Patents

Literature

34results about How to "Raise the upper temperature limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Online detection system of aerosol under severe environment

ActiveCN109855924ARealize long-term online monitoringRaise the upper temperature limitWithdrawing sample devicesParticle size analysisEngineeringProcess engineering

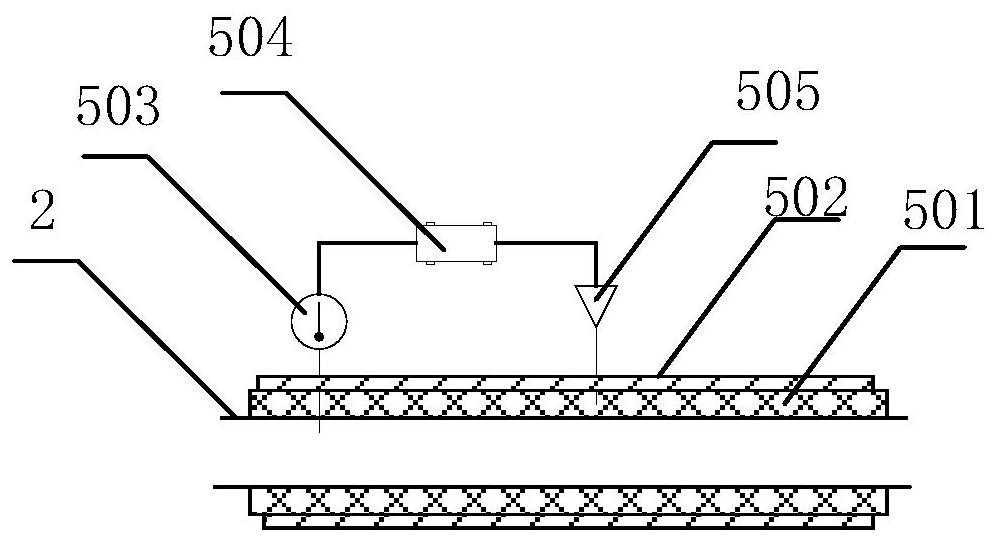

The invention discloses an online detection system of aerosol under a severe environment. The online detection system comprises an aerosol sampling mechanism, one or more stages of cooling dilution devices, an online measuring device, a rear flow measuring control device and an exhaust gas collecting device which are sequentially connected; the aerosol sampling mechanism is arranged in a pressurecontainer of to-be-measured gas to extract the to-be-measured gas and convey the to-be-measured gas to the cooling dilution devices; the cooling dilution devices mix the to-be-measured gas with particle-free dilution gas with the low temperature and low pressure in a dilution cavity for cooling and decompression; the online measuring device extracts the to-be-measured gas through a sampling probein the dilution cavity and detects the to-be-measured gas online; and the rear flow measuring control device controls the extraction flow and feeds the measured gas into the exhaust gas collecting device through a ventilation pipeline to complete measurement. The maintenance cost is low, and long-term online measurement can be achieved.

Owner:SHANGHAI JIAO TONG UNIV +1

Calibration device for high temperature and high pressure sensor

InactiveCN110006587APrevent proliferationRaise the upper temperature limitForce/torque/work measurement apparatus calibration/testingPressure curveData acquisition

The invention relates to a calibration device for a high temperature and high pressure sensor. The device comprises a high pressure metering pump (1) connected to an autoclave (3) through a hollow tube (2), the autoclave (3) is provided with a to-be-calibrated sensor (6), wherein a resistor disc (4) for heating the to-be-calibrated sensor (6) is arranged in the autoclave (3), the resistor disc (4)is wrapped around the to-be-calibrated sensor (6), a heat insulation cover (5) is arranged in the autoclave (3), and the resistor disc (4) and the to-be-calibrated sensor (6) are placed in the heat insulation cover (5). During the calibration, the autoclave needs to be pressurized by using the high pressure metering pump through the hollow tube, when the pressure is stabilized to a set value, direct current is applied to the resistor disc to achieve local rapid heating in the autoclave, a temperature-pressure curve can be drawn through pressure data read via a data collector, and the high temperature and high pressure sensor can be calibrated at different temperatures by comparing the pressure with the pressure in the autoclave shown by the high pressure metering pump.

Owner:AVIC BEIJING CHANGCHENG AVIATION MEASUREMENT & CONTROL TECH INST +2

Industrial-grade optical module, optical fiber communication equipment and optical fiber communication system

PendingCN111880269ARaise the upper temperature limitOffset the impactCoupling light guidesElectrical connectionHemt circuits

The invention discloses an industrial-grade optical module, optical fiber communication equipment and an optical fiber communication system. The industrial-grade optical module comprises: an electrical interface used for accessing an electrical signal; the laser emission assembly which is connected with the electrical interface and is used for converting the electrical signal accessed by the electrical interface into an optical signal of which the wavelength is lower than a preset typical value and outputting the optical signal; the temperature control circuit which is provided with a resistance element used for carrying out heating compensation on the laser emission assembly; the main control device which is electrically connected with the laser emission assembly and the temperature control circuit respectively; and the main control device which is used for detecting the working temperature of the laser emission assembly and controlling the temperature control circuit to work according to the working temperature of the laser emission assembly so as to enable the resistor element to perform heating compensation on the laser emission assembly. According to the industrial-grade optical module, industrial-grade temperature control can be realized on the premise of not using a TEC scheme.

Owner:SHENZHEN FIBERTOP TECH CO LTD

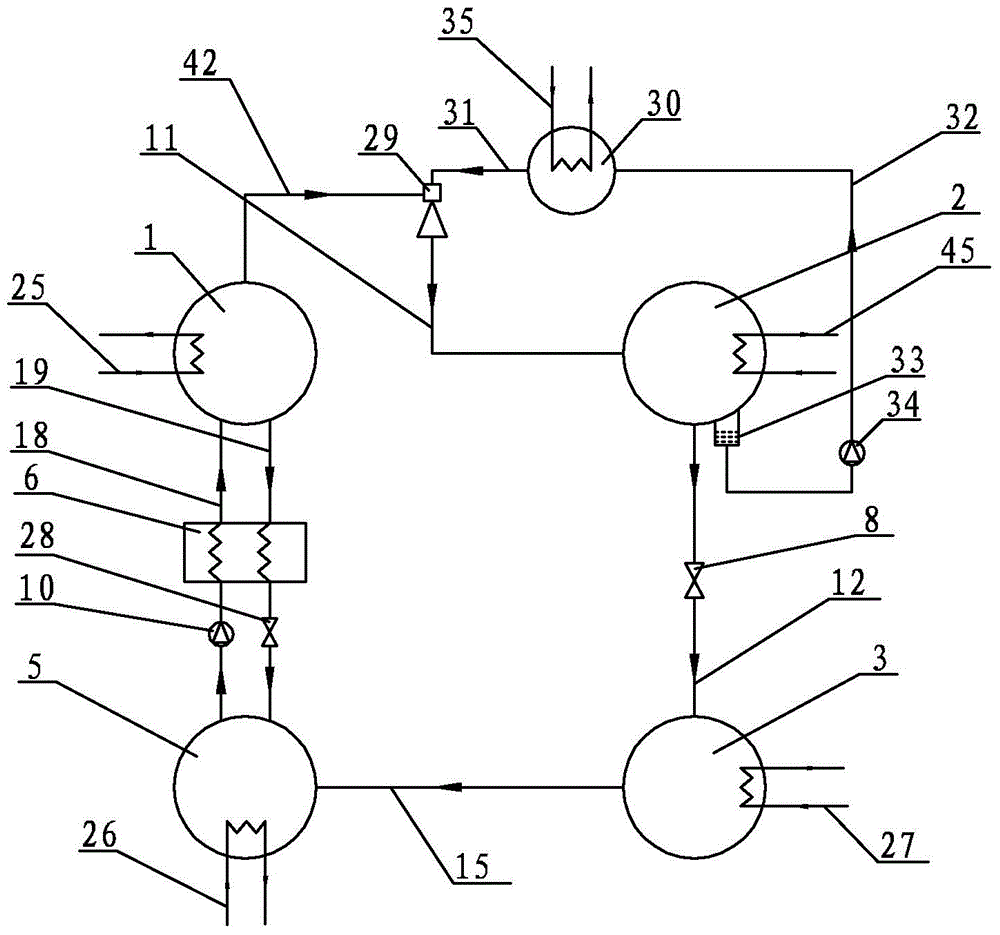

Refrigeration cycle system of lithium bromide jetting and absorbing type for condensation boosting

ActiveCN104154675ARaise the condensation temperatureIncrease pressureMechanical apparatusClimate change adaptationWater source heat pumpWater vapor

The invention discloses a refrigeration cycle system of a lithium bromide jetting and absorbing type for condensation boosting, and relates to an absorption refrigeration cycle system. A condenser is communicated with an evaporator through a first refrigerant passage, the evaporator is communicated with an absorber through a second refrigerant steam pipeline, one ends of a first dilute solution pipeline and a first concentrated solution pipeline are both communicated with the absorber, and the other ends of the first dilute solution pipeline and the first concentrated solution pipeline are both communicated with a generator; a solution heat exchanger is arranged on the first dilute solution pipeline and the first concentrated solution pipeline; one end of a first connecting pipe is communicated with an ebullator, and the other end of the first connecting pipe is communicated with an ejector; one end of the first refrigerant steam pipeline is communicated with the generator, and the other end of the first refrigerant steam pipeline is communicated with the ejector; one end of a third connecting pipe is communicated with the condenser, and the other end of the third connecting pipe is communicated with the ejector; one end of a second connecting pipe is communicated with the ebullator, and the other end of the second connecting pipe is communicated with a solution storing device which is arranged below the condenser; a refrigerant pump is arranged on the second connecting pipe. The cycle system disclosed by the invention is used for an absorption type water source heat pump system.

