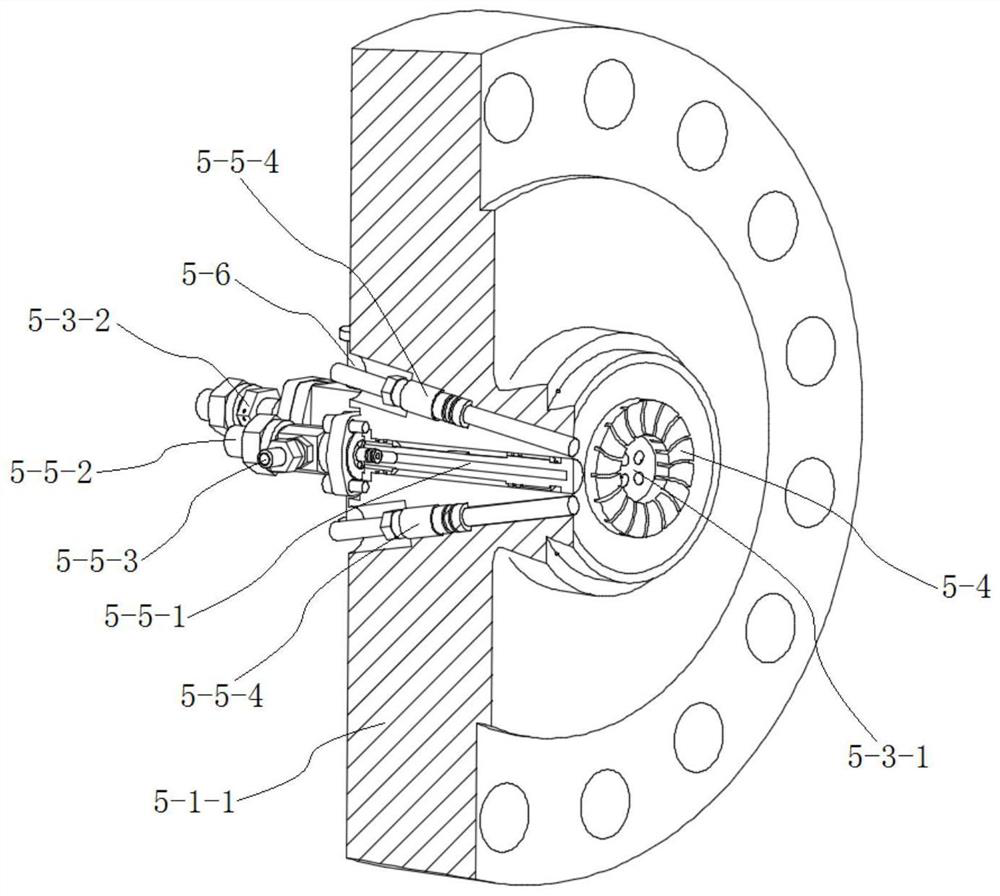

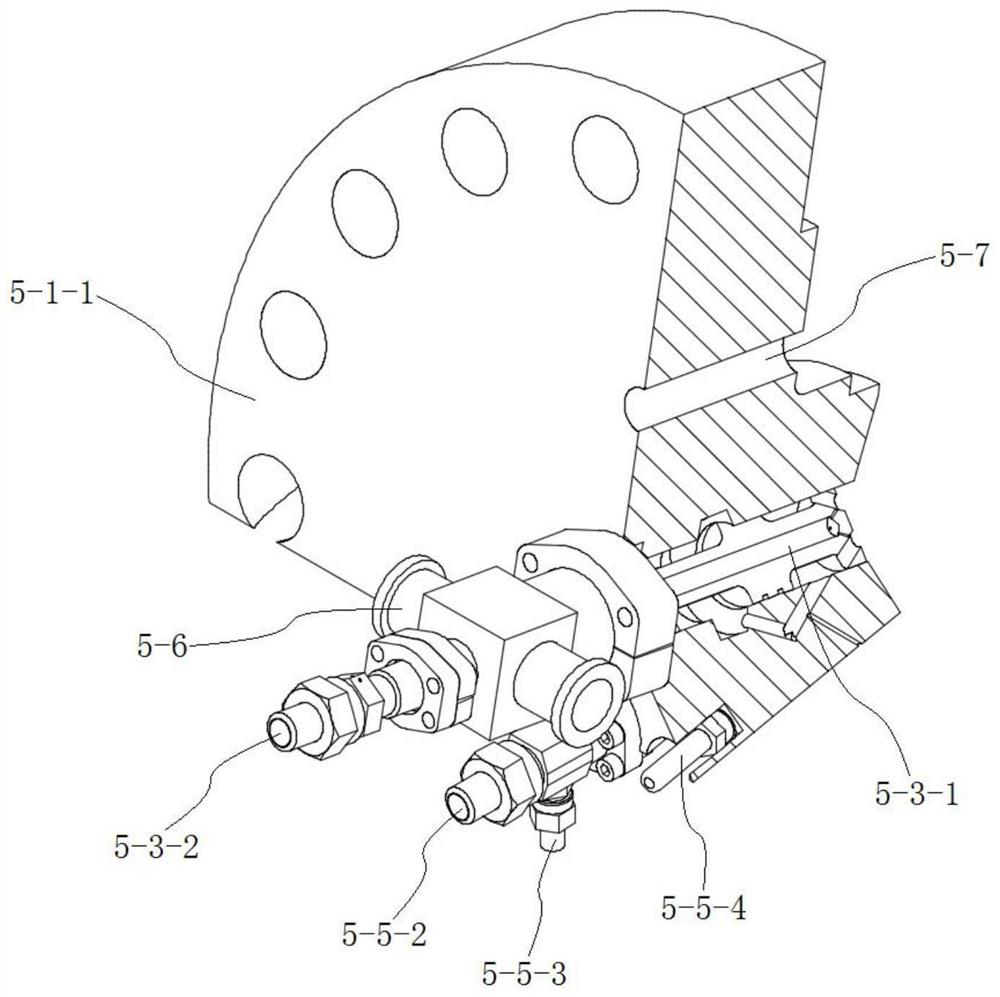

Heating module assembly of parking heater

The invention discloses a heating module assembly of a parking heater. The module comprises a housing, wherein an oil pump, a motor and an oil injector are arranged on the front side of the housing; combustion-supporting fan blades are arranged at a driving shaft at the rear end of the motor; a micro blowing pump is fixed on the inner side surface of the upper end of the housing; a circular tube is fixed on the inner side surface, at a position of the oil injector, of the rear side of the housing by connectors; an air outlet in the micro blowing pump is connected to the inner side surface of one end of the circular tube via an air guide tube; and injection convex ports are formed in the outer surface of the other end of the circular tube. The combustion-supporting fan blades are driven bythe own motor to rotate and blow air to support combustion, the micro blowing pump is added to blow the air, the air is blown out through the injection ports in outside of the circular tube at a portof the oil injector, air flow is more concentrated, oil mist can be quickly boosted, and the strong air flow can blow away the oil mist twice, and the atomization degree is increased, so that full combustion performance is improved.

Owner:温州富力电气有限公司

Anionic combustion apparatus of internal combustion engine

InactiveCN104763561ABurn fullyReduce formationNon-fuel substance addition to fuelMachines/enginesChemical LinkageProduction rate

The invention discloses an anionic combustion apparatus of an internal combustion engine. The anionic combustion apparatus comprises a combustion-supporting housing, wherein an air inlet and an air outlet are formed in the combustion-supporting housing, the air outlet is communicated with an engine air inlet through an air delivery pipe, and the air inlet is communicated with the outside through an air delivery pipe. The anionic combustion apparatus of the internal combustion engine further comprises a controller, wherein an