Patents

Literature

231results about How to "Stable outlet pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

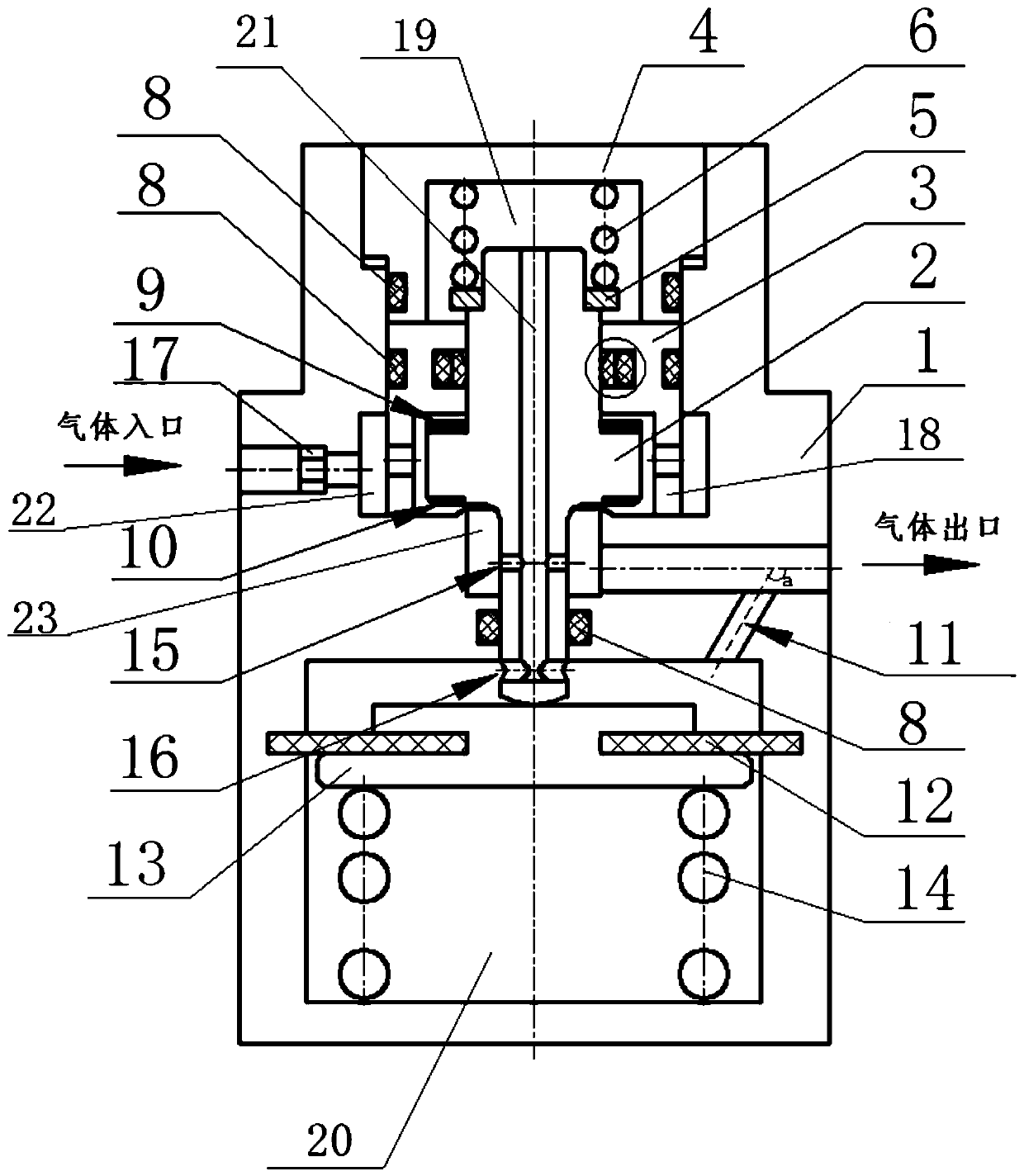

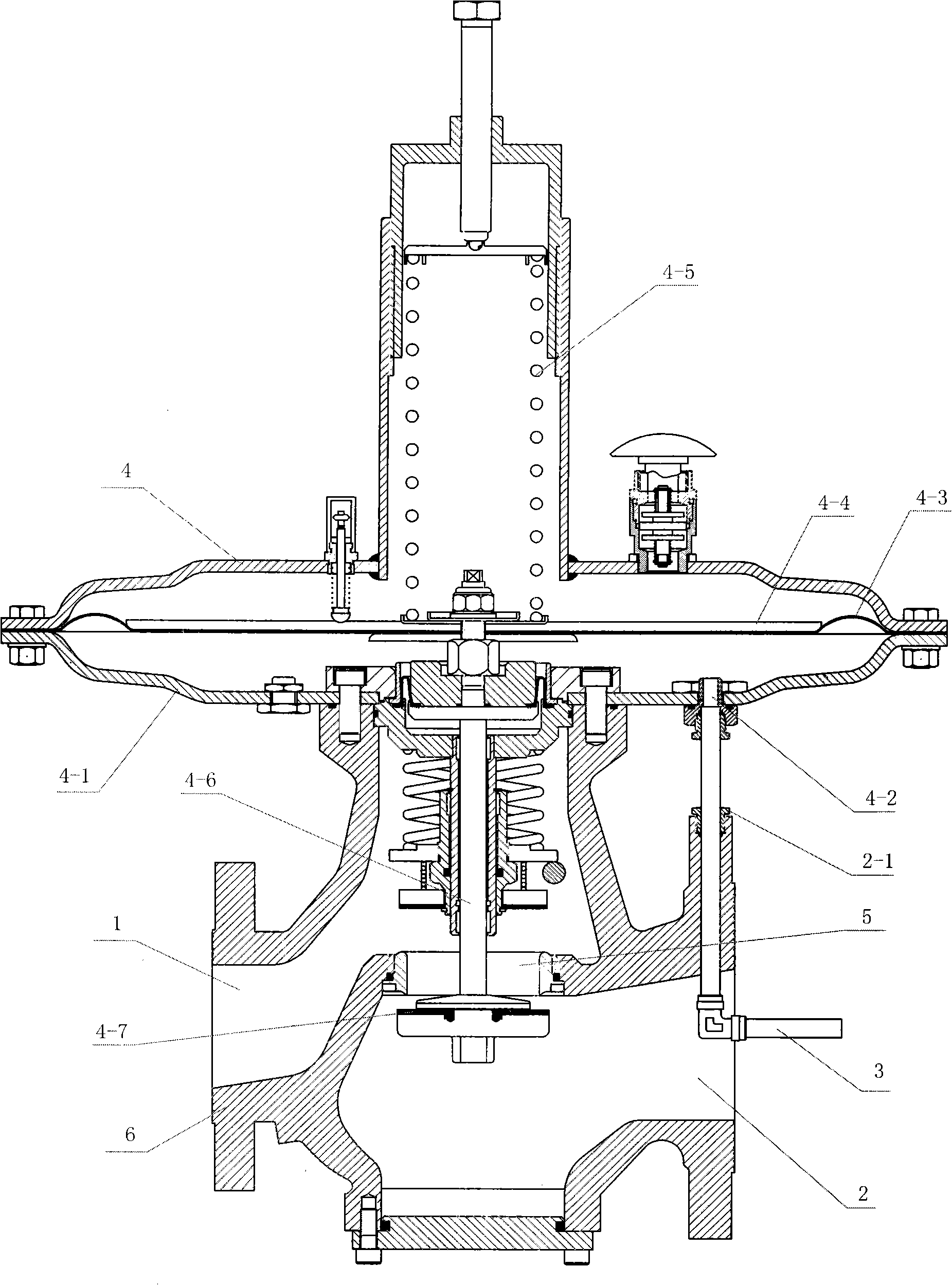

Pressure regulating device and pressure regulator thereof

ActiveCN103244727AShort balance periodStable outlet pressureOperating means/releasing devices for valvesEqualizing valvesMagnetic tension forceEngineering

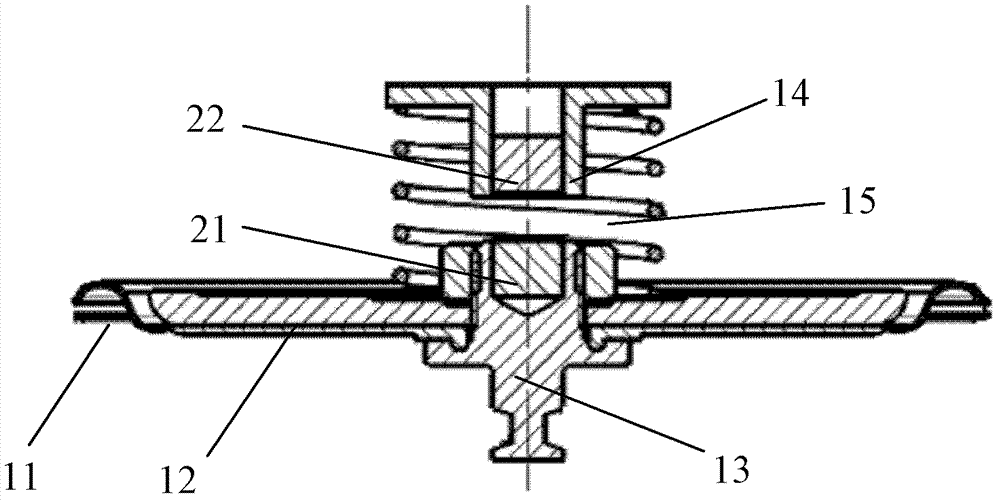

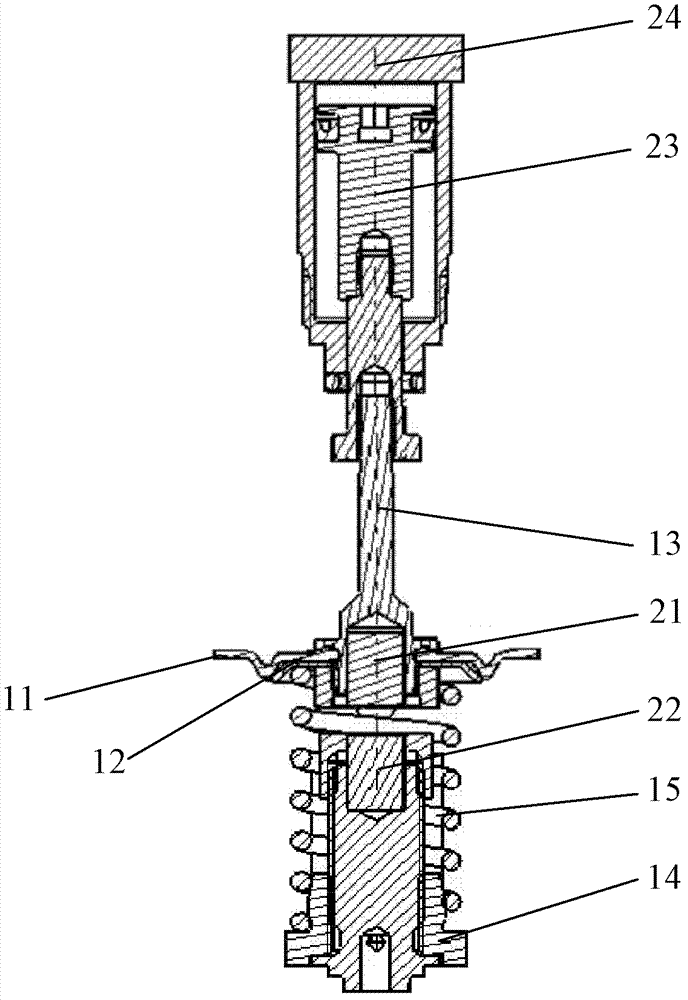

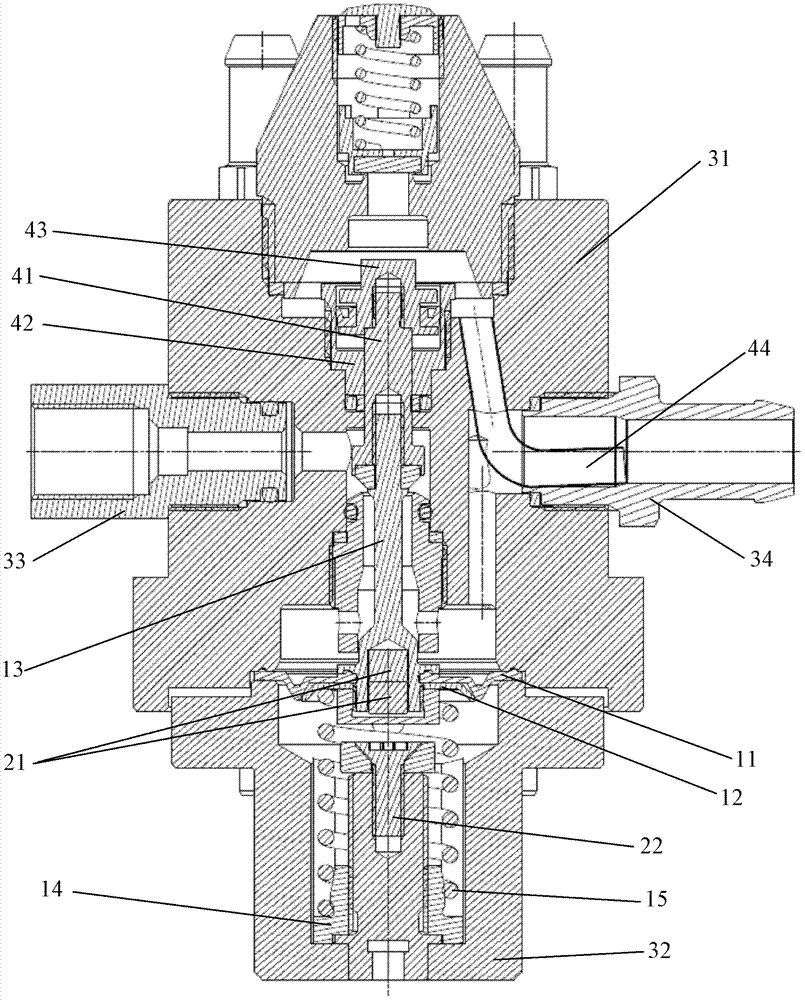

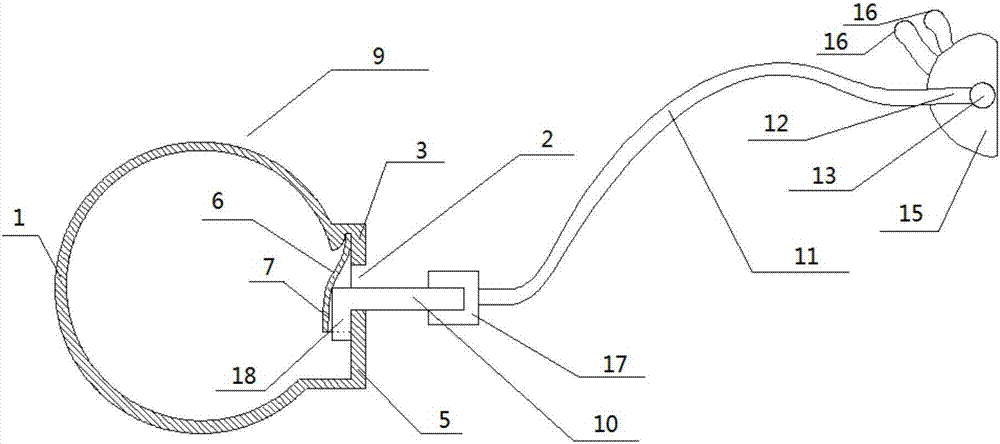

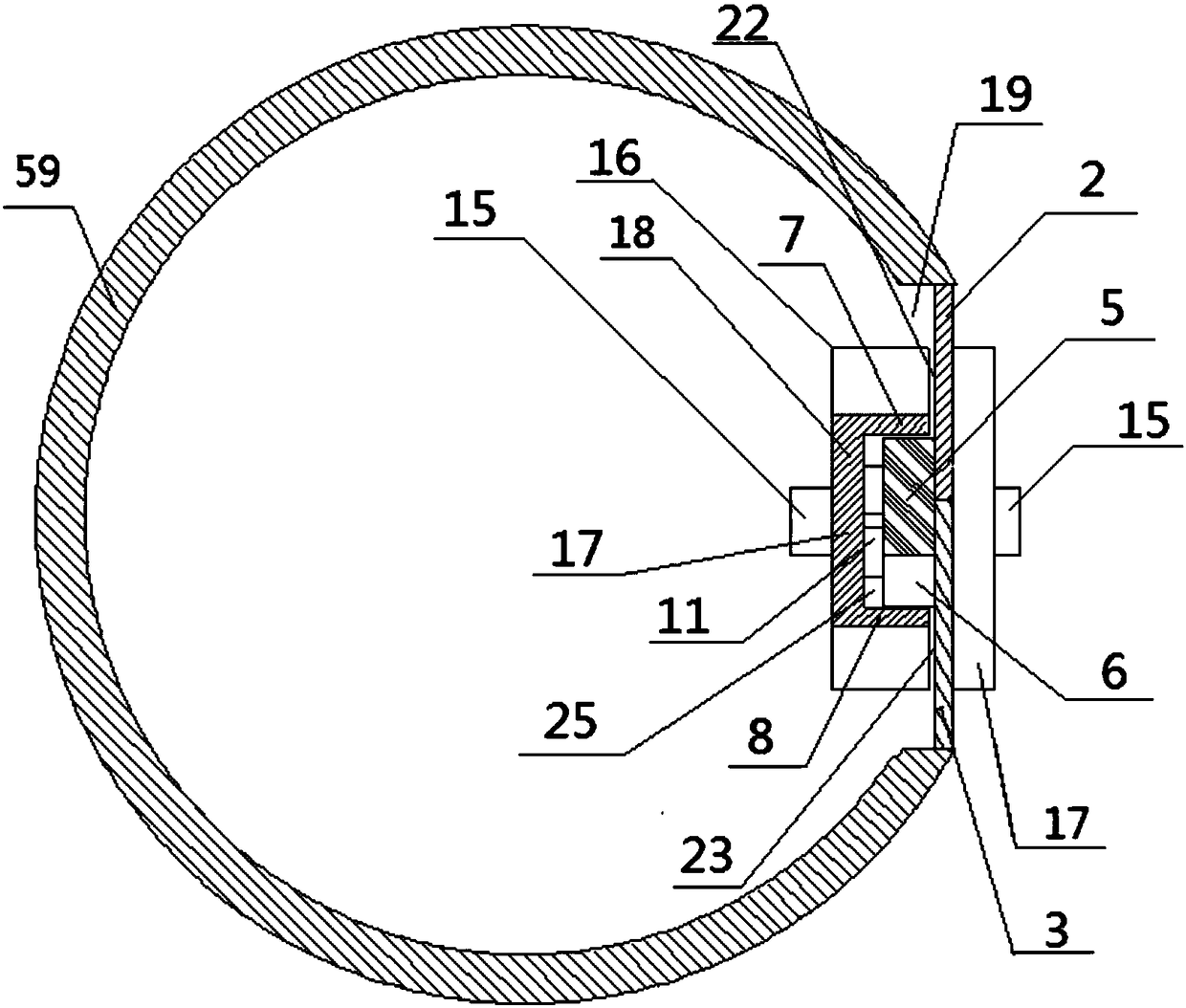

The invention discloses a pressure regulating device and a pressure regulator thereof. The pressure regulating device comprises a membrane cavity and a magnetic module. The membrane cavity comprises a flexible membrane (11), a rigid membrane (12), a membrane shaft (13) fixedly connected with the flexible membrane (11) and the rigid membrane (12), a pressure regulating spring seat (14) and a pressure regulating spring (15). One end of the pressure regulating spring (15) is sleeved on the pressure regulating spring seat (14), and the other end of the pressure regulating spring (15) is butted against the rigid membrane (12). The magnetic module comprises a pair of magnetic parts (21 and 22) subjected to magnetic force. The magnetic parts (21 and 22) and the pressure regulating spring (15) are arranged on the same axis (18) in a linkage manner. The pressure regulating device and the pressure regulator thereof has the advantages of short balance cycle, stable outlet pressure, low closing pressure, safety, quickness and stability.