Owner:HARBIN INST OF TECH

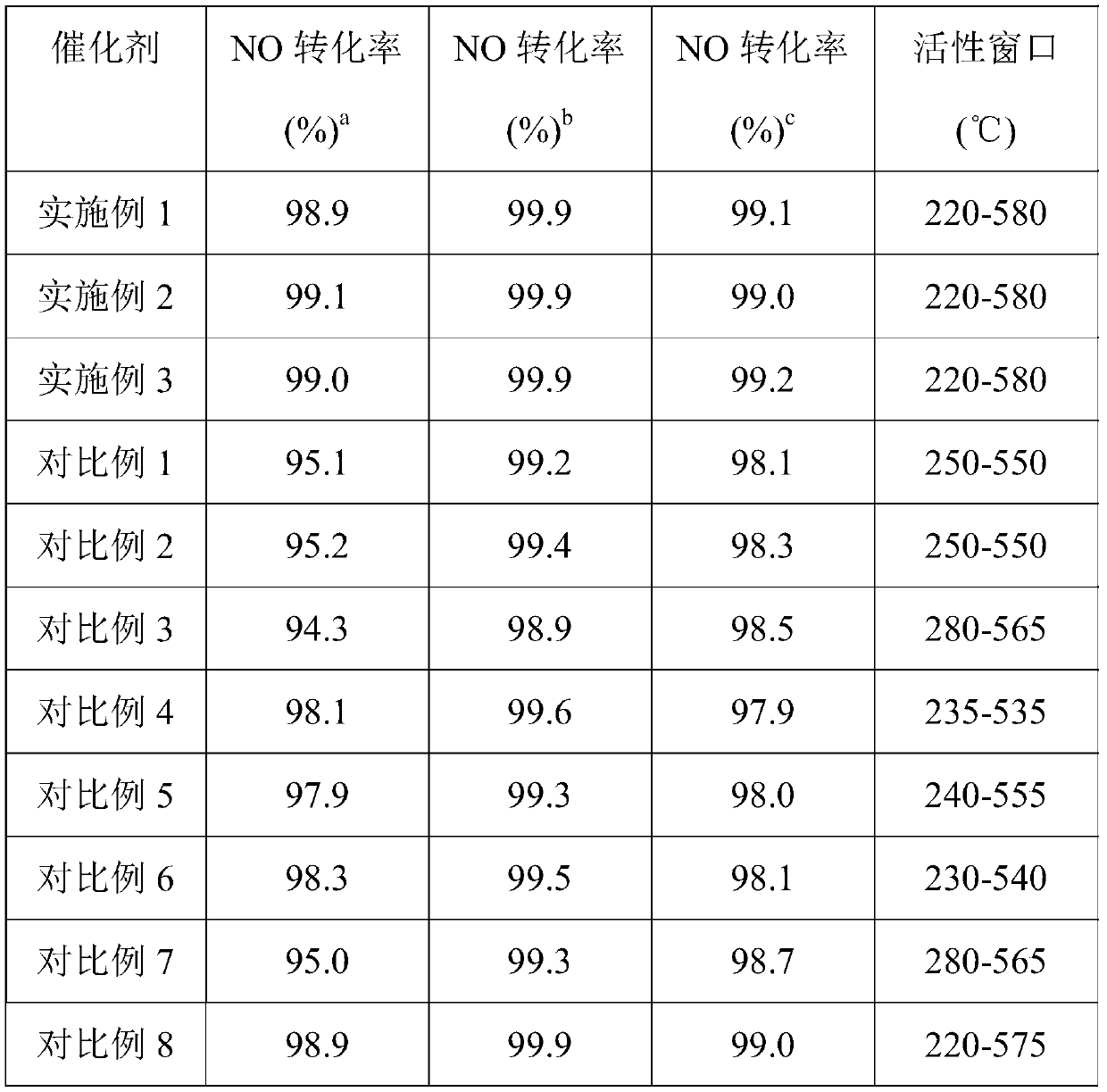

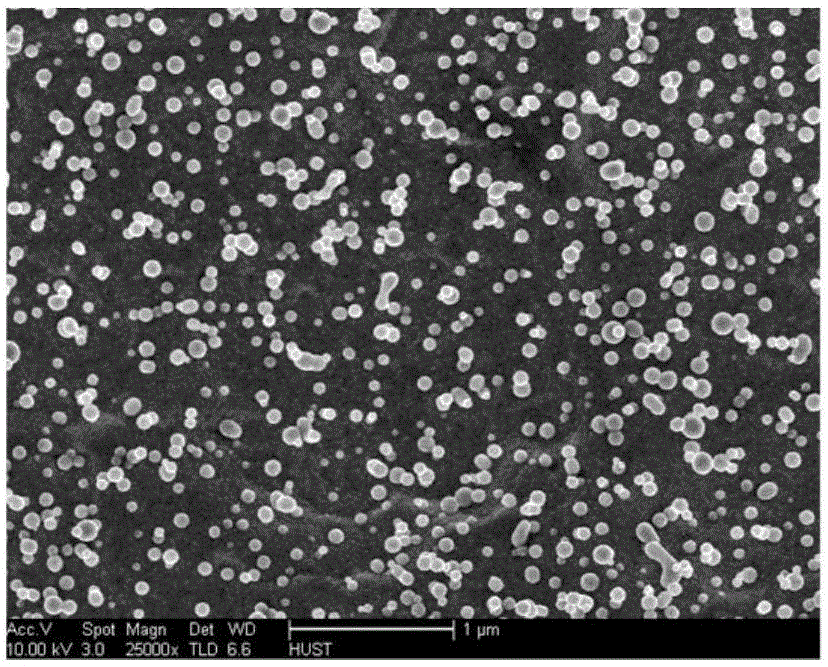

Wide window denitration non-vanadium rare earth based catalyst and preparation method thereof

InactiveCN109999825AImprove denitrification performanceImprove catalytic performanceHeterogenous catalyst chemical elementsDispersed particle separationRare earthViscosity

The invention provides a wide window denitration non-vanadium rare earth based catalyst and a preparation method thereof. The catalyst has the advantages that chitosan, La2O3 and CuO are introduced toperform joint modification on the basis of a CeO2-WO3-TiO2 catalyst, the fact that the adoption of chitosan and the synergistic effect among the La2O3, CuO and Ce oxide improve the activity of the catalyst at low temperature, medium temperature and high temperature and widen the application temperature range of the catalyst is found. Through the introduction of viscosity replacement part TiO2, the activity of the catalyst in a high-temperature section is further improved, and the upper limit temperature of the activity window of the catalyst is widened.

Owner:山东东源新材料科技有限公司

Silicone rubber coated high-temperature slow-expansion water-absorbing particle and preparation method thereof

ActiveCN111363361ARaise the upper temperature limitNo adverse effect by its natureDrilling compositionPtru catalystSilicic acid

The invention discloses a silicone rubber coated high-temperature slow-expansion water-absorbing particle and a preparation method thereof. The slow-expansion water-absorbing particle consists of a conventional temperature-resistant and salt-resistant matrix water-absorbing particle and a coating layer formed by a coating agent disclosed by the invention, wherein the coating agent is composed of silicone rubber base rubber, a vulcanizing agent, a reinforcing agent and a catalyst, the silicone rubber base rubber is at least one of hydroxyl-terminated polydimethylsiloxane and alkoxy-terminated polydimethylsiloxane, the vulcanizing agent is at least one of tetraethoxysilane, methyltriacetoxysilane and the like, the reinforcing agent is at least one of nanometer calcium carbonate, fumed silicaand the like, and the catalyst is at least one of dibutyltin dilaurate, dibutyltin diacetate and the like. According to the invention, the upper limit of the temperature of an existing slow-expansionwater-absorbing particle is obviously improved, and slow expansion can be conducted at a temperature as high as 130 DEG C; and meanwhile, a coating method of the invention is environmentally friendly, does not need organic solvents and high-temperature heating, and is free of adverse effects on the environment and the properties of the water-absorbing particle.

Owner:SOUTHWEST PETROLEUM UNIV

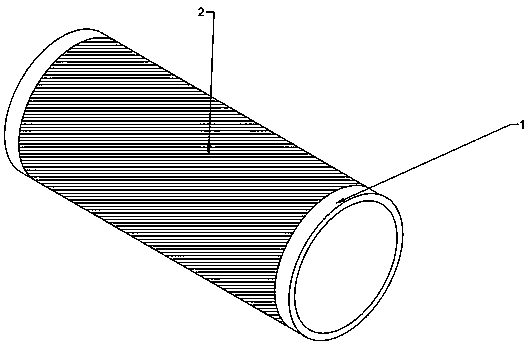

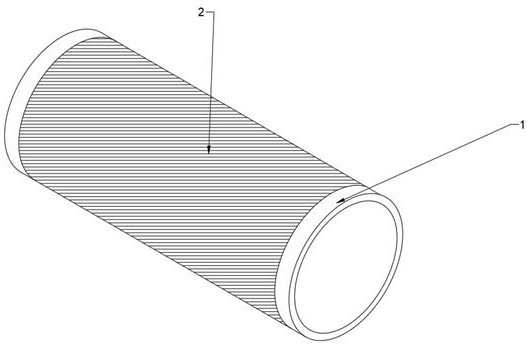

Heating assembly for electronic cigarette and preparation process of heating tube of heating assembly

ActiveCN110063524AReduce power consumptionHeating evenlyTobacco devicesElectricityElectronic cigarette

The invention discloses a heating assembly for an electronic cigarette and a preparation process of a heating tube of the heating assembly, and mainly relates to the technical field of electronic cigarettes. The heating assembly for the electronic cigarette consists of the heating tube and an electrode. The heating tube consists of a tubular body and a heating layer; the tubular body has the performance of transferring heat outside the tubular body to the inside of the tubular body and is used for accommodating an electronic cigarette bomb and carrying the heating layer; the heating layer is aconductive coating which is formed by printing conductive paste on the outer surface of the tubular body and generates heat after being electrified; the electrode is an annular electrode which is matched with the outer diameter of the tubular body, sleeved with the two ends of the tubular body and electrically connected with the heating layer. The heating assembly of the electronic cigarette hasthe advantages of high stability, excellent aging resistance, uniform heating performance, low manufacturing cost, simple structure and small size, and the size of the electronic cigarette can be obviously reduced.