anionic transmitter is connected to the controller, and the controller is connected with a starting circuit of an engine. The anionic transmitter is located in the combustion-supporting housing. The anionic combustion apparatus has the advantages that chemical bonds of oxygen molecules are broken through the anionic transmitter to obtain oxygen anions, the volume ratio of the oxygen anions to air is twice of the volume ratio of oxygen molecules to air so that fuel combustion can be full, and the production rate of products which are not completely combusted is reduced.

Owner:宋骁卿

Intelligent multi-level thermal power plant incineration flue gas circulating treatment system

ActiveCN114321955AUniform temperatureSuppress generationCombustion technology mitigationIncinerator apparatusThermodynamicsCombustor

The intelligent multi-level thermal power plant incineration flue gas circulation treatment system comprises a boiler body, a heat preservation layer is arranged outside the boiler body, and an air layer is formed between the heat preservation layer and the boiler body; a plurality of combustors which are distributed in a left row and a right row are arranged in the boiler body from bottom to top, and a gas filling pipe for supplementing gas for each combustor is arranged between the two rows of combustors; the top of the boiler body is connected with a separator through a smoke exhaust pipe, a discharge port of the separator is connected with a fuel pipe, and the fuel pipe extends into the air layer from the lower portion of the boiler body and spirally extends upwards around the boiler body to provide fuel for the burner on the uppermost layer. An exhaust port of the separator is connected with a waste gas pipe, a circulating pipe is arranged on the waste gas pipe, and the circulating pipe extends into the air layer from the upper portion of the boiler body and spirally extends downwards around the boiler body to be connected with a gas filling pipe. The invention has the characteristics of sufficient combustion, energy saving and environmental protection.