Owner:ROTAREX STAR

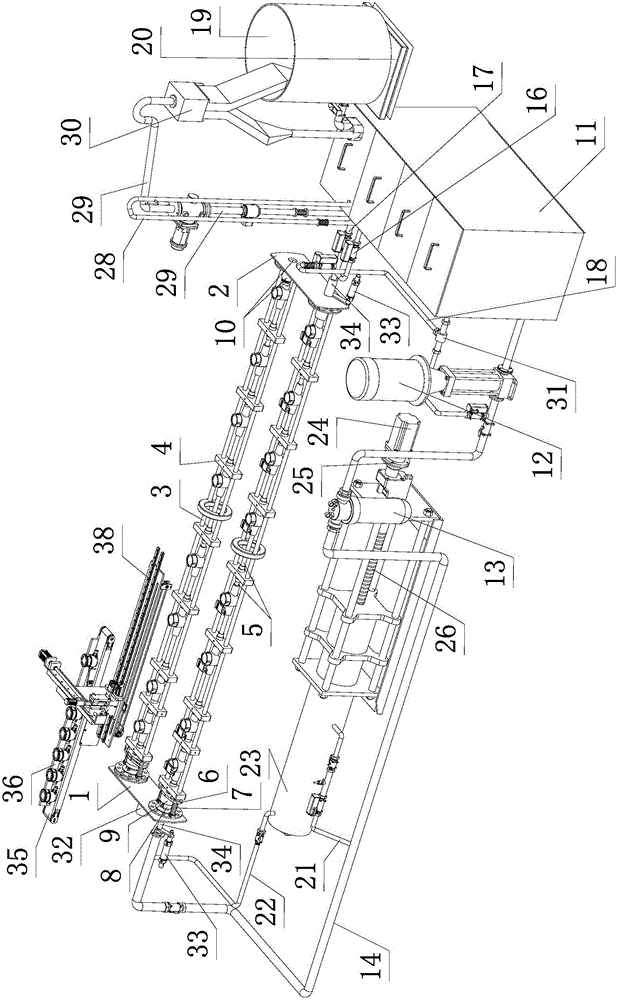

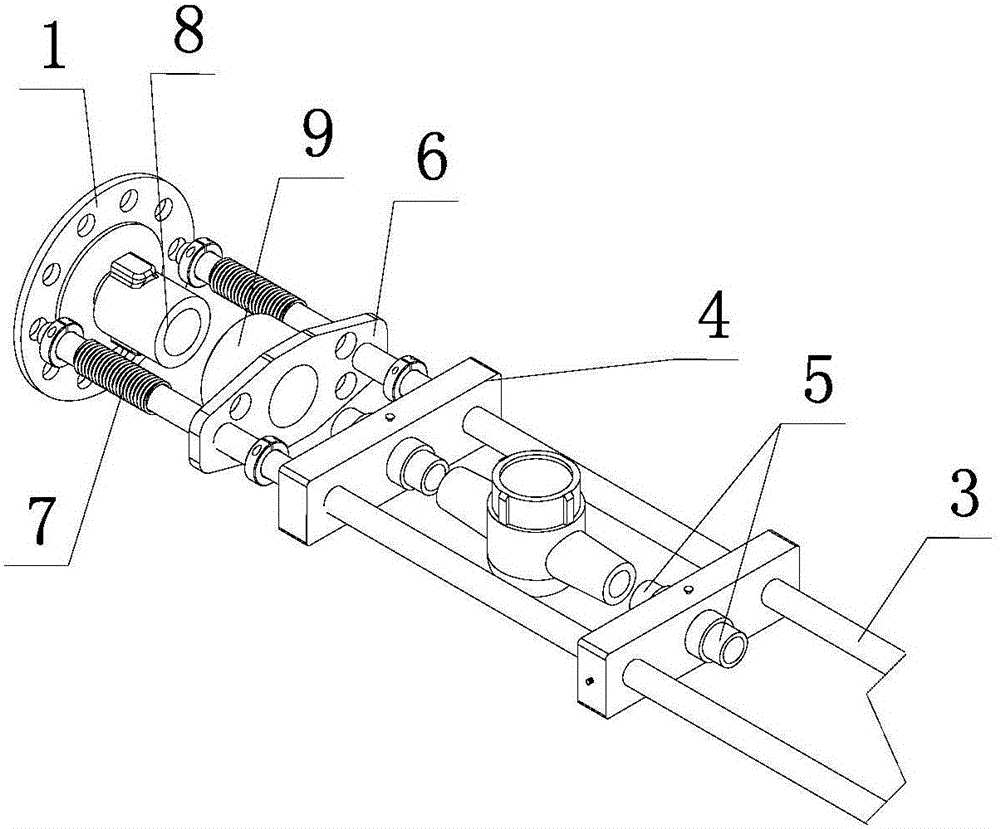

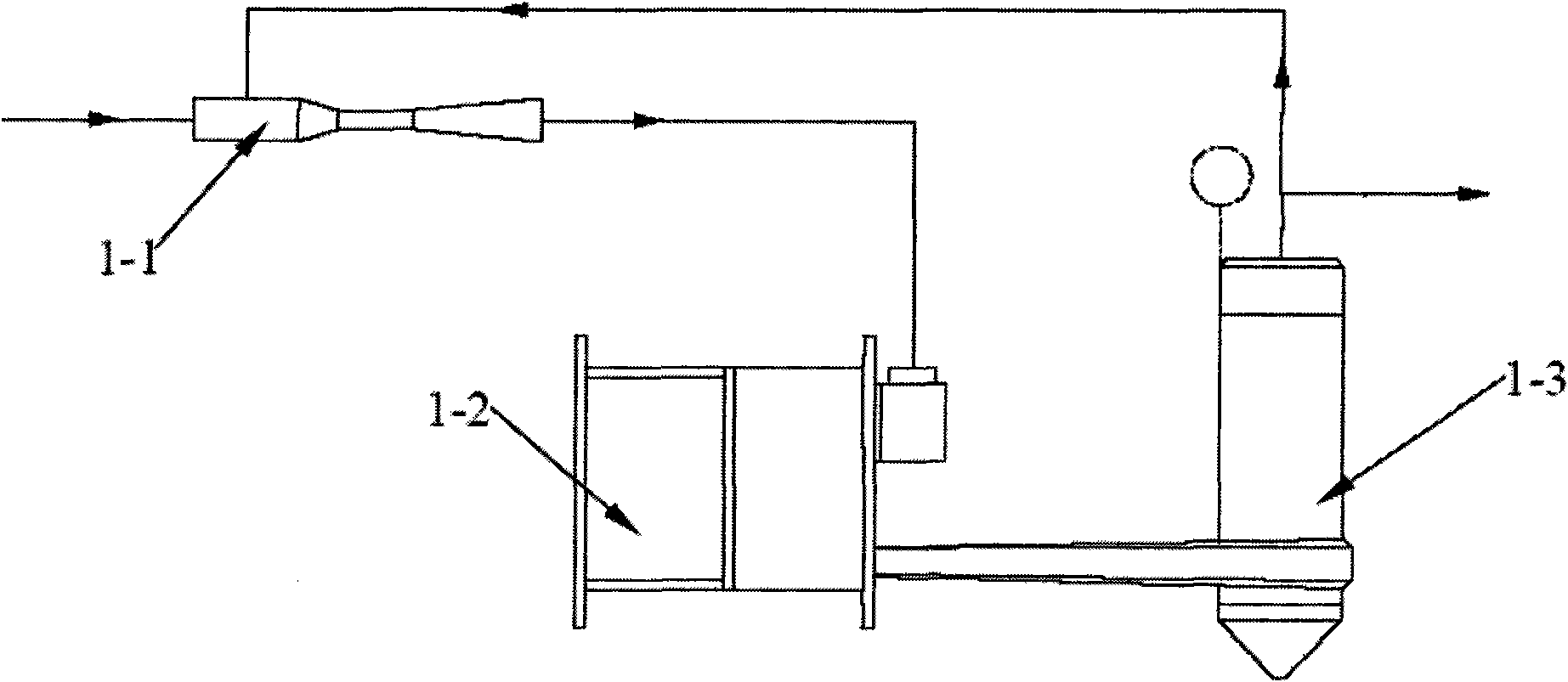

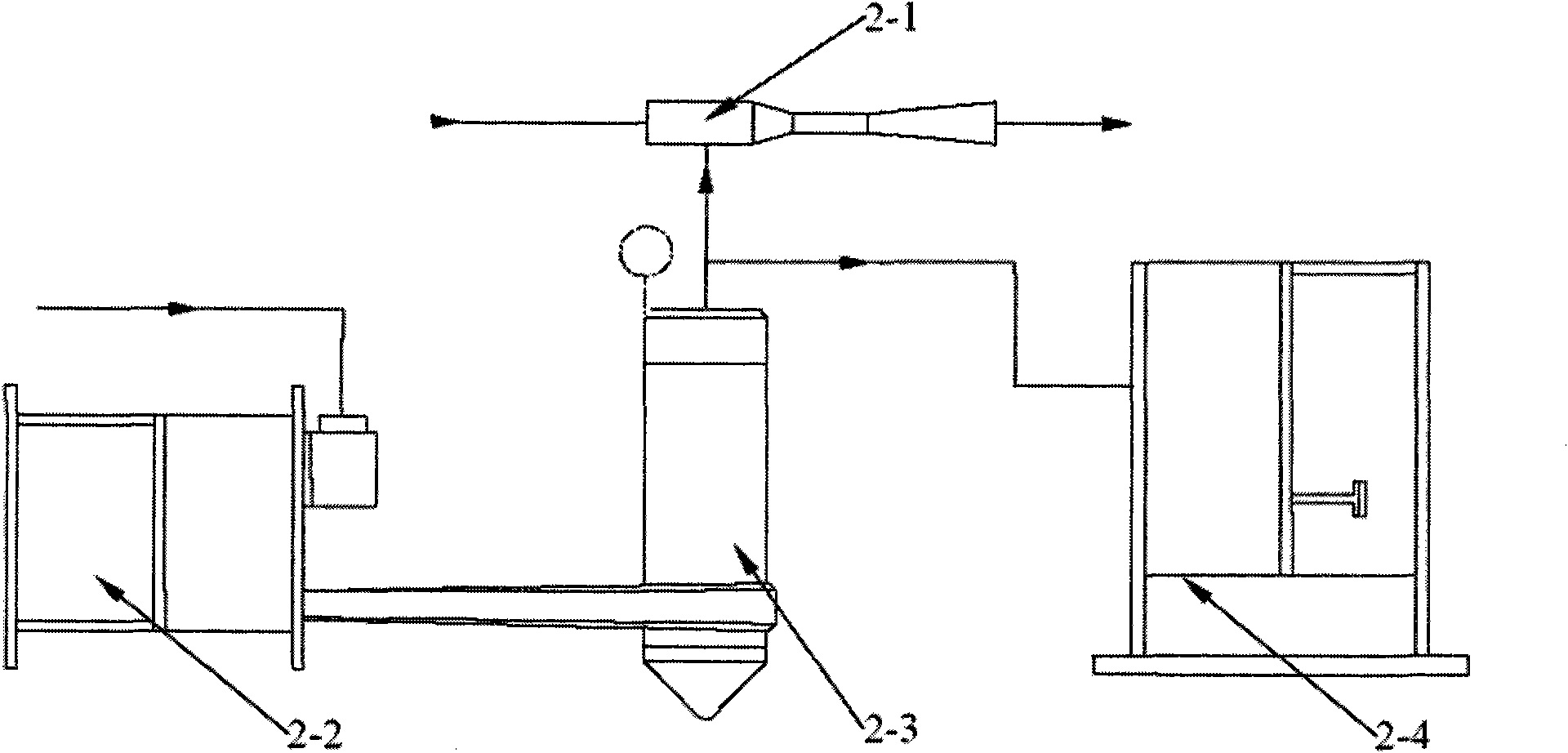

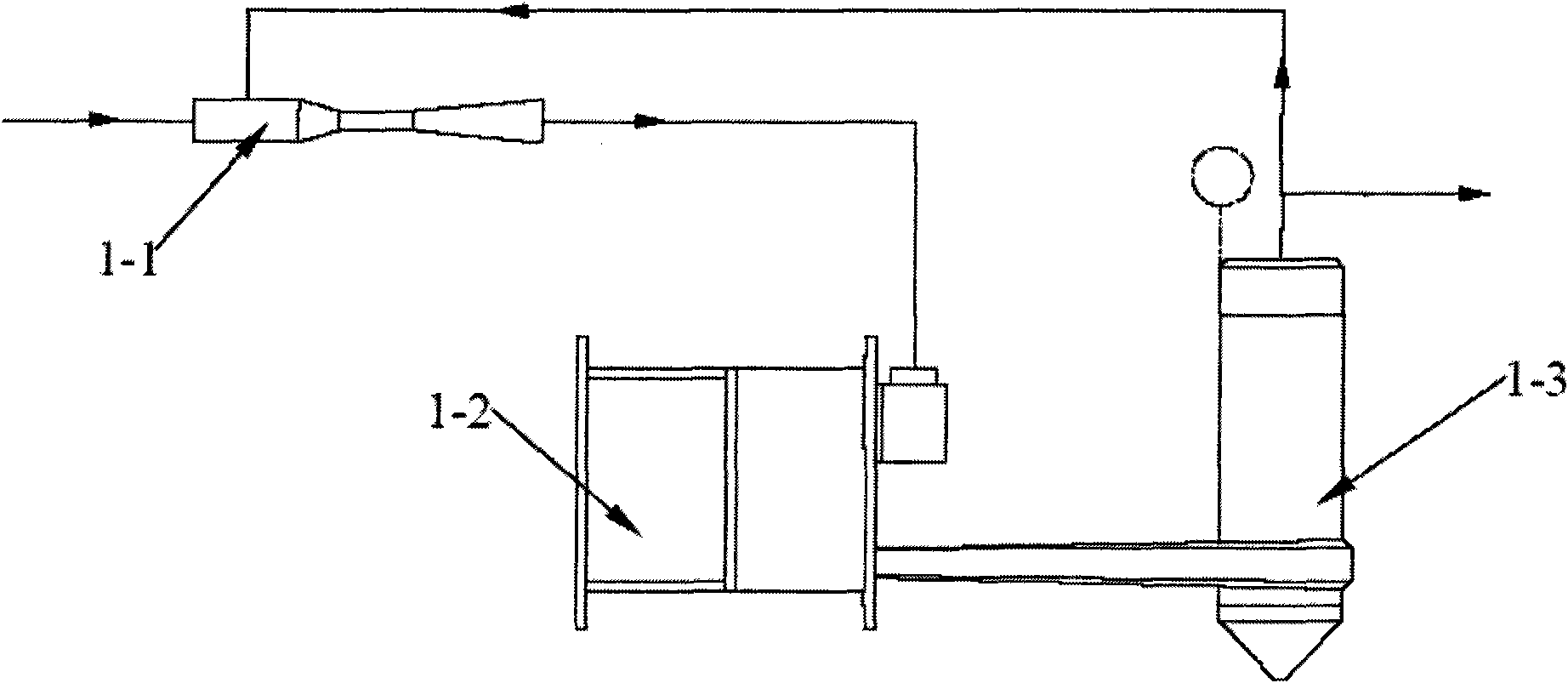

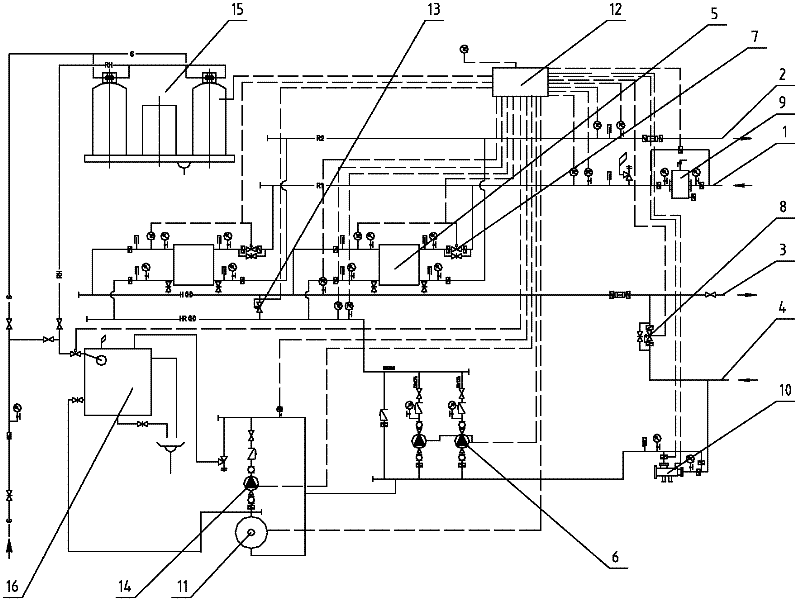

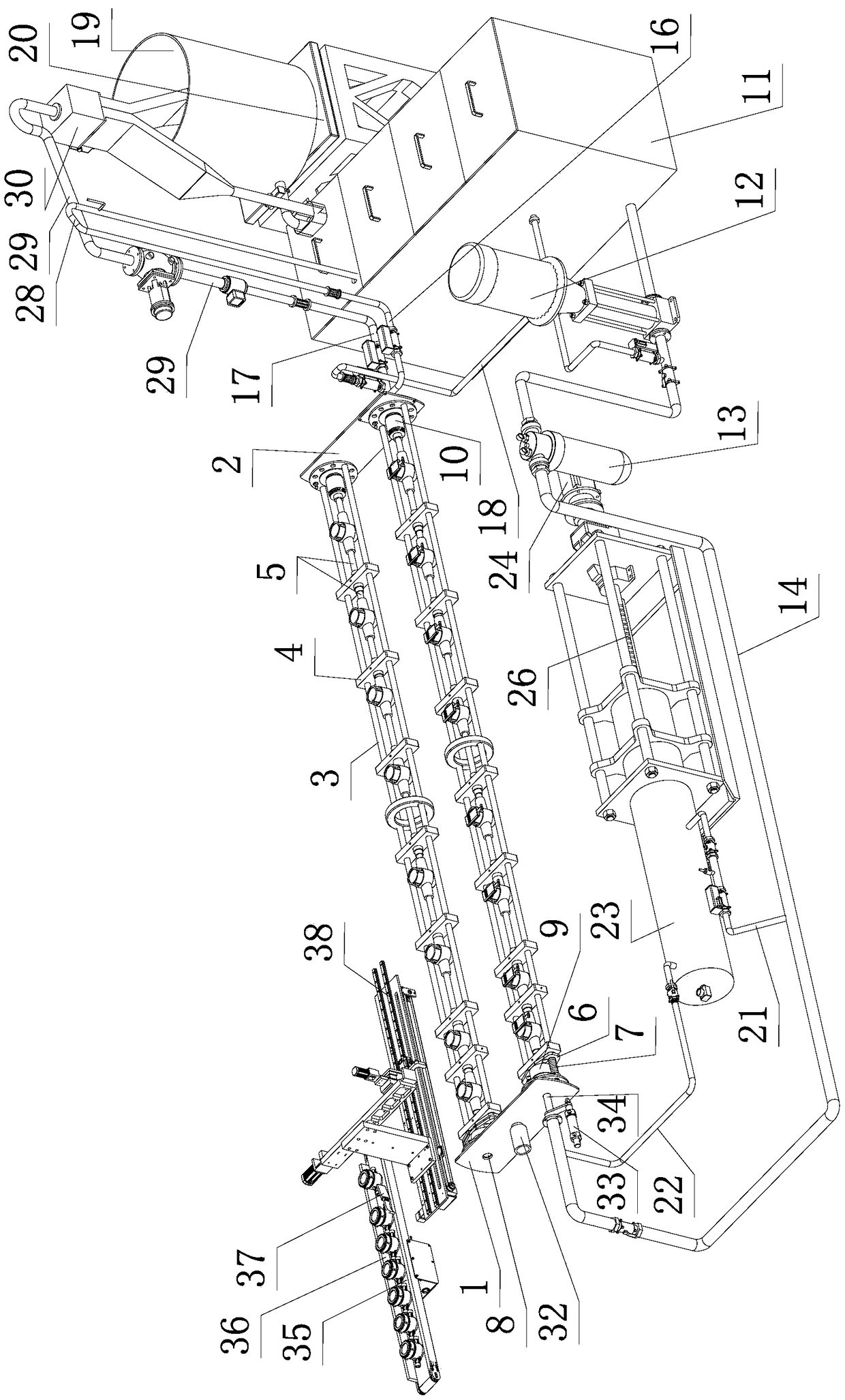

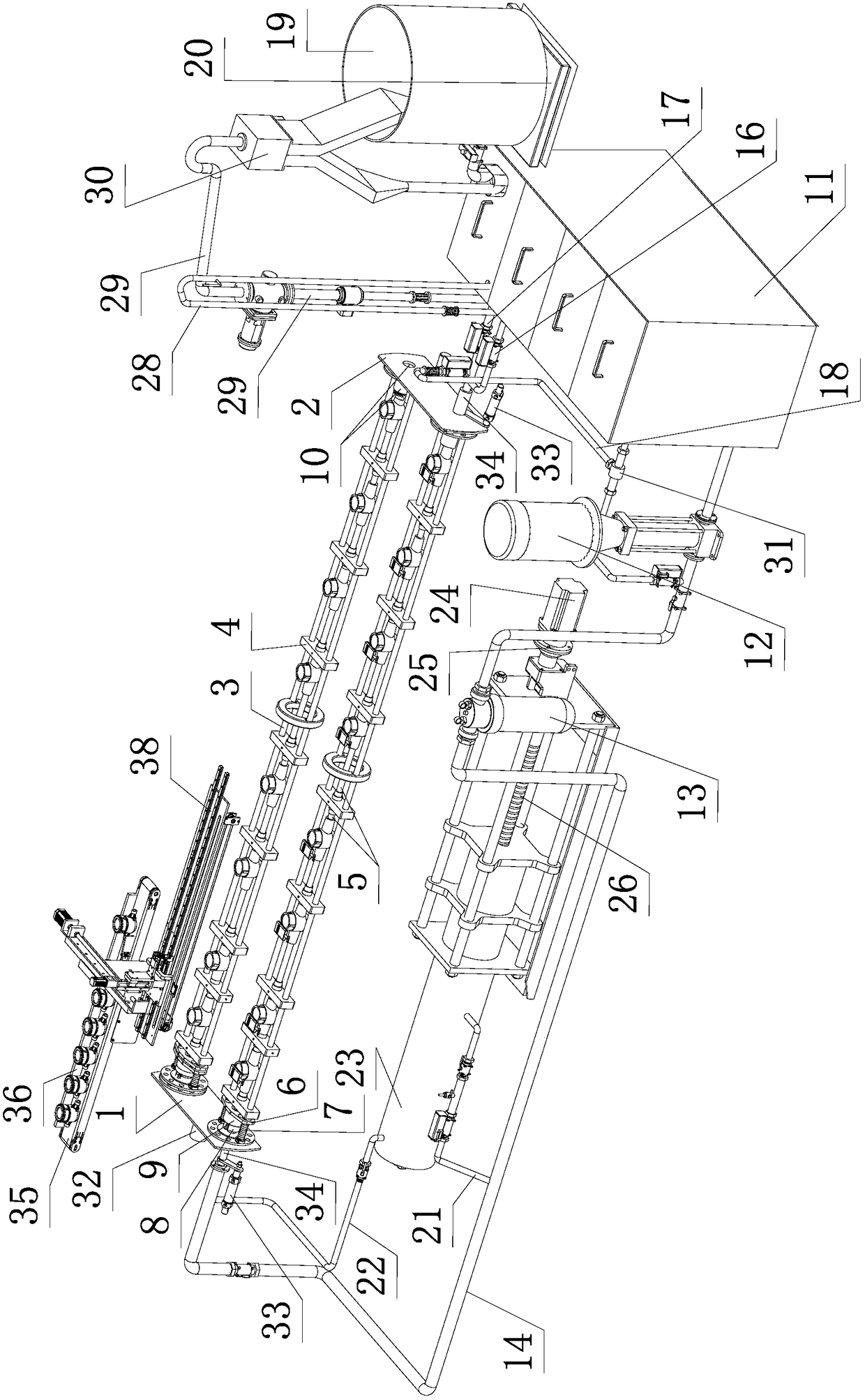

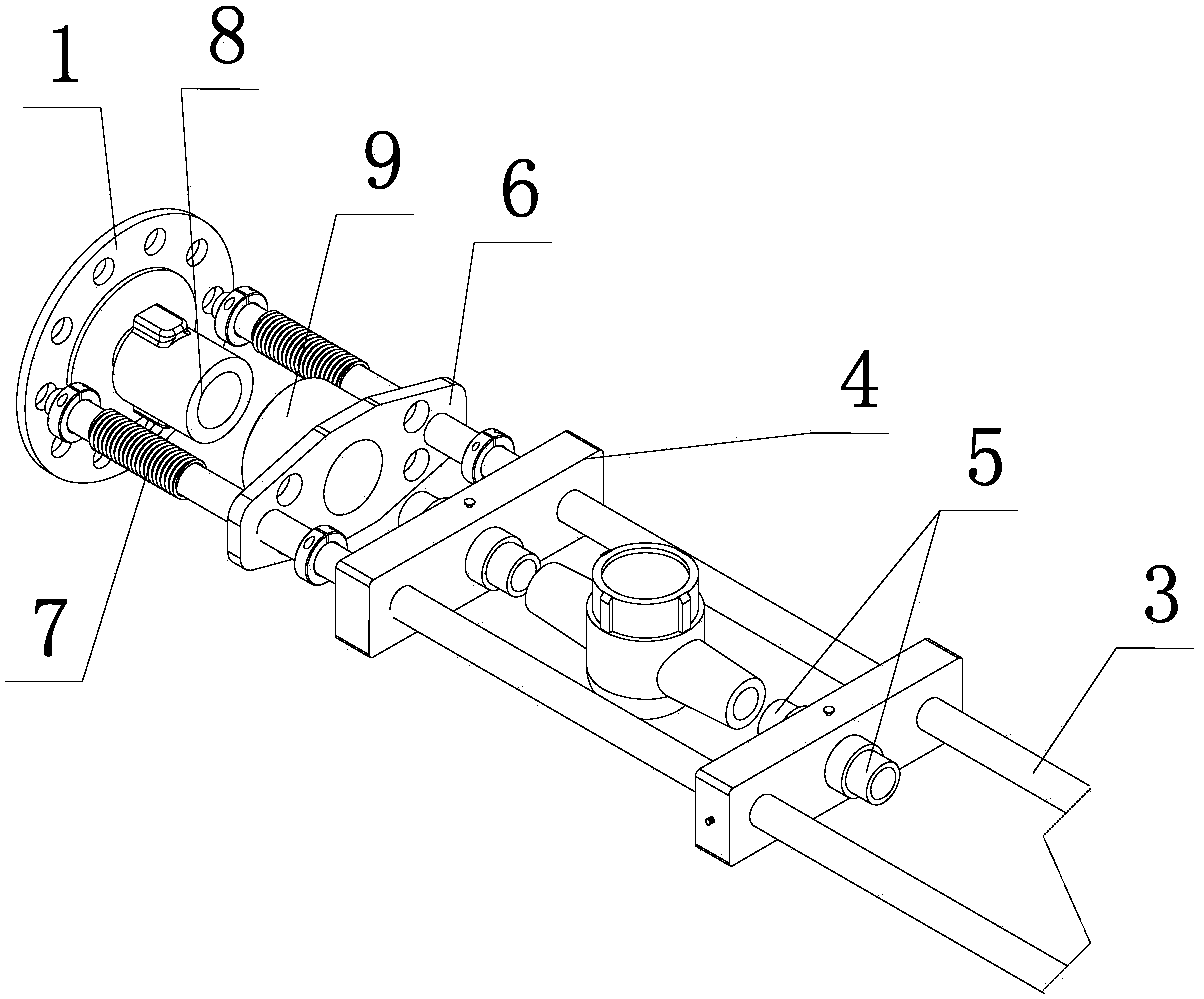

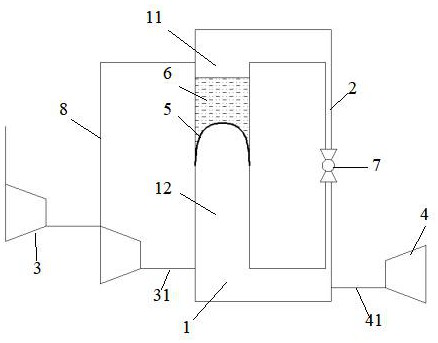

Intelligent full-flow-point full-automatic water meter calibration apparatus

ActiveCN105865589ARealize targeted detectionStable outlet pressureTesting/calibration apparatusPipingTraffic volume