Owner:RIZHAO ZHONGBANG ELECTRONICS CO LTD

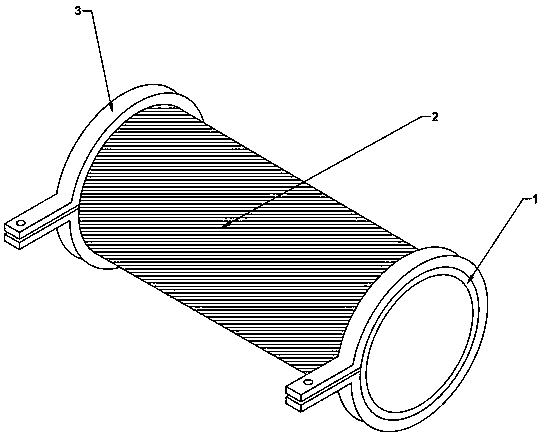

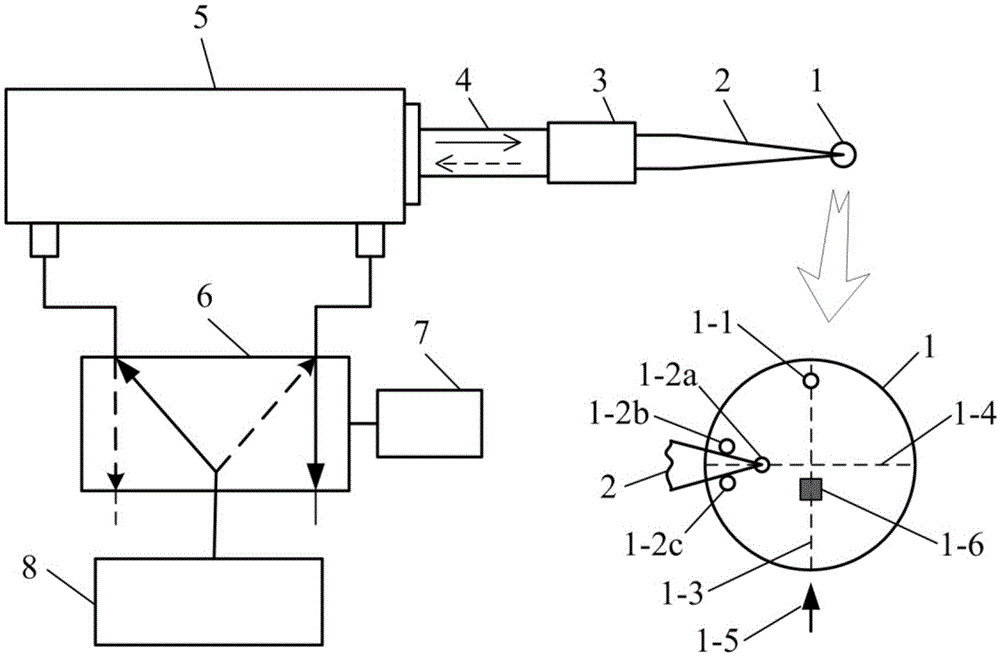

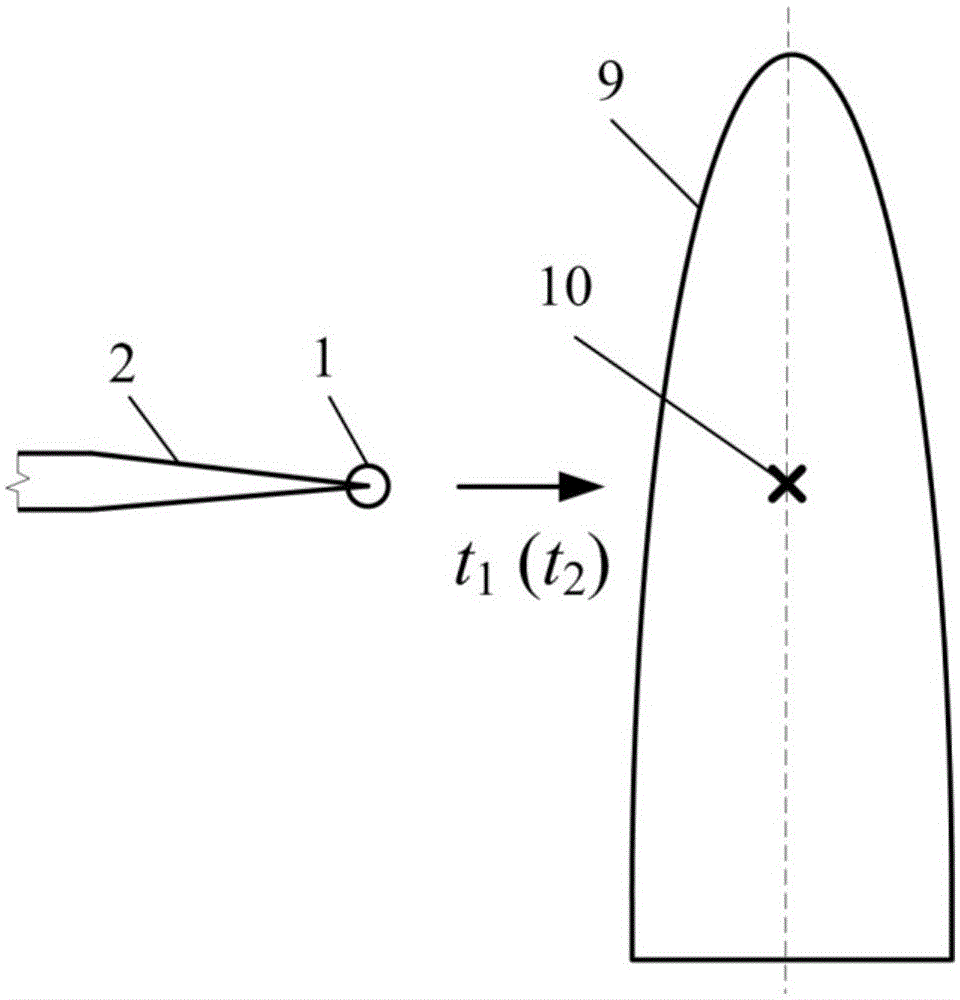

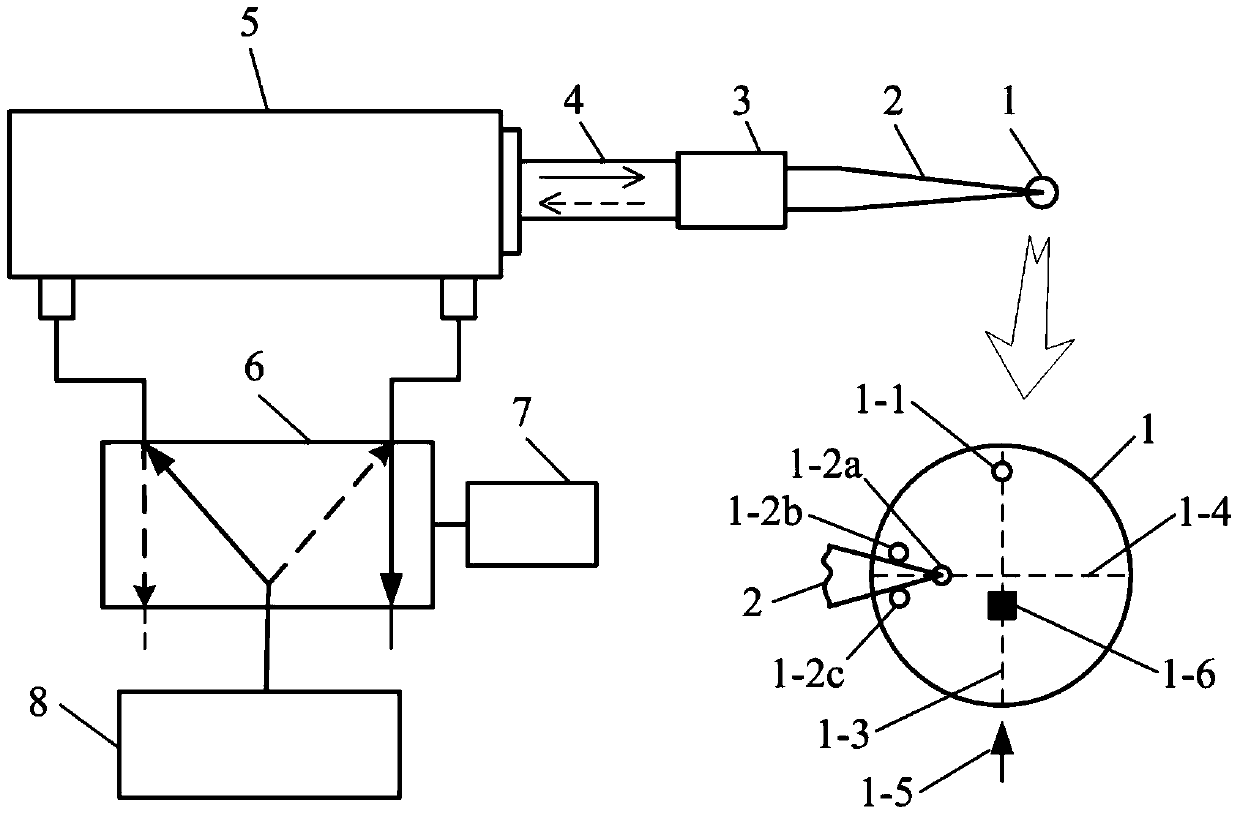

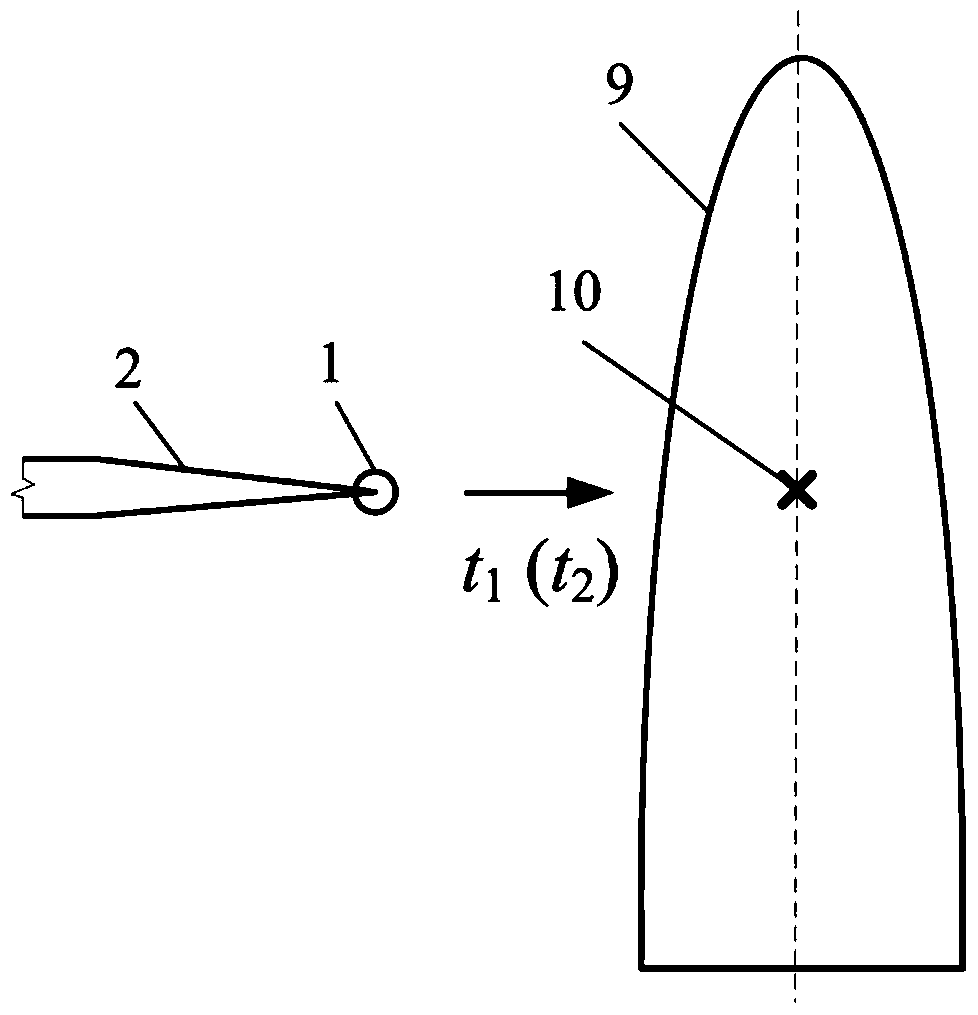

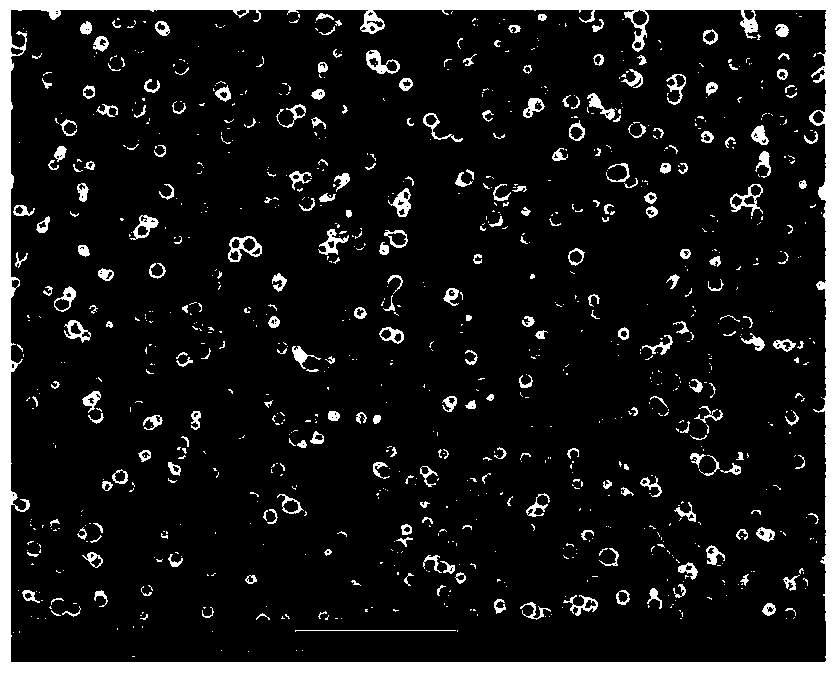

Device and method for measuring flow velocity of flame aerosol

The invention discloses a device for measuring the flow velocity of flame aerosol, and the device is characterized in that the device comprises a base supporting seat, an XYZ three-axis mobile platform, a bidirectional cylinder, a self-locking tweezers connecting part, a self-locking tweezers, a probe sheet, a solenoid valve, and a time relay; the XYZ three-axis mobile platform is disposed on the base supporting seat; the bidirectional cylinder is disposed on the XYZ three-axis mobile platform; the self-locking tweezers is disposed on the bidirectional cylinder through the self-locking tweezers connecting part; the probe sheet is integrally shaped like a circle, is disposed on the self-locking tweezers, and is used for extending into the flame aerosol for sampling; and the solenoid valve and the time delay are used for jointly controlling the movement of the bidirectional cylinder, thereby controlling the stay duration of the probe sheet in the flame aerosol. The device can greatly reduce the radiation and thermal condition loss of a probe through employing a thermophoresis sampling probe, and enables convective heat transfer to remain the main heat transfer between flame and the probe, so as to obtain the flow velocity of the flame aerosol.