Owner:湖州南太湖热电有限公司

Water gap baking equipment

ActiveCN109175344AIncrease profitImprove combustion sufficiencyMelt-holding vesselsCooking & bakingCombustor

The invention discloses water gap baking equipment. The water gap baking equipment comprises a furnace body, and the furnace body is provided with a baking chamber for baking a water gap. A combustorfor providing fuel gas through a fuel gas supply pipeline assembly is arranged on the baking chamber, and a smoke exhaust pipe is arranged at the top of the baking chamber. The furnace body further comprises a combustion aiding air preheating chamber which is located at the top of the baking chamber and wrap the circumferential direction of the smoke exhaust pipe, and an air inlet and an air outlet are formed in the combustion aiding air preheating chamber. The air outlet communicates with the combustor, and the fuel gas supply pipeline assembly is connected with a gas pressurizing assembly for increasing the flowing speed of the fuel gas. According to the water gap baking equipment, combustion aiding air is preheated through smoke generated by fuel gas combustion, and meanwhile the flowing speed of the fuel gas is increased through the gas pressurizing assembly. More combustion aiding air can be driven to get into combustion, the combustion sufficiency is improved effectively, and thebaking temperature is improved; and the energy utilization rate is increased, it is ensured that the baking temperature of the water gap meets the needs, and the continuous casting quality is guaranteed.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

An indoor range hood and its operation control method

ActiveCN111520787BReduce the temperatureReduce distractionsDomestic stoves or rangesLighting and heating apparatusFresh airEngineering

The invention relates to an indoor range hood and an operation control method thereof. The indoor range hood comprises an upper casing, a fan system, a fume collecting hood, a top plate is arranged above the fume collecting hood, the top plate is connected under the upper casing, and the top plate is connected with the upper casing. A gap is formed between the fume collecting hoods, which is characterized in that it also includes a supplementary air pipe, and a supplementary air valve is arranged in the supplementary air pipe. The gaps between the fume hoods communicate with each other, and air outlet components communicated with the gaps are arranged on the side surface or / and the top plate of the fume collecting hood. Compared with the prior art, the present invention has the advantages that fresh air can be actively introduced from the outside space of the kitchen, and the fresh air can easily form an outer surrounding flow field with the hot air near the cooker, thereby reducing the impact on the range hood when the doors and windows are opened and closed and other people move around. The interference of the nearby flow field can also provide the user with a facial blowing effect and improve the use experience.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

