Method for improving economical efficiency of engineering mechanical fuel

A technology of fuel economy and construction machinery, applied in mechanical equipment, engine control, fuel injection control, etc., can solve problems such as unsatisfactory fuel economy, reduced fuel economy, engine flameout, etc., to improve fuel economy and reduce Improve fuel consumption and combustion sufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The core of the present invention is to provide a method for improving the fuel economy of construction machinery, so that the working condition of the engine can be adjusted to the universal characteristic economic zone without changing the engine configuration, and the fuel economy can be improved on the premise of satisfying the output power sex.

[0025] The material distributing device of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can accurately understand the technical solution of the present invention.

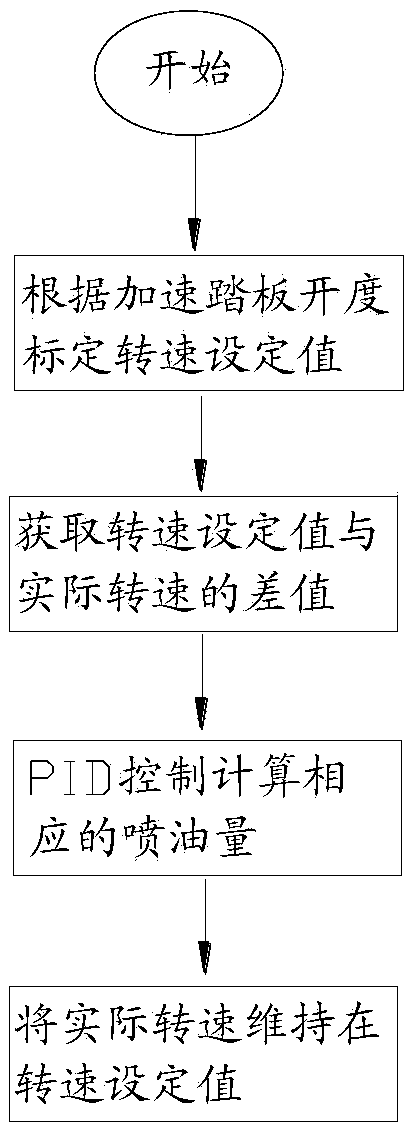

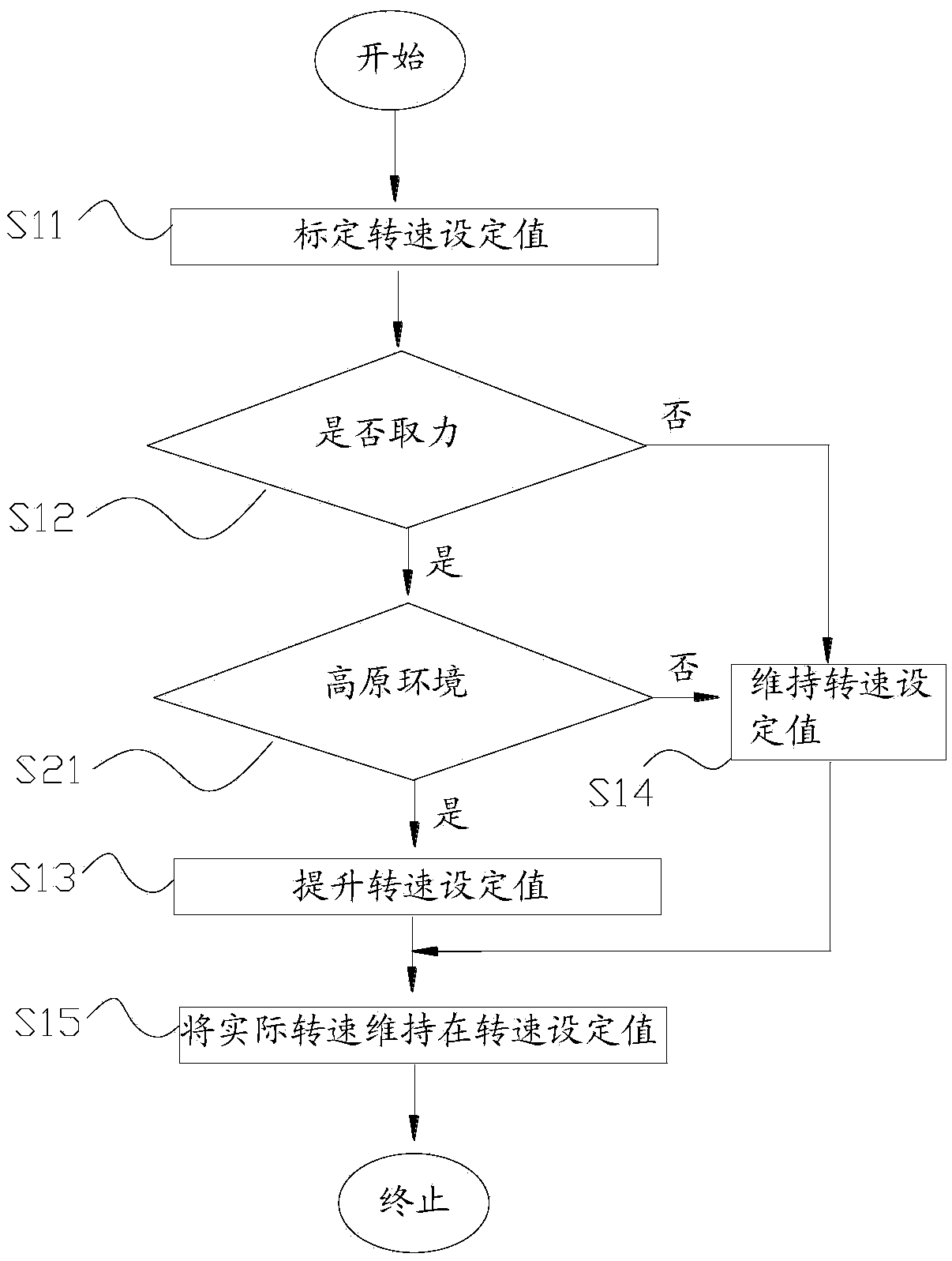

[0026] like figure 2 As shown, the present invention provides a kind of method that improves construction machine fuel economy, comprises the following steps:

[0027] S11: Calibrate the speed setting value according to the accelerator pedal opening, the universal characteristic area corresponding to the speed setting value is in the fuel economy zone, usually the idle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com