An energy-saving asphalt mixing plant

An asphalt mixing and energy-saving technology, applied in roads, buildings, cleaning methods and utensils, etc., can solve the problems of insufficient fuel and air contact, insufficient fuel combustion, etc., to increase combustion sufficiency and increase contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-10 The application is described in further detail.

[0044] The embodiment of the present application discloses an energy-saving asphalt mixing plant.

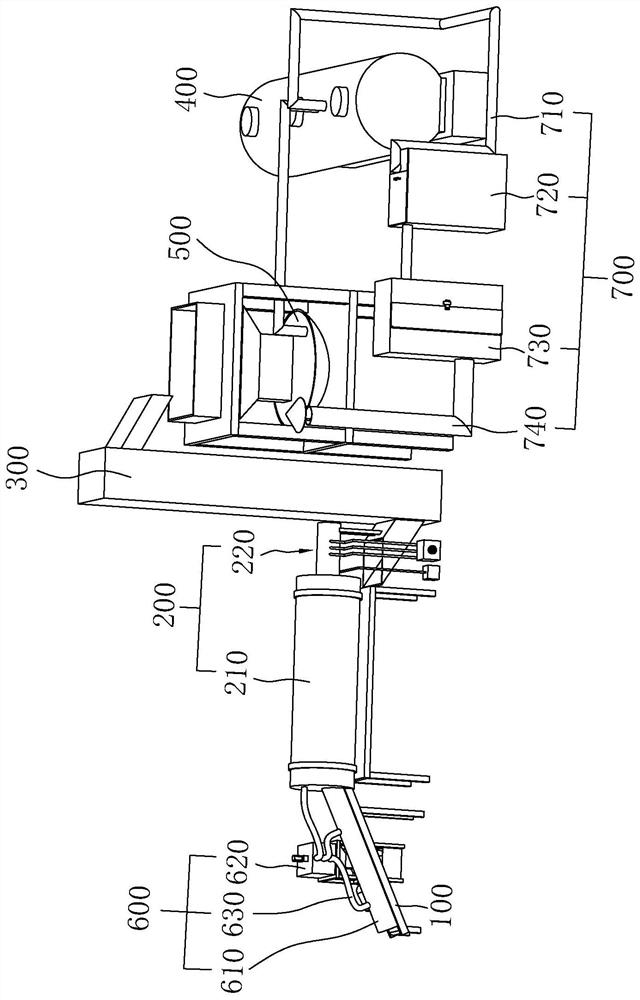

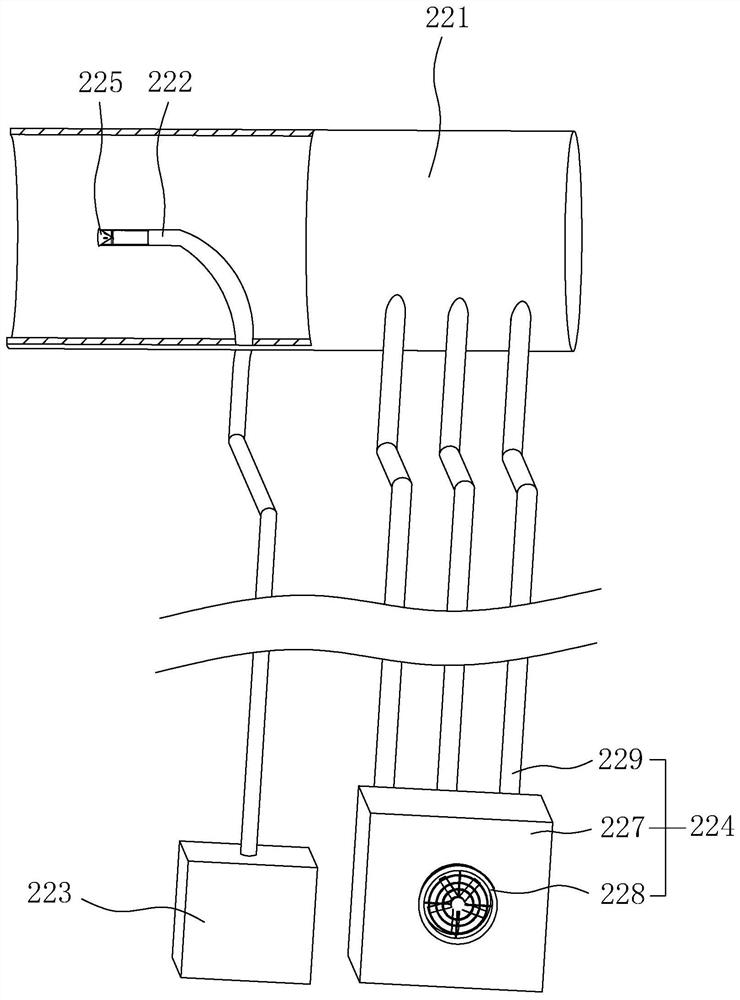

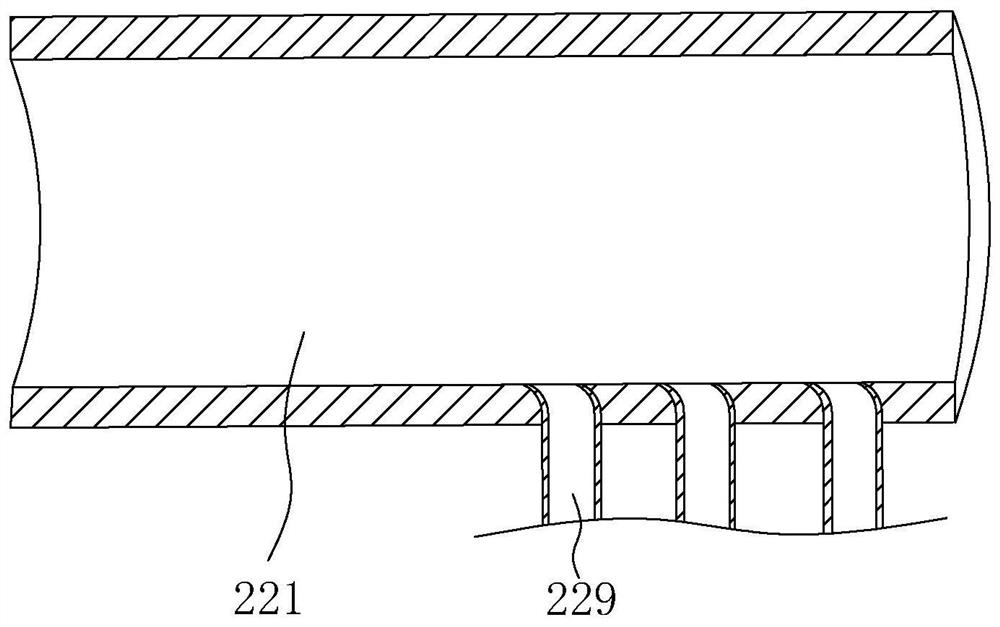

[0045] refer to figure 1 , an energy-saving asphalt mixing plant includes a feeding belt conveyor 100, a drying drum 200, a hot aggregate hoist 300, an asphalt tank 400 and a mixing pot 500, and also includes a dust suppression device for dust suppression for the feeding belt conveyor 100 600 and a waste treatment device for disposing of waste generated from the asphalt tank 400. The discharge end of the feeding belt conveyor 100 is located at the feed inlet of the drying drum 200 , and the feeding belt conveyor 100 is used to transport ore raw materials into the drying drum 200 . The feed inlet of the hot aggregate elevator 300 is located at the outlet of the drying drum 200 , and the hot aggregate elevator 300 is used to transport the ore raw materials in the drying drum 200 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com