Owner:HUAZHONG UNIV OF SCI & TECH

Upper electrode assembly and semiconductor process equipment

PendingCN114203511AReduce the difficulty of temperature controlImprove temperature control effectElectric discharge tubesSemiconductor/solid-state device manufacturingProcess equipmentHeating effect

The invention discloses an upper electrode assembly and semiconductor process equipment, the upper electrode assembly comprises an upper electrode cover plate, and the upper electrode cover plate is used for being arranged on a top opening of a reaction chamber; the flow uniformizing piece is a heat conduction structural piece and is installed on the upper electrode cover plate, at least one part of the flow uniformizing piece is located on the side, facing the reaction cavity, of the upper electrode cover plate, and the flow uniformizing piece is provided with an annular containing groove; the contact electrode is arranged on the surface of the side, away from the upper electrode cover plate, of the flow uniformizing piece, and an opening of the annular containing groove is arranged away from the contact electrode; and the heating ring is arranged in the annular accommodating groove. According to the technical scheme, the problems that the heated effect of an existing contact electrode is poor, and the temperature of the upper electrode cover plate is high can be solved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

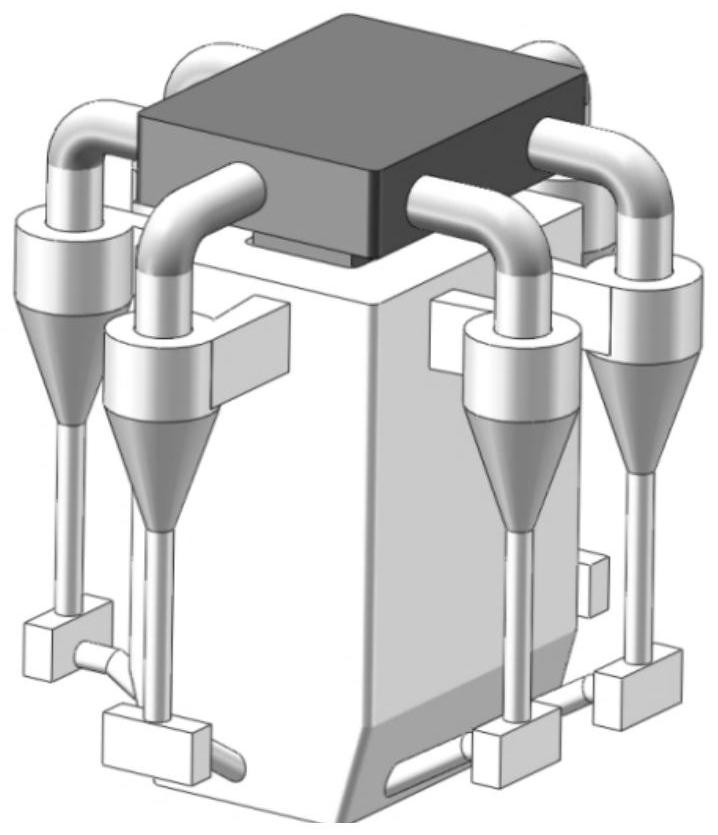

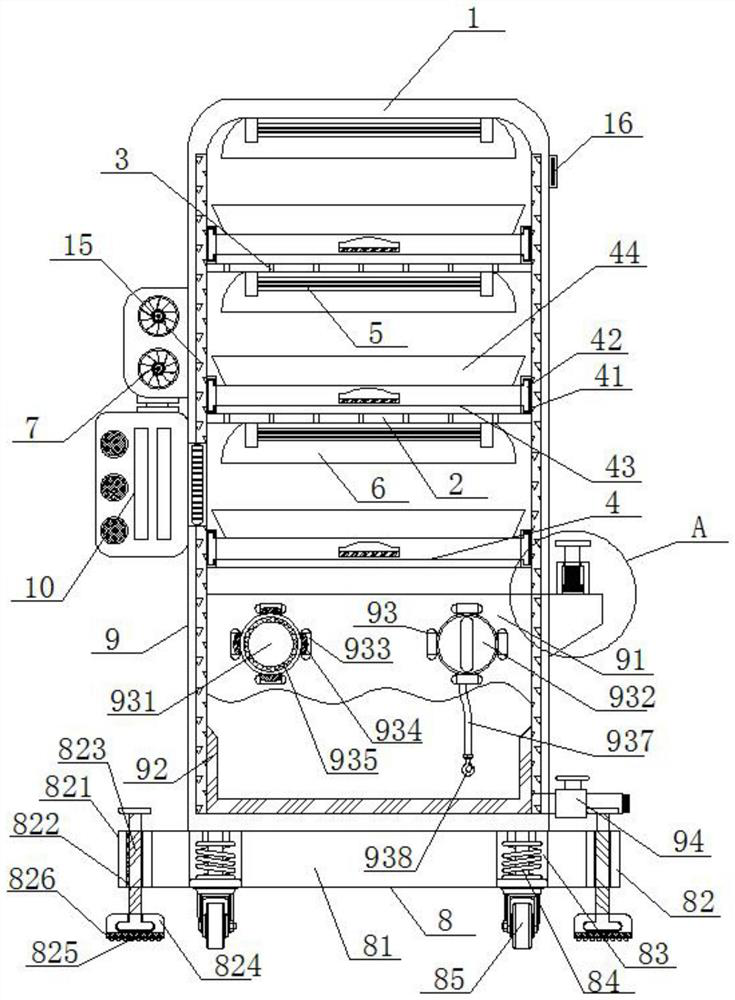

Vitrified micro-bead and Songmiwei platinum production equipment

The invention relates to vitrified micro-bead and Songmiwei platinum production equipment. The production equipment comprises an expansion furnace and a preheating furnace, wherein the expansion furnace comprises a heat preservation layer, a fireproof layer and a high-temperature-resistant furnace pipe, the upper end of the high-temperature-resistant furnace pipe is connected with a feeding hopper, and a plurality of low-nitrogen combustors are further arranged on the side wall of the expansion furnace; the preheating furnace comprises an outer shell and a central rotary drum, a first spiral blade is arranged on the inner wall of the central rotary drum, a second spiral blade is arranged on the outer wall of the central rotary drum, and the rotating direction of the first spiral blade is opposite to that of the second spiral blade; one end of the central rotary drum is provided with a finished product feeding port, and the other end is connected with a finished product discharging port. One end of the outer shell is provided with a raw material preheating inlet and one end is provided with a raw material preheating outlet. Cooling of high-temperature finished product particles andpreheating of to-be-preheated raw material particles can be achieved at the same time, energy consumption in the expanded and vitrified micro bubble machining process can be effectively reduced, energy is saved, continuous production operation can be achieved, and the production efficiency is high.

Owner:信阳金辉冶金新型保温材料有限公司

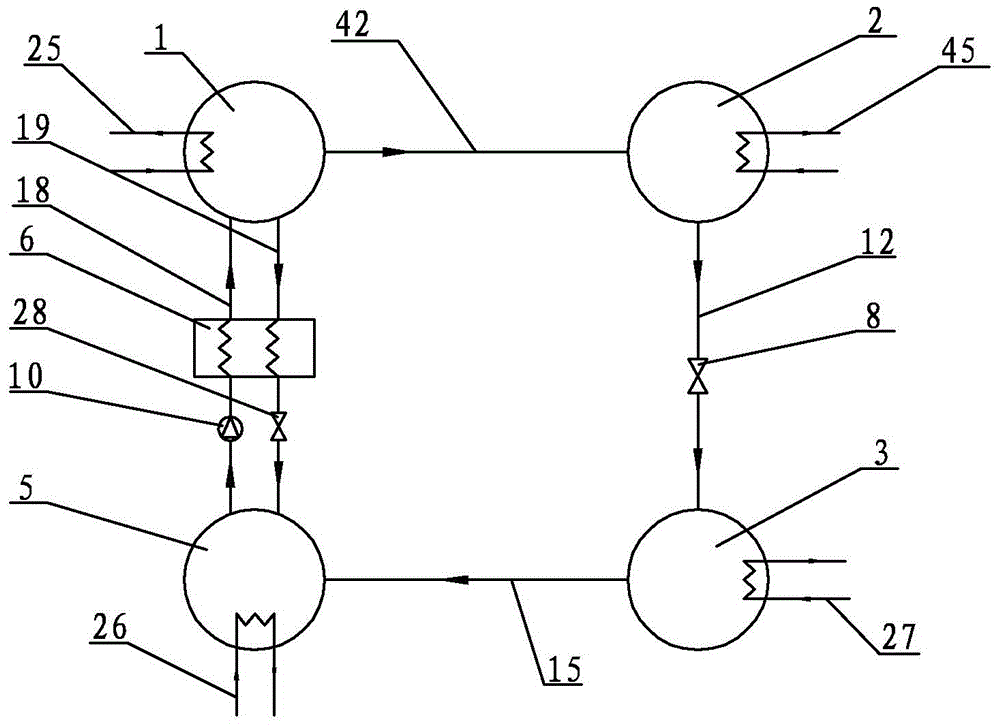

Cool double-effect lithium bromide absorption type refrigeration cycle system

ActiveCN104180561ARaise the upper temperature limitRaise the outlet temperatureEnergy efficient heating/coolingClimate change adaptationWater source heat pumpWater vapor

The invention relates to a cool double-effect lithium bromide absorption type refrigeration cycle system. A generator is communicated with a condenser, the condenser is communicated with an evaporator through a first refrigerant water passage, one end of a second refrigerant water passage is communicated with the condenser, the other end of the second refrigerant water passage passes through a first absorber to be communicated with a second absorber, the first absorber is communicated with the evaporator through a second refrigerant water vapor pipeline, one end of a first dilute solution pipeline and one end of a second dilute solution pipeline are communicated with the second absorber, the other ends of the first dilute solution pipeline and the second dilute solution pipeline are communicated with the generator, one end of a second concentrated solution pipeline is communicated with the first absorber, the other end of the second concentrated solution pipeline is communicated with a first concentrated solution pipeline, one end of the second dilute solution pipeline is communicated with the first absorber, the other end of the second dilute solution pipeline is communicated with the first dilute solution pipeline, a first solution pump is arranged on the first dilute solution pipeline, the generator is heated by a first high-altitude heat source, the condenser is cooled by a second cooling heat source, the evaporator is heated by a low-altitude heat source, and the absorbers are cooled by a first cooling heat source. The system is used in an absorption type water source heat pump system.

Owner:HARBIN INST OF TECH

Turbine outer ring connection assembly, gas turbine engine and connection method

ActiveCN114151150ARealize limitWon't breakEfficient propulsion technologiesStatorsEngineeringTurbine

The invention relates to a turbine outer ring connecting assembly, a gas turbine engine and a connecting method. The turbine outer ring connecting assembly comprises a turbine outer ring extending piece, the turbine outer ring extending piece comprises an upstream installation part and a downstream installation part which extend outwards in the radial direction of a turbine outer ring body and are adjacent in the axial direction, and the upstream installation part comprises a first rib plate and a first axial extending body extending towards the two axial sides from the first rib plate; the downstream mounting part comprises a second rib plate and a second axial extension body extending from the second rib plate to one axial side; and the first rib plate and the second rib plate are respectively provided with a first mounting hole and a second mounting hole. The mounting assembly comprises a middle bearing case, and the middle bearing case comprises a middle bearing case body and a first mounting part extending inwards from the body in the radial direction; the pressing piece comprises a first pressing piece and a second pressing piece; the connecting piece comprises a first connecting piece and a second connecting piece; an elastic piece and a mounting seat.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Preparation process of heating components and heating tubes for electronic cigarettes

ActiveCN110063524BReduce volumeReduce manufacturing costTobacco devicesTobaccoConductive pasteConductive coating

The invention discloses a heating component for electronic cigarettes and a preparation process for heating tubes thereof. The invention mainly relates to the technical field of electronic cigarettes. The invention discloses a heating component for electronic cigarettes, which consists of heating tubes and electrodes. The heating tube is composed of a tubular body and a heating layer. The tubular body has the performance of transferring heat from the outside of the tubular body to its interior, and is used to accommodate electronic cigarette cartridges and carry the heating layer; the heating layer is a conductive paste The conductive coating formed on the outer surface of the tubular body by printing materials will generate heat after being energized; the electrode is a ring-shaped electrode, which matches the outer diameter of the tubular body and is sleeved at both ends of the tubular body and electrically connected to the heating layer. The heating component of the electronic cigarette of the present invention has the advantages of high stability, strong aging resistance, uniform heating, low manufacturing cost, simple structure and small volume, and can significantly reduce the volume of the electronic cigarette.

