Intelligent multi-level thermal power plant incineration flue gas circulating treatment system

A technology of incineration flue gas and recycling treatment, applied in the direction of incinerators, combustion types, combustion methods, etc., can solve problems such as energy waste and environmental pollution, and achieve the effects of energy saving, uniform temperature, and increased combustion share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

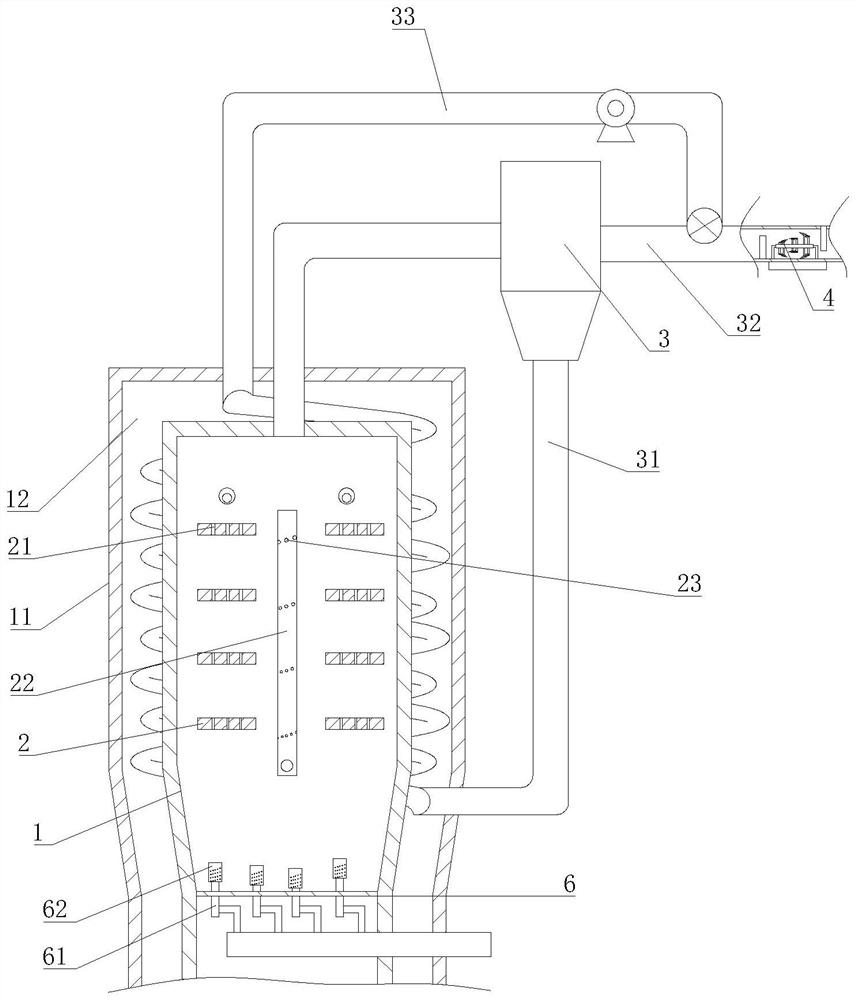

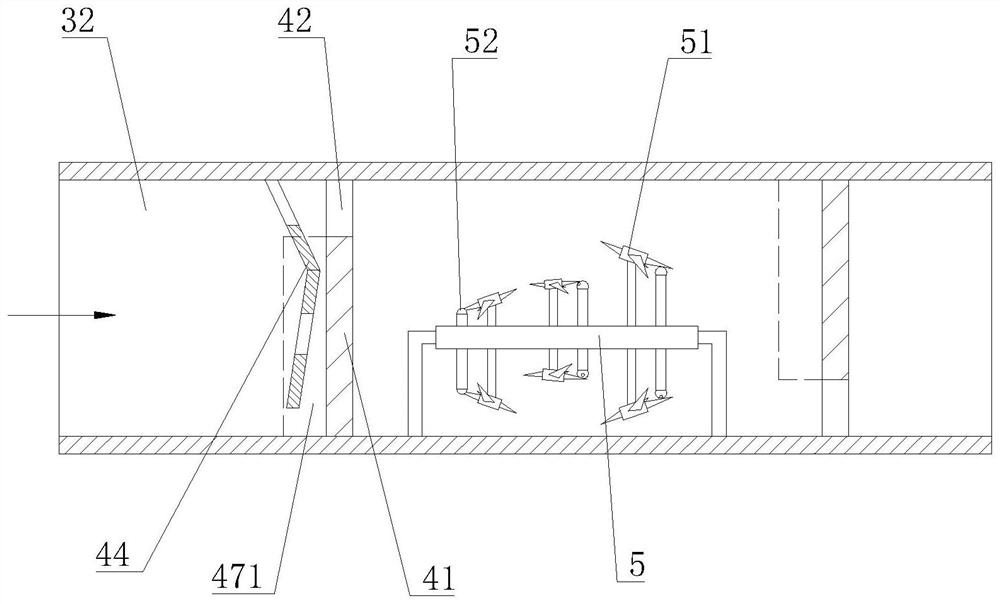

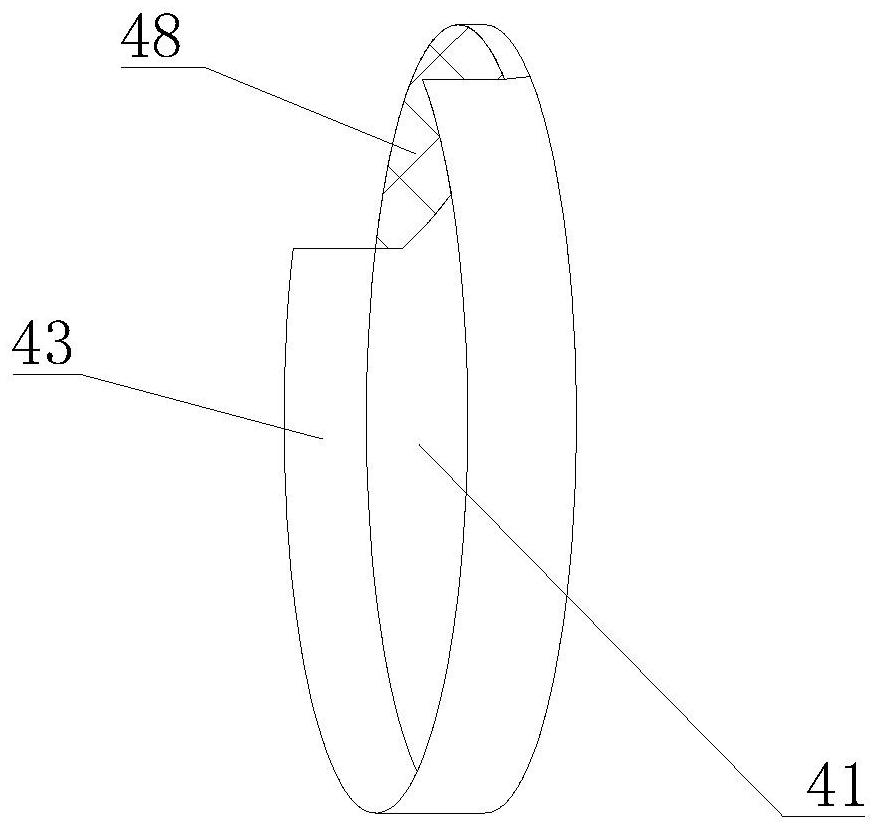

[0023] Such as Figure 1-7 As shown, an intelligent multi-level thermal power plant incineration flue gas circulation treatment system includes a boiler body 1, an insulation layer 11 is provided outside the boiler body 1, and an air layer 12 is formed between the insulation layer 11 and the boiler body 1; the boiler body 1 There are a number of burners 2 distributed in left and right rows from bottom to top, and a gas supply pipe 22 for supplementing fuel gas for each burner 2 is provided between the two rows of burners 2; the top of the boiler body 1 is connected to a separator through a smoke exhaust pipe 3. A fuel pipe 31 is connected to the discharge port of the separator 3. The fuel pipe 31 extends from the bottom of the boiler body 1 into the air layer 12 and spirals upward around the boiler body 1 to provide fuel for the uppermost burner 2; The exhaust port of the separator 3 is connected with a waste gas pipe 32, and the waste gas pipe 32 is provided with a circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com