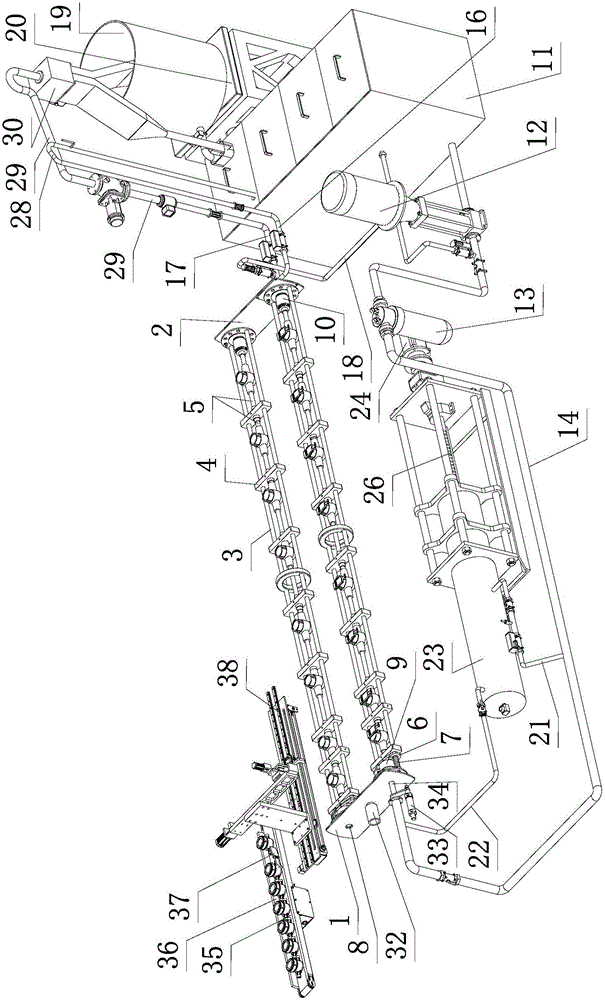

The invention discloses an intelligent full-flow-point full-automatic water meter calibration apparatus, comprising a water pipeline system and a water meter fixture; a water tank (11) of the water pipeline system is communicated sequentially with a water pump (12), a filter (13) and a main water supply pipe (14), the main water supply pipe (14) being communicated with a total outflow pipe; a branch inflow pipe (21), a piston hydraulic meter and a branch outflow pipe (22) are parallelly connected with the main water supply pipe (14); an outlet of the total outflow pipe is communicated respectively with an inlet of a high-precision outflow pipe (16), an inlet of a low-precision outflow pipe (17) and an inlet of a relief outflow pipe (18), and an outlet of the high-precision outflow pipe (16) is communicated with the water tank (11) through an inverted U-shaped pipe (28); the low-precision outflow pipe (17) is communicated with an inlet of a divider (30) through an L-shaped pipe (29), a first outlet of the divider (30) is communicated with a measuring tube (19), and the measuring tube (19) is rested on a scale (20). The intelligent full-flow-point full-automatic water meter calibration apparatus is suitable for household and public precision water meters.