Owner:RIZHAO ZHONGBANG ELECTRONICS CO LTD

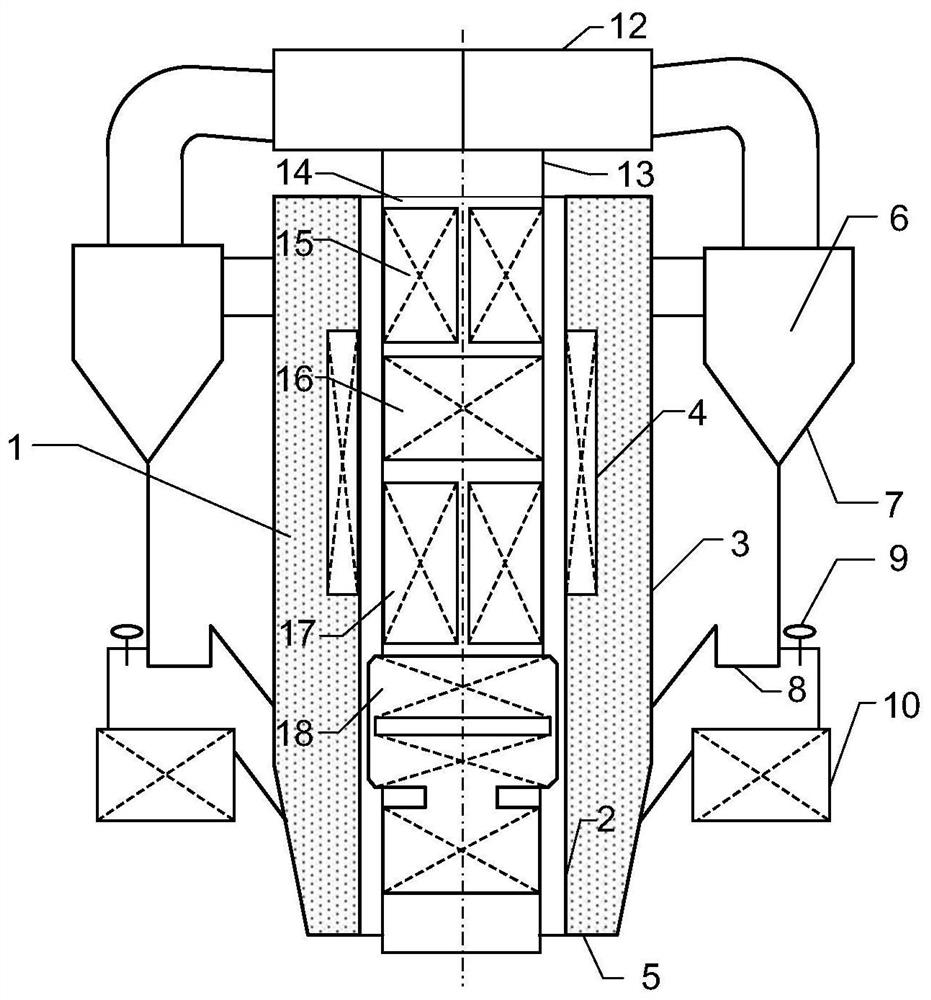

A circular circulating fluidized bed boiler with a built-in tail flue and its driving power generation system

ActiveCN110657424BAchieve compact integrationSmall footprintFluidized bed combustionMachines/enginesAir preheaterGas solid

The invention discloses a tail flue built-in loop-shaped circulating fluidized bed boiler and a driving power generation system thereof. The boiler comprises a loop-shaped hearth, a tail flue arrangedin a boiler loop-shaped inner cavity and separators symmetrically arranged with respect to the center of the hearth, wherein cold walls are uniformly distributed on an inner ring and an outer ring ofthe loop-shaped hearth, and are divided into a first region cold wall and a second region cold wall according to functional characteristics, and a flue gas mixing chamber, a low-temperature reheater,a primary air preheater, a flue gas cooler and a secondary air preheater are sequentially arranged in the tail flue in the flue gas flow direction. The boiler has the beneficial effects that the structure of the existing boiler is compact and integrated, the boiler island occupied space is reduced about one third, meanwhile, the separators which are symmetrically arranged in the center and the flue gas mixing chamber enable flue gas to be symmetrically collected, so that the uniformity of the load of the separators are effectively increased, according to the gas-solid flow state and the heatdistribution in the hearth, the side wall area and the four-corner area in the hearth the width and the deep direction are divided into heating areas with different functions, energy loss is reduced,and flexible adjustment is realized.

Owner:SOUTHEAST UNIV

Capillary tube control method and device of air conditioner, air conditioner and storage medium

ActiveCN111878963ARaise the upper temperature limitGuaranteed reliabilityMechanical apparatusSpace heating and ventilation safety systemsCapillary TubingEngineering

The invention provides a capillary tube control method and device of an air conditioner, the air conditioner and a storage medium, and relates to the technical field of air conditioners. Capillary tubes comprise the first capillary tube, the second capillary tube and the third capillary tube which are arranged in parallel. The control method comprises the steps that when the air conditioner operates in a refrigeration mode, the first capillary tube is started; the outdoor temperature, the exhaust temperature and the outer coil pipe pressure are obtained; when the outdoor temperature, the exhaust temperature and the outer coil pipe pressure meet a first preset condition, the first capillary tube is closed, and the second capillary tube is opened; and when the outdoor temperature, the exhaust temperature and the outer coil pipe pressure meet a second preset condition, the first capillary tube is closed, and the third capillary tube is opened. Thus, the three capillary tubes with different lengths are installed in parallel, the load condition of an outdoor unit is judged by obtaining the outdoor temperature, the exhaust temperature and the outer coil pipe pressure in different scenes,the capillary tubes with different lengths are selected according to the different load conditions, and therefore adjustment of the refrigerating capacity is achieved.

Owner:NINGBO AUX ELECTRIC +1

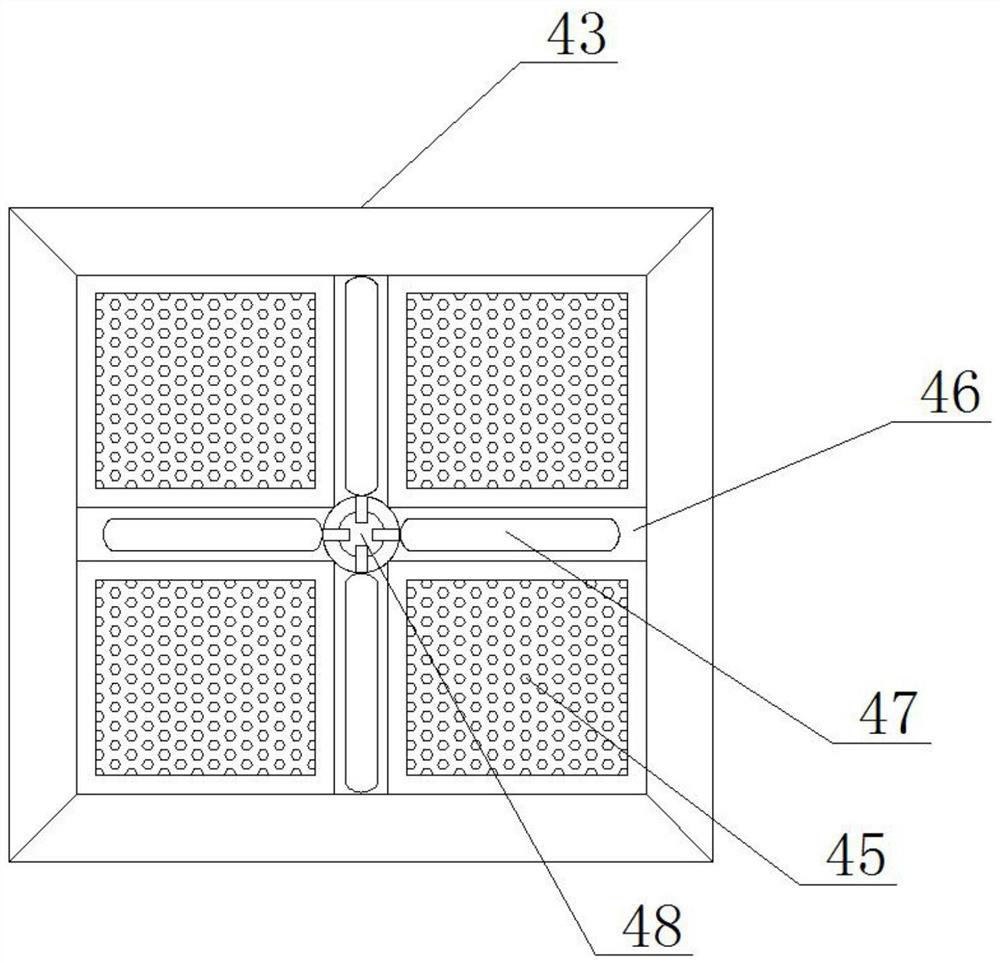

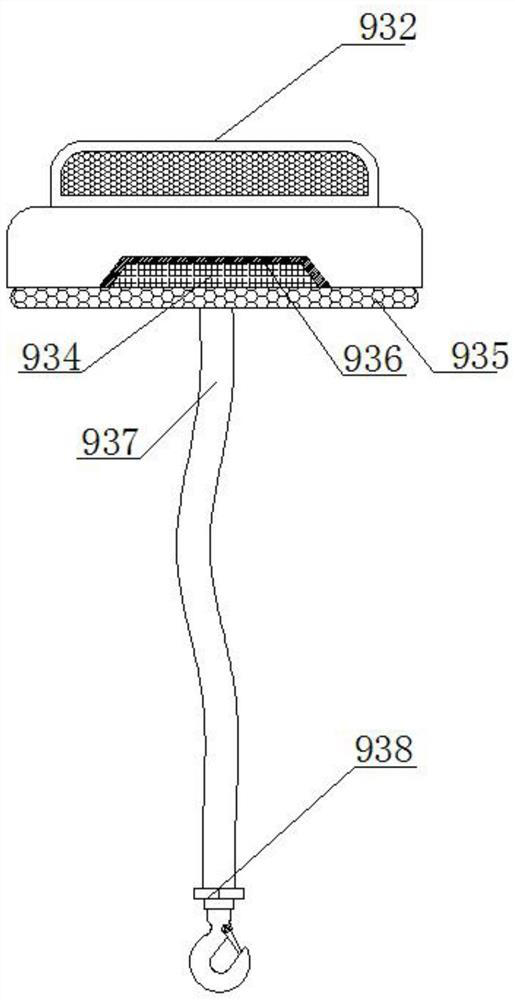

Infant food constant-temperature sterilizer

PendingCN112868975AImprove ventilationImprove sterilization efficiencyFood preservationEqualizing valvesUltraviolet lightsEngineering

An infant food constant-temperature sterilizer comprises a cabinet body, transverse plates are fixedly installed at the upper end in the cabinet body at equal intervals, ventilation holes are formed in the surfaces of the transverse plates at equal intervals, storage assemblies are fixedly installed at the tops of the transverse plates, and ultraviolet lamps are fixedly installed at the bottoms of the two transverse plates at the top and the upper end in the cabinet body. A condensation screen is fixedly installed on the outer side of the ultraviolet lamp, an air heater is fixedly installed at the upper end of the left side of the cabinet body, and an ozone generator is fixedly installed in the middle of the left side of the cabinet body. The interior of the cabinet body can be well kept warm by arranging the heat preservation plate, so that the sterilization effect of the device is effectively improved, meanwhile, energy consumption is reduced, the ventilation degree in the cabinet body can be improved by arranging the ventilation holes, and the sterilization efficiency of the ozone generator is improved. And the bridge-type handrail is arranged, so that the cabinet door body can be opened more conveniently, and food can be taken and placed more conveniently.

