Preparation process of heating components and heating tubes for electronic cigarettes

A technology of heating components and preparation process, which is applied in the field of electronic cigarettes, can solve the problems of complex heating devices, short service life of electronic cigarettes, uneven heating, etc., and achieve the effect of simple structure, high temperature upper limit, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

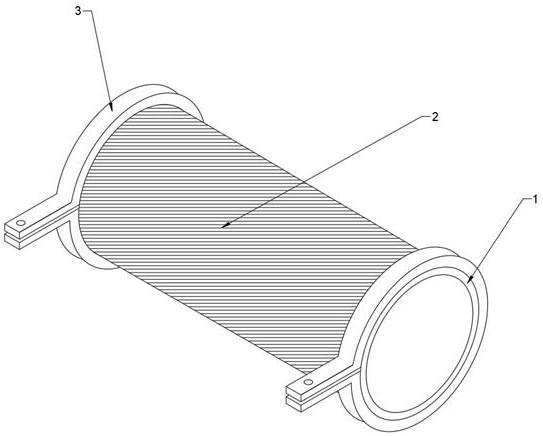

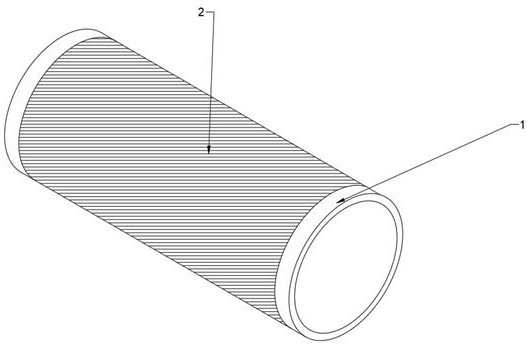

[0048] The heating component for electronic cigarettes using solid cartridges is composed of a heating tube and an electrode ring 3, wherein the heating tube is composed of a quartz glass tube 1 and a heating layer 2 printed with conductive paste on the outer surface of the quartz glass tube, and the quartz glass The tube 1 can transfer the heat generated by the heating layer to its interior to heat the electronic cigarette bomb placed inside the quartz glass tube 1; the inner diameter of the electrode ring 3 matches the outer diameter of the quartz glass tube 1 and is set on the quartz glass Both ends of the tube 1 are electrically connected to the heating layer 2 . The above is a description of the specific structure of the heating element of the present invention. The present invention adopts external heating and internal heating during use. This heating method can make the electronic cigarette bomb heated evenly, the smoke taste is pure, and the service life of the cartridg...

Embodiment 2

[0057] The structure of its heating element is as in the first embodiment.

[0058] The following is aimed at the problem of uneven layout of the sintered coating on the quartz glass tube when the electronic paste is printed in this industry. The present invention proposes a screen printing process for printing the conductive paste on the tubular body. The process includes the following steps :

[0059] Step 1. Selection of stencil: This process selects a polyester mesh with a mesh number of 270 mesh, an aluminum mesh frame, a mesh stretching angle of 20 degrees, a mesh tension of 25N, a film thickness of 20μm, and a mesh with a graphic-to-text frame ratio of 25. Plate, put the screen into the screen printing machine;

[0060] Step 2. Fix the substrate, choose a ceramic tube as the substrate, and adjust the distance between the substrate and the screen to control the distance at 1.7mm;

[0061] Step 3. Select a flat scraper with a Shore hardness of 70, and adjust the angle o...

Embodiment 3

[0065] Embodiment 3: The structure of the heating element is as in Embodiment 1.

[0066] The following is aimed at the problem of uneven layout of the sintered coating on the quartz glass tube when the electronic paste is printed in this industry. The present invention proposes a screen printing process for printing the conductive paste on the tubular body. The process includes the following steps :

[0067] Step 1. Selection of stencil: This process uses stainless steel wire mesh with a mesh number of 380mesh, a steel mesh frame, a mesh stretching angle of 30 degrees, a mesh tension of 30N, a film thickness of 50μm, and a graphic-text frame ratio of 30%. Stencil, put the stencil into the screen printing machine;

[0068] Step 2. Fix the substrate, choose a quartz tube as the substrate, and adjust the distance between the substrate and the screen gap to control the distance at 1.5 mm;

[0069] Step 3. Select a pointed scraper with a Shore hardness of 80, and adjust the angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com