Owner:NINGBO DONGHAI GRP CORP +1

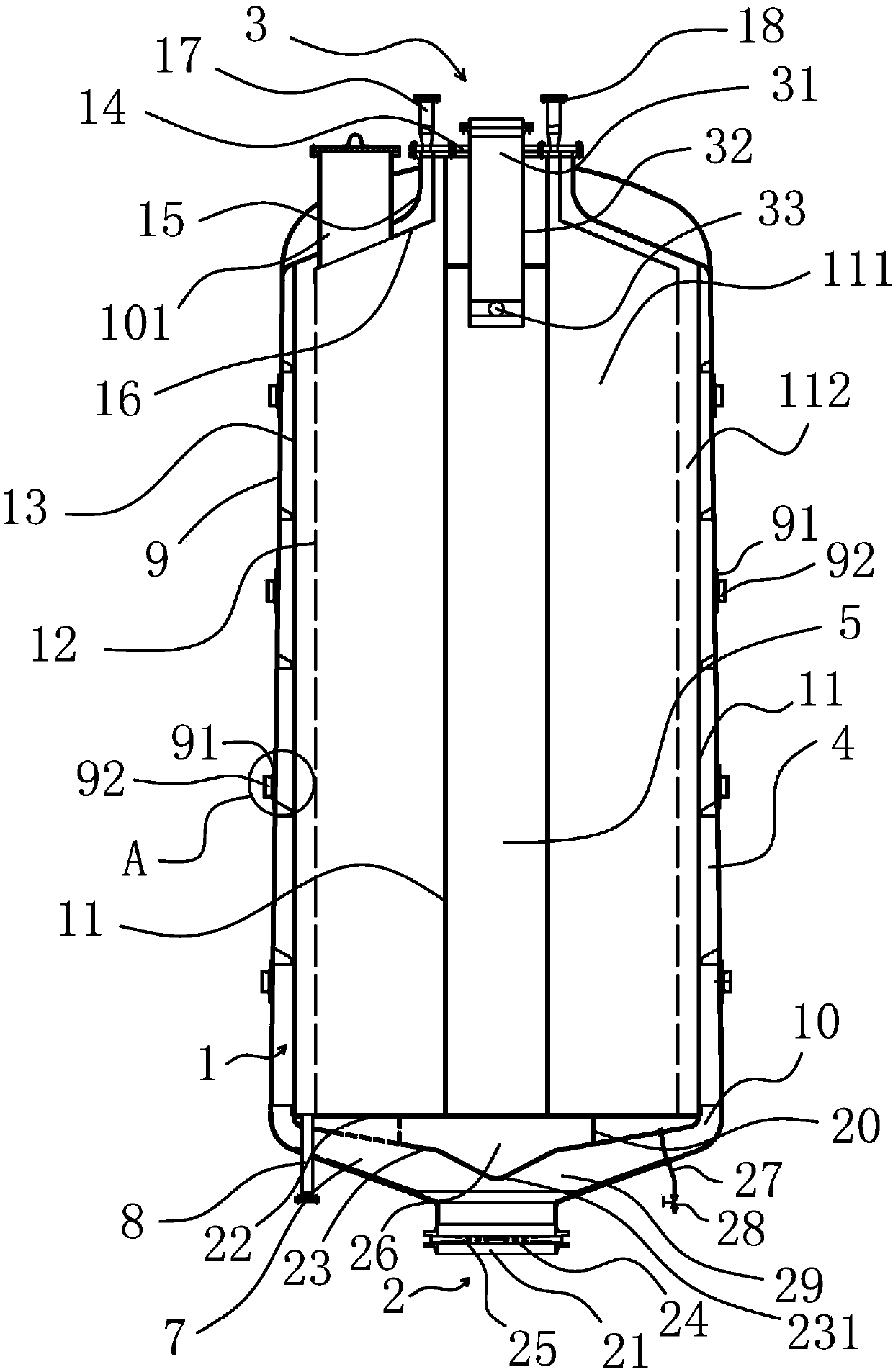

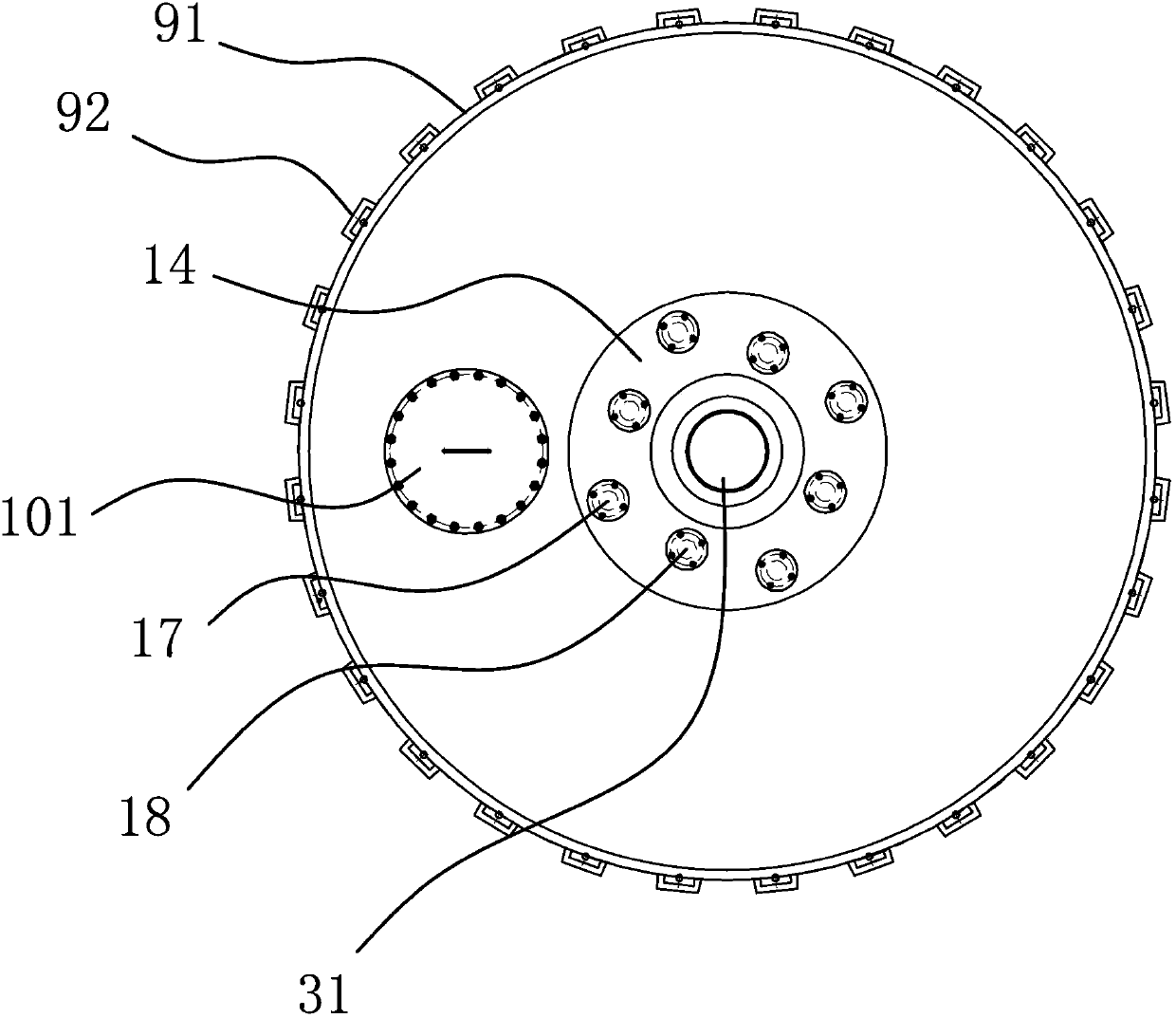

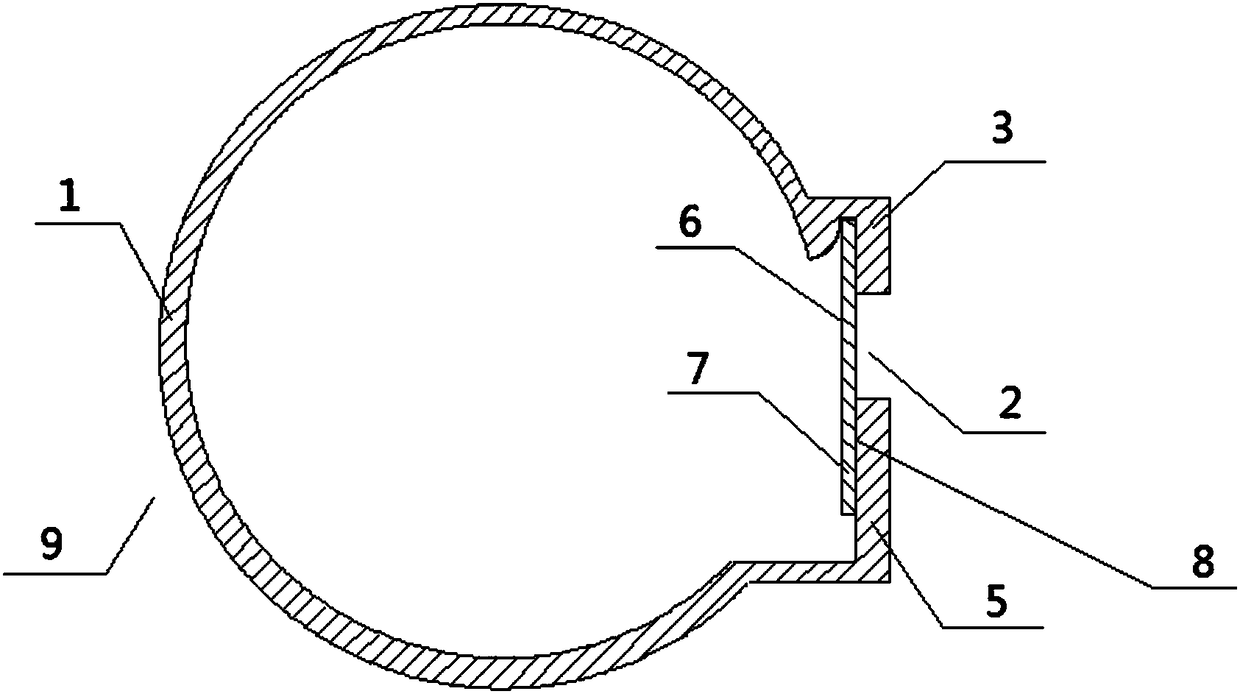

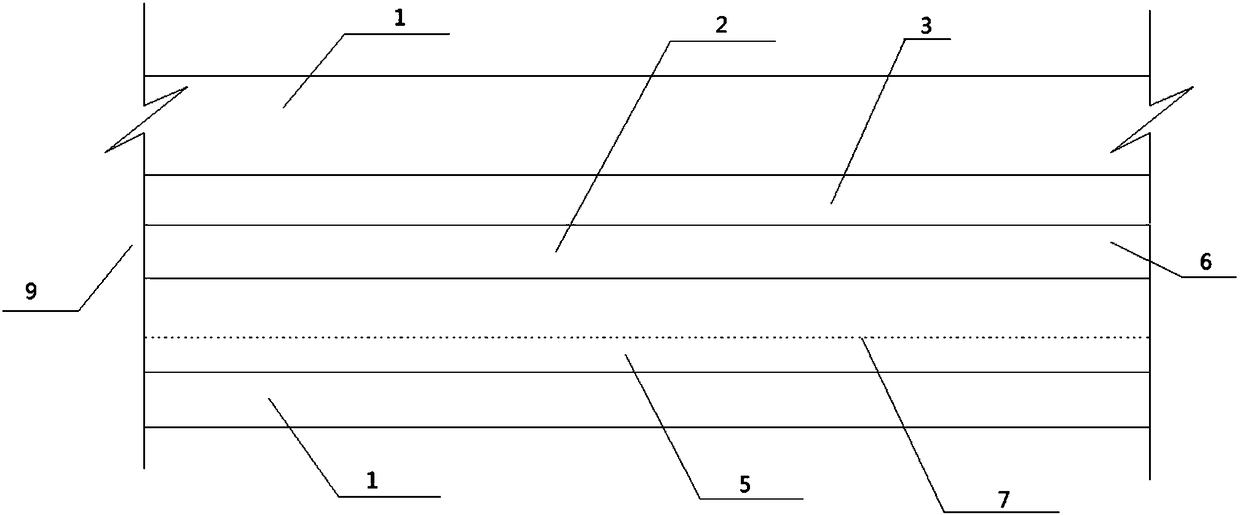

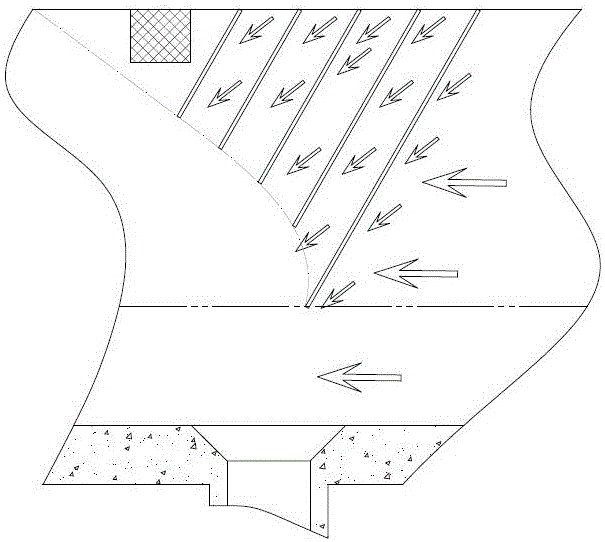

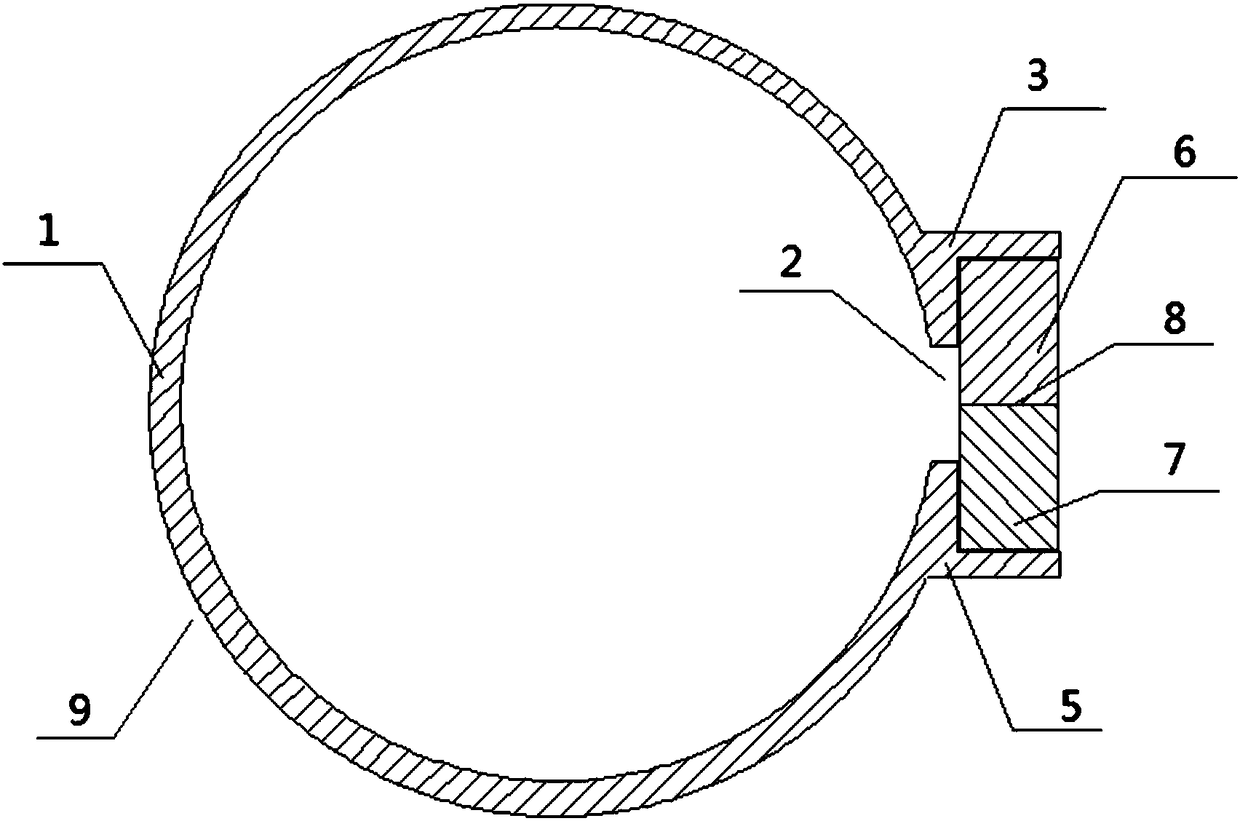

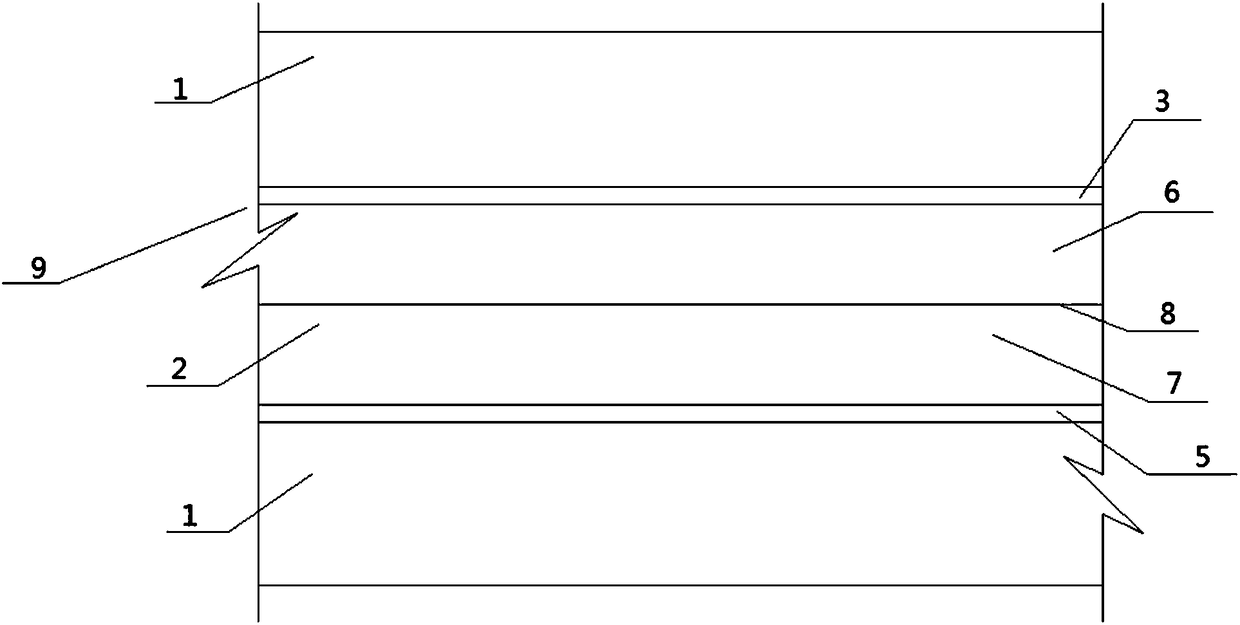

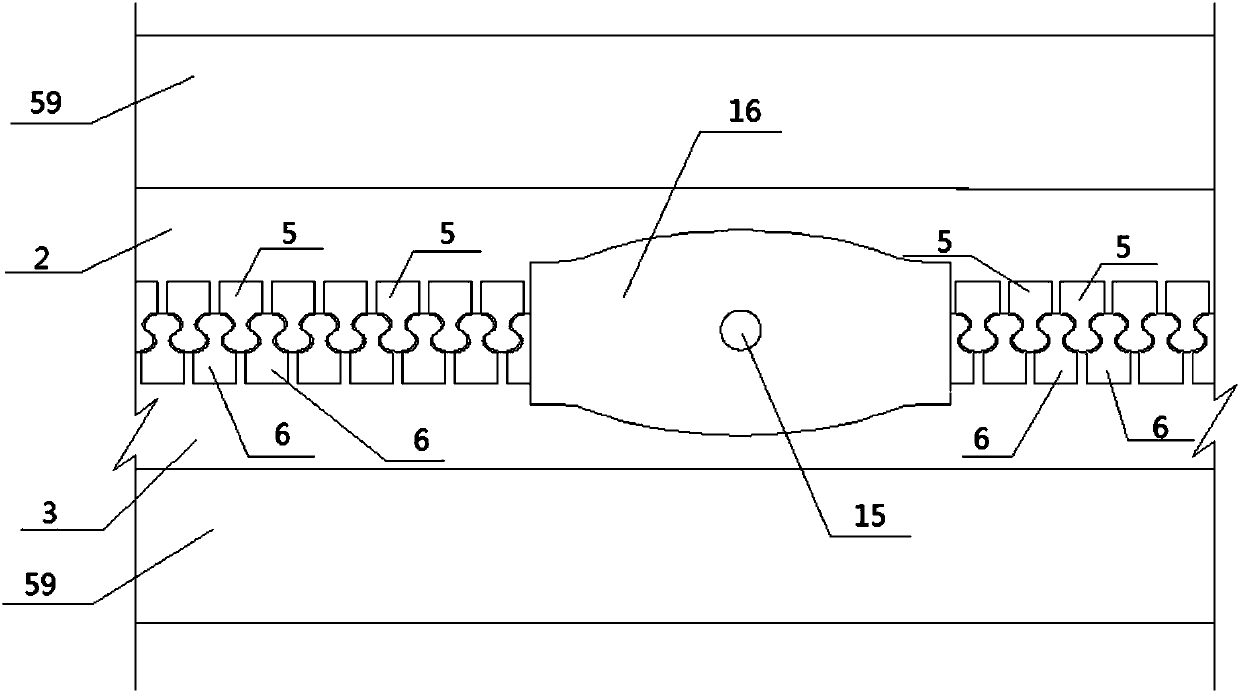

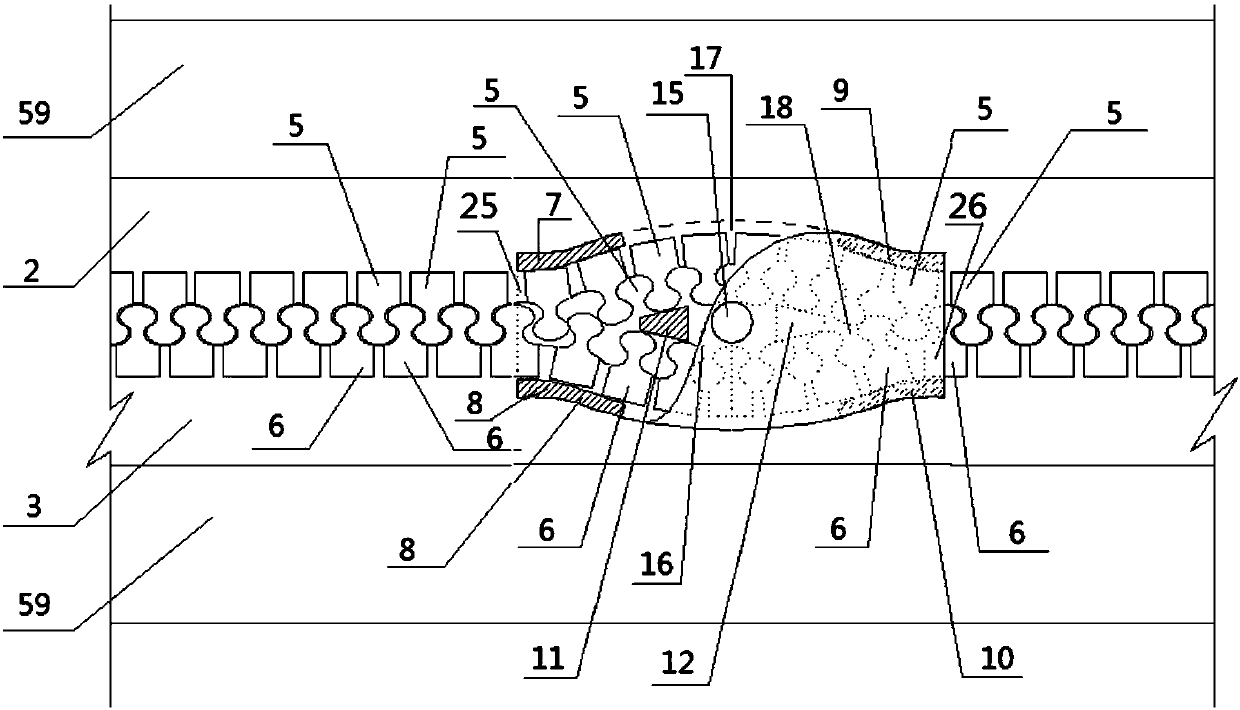

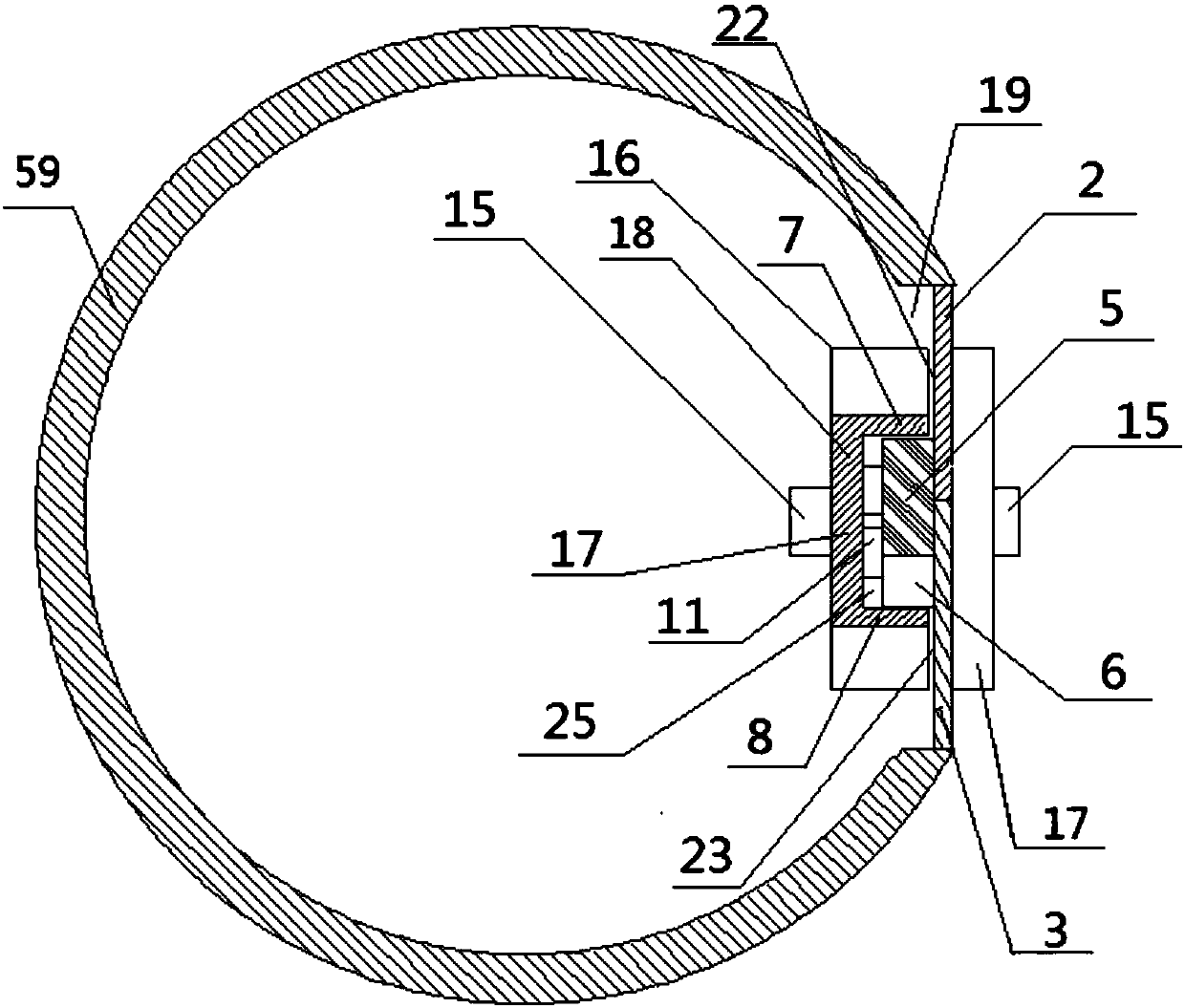

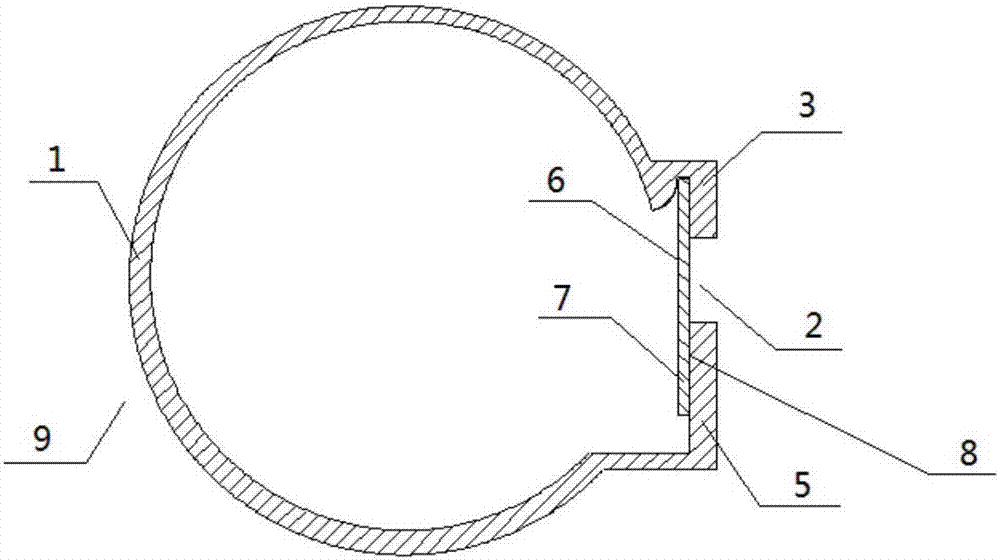

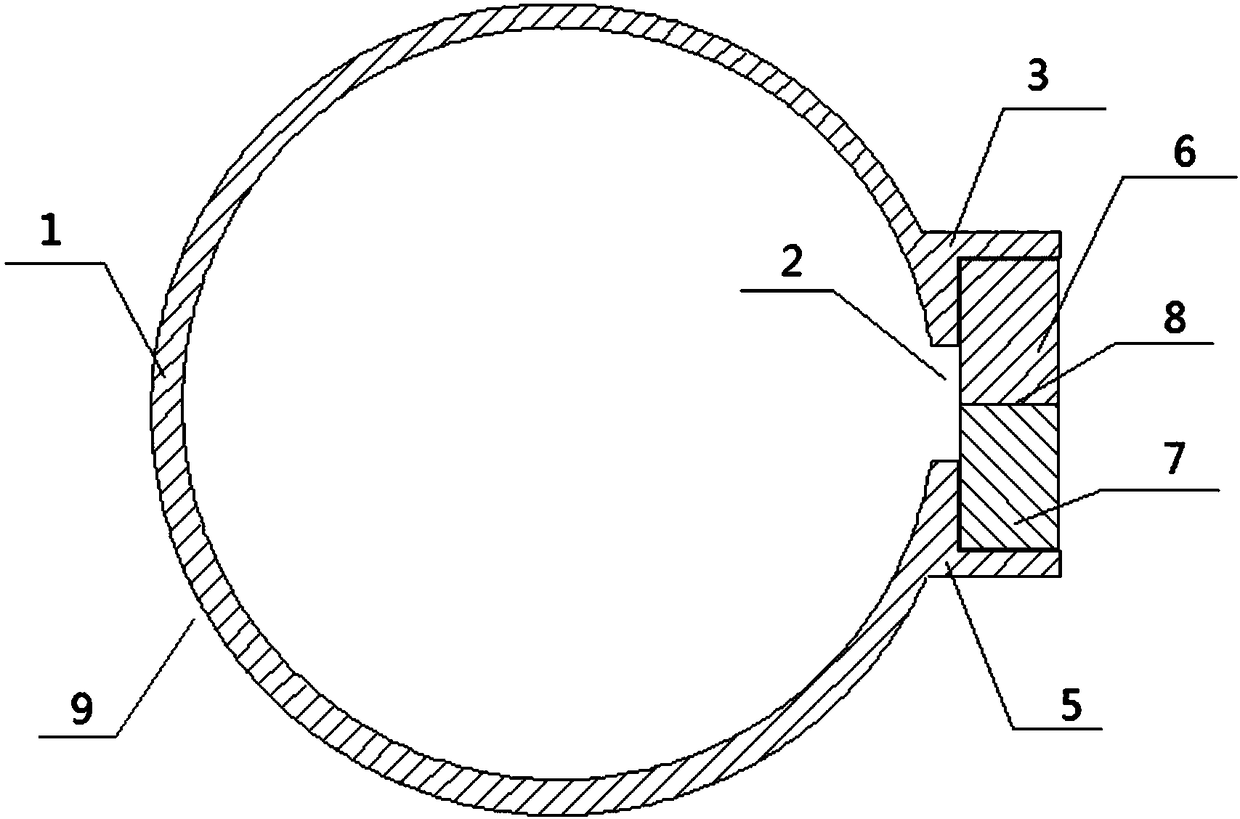

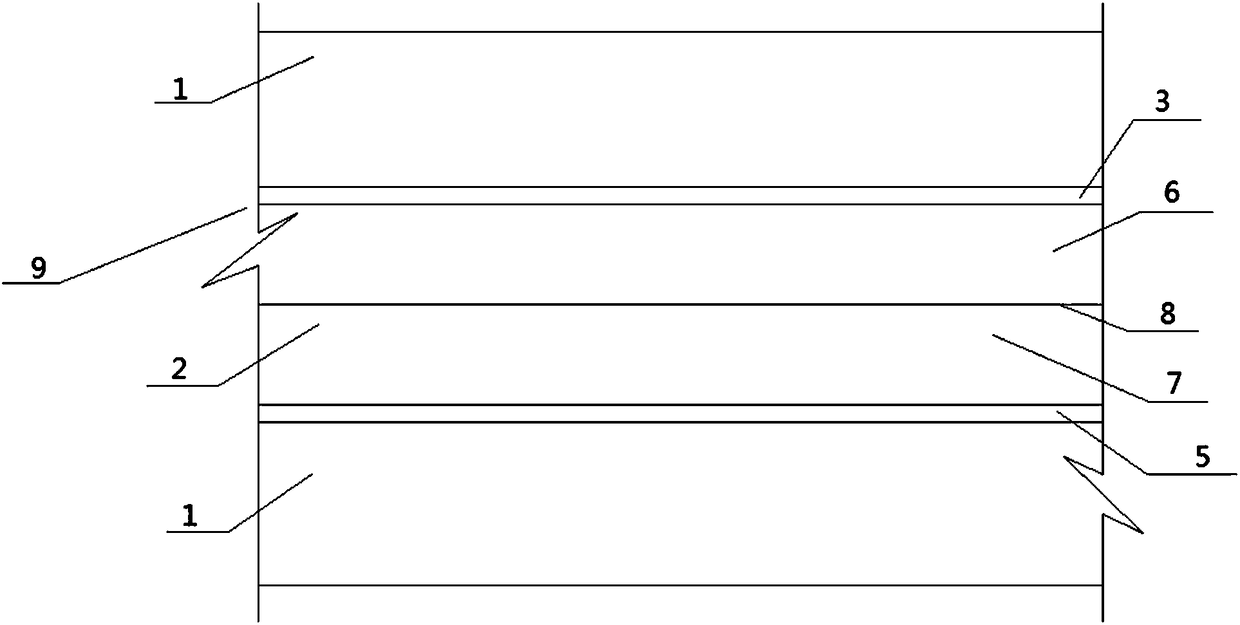

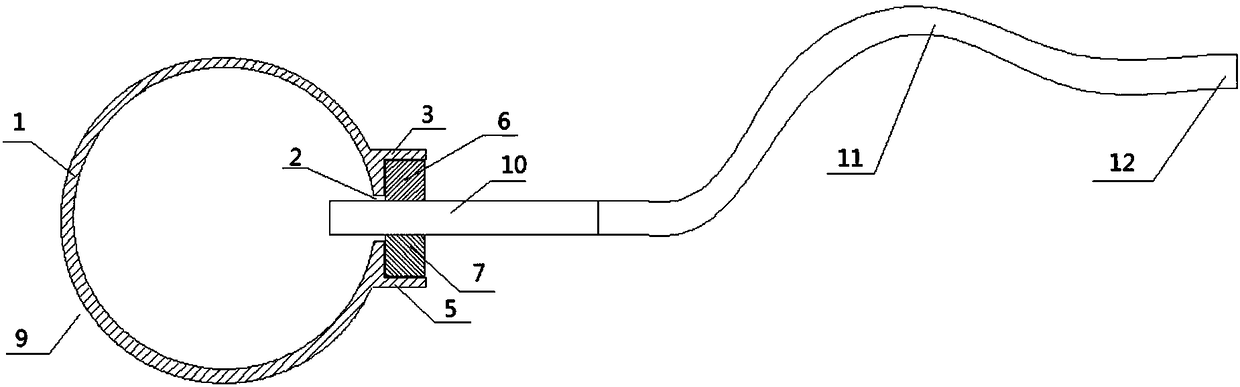

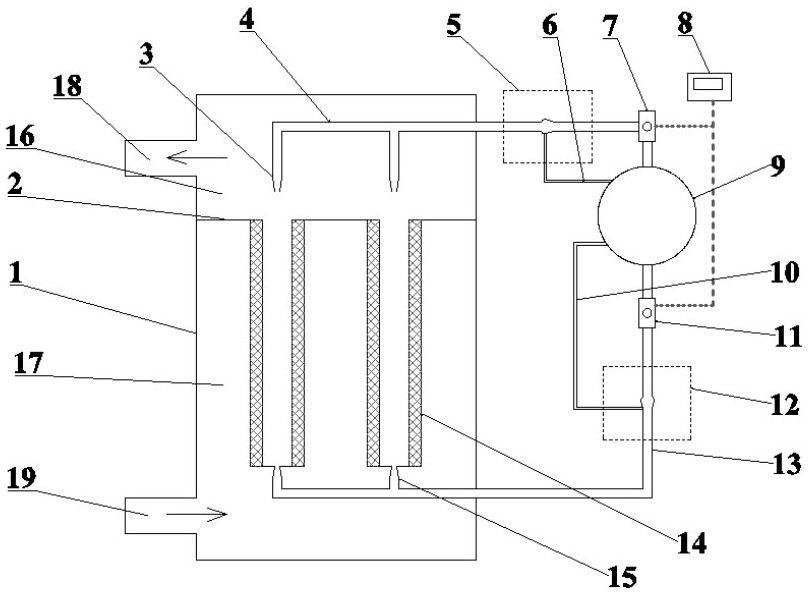

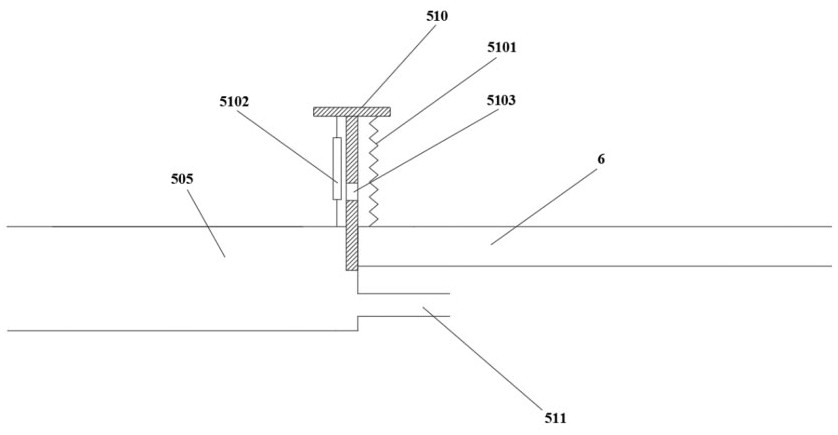

Radial oxygen production adsorption tower

ActiveCN103357243AUniform adsorptionImprove adsorption efficiencyDispersed particle separationOxygen preparationDiameter ratioMechanical equipment