Owner:余莲

Capillary control method and device for air conditioner, air conditioner and storage medium

ActiveCN111878963BRaise the upper temperature limitGuaranteed reliabilityMechanical apparatusSpace heating and ventilation safety systemsPlate pressureCapillary Tubing

The invention provides a capillary control method and device of an air conditioner, an air conditioner and a storage medium, and relates to the technical field of air conditioners. The capillary tube includes a first capillary tube, a second capillary tube and a third capillary tube arranged in parallel, and its control method includes: when the air conditioner operates in cooling mode, open the first capillary tube; obtain the outdoor temperature, exhaust temperature and external disk pressure; when the outdoor temperature , exhaust temperature and external disk pressure meet the first preset condition, close the first capillary, and open the second capillary; when the outdoor temperature, exhaust temperature and external disk pressure meet the second preset condition, close the first capillary, and Turn on the third capillary. In this way, three capillary tubes of different lengths are installed in parallel, and the load of the external unit is judged by obtaining the outdoor temperature, exhaust temperature, and external disk pressure in different scenarios, and capillary tubes of different lengths are selected according to different load conditions to achieve cooling capacity. adjustment.

Owner:NINGBO AUX ELECTRIC +1

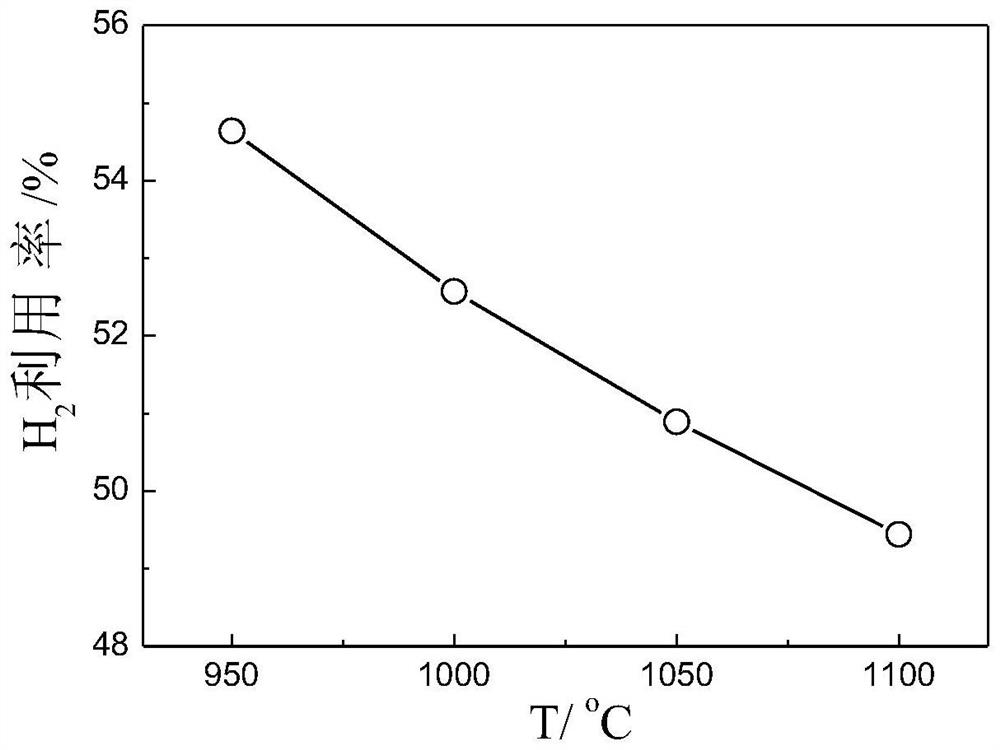

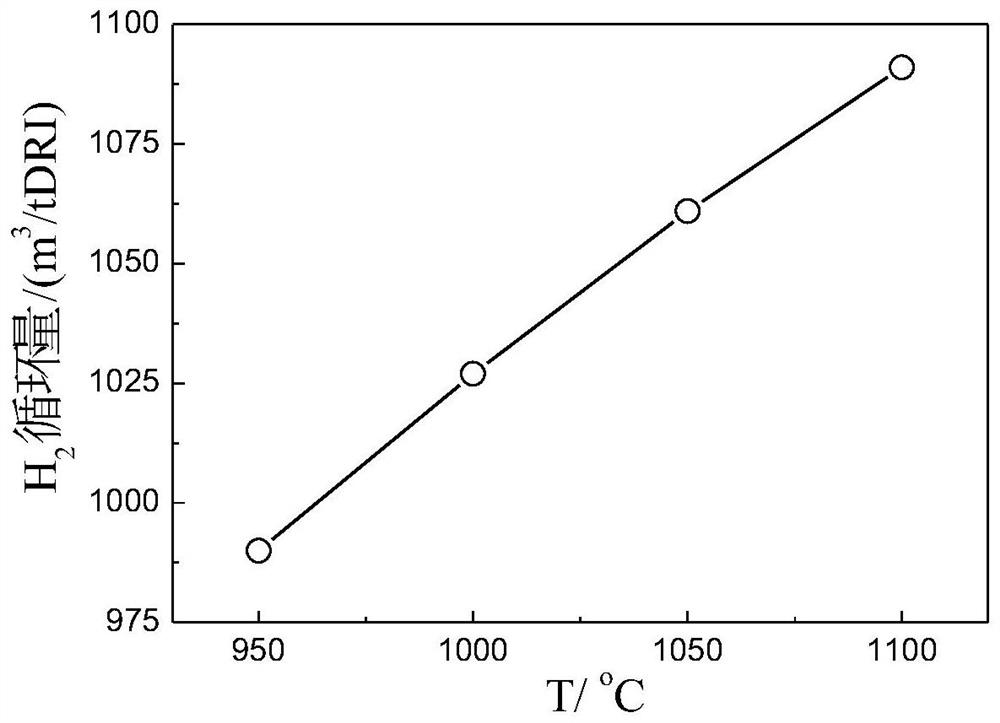

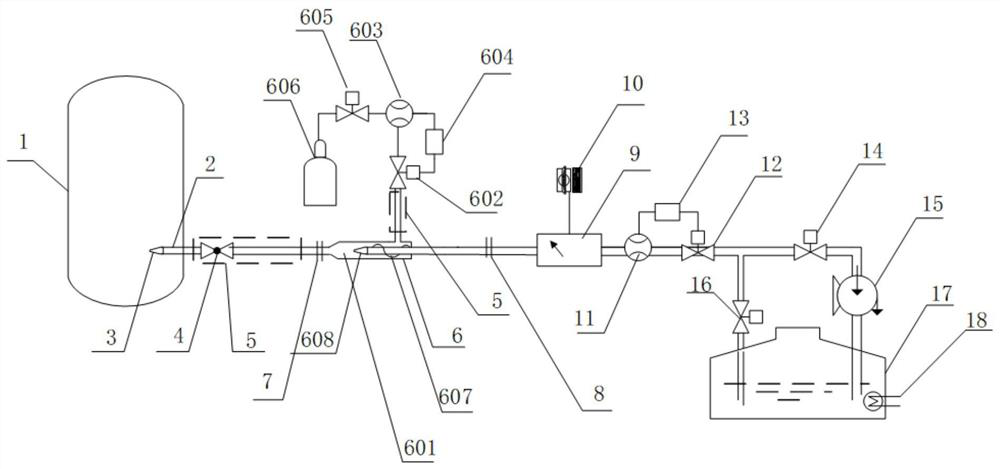

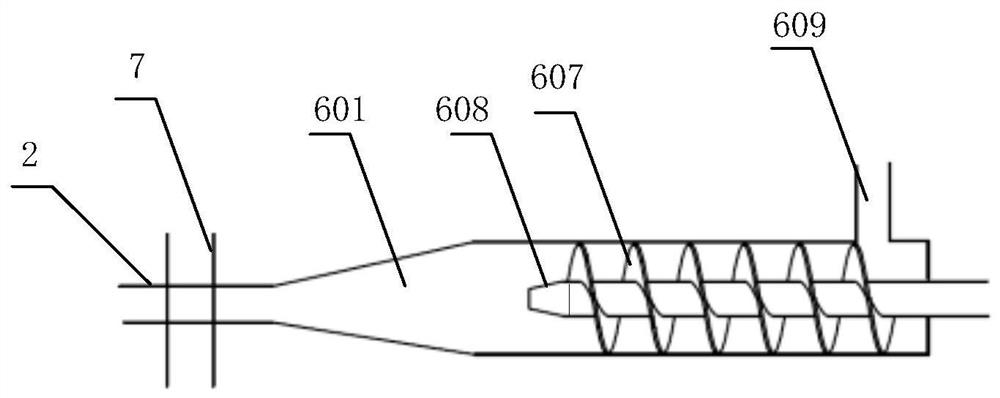

Heating-pure hydrogen reduction cooling system and method

The invention relates to a heating-pure hydrogen reduction cooling system and method, belongs to the technical field of shaft furnace reduction in the metallurgical process, and solves the problem of low hydrogen utilization rate in the prior art. The heating-pure hydrogen reduction cooling system comprises a heating section, an isobaric section and a reduction cooling section which are sequentially communicated from top to bottom; the heating section is provided with an oxidized pellet inlet, a hot flue gas inlet and a flue gas outlet, oxidized pellets from the oxidized pellet inlet are in contact with hot flue gas from the hot flue gas inlet in the heating section, the flue gas after contact is discharged from the flue gas outlet, and the oxidized pellets after contact enter the isobaric section; the reduction cooling section is provided with a hydrogen inlet and a gas outlet, oxidized pellets from the isobaric section and hydrogen from the hydrogen inlet are reduced and cooled in the reduction cooling section, and gas generated in the reduction and cooling process is discharged from the gas outlet. The hydrogen utilization rate is improved.

Owner:CENT IRON & STEEL RES INST +1

A cold double-effect lithium bromide absorption refrigeration cycle system

ActiveCN104180561BRaise the upper temperature limitRaise the outlet temperatureClimate change adaptationEnergy efficient heating/coolingWater source heat pumpWater vapor

The invention relates to a cool double-effect lithium bromide absorption type refrigeration cycle system. A generator is communicated with a condenser, the condenser is communicated with an evaporator through a first refrigerant water passage, one end of a second refrigerant water passage is communicated with the condenser, the other end of the second refrigerant water passage passes through a first absorber to be communicated with a second absorber, the first absorber is communicated with the evaporator through a second refrigerant water vapor pipeline, one end of a first dilute solution pipeline and one end of a second dilute solution pipeline are communicated with the second absorber, the other ends of the first dilute solution pipeline and the second dilute solution pipeline are communicated with the generator, one end of a second concentrated solution pipeline is communicated with the first absorber, the other end of the second concentrated solution pipeline is communicated with a first concentrated solution pipeline, one end of the second dilute solution pipeline is communicated with the first absorber, the other end of the second dilute solution pipeline is communicated with the first dilute solution pipeline, a first solution pump is arranged on the first dilute solution pipeline, the generator is heated by a first high-altitude heat source, the condenser is cooled by a second cooling heat source, the evaporator is heated by a low-altitude heat source, and the absorbers are cooled by a first cooling heat source. The system is used in an absorption type water source heat pump system.