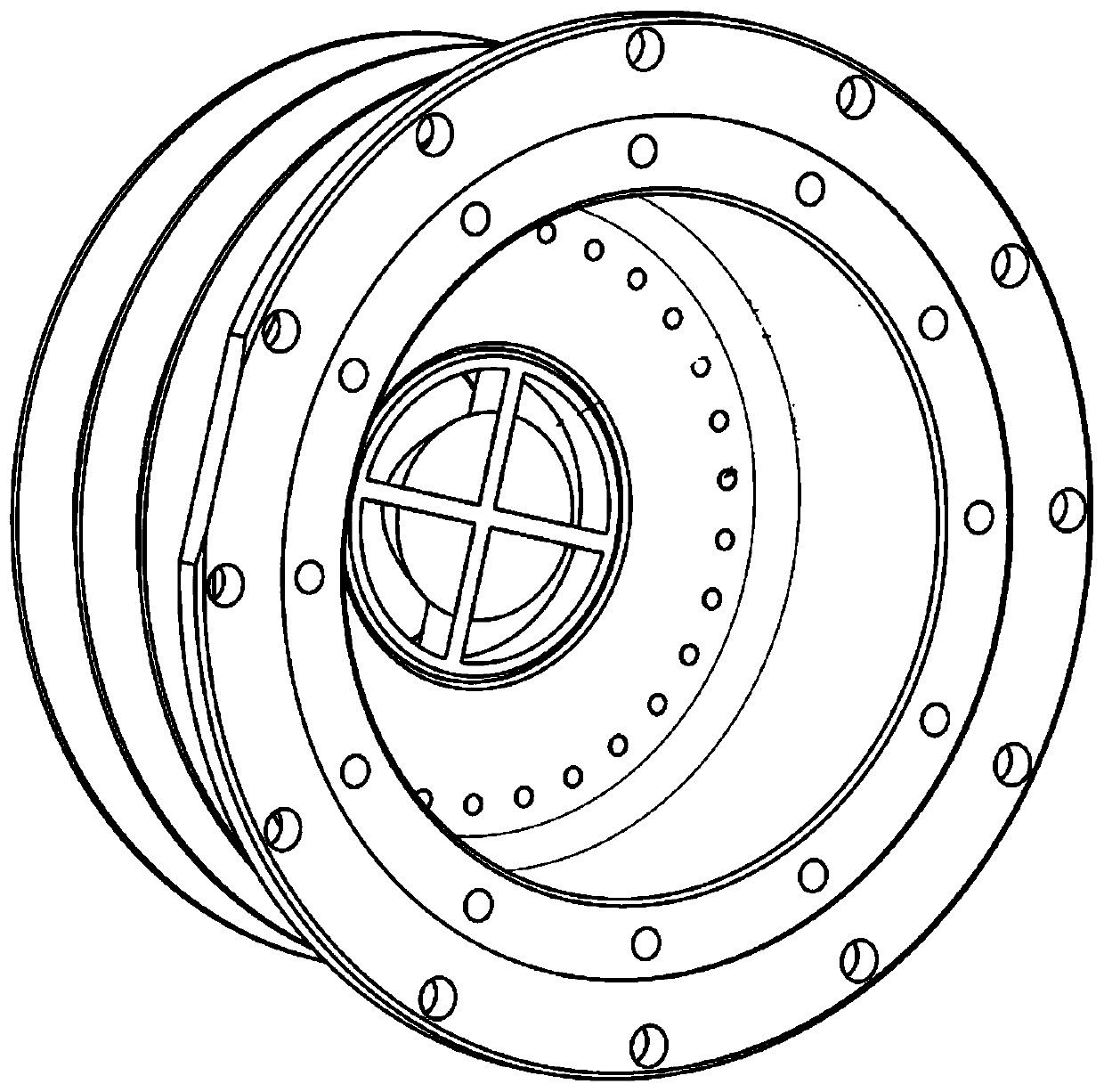

Gas diffusion device

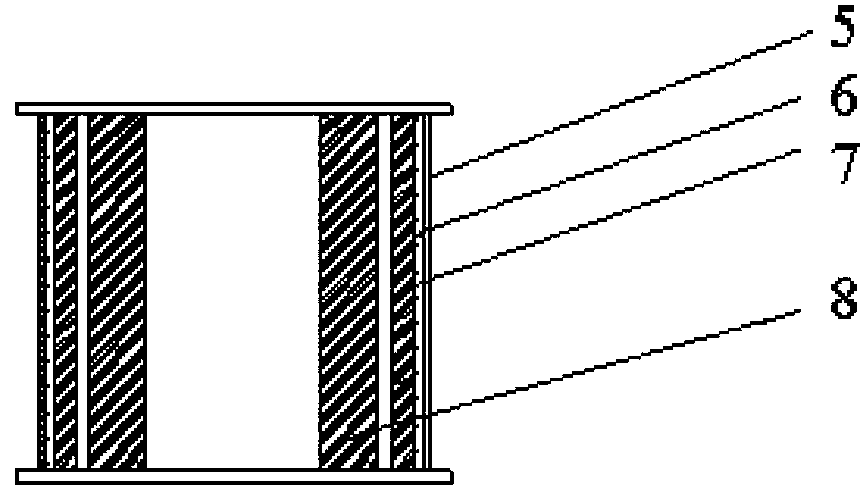

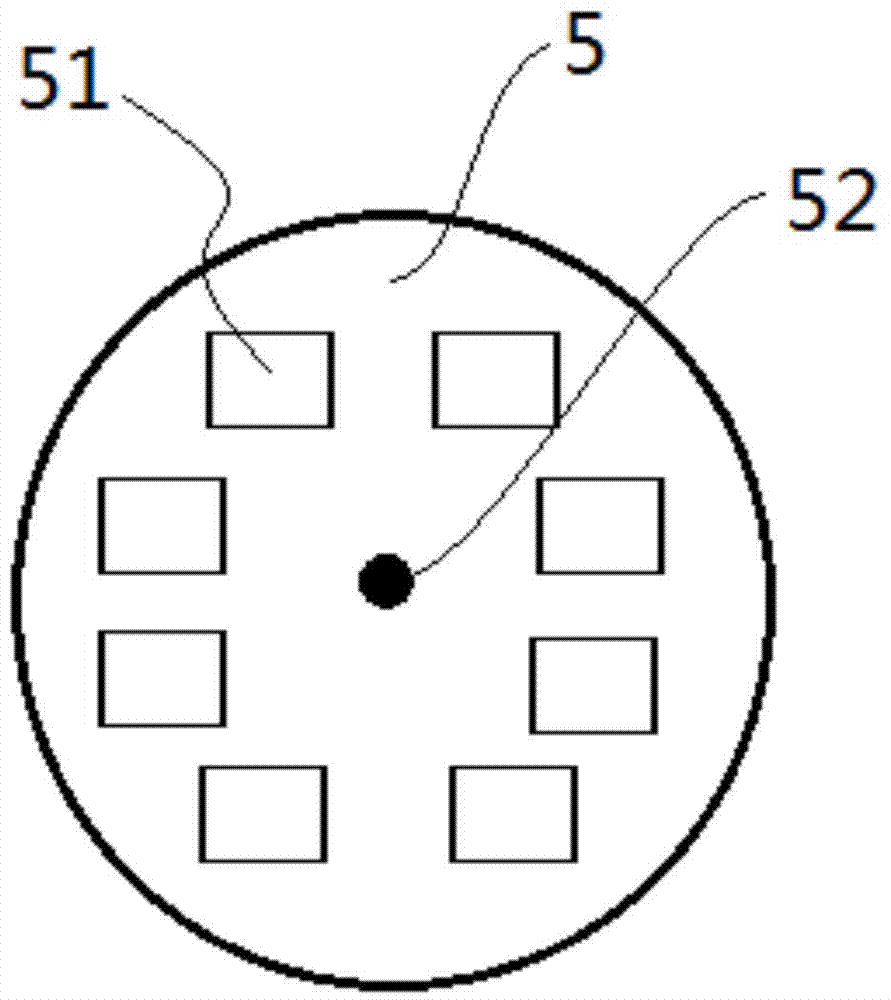

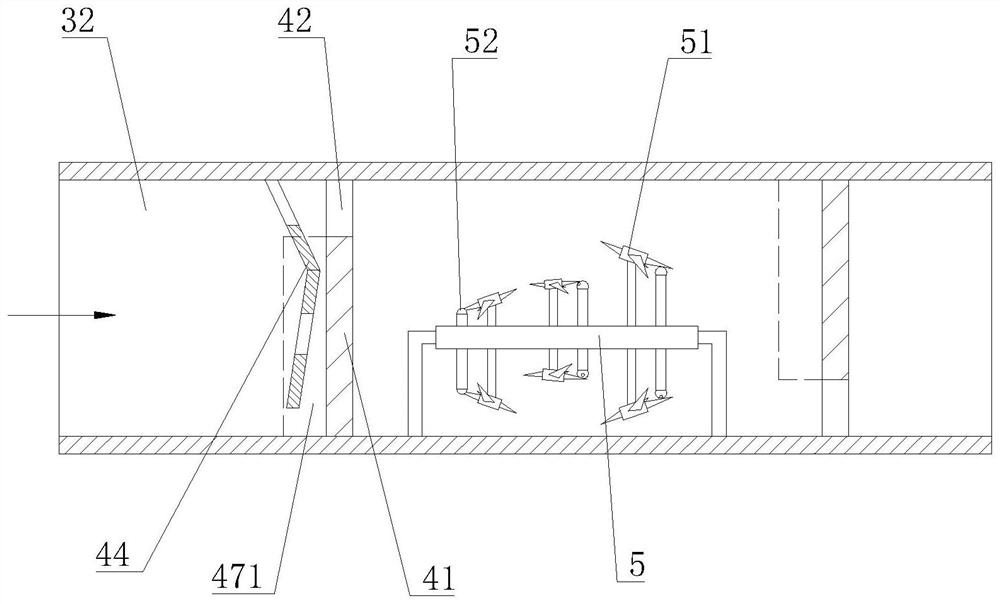

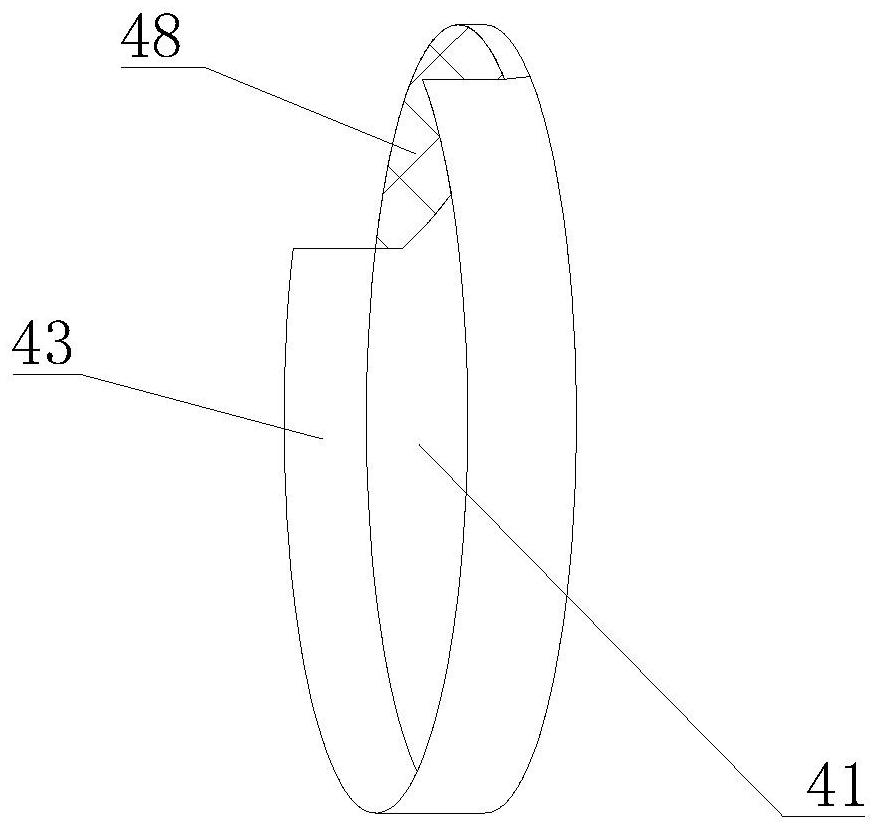

ActiveCN109519939AReliable ignitionReduce consumptionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberFlameout

The invention discloses a gas diffusion device. The gas diffusion device comprises an inner cylinder and an outer cylinder surrounding the periphery of the inner cylinder. Spacing exists between the inner wall of the outer cylinder and the outer wall of the inner cylinder, and a first annular partition plate and a second annular partition plate in the circumferential direction of the inner cylinder are arranged on the outer wall of the inner cylinder at intervals in the axial direction from bottom to top. The circumferential peripheries of the first partition plate and the second partition plate are connected to the inner wall of the outer cylinder, and