Pellet roasting device

A roasting device and roasting technology, which are applied in the field of pellet production, can solve the problems of large heat dissipation of the edge effect cup, affect the pellet roasting test, and uneven combustion process, so as to improve combustion adequacy, reduce edge effect, and solve the problem of The effect of uneven flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

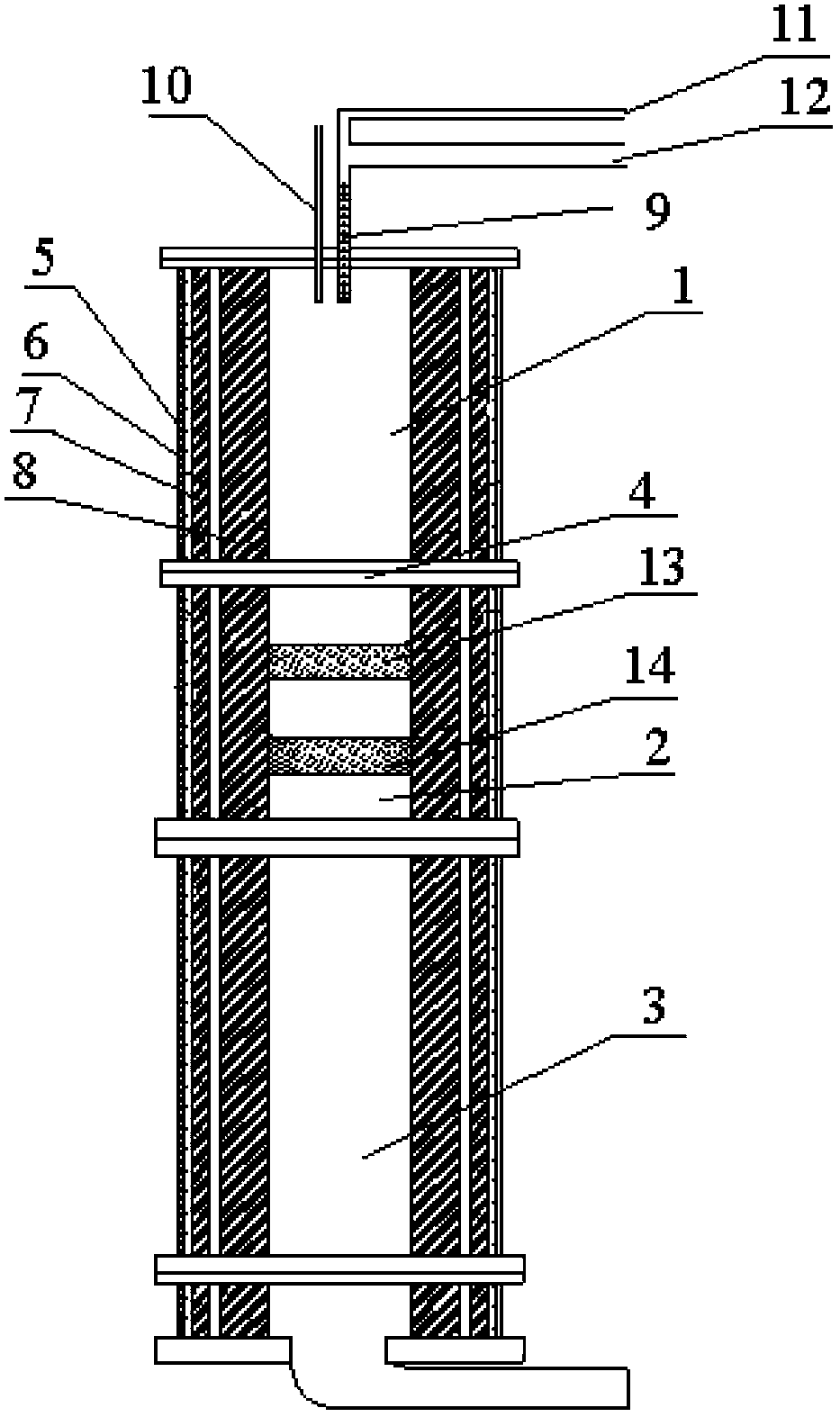

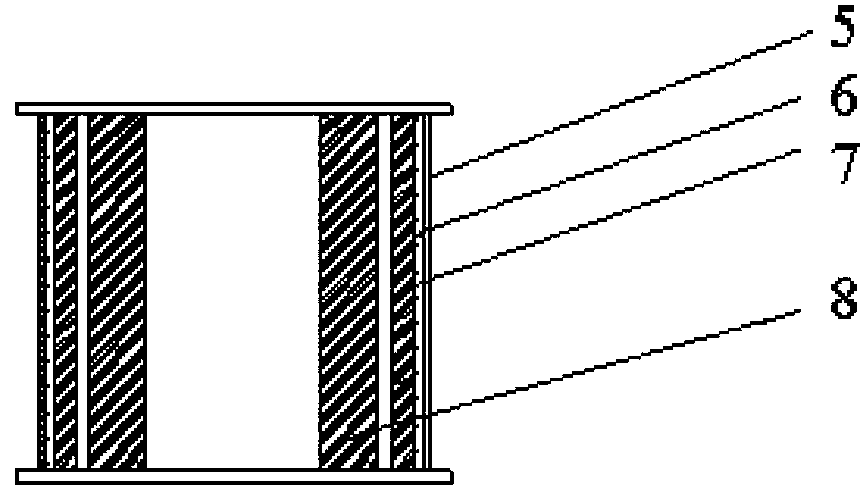

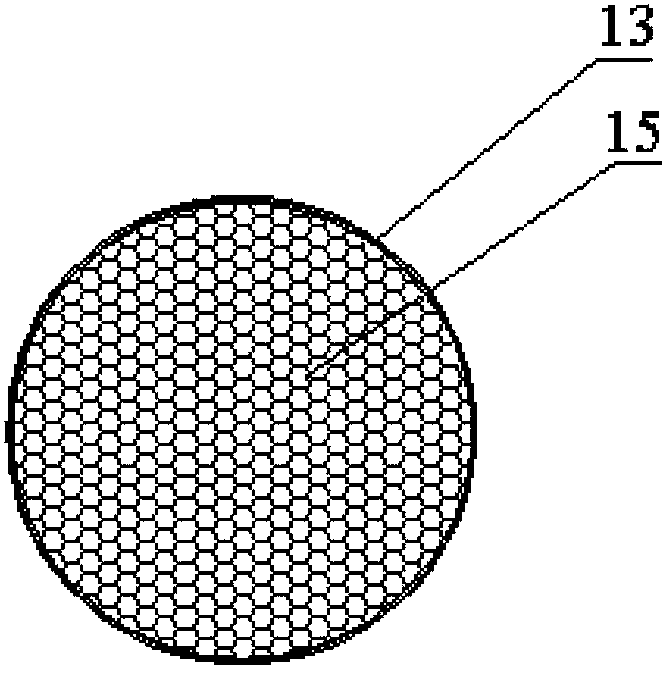

[0021] combine figure 1 , figure 2 , image 3 and Figure 4 As shown, a kind of pellet roasting device provided by the present invention includes: upper combustion chamber 1, lower combustion chamber 2, roasting cup 3 and flange 4, upper combustion chamber 1, lower combustion chamber 2 and roasting cup 3 from top to bottom The bottom is connected successively, and the whole is cylindrical. Upper combustion chamber 1 and lower combustion chamber 2 are connected by flange 4 sealing. The outer walls of the upper combustion chamber 1, the lower combustion chamber 2 and the roasting cup 3 are all made of steel shell 5, refractory asbestos 6, outer refractory brick 7 and inner refractory brick 8, and the steel shell 5, refractory asbestos 6, outer refractory brick 7 and The inner refractory bricks 8 are sequentially connected from outside to inside, and are used to reduce heat dissipation from the upper combustion chamber 1, the lower combustion chamber 2 and the roasting cup 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com