Owner:HARBIN INST OF TECH

Temperature calibration device for waterproof infrared thermometer

InactiveCN113188665AAvoid interferenceShield interferenceRadiation pyrometryInfrared thermometryEngineering

The invention discloses a temperature calibration device for a waterproof infrared thermometer, which relates to the technical field of thermometer production and inspection, and comprises a base, a comparison box body and an adjusting mechanism, wherein the adjusting mechanism is fixedly connected to one side of the base, and a locking assembly is arranged on the adjusting mechanism in a matched mode. The comparison box body is fixed on the base, the comparison box body is composed of a plurality of temperature bins which are divided by partition plates which are uniformly distributed in parallel, and a cover plate is rotationally hinged to the temperature bins through the comparison box body. Compared with the prior art, the device has the beneficial effects that interference among the temperature bins is effectively prevented by the comparison box body with interlayers on the partition plates, so that the measurement and calibration precision is ensured, when the device is used, the cover plate is closed, the corresponding temperature generation device is started, and the infrared thermometer located on the locking assembly moves, can measure temperature data on different cover plates, the large-area cover plate effectively shields interference of a temperature generating device with the inner wall serving as a radiation source, and calibration precision is further guaranteed.

Owner:SHENZHEN CHEERMAN TECH C

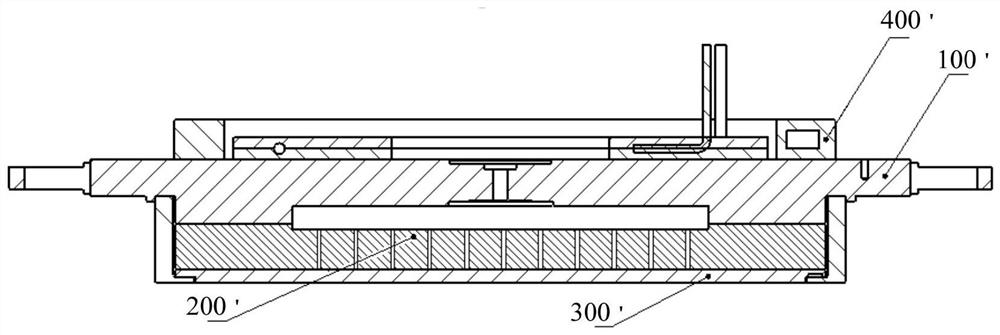

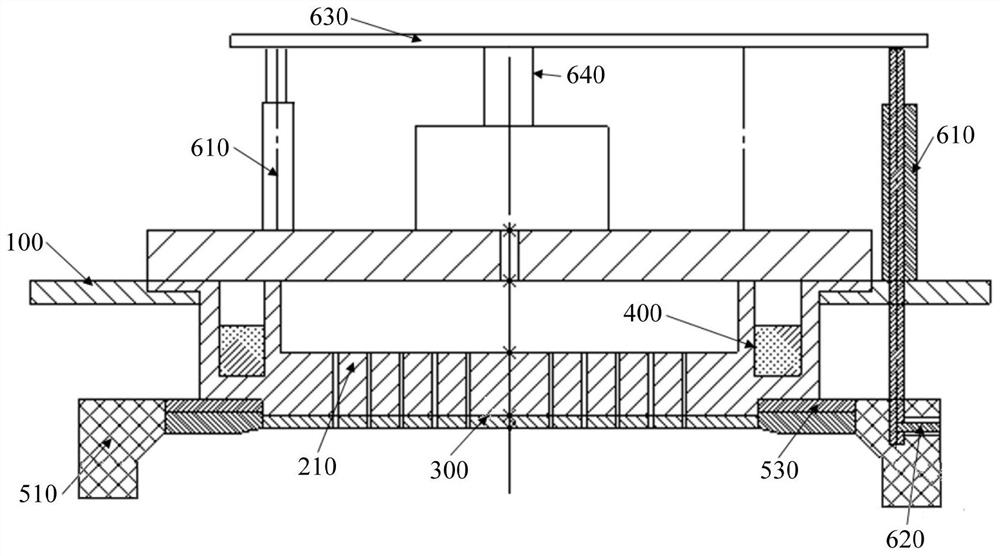

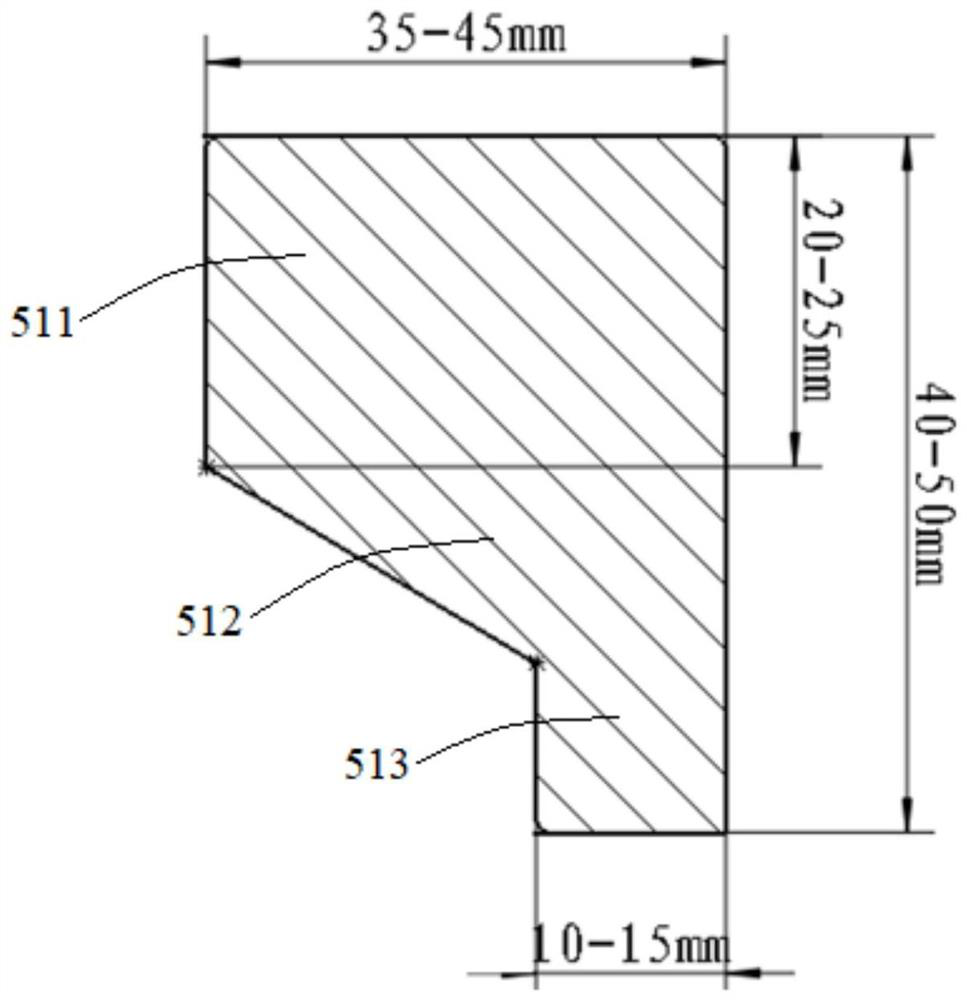

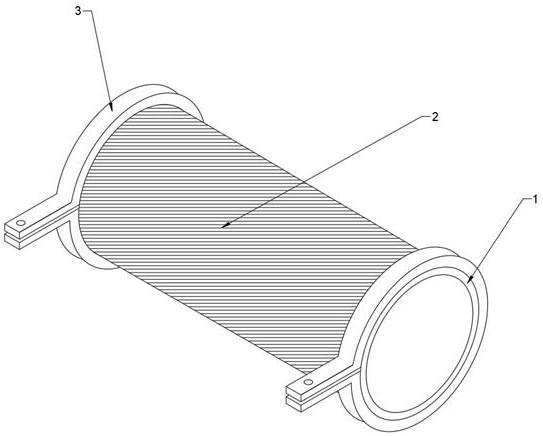

A piezo-driven droplet ejection device for additive manufacturing of high melting point metals

ActiveCN109434113BPrecise amplitude controlAdjustable distanceAdditive manufacturing apparatusThermal insulationEngineering

Owner:BEIJING UNIV OF TECH

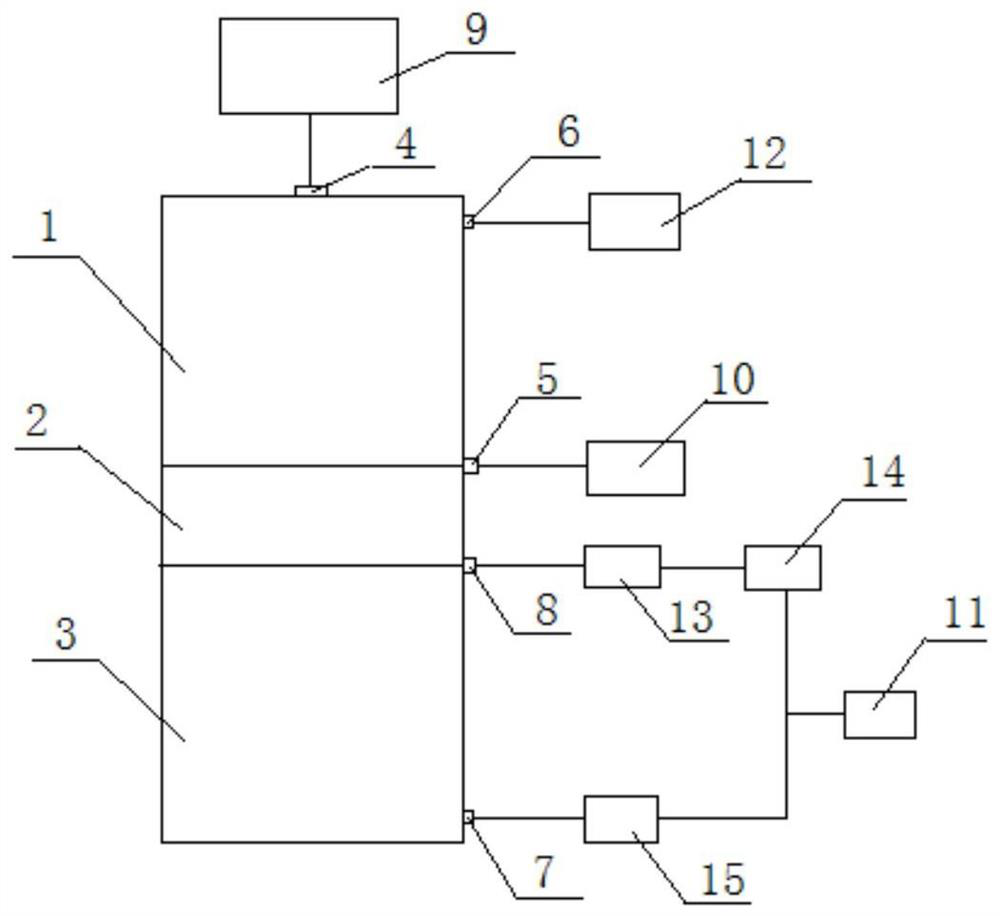

High temperature thermostatic bath of high capacity and high precision

InactiveCN102350385BRaise the upper temperature limitInfluence of temperature fluctuationWater/sand/air bathsTemperature controlRs 232 interface

The invention discloses a high temperature thermostatic bath of high capacity and high precision. The thermostatic bath comprises three parts: a thermostatic bath main body, a temperature control system and a temperature measuring system. The thermostatic bath main body mainly comprises an insulation material, 6 heating plates and a thermostatic medium. The temperature measuring system consists of a first precision platinum resistance thermometer, a temperature measuring device, a computer and an RS232 interface. The temperature control system includes a second precision platinum resistance thermometer and a temperature control unit. The outside wall of the thermostatic bath main body is provided with the insulation material, and the inside of the thermostatic bath main body is provided with the thermostatic medium, where the first precision platinum resistance thermometer and the second precision platinum resistance thermometer are both inserted. The first precision platinum resistance thermometer is connected to the temperature measuring device, which is in connection with the computer through the RS 232 interface. The second precision platinum resistance thermometer is connected to the temperature control unit that is in connection with the heating plates simultaneously. The high temperature thermostatic bath of the invention is completely ahead of high temperature thermostatic baths developed at home and abroad, and solves a major problem in high temperature fluid thermophysical property experiments, as well as overcomes the temperature scope restriction to the thermostatic medium in previous thermostatic baths.

