Low-cost trapped vortex combustor

A combustion chamber, low-cost technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as energy waste, and achieve the effects of reducing costs, improving combustion sufficiency, and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

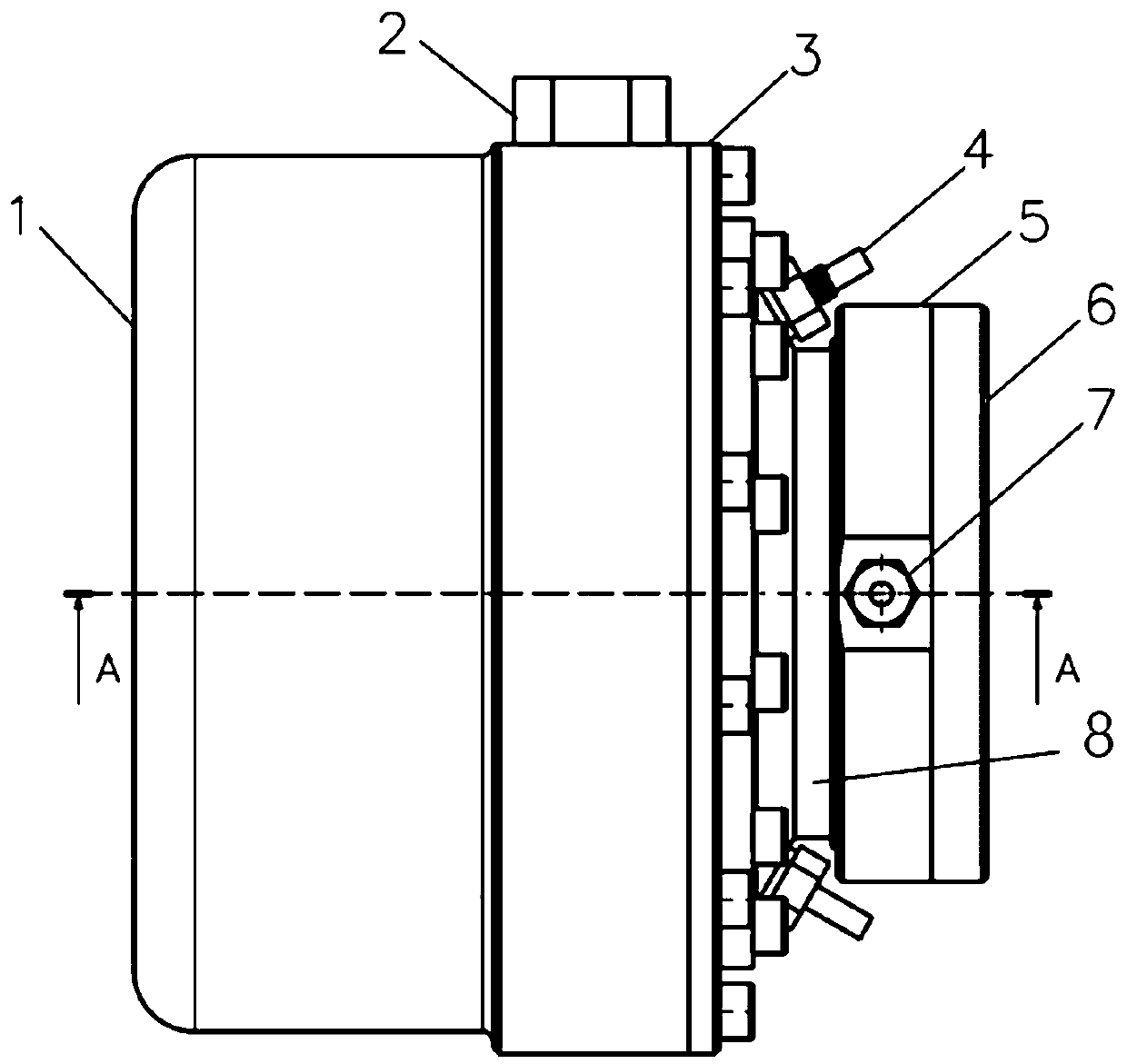

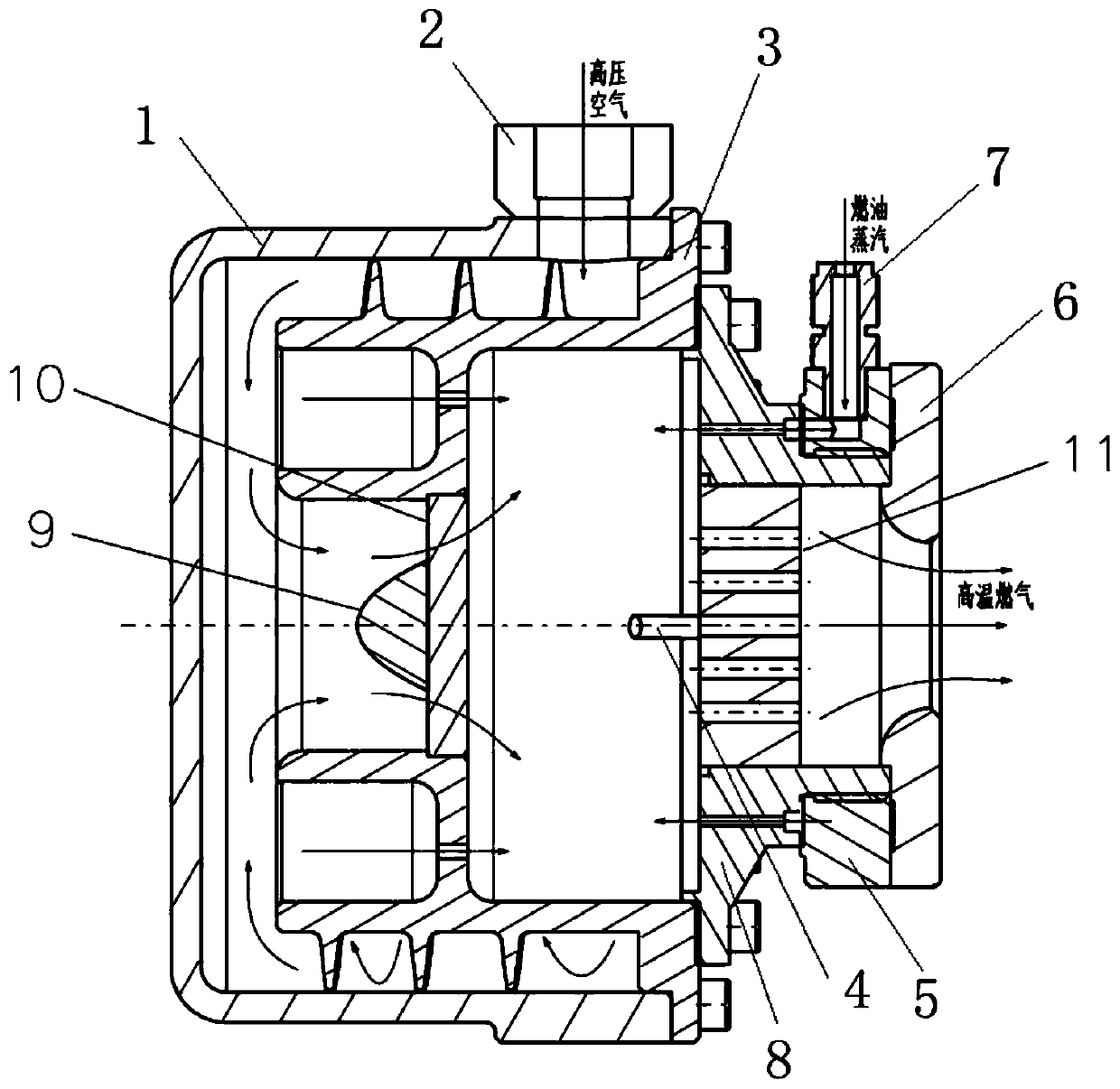

[0032] This embodiment provides a low-cost trapped vortex combustor, see attached figure 1 and 2 , including: air intake chamber 1, air intake valve 2, front section of combustion chamber 3, glow plug 4, fuel vapor intake chamber 5, exhaust flange 6, fuel vapor intake valve 7, rear section of combustion chamber 8, Rectification block 9, rectification block bracket 10 and honeycomb block 11;