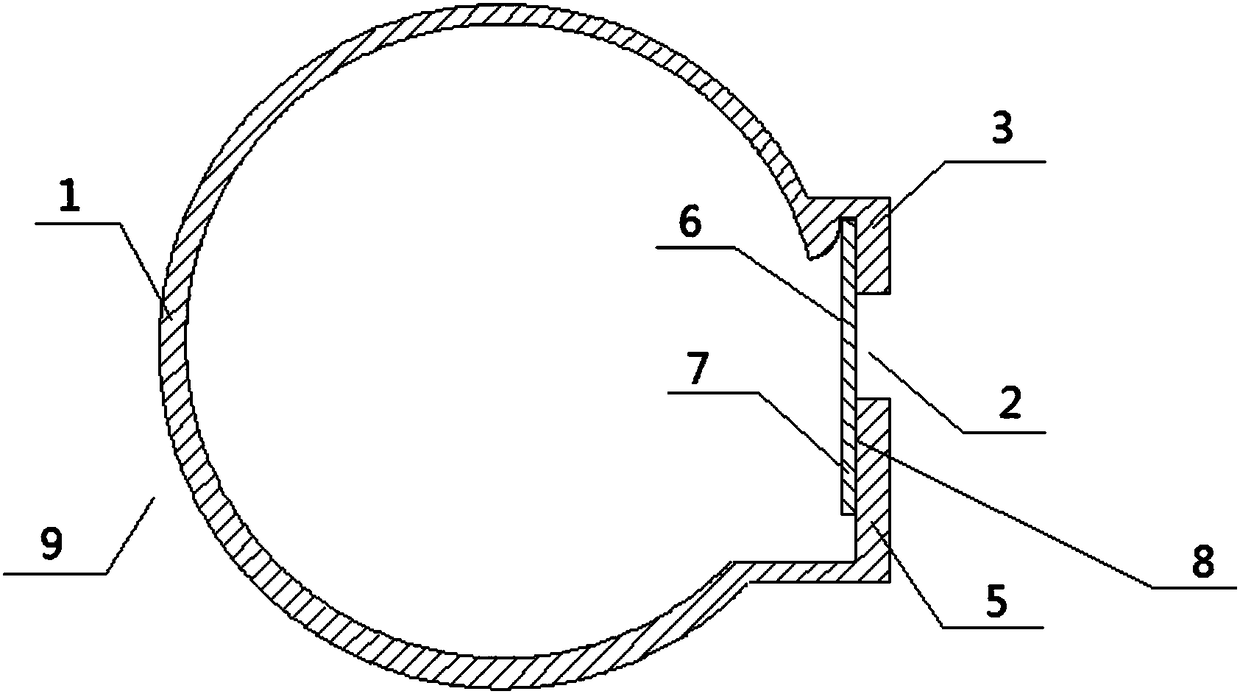

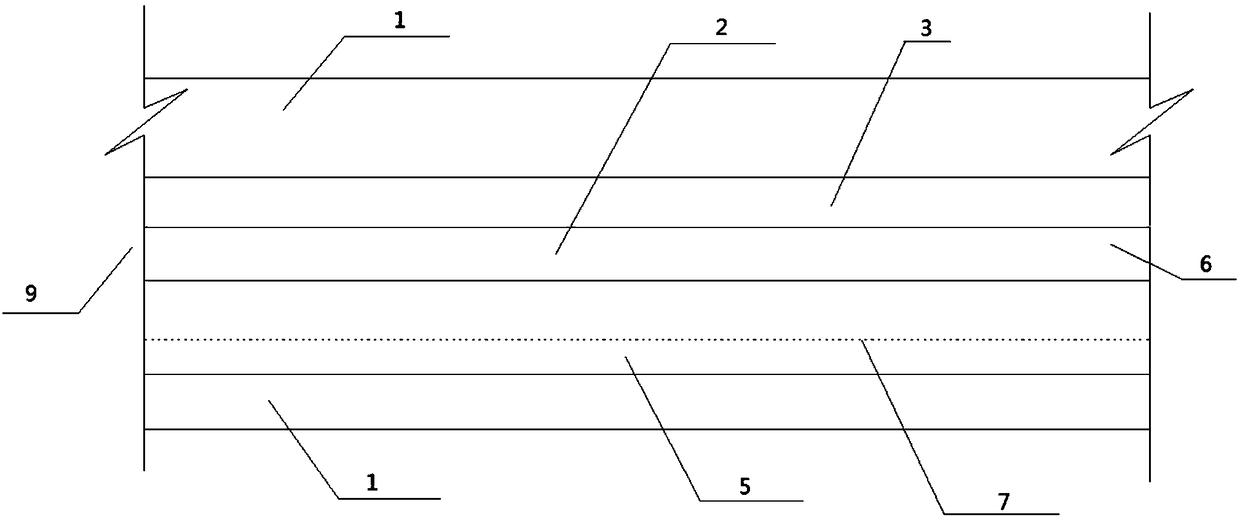

The invention provides a radial oxygen production adsorption tower, belongs to the technical field of mechanical equipment, and solves the technical problems of too small height-diameter ratio, too large occupied floor space, non-uniform adsorption and the like in the prior art. The oxygen production adsorption tower comprises a cylindrical tower body, an gas inlet assembly disposed at the bottom of the tower body, an gas outlet assembly disposed at the top of the adsorption assembly, an adsorption assembly disposed in the tower body and a circular gas transportation cavity formed between the inner wall of the tower body and the outer wall of the adsorption wall, wherein the gas inlet assembly is provided with a circular gas vent disposed at the periphery of the lower end of the adsorption assembly; the circular gas vent is communicated with the gas transportation cavity; a gas flow can be transported to the adsorption assembly radially by the gas transportation cavity; two ends of the adsorption assembly are sealed; the center of the adsorption assembly is provided with a gas collection channel for collecting finished product oxygen; the lower end of the gas collection channel is sealed; and the upper end of the gas collection channel is communicated with the gas outlet assembly. The radial oxygen production adsorption tower has the advantages of uniform adsorption, high adsorption efficiency, small occupied floor space, large-scale designability, etc.

Owner:杭州普菲科空分设备有限公司

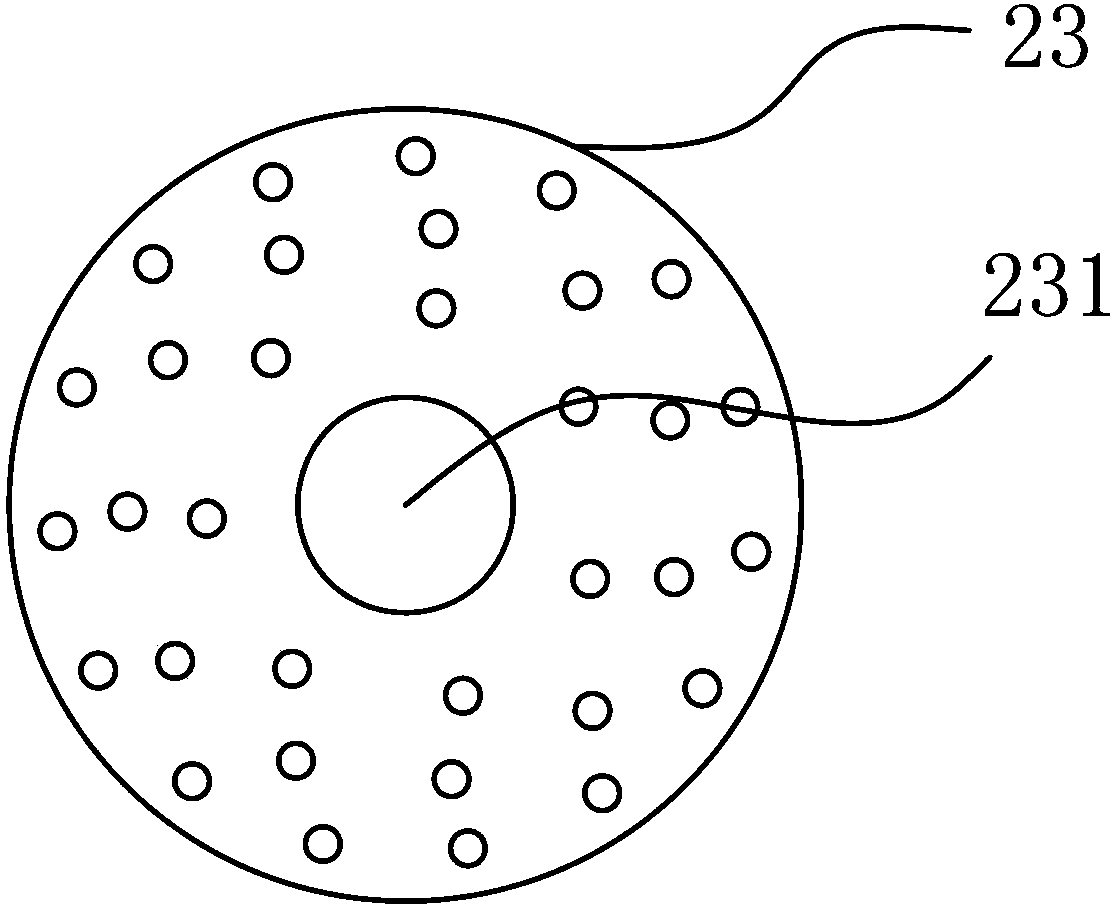

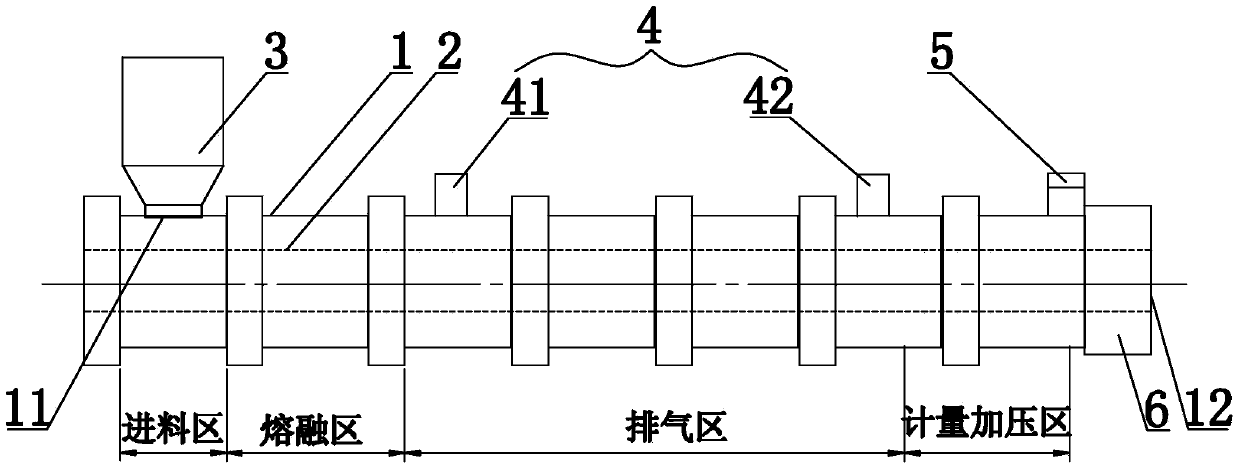

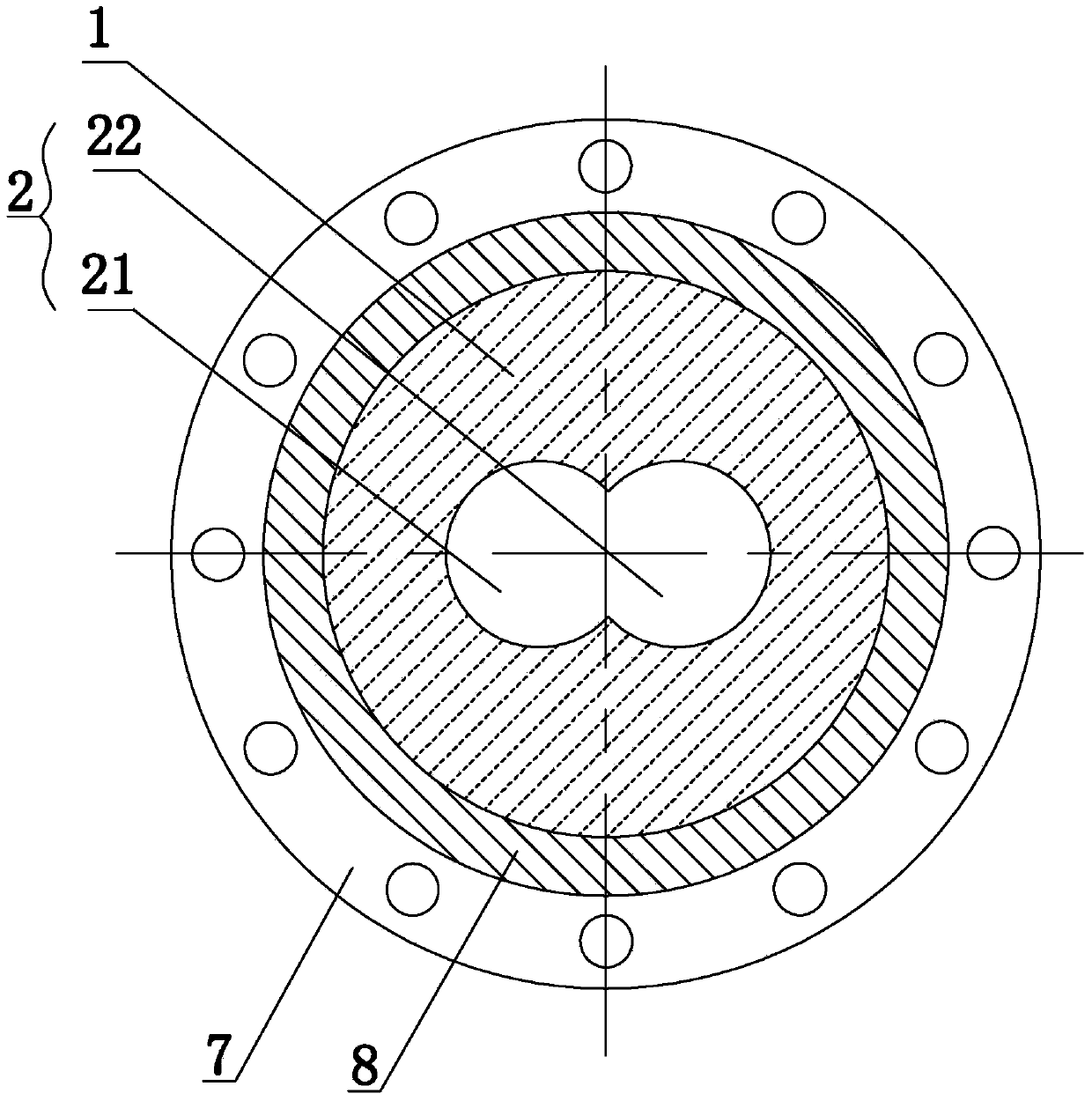

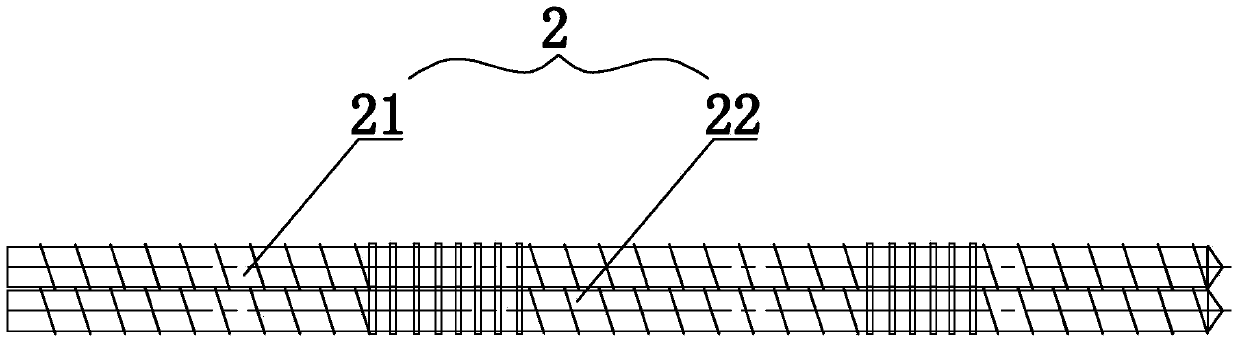

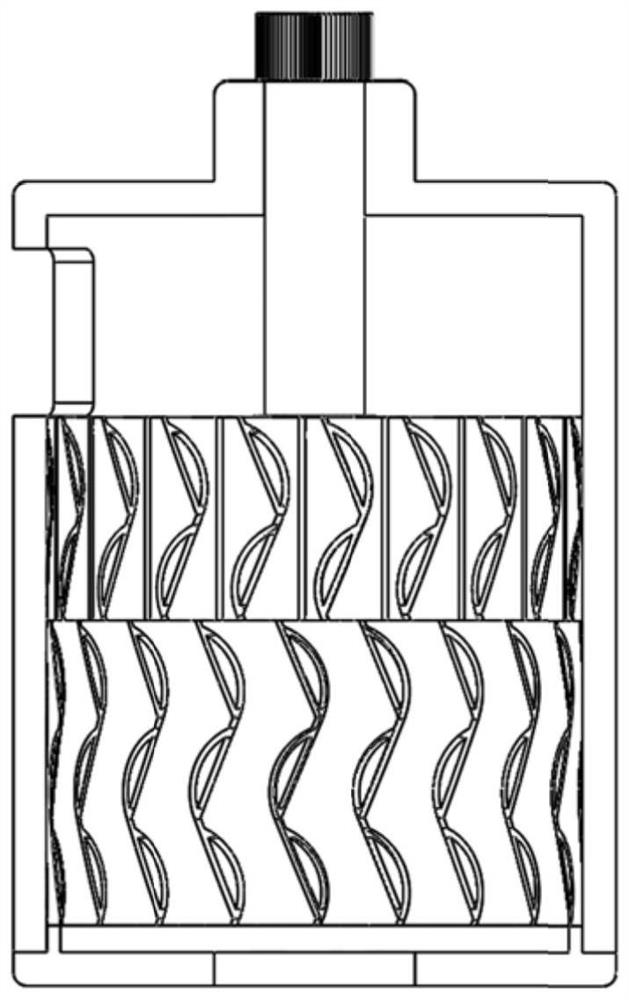

Full double-screw extruder and BOPET thin film extrusion process using same

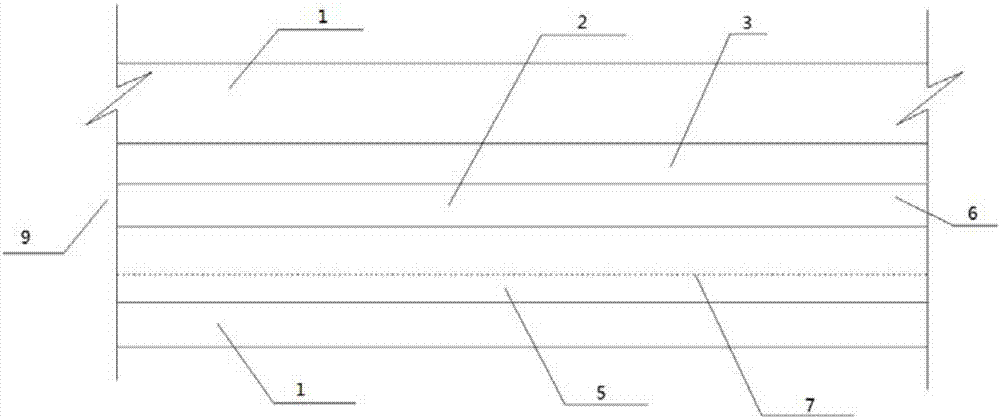

The invention relates to a full double-screw extruder and a BOPET thin film extrusion process using the same, and belongs to the technical field of plastic thin film machining. The extruder comprises a screw cylinder, a double-screw body arranged in the screw cylinder, a feeding opening, an exhaust opening and a metering pump. The feeding opening, the exhaust opening and the metering pump are arranged on the screw cylinder. The extruder is applied to plastic thin film machining and has the advantages of being short in machining procedure time, simple in equipment, high in machining efficiency, high in raw material utilization rate and the like.

Owner:浙江绍兴华东包装有限公司

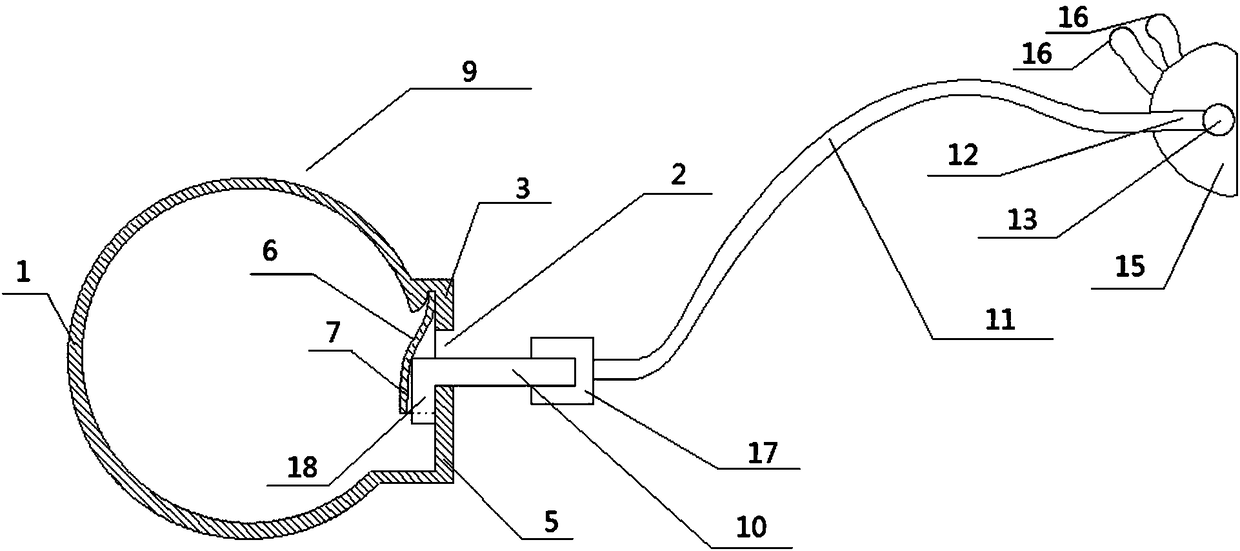

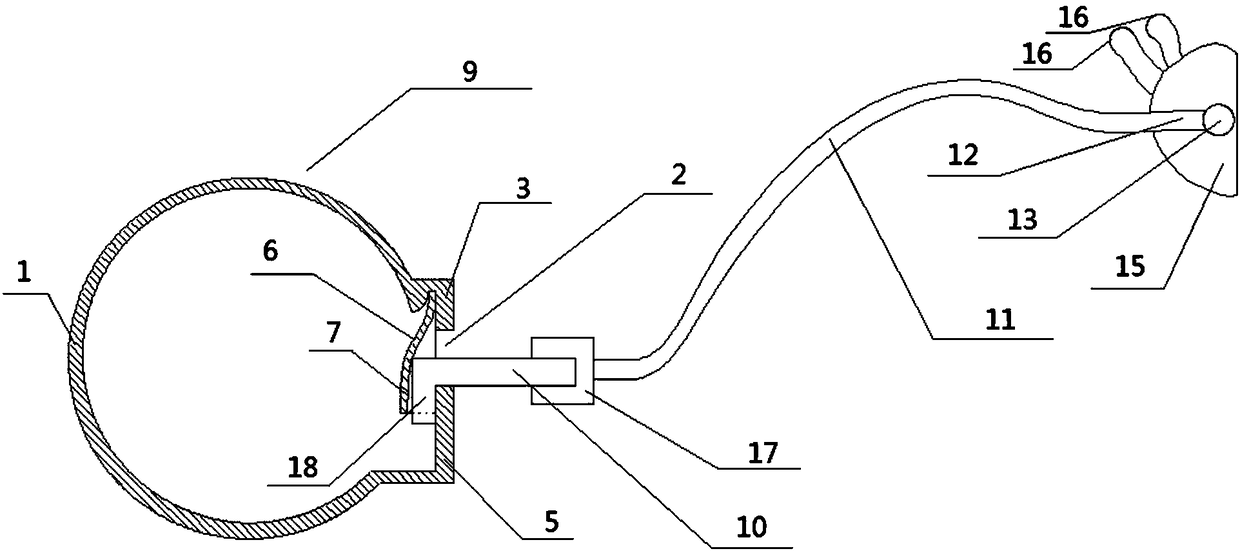

Air supply pipeline for inspiration

InactiveCN108261631AImprove convenienceIncrease inhalationFire rescueRespiratory apparatusEngineeringIndustrial engineering

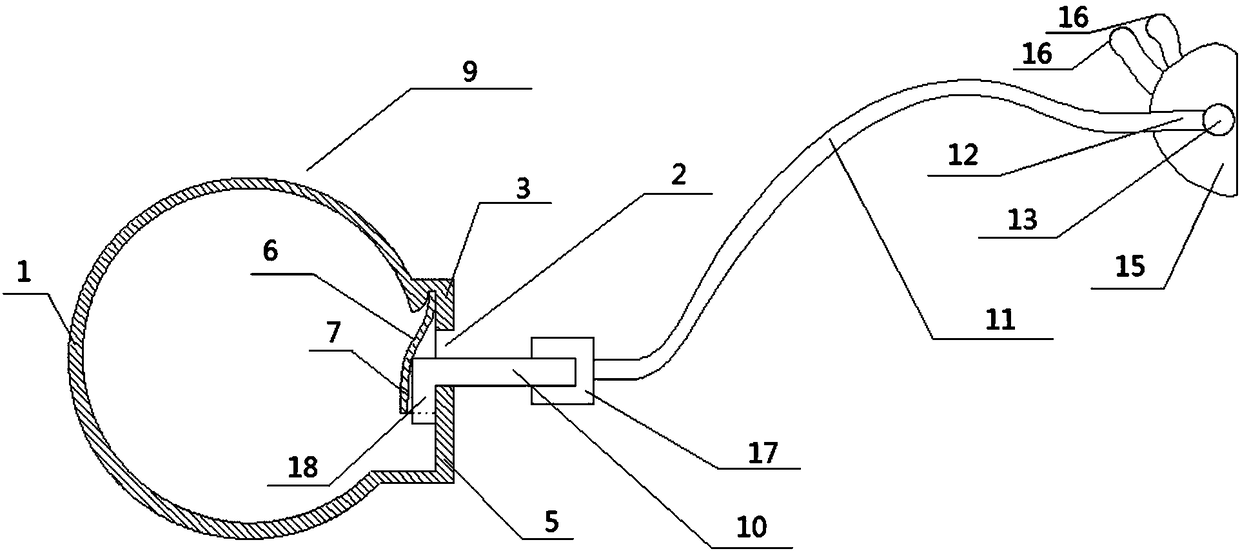

The invention discloses an air supply pipeline for inspiration. An opening in the internal hole direction of the air supply pipeline is formed in a pipe wall of the air supply pipeline; the pipe wallis made of rigid materials; the parts, on the two sides of the opening, of the pipe wall are separated by a distance; the part, on one side of the opening, of the pipe wall is fixedly connected with asealing strip; and the other side of the sealing strip is movably connected with the part, on the other side of the opening, of the pipe wall.

