Garbage incinerator and whole-set garbage treatment system adopting same

A waste incinerator and a complete set of treatment technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problem of low efficiency of waste gas purification and treatment, and achieve the effect of protecting the environment clean, reducing harmful substances, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

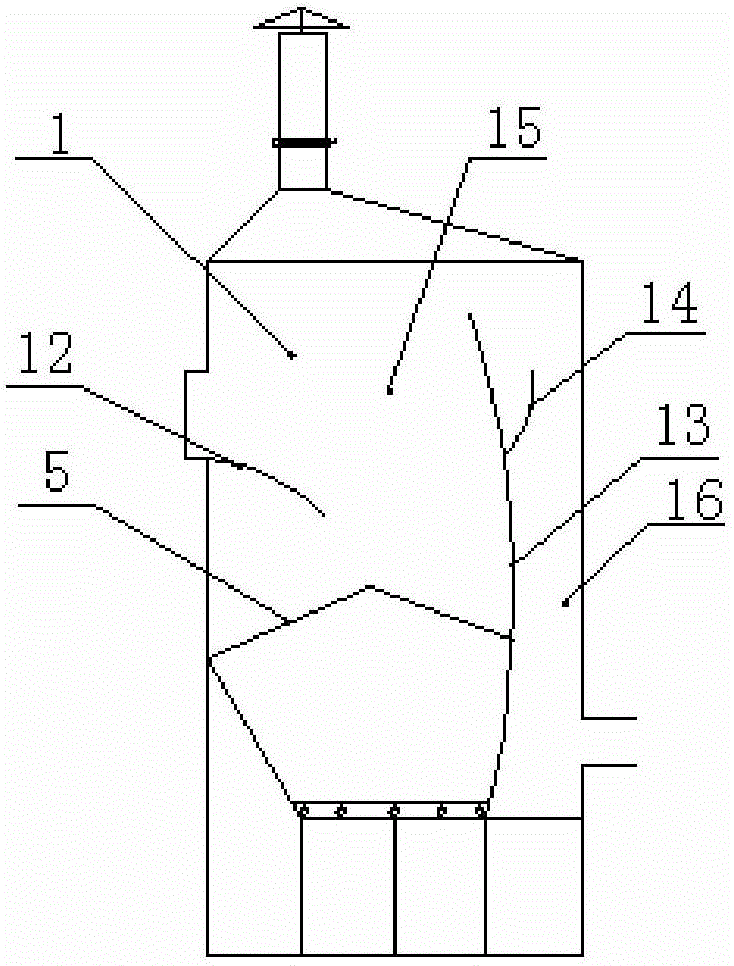

[0028] see figure 1 , the garbage incinerator in the illustration is a preferred embodiment of the present invention, and the partition 13 in the garbage incinerator divides the body of furnace into two areas, a garbage burning zone 15 and a flue gas decomposition zone 16, wherein the garbage burning zone 15 It is mainly used for putting in garbage and breaking it up for combustion. In this area, there is a feed inlet of the garbage incinerator, and a garbage deflector 12 is provided below the feed inlet. The garbage put into the furnace door enters through the garbage deflector 12 In the garbage incinerator, the purpose of guiding the garbage to fall to the center of the furnace arch is played. The garbage deflector 12 is made of refractory steel with a thickness of 20mm. The bottom of the garbage deflector 12 is provided with a furnace arch 5, and the furnace arch disperses the garbage introduced by the garbage deflector 12 to prevent the garbage from agglomerating and being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com