[0033] The air intake cavity 1 is a hollow shell with an open end, and an air intake port is processed on the circumferential surface of the opening end of the air intake cavity 1;

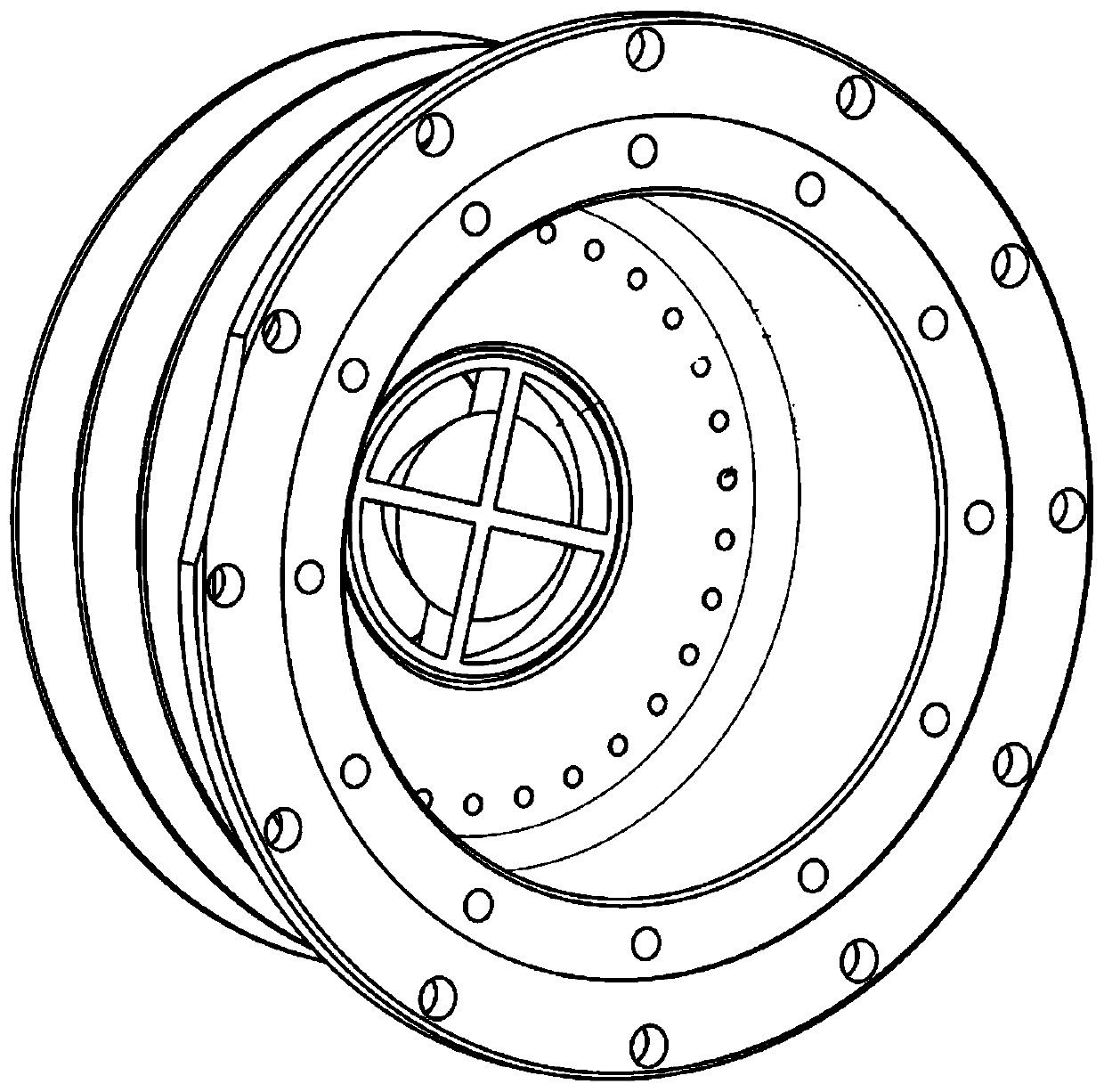

[0034] See attached image 3 , one end of the front section 3 of the combustion chamber is open, the other end is processed with a central through hole and an annular groove coaxial with the central through hole, and the groove bottom of the annular groove is processed with a first axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com