Owner:福州市鼓楼区撰歌亿自动化设备有限公司

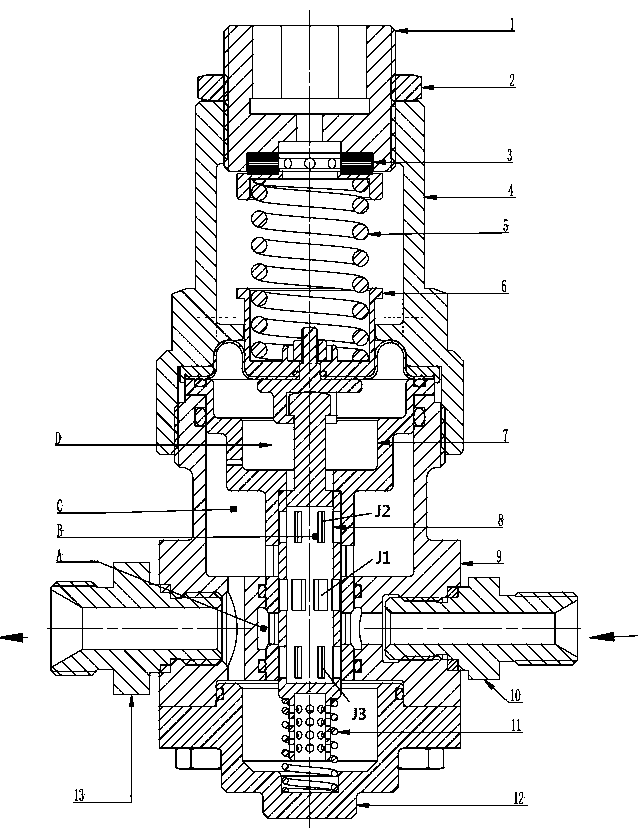

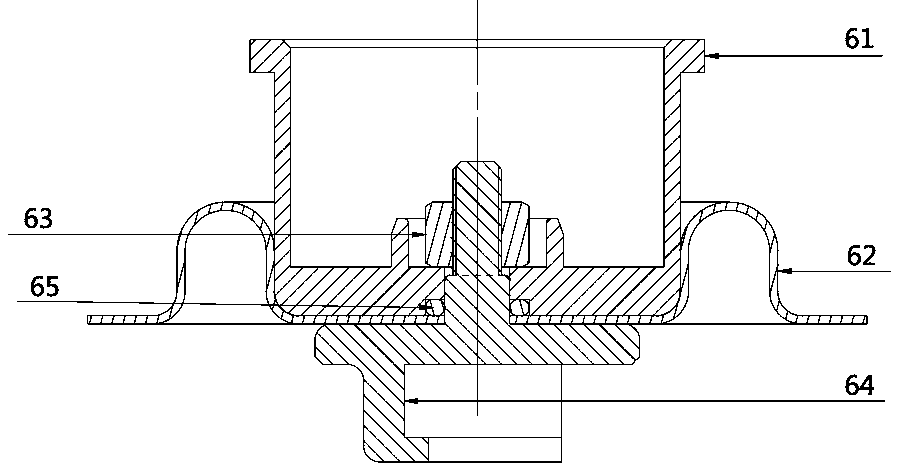

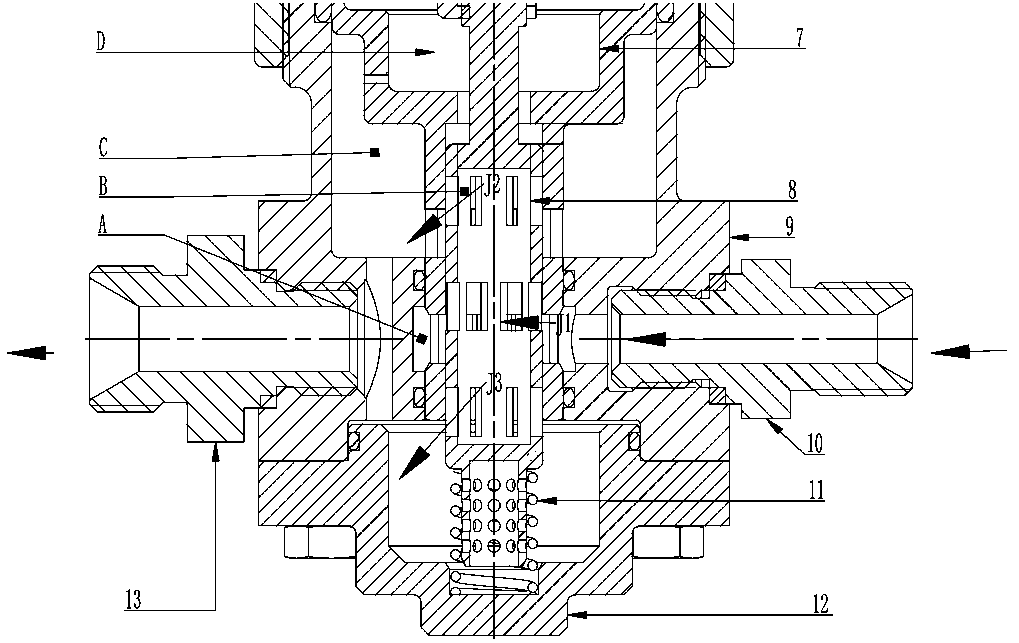

Impact-resistant reverse unloading distribution type high-precision gas pressure reduction device

ActiveCN110260005AReduce outlet pressure deviationHigh sensitivityValve members for absorbing fluid energyEqualizing valvesProduct gasInlet pressure

The invention provides an impact-resistant reverse unloading distribution type high-precision gas pressure reduction device. The device is designed by adopting a distribution pressure guide structure, outlet low-pressure gas at different positions is guided to the upper cavity of the valve core through feedback holes located in different sections of the valve core, the pressure deviation of the upper cavity and the lower cavity of the valve core is reduced, the upper cavity of the pressure reducing device is rapidly and accurately modeled in the adjusting process, and the sensitivity and the stability are improved. Meanwhile, the influence of inlet pressure is eliminated by adopting a reverse unloading structure design, the valve core has the unloading rod function, the high-pressure stress part of the valve element is isolated from the low-pressure stress part through the sealing assembly, pressure unloading design is realized, the upper sealing surface and the lower sealing surface of the valve body are subjected to equal-section design, so that the acting force of the inlet pressure acting on the upper end surface and the lower end surface of the valve core moving part is counteracted, the complete unloading of the inlet pressure is realized, so that the valve element is not influenced by the change of the inlet pressure in the adjusting process, so that the opening degree of the valve element is only influenced by the pressure change of the outlet.

Owner:XIAN AEROSPACE PROPULSION INST

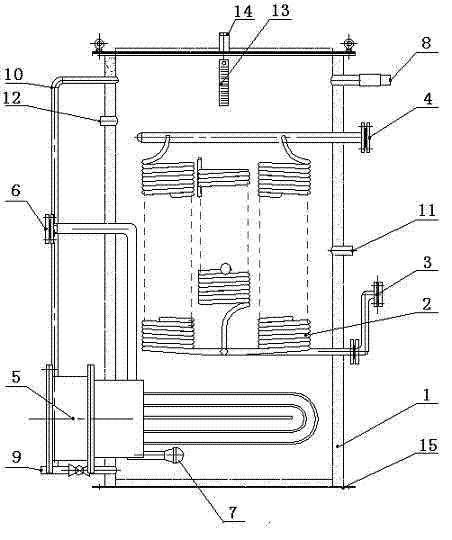

Plate type evaporating apparatus with steam heat pump

ActiveCN102309860ASimple structureCompact structureMultiple-effect evaporationSpray nozzleEngineering

The invention discloses a plate type evaporating apparatus with a steam heat pump, which comprises the steam heat pump, an evaporator and a separator, wherein the two input ends of the steam heat pump are respectively connected to a high-pressure driving steam inlet and a low-pressure driving steam inlet; the output end of the separator is connected with the steam heat pump through the low-pressure driving steam inlet; and the output outlet of the steam heat pump is connected with the evaporator or a pre-heater. The plate type evaporating apparatus has the following advantages that: (1) the energy-saving efficiency is high and the production cost is low; (2) the structure of the steam heat pump is very simple, because the steam heat pump is only internally provided with one nozzle and a rotating part is not required, the service life is long, and the running is reliable; (3) the apparatus is convenient to use and operate simply, an adjusting device is not required to be arranged if technical parameters are relatively stable, the apparatus is used according to designed parameters, and an automatic adjusting device can be additionally arranged to ensure the stability of outlet pressure of the apparatus; (4) the structure is compact, and the apparatus is convenient to mount; and (5) a silencer can be additionally arranged to reduce noise and meet the requirement of environmental protection.

Owner:上海普林克斯能源技术有限公司

Multi-stage throttling labyrinth pressure reducing valve

ActiveCN110131477ASmooth pressure regulationPrecise pressure regulationValve members for absorbing fluid energyEqualizing valvesCavitationEngineering

The invention provides a multi-stage throttling labyrinth pressure reducing valve which comprises a spring cover, a shell and a lower end cover. An adjusting nut is arranged at the upper end of the spring cover, an adjusting spring is arranged between the adjusting nut and a valve element, a return spring is arranged between the valve element and the lower end cover, the valve element is located in a sliding sleeve, the sliding sleeve is fixed in the shell, the shell forms a high-pressure cavity of an inlet and an outlet, a transition cavity is formed in the valve element, the shell and the sliding sleeve form a low-pressure cavity I, the lower end cover and the valve element form a low-pressure cavity II, the sliding sleeve and the valve element are correspondingly provided with upper throttling ports which communicate with the low-pressure cavity I and the transition cavity, the sliding sleeve and the valve element are correspondingly provided with middle throttling ports which communicate with the high-pressure cavity and the transition cavity, and the valve element is provided with a lower throttling port which communicates with the low-pressure cavity II and the transition cavity. The multi-stage throttling labyrinth pressure reducing valve has the advantages that pressure regulation is smooth and accurate, the anti-interference capability of the valve is improved, the structure is simple, maintenance is convenient, the service life is long, the cavitation risk of primary throttling high pressure difference is reduced, medium pressure feedback is more sensitive, and precision is higher.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

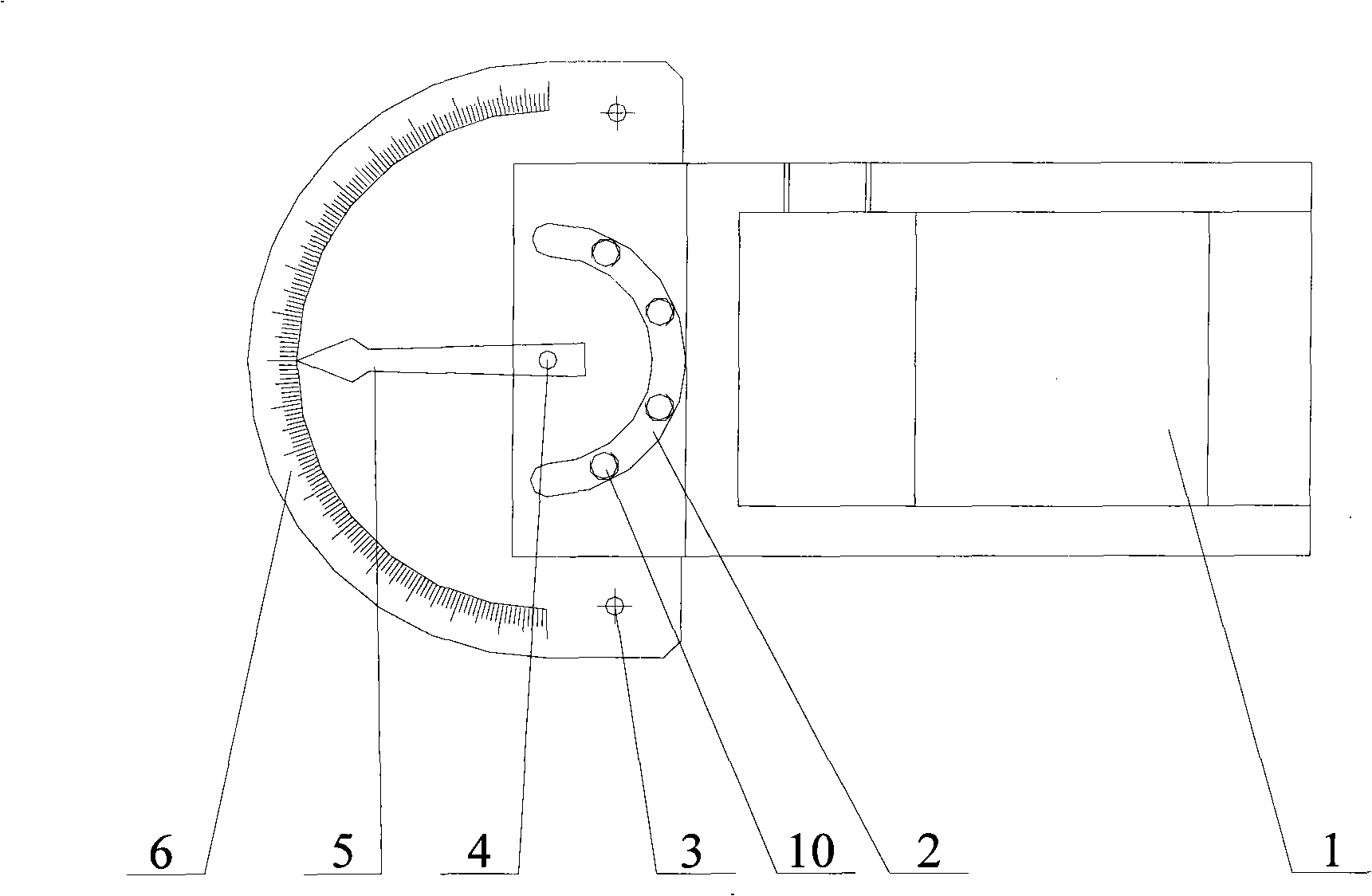

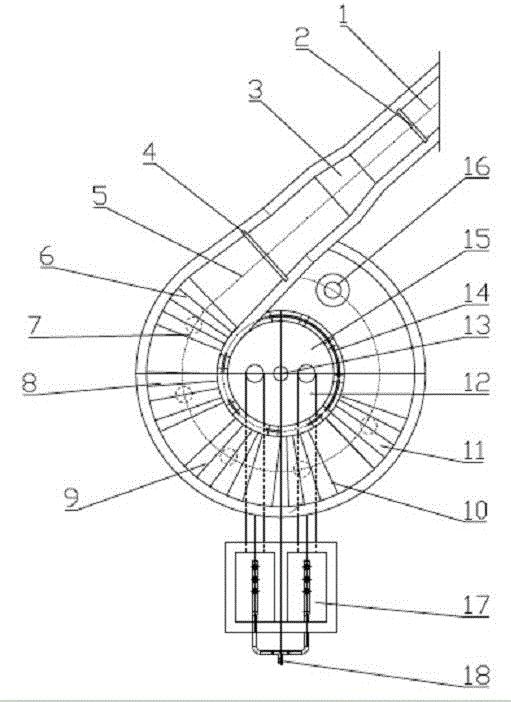

Air purge spray nozzle for rolling production

InactiveCN101406903AReduce consumptionLarge aspect ratioWork treatment devicesSpray nozzlesLow noiseCurrent distribution

The invention provides an air purging nozzle for rolling production. The air purging nozzle comprises a flat nozzle, a position pointer and an indicating dial, wherein the indicating dial is fixed on a mounting base; the position pointer is positioned on the flat nozzle; the position pointer and the flat nozzle are hinged with the indicating dial through a hinged joint; the flat nozzle comprises an air inlet, an air outlet and a nozzle body; the side part of the nozzle body is provided with an annular groove; an adjusting bolt runs through the annular groove and is connected with the indicating dial; the adjusting bolt is locked or loosened to realize the locking or separation between the flat nozzle and the indicating dial; the inside of the nozzle body is provided with a hollow cubage cavity; the air inlet is communicated with the air outlet through the hollow cubage cavity of the inside of the nozzle body; and the section of the air outlet is rectangular. The air purging nozzle has the characteristics of stable outlet pressure, even current distribution, less air consumption and low noise; the position indication is convenient for field adjustment and process stability; and the air purging nozzle has energy conservation and environmental protection, is a new practical design, and is simple and applicable.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

High-position water source drip-irrigation gravity turbine desilting filter system

ActiveCN106693458AZoom in timeImprove work efficiencySedimentation settling tanksWater sourceDrip irrigation

The invention relates to a high-position water source drip-irrigation gravity turbine desilting filter system. The system comprises an approach channel, an annular desilting filter tank, a sand accumulation and discharge tank, a clean water tank and laminated filter systems, wherein a front end inlet of the approach channel is connected with the sand accumulation and discharge tank through a coarse filter screen; the approach channel is provided with a water inlet gate, and the tail end is provided with an approach channel transition section; the approach channel transition section communicates with the desilting filter tank; a primary five-stage filter screen set, a secondary five-stage filter screen set, a tertiary five-stage filter screen set, a quaternary five-stage filter screen set and a quinary five-stage filter screen set are sequentially arranged in the desilting filter tank; the inner wall of the desilting filter tank is provided with an overflow filter screen, and connected with the clean water tank; the bottom of the clean water tank is respectively provided with two clean water tank water outlets and one clean water tank sand outlet; the two clean water tank water outlets are respectively connected with the two laminated filter systems; and the two laminated filter systems are connected with a micro irrigation system through an outlet pressure maintaining valve. The system has the advantages of low operating cost and high work efficiency.

Owner:GANSU DAYU WATER SAVING +2

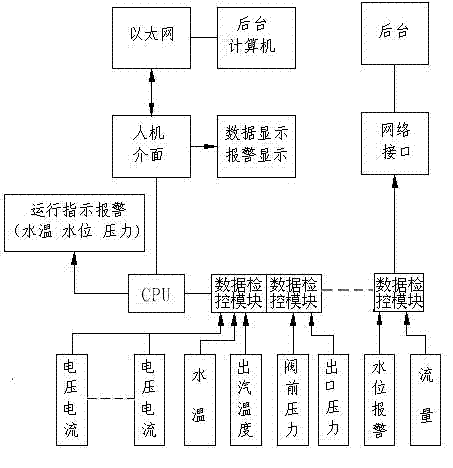

Liquid-gas state converter of carbon dioxide/nitrogen and conversion system

ActiveCN103573282AEvenly heatedReduce lossDust removalFire preventionAutomatic controlCarbon dioxide

The invention relates to a liquid-gas state converter of carbon dioxide / nitrogen and a conversion system. The converter comprises a casing. Liquid inlet pipes and gas exhaust pipes are arranged; a heat exchange device is arranged in the casing; a heater is arranged below the heat exchange device; a heating pipe of the heater is located below the heat exchange device; the conversion system comprises a plurality of converters; the liquid inlet pipes of the plurality of the converters are connected with one conveying pipe; the gas exhaust pipes of the plurality of the converters are connected with a conveying pipe; each converter is provided with a monitoring cabinet; and the monitoring cabinets can monitor the working conditions and the working parameters of the converters and automatically control and regulate the operation of the converters according to the detected working parameters. According to the converter and the conversion system, the heat energy loss is small, the heat efficiency is high, and the energy-saving effect is good; and the conversion system can realize automatic segmentation control and regulation according to the operation state of the system and can also realize automatic control of all parameters of output gaseous carbon dioxide / nitrogen. The converter and the conversion system are mainly applicable to fire prevention and extinguishing under mines.

Owner:冯琛

Gas pressure regulator valve body

ActiveCN101260949AStable outlet pressureAvoid noiseOperating means/releasing devices for valvesEqualizing valvesPneumatic pressurePressure regulator

The invention relates to a valve body of a gas-pressure regulator capable of reducing noises, comprising an inlet and an outlet. The caliber of the inlet is less than that of the outlet. In the invention, the caliber of the inlet is less than that of the outlet, which facilitates improving the situation that local gas disorder occurs at the outlet after a barometric pressure of the outlet reduces, so as to stabilize the pressure of the outlet and prevent the generation of noises.