Owner:XI AN JIAOTONG UNIV

Diesel engine catalyst

InactiveCN101984241ARaise the upper temperature limitImprove combustion sufficiencyInternal combustion piston enginesNon-fuel substance addition to fuelCombustionNitrogen

The invention provides a diesel engine catalyst. The common point of the invention with other catalysts is to generate power through the combustion of diesel in oxygen. The invention is characterized in that a gas cavity is additionally arranged behind the turbocharging; an oxygen filter membrane and a nitrogen discharge port are arranged in the gas cavity; the oxygen filter membrane can increase a certain cache space; during the induction stroke of the diesel engine, high pressure oxygen in the cache space is discharged into the device in the cylinder, thereby raising the temperature upper limit by increasing the oxygen concentration and adequately ensuring pressure, temperature and oxygen; and thus, the invention enhances the completeness of combustion and reduces the smoke intensity and hydrocarbons.

Owner:陈晓英

Turbine outer ring connection assembly, gas turbine engine and connection method

PendingCN113882910AFirmly connectedSufficient installation rigidityStatorsMachines/enginesEngineeringTurbine

The invention relates to a turbine outer ring connection assembly, a gas turbine engine and a connection method. The turbine outer ring connection assembly comprises a turbine outer ring extending piece and a mounting assembly. The turbine outer ring extending piece comprises a first rib plate and a second rib plate which extend outwards in the radial direction of a turbine outer ring and are adjacent in the axial direction, and the first rib plate and the second rib plate are provided with a first mounting hole and a second mounting hole correspondingly; the mounting assembly comprises a middle-layer casing, a cover plate and a connecting piece, the middle-layer casing comprises a middle-layer casing body, a third rib plate and a fourth rib plate, the third rib plate and the fourth rib plate extend inwards from the body in the radial direction and are adjacent in the axial direction, and the third rib plate and the fourth rib plate are provided with a third mounting hole and a fourth mounting hole respectively; the cover plate comprises a first cover plate and a second cover plate which are respectively provided with a fifth mounting hole and a sixth mounting hole; and the connecting piece comprises a first connecting piece and a second connecting piece.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Online Detection System for Harsh Environment Aerosols

ActiveCN109855924BRealize long-term online monitoringRaise the upper temperature limitWithdrawing sample devicesParticle size analysisEngineeringAtmospheric sciences

An on-line detection system for aerosols in harsh environments, comprising: sequentially connected aerosol sampling mechanisms, at least one level of cooling and dilution devices, on-line measuring devices, post-installed flow measurement control devices, and exhaust gas collection devices, wherein: the aerosol sampling mechanism is set The gas to be tested is extracted from the pressure vessel of the gas to be tested and sent to the cooling and dilution device. The cooling and dilution device mixes the gas to be tested with the dilution gas with a lower temperature, lower pressure and no particles in the dilution chamber to lower the temperature and pressure. , the online measurement device extracts the gas to be tested through the sampling probe inside the dilution chamber and detects it online, and the post-installed flow measurement control device controls the extraction flow and the measured gas enters the exhaust gas collection device through the ventilation pipe to complete the measurement. The invention has low maintenance cost and can realize long-term on-line measurement.

Owner:SHANGHAI JIAOTONG UNIV +1

Silicone rubber film-coated high-temperature slow-swelling water-absorbing particles and preparation method thereof

ActiveCN111363361BRaise the upper temperature limitNo adverse effect by its natureDrilling compositionPolymer sciencePtru catalyst

The invention discloses a silicone rubber-coated high-temperature slow-swelling water-absorbing particle and a preparation method thereof. The slow-swelling water-absorbing particle is composed of a coating layer composed of conventional temperature-resistant and salt-resistant substrate water-absorbing particles and the coating agent of the present invention. The film agent is composed of silicone rubber base rubber, vulcanizing agent, reinforcing agent and catalyst, wherein the silicone rubber base rubber is polydimethylsiloxane terminated by hydroxyl group and polydimethylsiloxane terminated by alkoxy group. At least one, the vulcanizing agent is at least one of orthosilicate, methyltriacetoxysilane, etc., the reinforcing agent is at least one of nano-calcium carbonate, fumed white carbon black, etc., and the catalyst is dilaurel At least one of dibutyltin diacetate, dibutyltin diacetate, etc., which significantly improves the upper temperature limit of the existing slow-swelling water-absorbing particle technology, and can slow-swell at a temperature as high as 130°C. At the same time, the coating method is environmentally friendly and does not use Organic solvents do not require high-temperature heating, and have no adverse effects on the environment and the properties of the water-absorbing particles themselves.

Owner:SOUTHWEST PETROLEUM UNIV

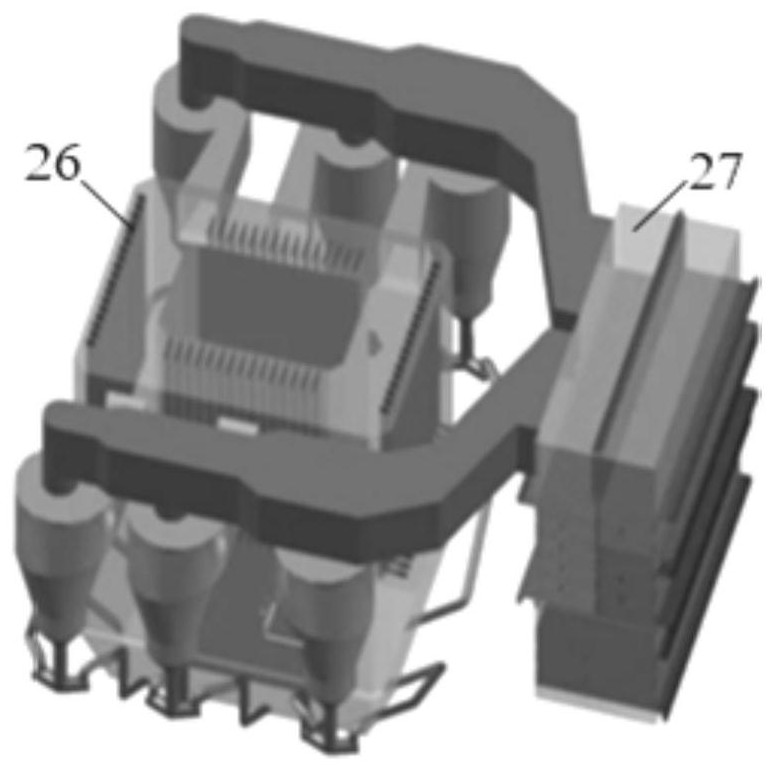

Injection mould for machining highly-glossy products

The invention discloses an injection mould for machining highly-glossy products, which is characterized in that the injection mould is provided with a heating oil path and a cooling water path in a fixed mould, wherein the heating oil path is arranged at one side close to the highly-glossy surfaces of the moulded products in a mould cavity, and located between a product cavity and the cooling water path. According to the injection mould disclosed by the invention, plastic is heated via the heating oil path, thus overcoming the defect of the upper temperature limit of common water paths, so that the products can obtain good glossy and smooth effects.

Owner:SHENGYANG PRECISION MOLD KUSN

Special gas pipeline assembly and powder coating equipment

PendingCN113418140ARaise the upper temperature limitHigh temperature control accuracyVacuum evaporation coatingSputtering coatingTemperature controlEngineering

The invention discloses a special gas pipeline assembly. The special gas pipeline assembly comprises a metal pipeline, a power source and multiple conductive fixing parts, wherein the multiple conductive fixing parts are sequentially fixed to the metal pipeline in the extending direction of the metal pipeline, the power source is connected with the conductive fixing parts through wires, the conductive fixing parts are arranged at intervals, and the portions, between the adjacent conductive fixing parts, of the metal pipeline and the power supply form loops, so that current is loaded on the metal pipeline. The current is directly loaded on the metal pipeline, the metal pipeline serves as a heating element for spontaneous heating, a traditional mode that a pipeline Is sleeved with a heating sleeve is replaced, the highest temperature resistance is the temperature resistance of the metal pipeline, thus the temperature upper limit is improved, the structure is simpler, the pipeline temperature can be directly measured, thus the temperature control precision is improved, the whole pipeline serves as a heating unit, and effects of elbows do not need to be considered, so that the cost is effectively reduced. The invention further discloses powder coating equipment comprising the assembly.

Owner:JIANGSU MICROVIA NANO EQUIP TECH CO LTD

A condensing and boosting lithium bromide jet absorption refrigeration cycle system

ActiveCN104154675BRaise the condensation temperatureIncrease pressureMechanical apparatusEnergy efficient heating/coolingWater source heat pumpLithium bromide

The invention relates to a condensing and boosting lithium bromide jet absorption refrigeration cycle system, which relates to an absorption refrigeration cycle system. The condenser communicates with the evaporator through the first refrigerant water passage, the evaporator communicates with the absorber through the second refrigerant water vapor pipeline, and both ends of the first dilute solution pipeline and the first concentrated solution pipeline communicate with the absorber , the other ends are connected with the generator, the solution heat exchanger is arranged on the first dilute solution pipeline and the first concentrated solution pipeline, one end of the first connecting pipe is connected with the boiler, the other end is connected with the injector, the first cooling One end of the agent water vapor pipeline communicates with the generator and the other end communicates with the ejector; one end of the third connecting pipe communicates with the condenser and the other end communicates with the ejector; one end of the second connecting pipe communicates with the boiler and the other end communicates with the It communicates with the liquid storage device, the liquid storage device is arranged under the condenser, and the refrigerant water pump is arranged on the second connecting pipe. The invention is used in an absorption water source heat pump system.

Owner:HARBIN INST OF TECH

Device and method for measuring flame aerosol flow rate

ActiveCN105092885BReduce radiationReduce lossesFluid speed measurementMeasurement deviceSolenoid valve

The invention discloses a flame aerosol flow rate measuring device, which is characterized in that it includes a basic support seat, an XYZ three-axis moving platform, a bidirectional cylinder, a self-locking tweezer connector, a self-locking tweezer, a probe sheet, an electromagnetic valve and a time relay , the XYZ three-axis moving platform is installed on the basic support base; the two-way cylinder is installed on the XYZ three-axis moving platform; the self-locking tweezers are installed on the two-way cylinder through the self-locking tweezers connector; the probe sheet is round as a whole shape, which is installed on the self-locking tweezers, and is used to extend into the flame aerosol for sampling; the solenoid valve and time relay are used to jointly control the movement of the two-way cylinder, and then control the stay of the probe sheet in the flame aerosol time. The invention adopts the thermophoresis sampling probe, which can greatly reduce the radiation and heat conduction loss of the probe, and keep the convection heat transfer dominant in the heat transfer between the flame and the probe, so as to solve the flow velocity of the flame aerosol.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com