Wide window denitration non-vanadium rare earth based catalyst and preparation method thereof

A rare earth-based catalyst technology, applied in the field of denitration catalysts, can solve the problems of catalyst performance decline, catalytic performance decline, etc., and achieve the effects of improving denitration performance, broadening the upper temperature limit, and improving catalyst effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

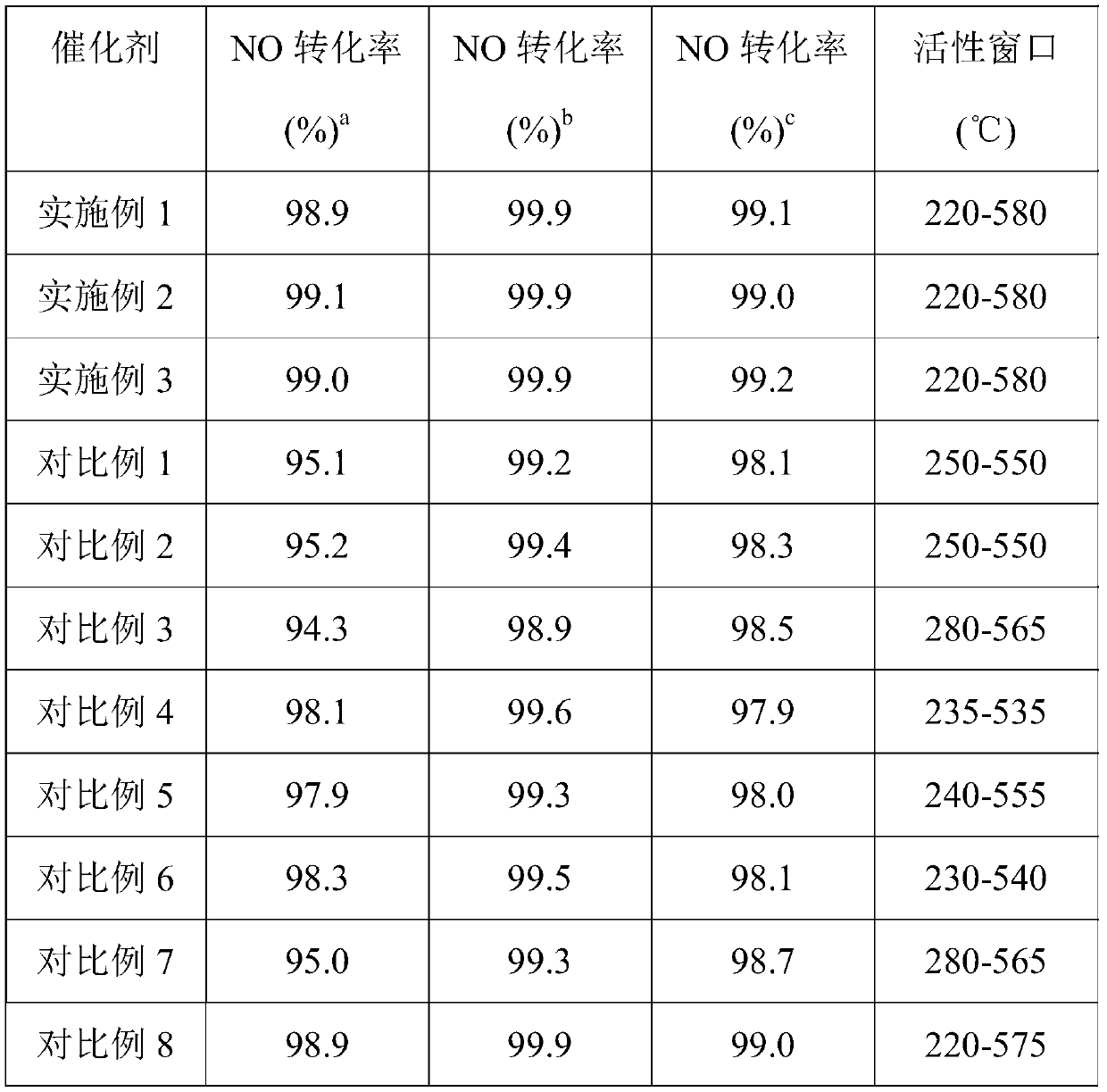

Examples

Embodiment 1

[0022] Inject 100 parts by mass of deionized water into the reaction kettle, start stirring, and control the temperature. After the water temperature reaches 65°C, add 0.3g of ammonia water and stir evenly; at this temperature, add 0.8g of citric acid, 10g Stir chitosan evenly; then add 3g ammonium metatungstate, 9g cerium oxalate, 3g lanthanum oxalate, 0.3g copper chloride, and stir evenly; then add 0.3g sodium dodecylsulfonate, 60g titanium dioxide, and stir evenly; Then add 8g of clay and stir evenly; then add 30g of titanium dioxide and stir evenly to obtain a well-stirred slurry;

[0023] Natural aging in the reactor for 3 hours;

[0024] The aged slurry is continuously heated and stirred in the evaporation pool to evaporate the liquid until the slurry is agglomerated and the surface is cracked to obtain dry agglomerated slurry;

[0025] Put the above-mentioned agglomerated slurry into a muffle furnace, raise the temperature to 120°C at room temperature, and keep it for ...

Embodiment 2

[0027] Inject 100 parts by mass of deionized water into the reaction kettle, start stirring, and control the temperature. After the water temperature reaches 65°C, add 0.3g of ammonia water and stir evenly; at this temperature, add 0.8g of citric acid, 20g Stir chitosan evenly; then add 3g ammonium metatungstate, 9g cerium oxalate, 2g lanthanum oxalate, 0.1g copper chloride, and stir evenly; then add 0.3g sodium dodecylsulfonate, 60g titanium dioxide, and stir evenly; Then add 8g of clay and stir evenly; then add 30g of titanium dioxide and stir evenly to obtain a well-stirred slurry;

[0028] Other steps are identical with embodiment 1.

Embodiment 3

[0030] Inject 100 parts by mass of deionized water into the reaction kettle, start stirring, and control the temperature. After the water temperature reaches 65°C, add 0.3g of ammonia water and stir evenly; at this temperature, add 0.8g of citric acid, 10g Stir chitosan evenly; then add 3g ammonium metatungstate, 9g cerium oxalate, 4g lanthanum oxalate, 0.5g copper chloride, and stir evenly; then add 0.3g sodium dodecylsulfonate, 60g titanium dioxide, and stir evenly; Then add 8g of clay and stir evenly; then add 30g of titanium dioxide and stir evenly to obtain a well-stirred slurry;

[0031] Other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com