Owner:JIANGSU COSHIN GAS EQUIP

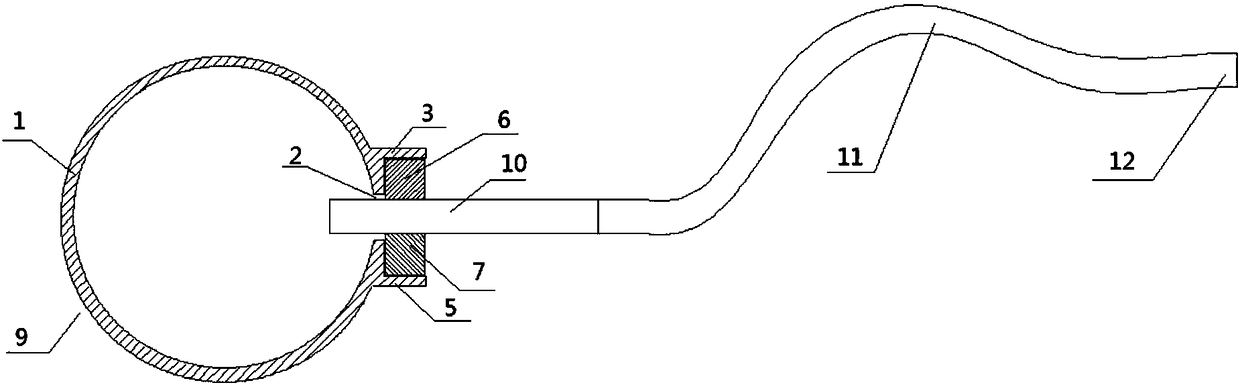

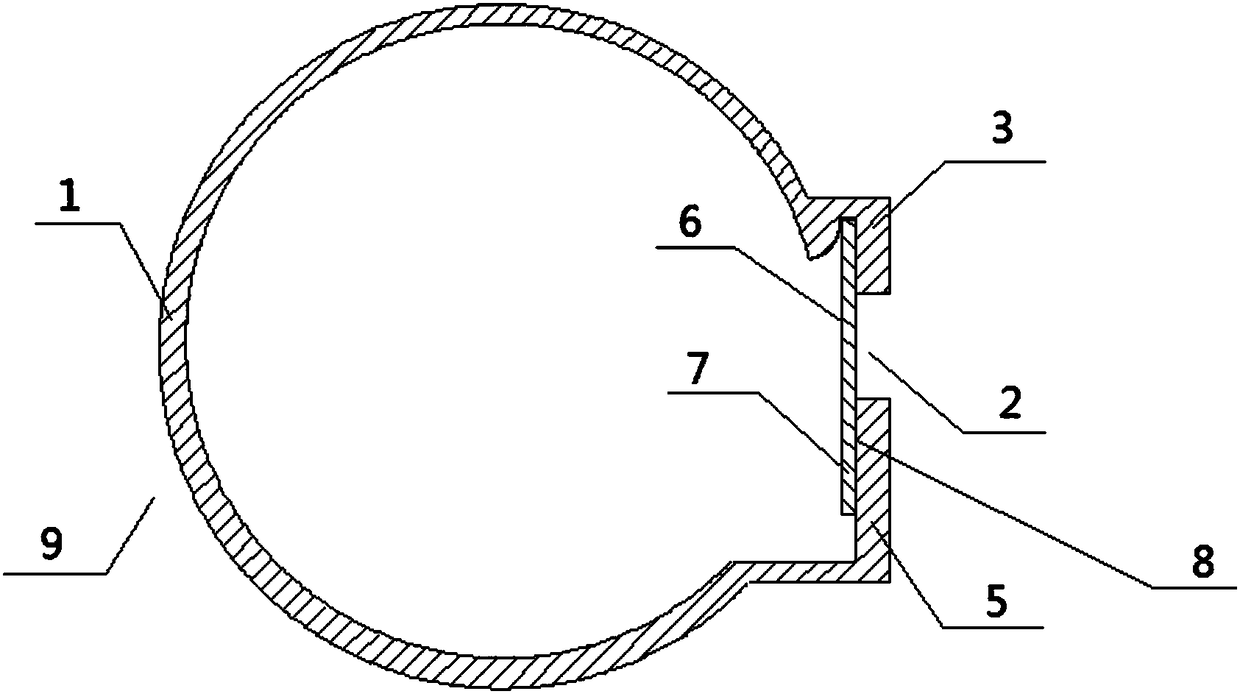

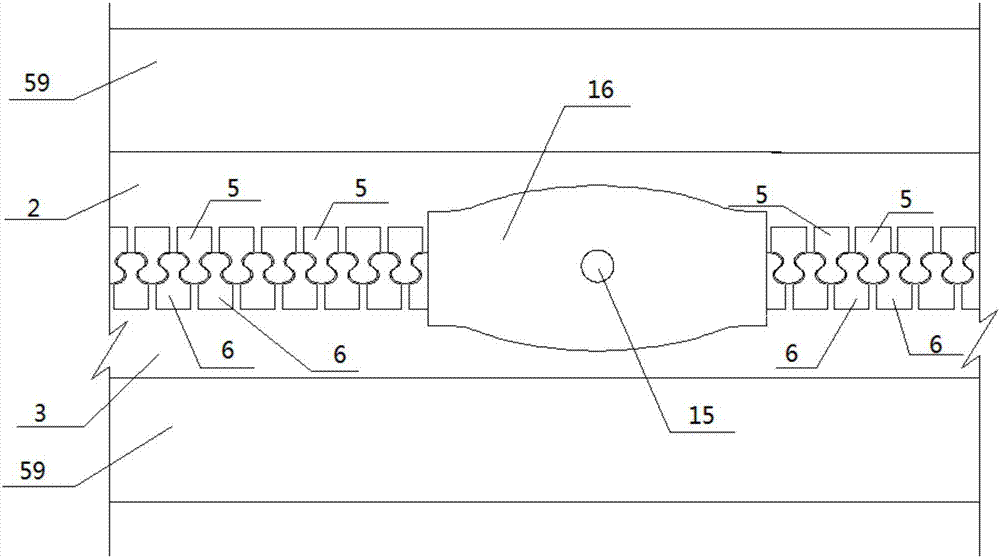

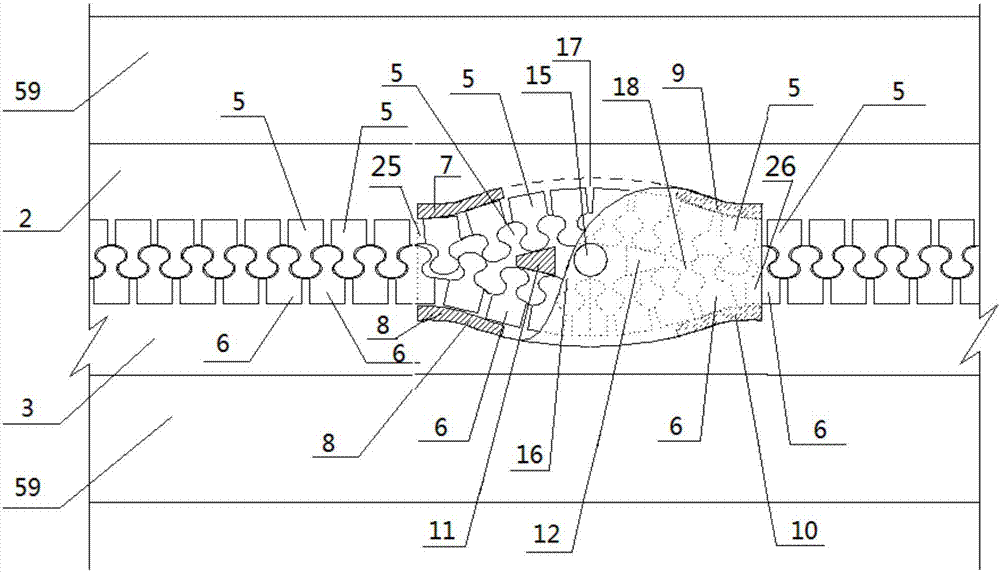

Gas supply pipeline

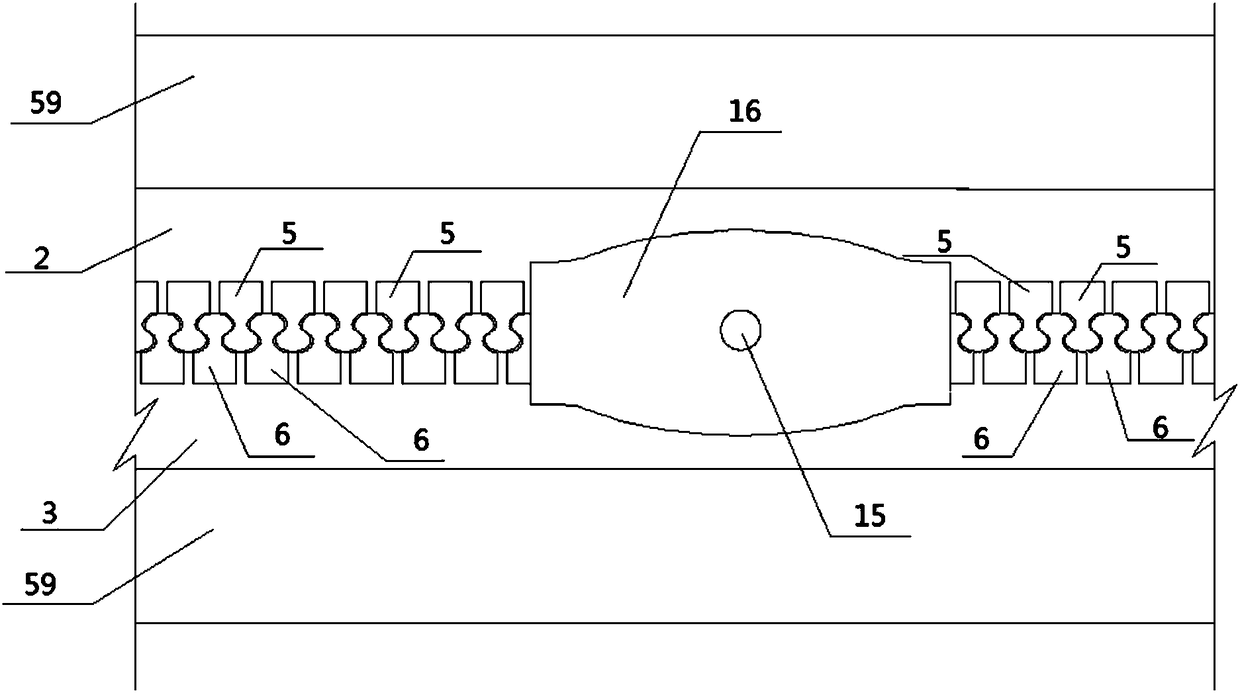

InactiveCN108261648AEasy to useGuaranteed oxygen demandFire rescueRespiratory apparatusEngineeringGas supply

The invention discloses a gas supply pipeline. According to the technical scheme, the pipe wall of the gas supply pipeline is provided with a linear opening in the extending direction of the gas supply pipeline, the pipe walls on the two sides of the opening are separated and are away from each other by a certain distance or the pipe walls on the two sides of the opening are closed and can be opened, all or part of the pipe wall is made of an elastic material, the opening of the gas supply pipeline can simultaneously allow a plurality of people to be close for sucking the air directly throughmouths or sucking the air by inserting a vent pipe into the opening, after the vent pipe is inserted into the gas supply pipeline, the pipe wall of the part, on the side edge of the opening, of the gas supply pipeline or a sealing component connected with the pipe wall of the part, on the side edge of the opening, of the gas supply pipeline can be wrapped around the vent pipe, and the vent pipe can move in the extending direction of the gas supply pipeline in the opening.

Owner:吴超然

Industrial heat energy recycling system

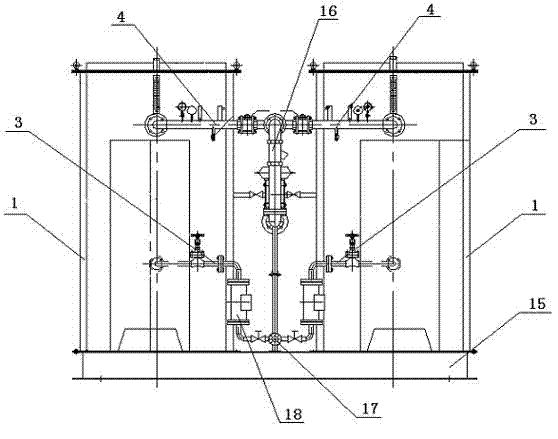

ActiveCN102313311AAvoid cloggingImprove heat transfer effectLighting and heating apparatusSpace heating and ventilation detailsParticulatesAutomatic control

The invention discloses an industrial heat energy recycling system, which comprises a heat side water inlet pipe, a heat side water return pipe, a water supply pipe and a water return pipe, wherein the heat side water inlet pipe and the heat side water return pipe input industrial heat energy; the water supply pipe and the water return pipe recycle the industrial heat energy; the heat side water inlet pipe and the heat side water return pipe as well as the water supply pipe and the water return pipe respectively form two water circulation systems; the water circulation system formed by the water supply pipe and the water return pipe is a closed circulation system; and heat energy between the two water circulation systems is exchanged by a heat exchanger so as to recycle the industrial heat energy. The industrial heat energy recycling system has the beneficial effects that heat exchange effect is obviously improved, outlet pressure is more stable, scale formation and particulate matterblockage can be effectively prevented, a multipoint control strategy of small flow / big temperature difference is adopted to reduce flow, lower electrical load and save operation cost, the industrialheat energy recycling system has the characteristics of artificial intelligence and full automatic control, remote control is realized by a communication interface, heat supply energy consumption is saved, and the operation cost is lowered.

Owner:江苏安众环保技术有限公司

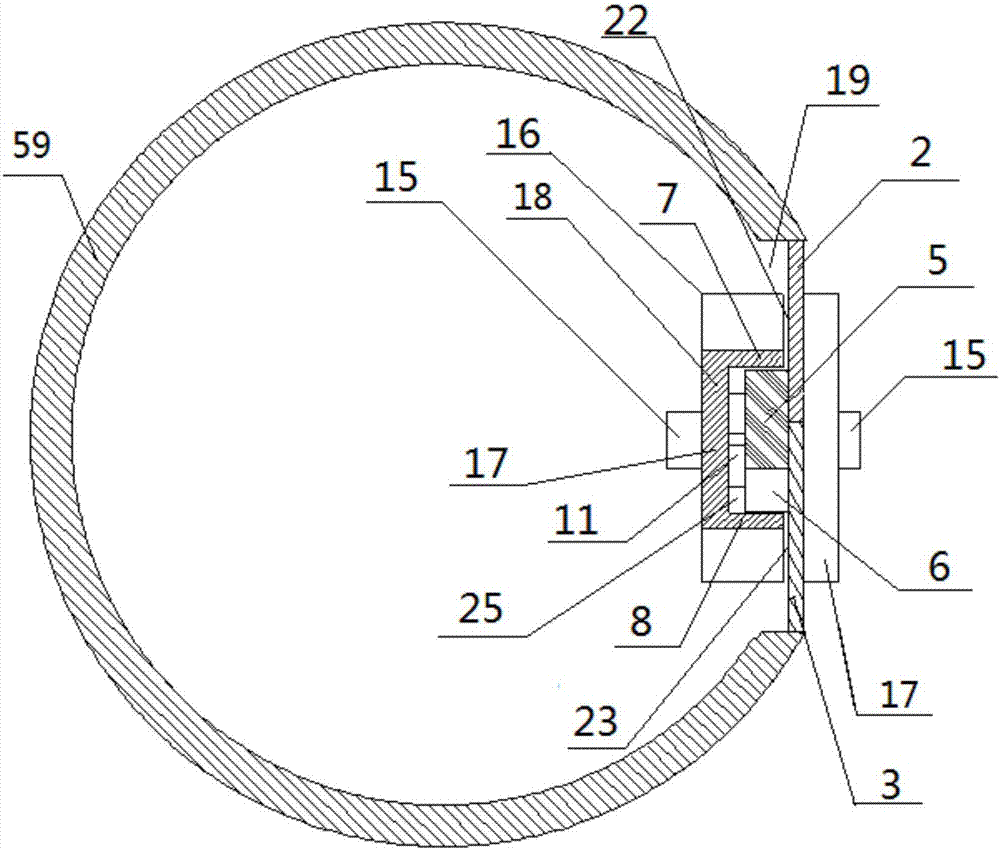

Air supply pipeline

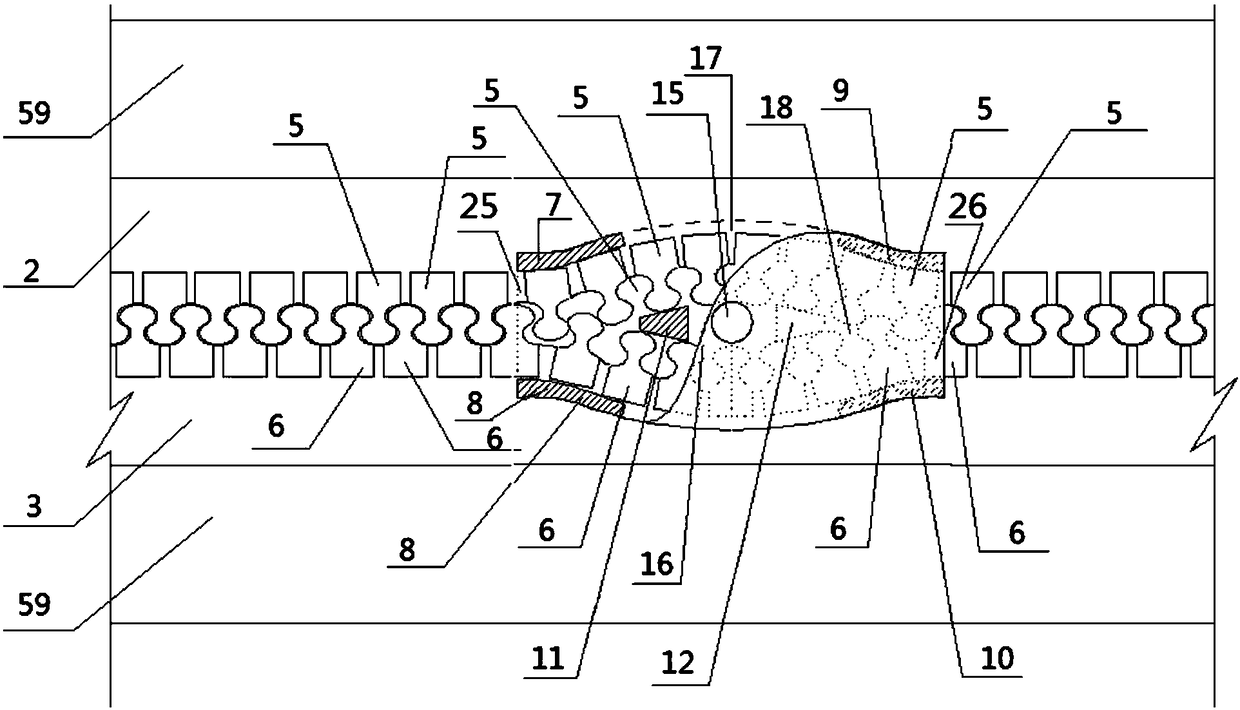

InactiveCN110478821APositive pressure guaranteeRealize automatic controlFire rescueRespiratory apparatusMechanical engineeringBreathing

The invention provides an air supply pipeline. The pipe wall of the air supply pipeline is provided with an opening in the length direction of the pipeline, the two sides of the opening are correspondingly connected and provided with a chain belt I and a chain belt II, chain teeth I are arranged on one side edge of the chain belt I, chain teeth II are arranged on one side edge of the chain belt II, a ventilation sliding block device is arranged at the joint between the chain belt I and the chain belt II, the ventilation sliding block device structurally comprises guide ports formed in the twoends, a bottom plate, a cover plate and an inner core body, and the bottom plate is connected with the cover plate through the inner core body. According to the air supply pipeline, the parts, on theouter sides of the guide ports of the ventilation sliding block device, of the chain teeth I of the chain belt I and the chain teeth II of the chain belt II are in an engaged state, the parts, locatedin the ventilation sliding block device, of the chain teeth I and the chain teeth II are disengaged by the inner core body, and air outlet holes are formed in the part, located inside the air supplypipeline, of the bottom plate or the cover plate of the ventilation sliding block device.

Owner:吴旭榕

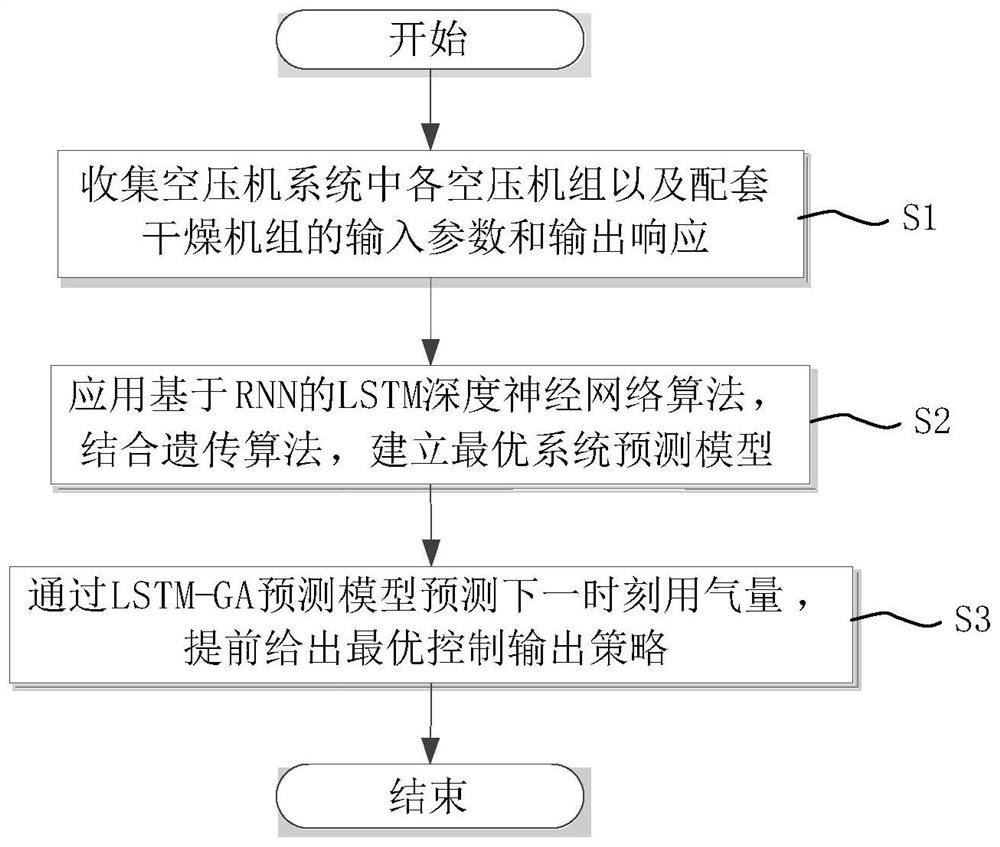

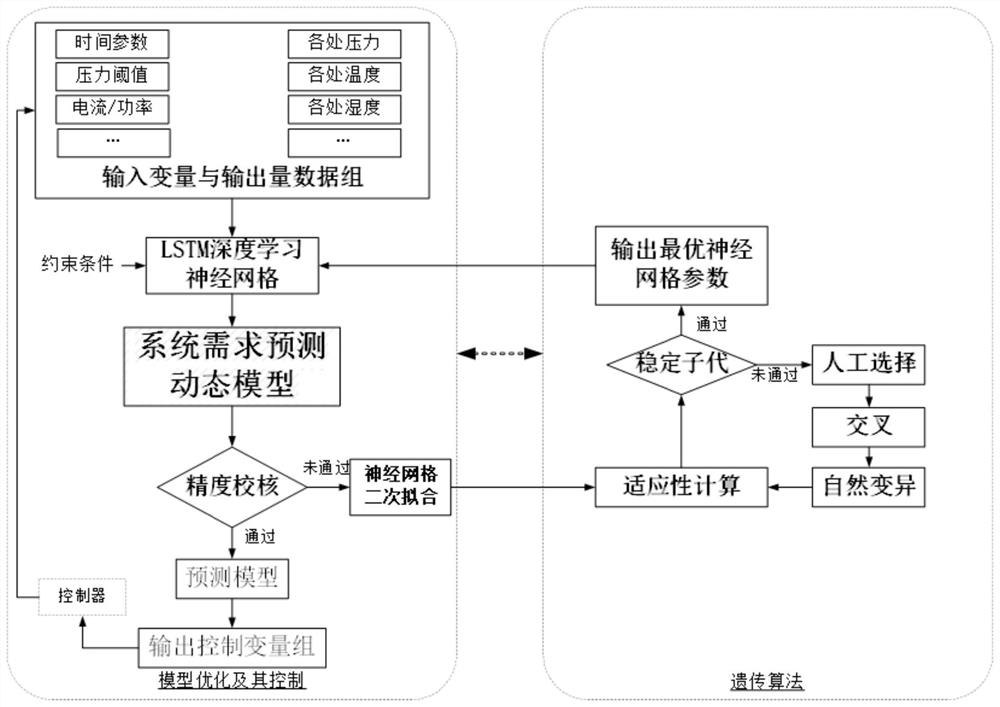

Air compressor system control method based on data driving

PendingCN112539161AReduce human interventionStable outlet pressurePump controlPump installationsGenetics algorithmsDeep neural networks

The invention discloses an air compressor system control method based on data driving. The air compressor system control method comprises the following steps of S1) collecting input parameters and output responses of each air compressor unit and a matched drying unit in an air compressor system; S2) establishing an optimal system prediction model by applying an RNN-based LSTM deep neural network algorithm and combining a genetic algorithm; and S3) predicting the air consumption at the next moment through an LSTM-GA prediction model, and giving an optimal control output strategy in advance. According to the air compressor system control method based on data driving, on the premise that the air supply requirement is met, human intervention is reduced, it is guaranteed that the air outlet pressure is stable, the overall energy efficiency of the system is improved to the maximum degree, and the purpose of saving energy is achieved.

