Alcohol-based fuel for compression ignition type internal combustion engine and preparation method of alcohol-based fuel

A technology of alcohol-based fuel and internal combustion engine, which is applied in the direction of fuel, fuel additive, liquid carbon-containing fuel, etc. It can solve the problems of insufficient utilization and achieve the effects of improving combustion sufficiency and thermal efficiency, reducing use cost, and good combustion-supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The percentages of raw materials used in this example are: higher alcohols 13%, aromatics 4%, n-paraffins 45.5%, white oil 17.5%, polymethoxy dimethyl ether DMM3-6 1%, coal-based Fischer-Tropsch synthetic liquid wax 18%, cetane number improver 1%.

[0031] The sources, selection requirements or uses of the above raw materials are as follows:

[0032] High-carbon alcohols are products obtained by separating C9-C15 straight-chain and isomeric fatty alcohols with a mass fraction of not less than 95% after oxygen-containing oil (heavy) is treated; the specific process of the above-mentioned treatment is: In the oxygenated oil (heavy weight) with a mass fraction of C9-C15 linear and isomeric fatty alcohols not less than 85%, add potassium hydroxide with a mass fraction of 50% according to 0.1% of the mass of the oxygenated oil (heavy weight) Aqueous solution, after 30-45 minutes of continuous reaction, settling at 20-40°C for 24-36 hours, separating the pasty esters in the ...

Embodiment 2、3、4

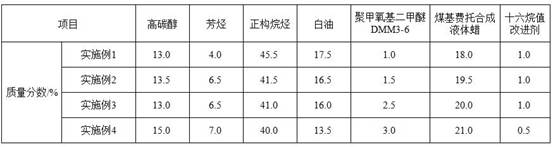

[0047] Embodiment 2, 3, 4 are all identical with the raw material category that embodiment 1 adopts, process parameter, and difference is: the higher carbon alcohol that adopts, aromatic hydrocarbon, normal paraffin, white oil, polyoxymethylene dimethyl ether The mass fractions of DMM3-6, coal-based Fischer-Tropsch synthetic liquid wax, and cetane number improver are different, and the mass fractions are shown in Table 1.

[0048] The raw material mass fraction of table 1 embodiment 1-4

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com