the first partition plate and the second partition plate are provided with through holes. A first combustion chamber is arranged at an area between the first partition plate and the second partition plate, and a second combustion chamber is arranged at the position, above the second partition plate, in the outer cylinder. The first combustion chamber is internally provided with first burners and second burners at intervals from bottom to top in the axial direction of the inner cylinder, the first burners are connected with a blast furnace gas pipe and maintained in a normally open flame state, and the second burners are in communication with the inner cylinder through branch pipes. The gas diffusion device can enable diffused gas to be reliably ignited, can preheat the gas and air, improves the sufficiency of combustion, and avoids the situations of flame lifting and flameout.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Diesel engine catalyst

InactiveCN101984241ARaise the upper temperature limitImprove combustion sufficiencyInternal combustion piston enginesNon-fuel substance addition to fuelCombustionNitrogen

The invention provides a diesel engine catalyst. The common point of the invention with other catalysts is to generate power through the combustion of diesel in oxygen. The invention is characterized in that a gas cavity is additionally arranged behind the turbocharging; an oxygen filter membrane and a nitrogen discharge port are arranged in the gas cavity; the oxygen filter membrane can increase a certain cache space; during the induction stroke of the diesel engine, high pressure oxygen in the cache space is discharged into the device in the cylinder, thereby raising the temperature upper limit by increasing the oxygen concentration and adequately ensuring pressure, temperature and oxygen; and thus, the invention enhances the completeness of combustion and reduces the smoke intensity and hydrocarbons.

Owner:陈晓英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com