Owner:SHANGHAI ANYO ENERGY SAVING TECH

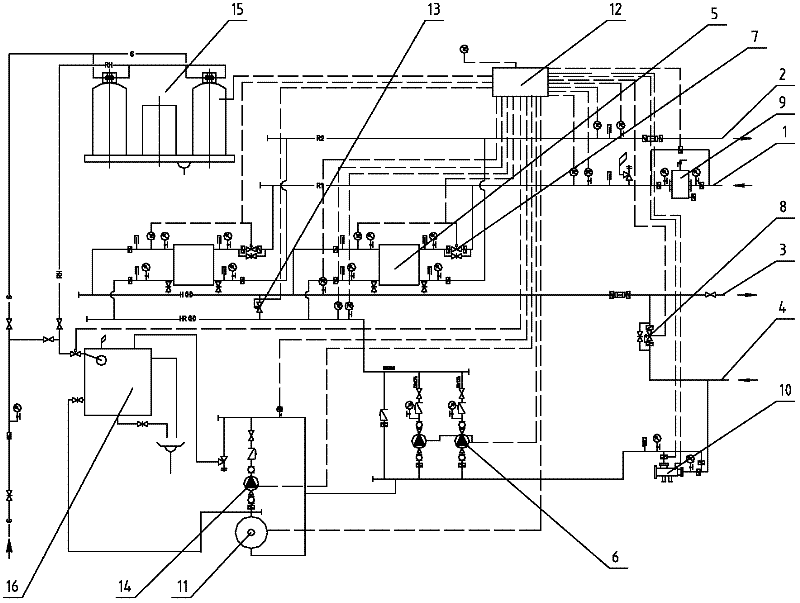

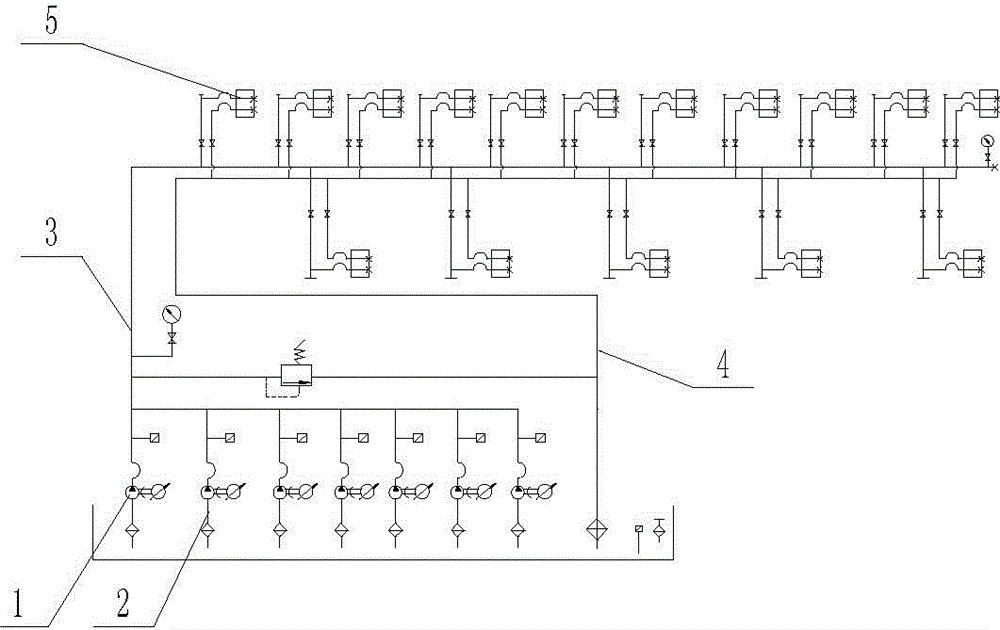

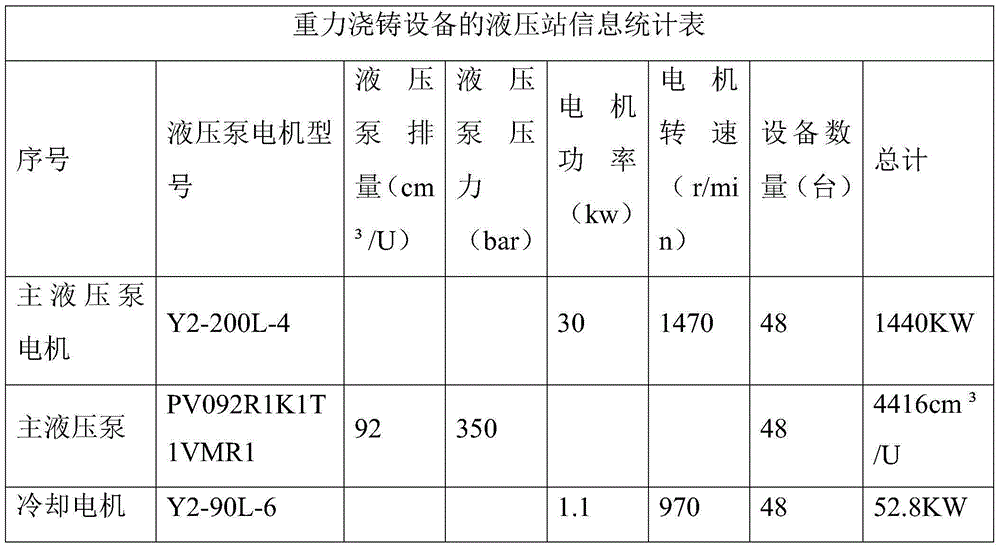

Centralized pressure supplying method of hydraulic stations

ActiveCN104989691AImprove effective utilizationReduce the numberServomotor componentsFluid-pressure actuator componentsEngineeringComputer terminal

The invention provides a centralized pressure supplying method of hydraulic stations to overcome the defects that in traditional large and medium machining factories, the effective utilization rate of hydraulic stations is low, and waste of electric energy is serious. The method comprises the following steps that A, when machine tools including the hydraulic stations work with the full load, the needed maximum flow and the needed maximum pressure are counted, and the accumulated values of the maximum flow and the maximum pressure are calculated respectively; B, 20%-30% of the maximum flow accumulated value and 20%-30% of the maximum pressure accumulated value are taken as the rated flow value and the rated pressure value of a new hydraulic station; C, a pressure oil pipe and an oil return pipe are connected to the new hydraulic station, and terminal valve sets of all the machine tools are connected to the pressure oil pipe and the oil return pipe in parallel; and D, pressure is supplied to the pressure oil pipe through the new hydraulic station, the terminal valve set, corresponding to the machine tool, on the pressure oil pipe is opened according to the specific working machine tool, hydraulic branches corresponding to the machine tools need pressure maintaining by adjusting the terminal valve sets, and the terminal valve sets corresponding to the machine tools are closed when the machine tools do not work.

Owner:重庆市博平液压机械有限公司

Air supply pipeline for providing breathing air

PendingCN107115602AGuaranteed oxygen demandFirmly connectedFire rescueRespiratory apparatusGas supplyMechanics

The invention provides an air supply pipeline for providing breathing air. The air supply pipeline is characterized in that an opening or openable opening is formed in a pipe wall of the air supply pipeline; the pipe walls on the two sides of the opening are separated and are away from each other by a certain distance or the pipe walls on the two sides of the opening are combined into a crack; the length of the opening is equal to the length of the air supply pipeline or the length of the opening is smaller than the length of the air supply pipeline; the pipe wall on one side of the opening is fixedly connected with one end of a sealing strip; the other end of the sealing strip and the pipe wall on the other side of the opening are in magnetic attraction or the other end of the sealing strip and another sealing strip connected with the pipe wall on the other side of the opening are in magnetic attraction; vent pipes can be inserted into the opening and communicate with inner holes of the air pulley pipeline after the sealing strips are moved; and the sealing strips wrap the vent pipes through magnetic attraction or the pipe wall, on the side edge of the opening, of the air supply pipeline wraps the vent pipes.

Owner:福州超高层消防科技有限公司

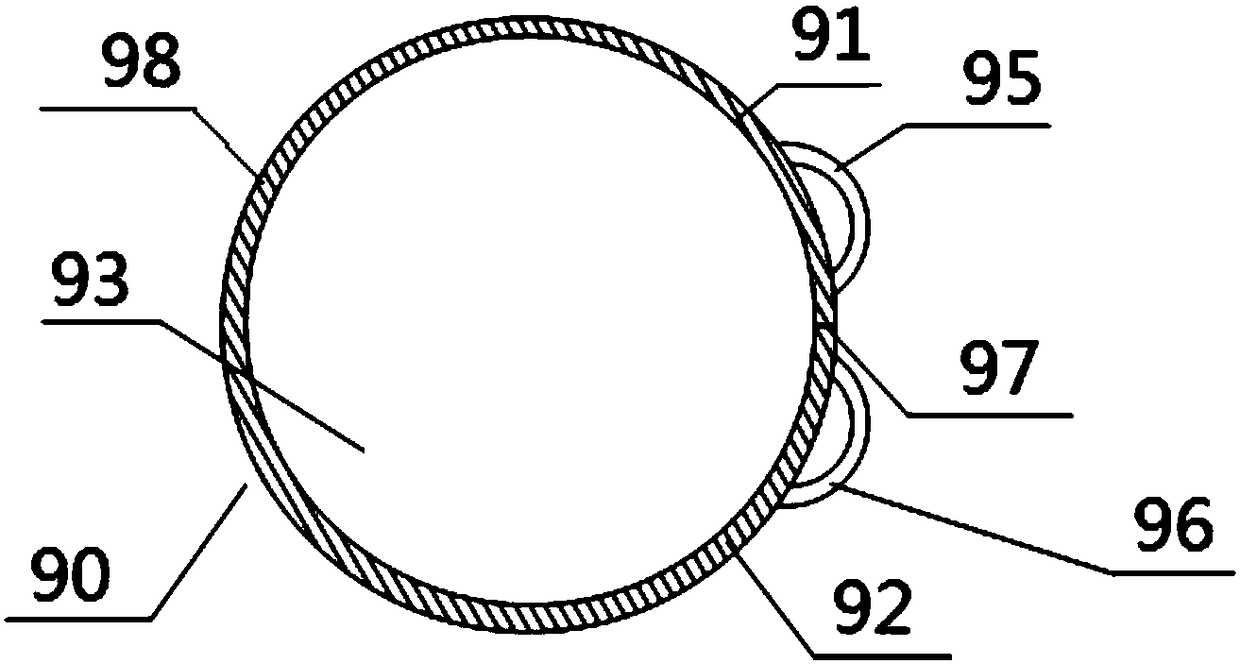

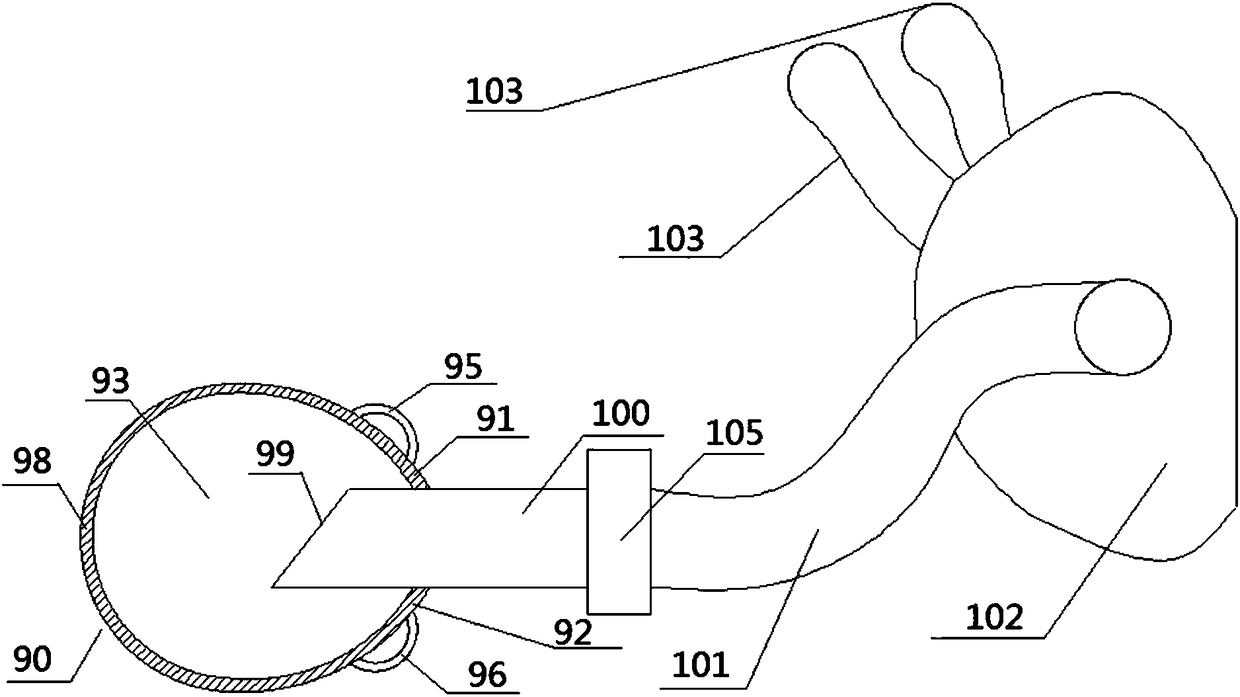

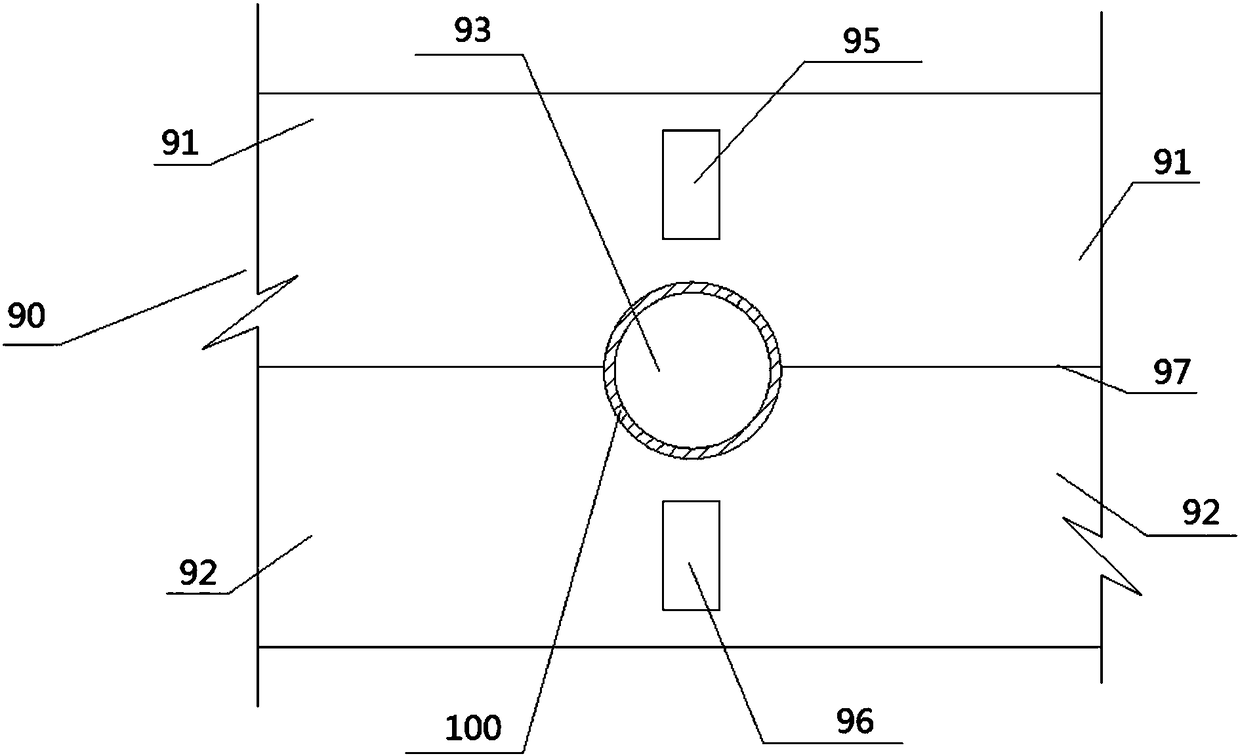

Anti-smog handrail

The invention provides an anti-smog handrail. The anti-smog handrail employs an air supply pipeline. The pipe wall of the air supply pipeline is provided with an opening along the length direction ofthe pipeline; both sides of the opening are respectively connected to a chain belt I and a chain belt II; one side edge of the chain belt I is provided with arrayed chain teeth I; one side edge of thechain belt II is provided with arrayed chain teeth II; a ventilation sliding block device is disposed on a joint between the chain belt I and the chain belt II; the ventilation sliding block device can slide on the chain belt I and the chain belt II; the structure of the ventilation sliding block device includes two guiding mouths, a bottom plate, a cover plate and inner core bodies; the bottom plate is connected to the cover plate through the inner core bodies; a gap is disposed between the bottom plate and the cover plate; in the outer sides of the guiding mouths of the ventilation slidingblock device, the chain teeth I of the chain belt I are meshed with the chain teeth II of the chain belt II; the chain teeth I and the chain teeth II located inside the ventilation sliding block device are opened by the inner core bodies; and the bottom plate or the cover plate of the ventilation sliding block device inside the air supply pipeline is provided with an air outlet hole.

Owner:福州超高层消防科技有限公司

Building

InactiveCN108853797AGuaranteed oxygen demandFirmly connectedFire rescueRespiratory apparatusEngineeringMechanical engineering

Provided is a building. The building is provided with an air supply pipeline. The pipe wall of the air supply pipeline is provided with a line-shaped opening, and is all or partially made of an elastic material. The pipe walls on the two sides of the opening are separated and spaced by a distance, or the pipe walls on the two sides of the opening can be separated and opened, or the opening is closed and can be opened. The pipe walls are connected with magnetic sealing bars or connected with sealing bars with ferromagnetism. The sealing bar seals the openings through magnetic attraction, and the air supply pipeline can provide air meeting the breathing demand.

Owner:福州超高层消防科技有限公司

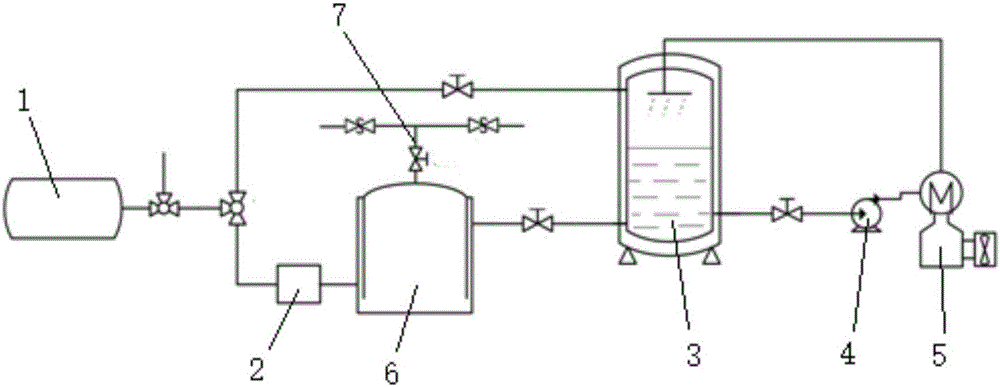

Gas cylinder static evaporation rate detecting device and method with BOG recovery function

ActiveCN105805551AAchieve negative pressureStable outlet pressureContainer filling methodsNon-pressured vesselsGas cylinderControl system

The invention discloses a gas cylinder static evaporation rate detecting device and a method with a BOG recovery function. The device comprises a gas cylinder, a flow meter, a storage tank and a control system; the gas cylinder is connected with an inlet in the upper part of the storage tank through a pipelines and a valve body for emptying of the gas cylinder and recovery of BOG in the standing process; the gas cylinder is connected with the flow meter through a pipeline and the valve body; the flow meter is connected with an inlet in the lower part of the storage tank through a pipeline for recovery of BOG in the gas cylinder static evaporation rate detecting process; and the valve body and the flow meter are both connected with the control system. The BOG is recovered in three phases of natural emptying, normal-pressure standing and evaporation rate detection in the gas cylinder static evaporation rate detecting process, so that the energy waste and the environmental pollution are effectively prevented, and the higher practicability is achieved.

Owner:JIANGSU CRYOTE CRYOGENIC TECH

Gas supplying pipeline

InactiveCN108261657AEasy to useGuaranteed oxygen demandFire rescueRespiratory apparatusGas passingGas supply

Provided is a gas supplying pipeline. The pipe wall of the gas supplying pipeline is provided with a linear opening in the hole direction of the gas supplying pipeline; the pipe wall is fully or partially made of an elastic material; and according to the opening, a plurality of persons can get close to the opening to directly inhale with the mouths at the same time, or gas passing pipes are used and are inserted into the opening for inhaling.

Owner:吴超然

Intelligent full flow point automatic water meter verification equipment

ActiveCN105865589BRealize targeted detectionStable outlet pressureTesting/calibration apparatusGraduated cylinderEngineering

The invention discloses an intelligent full-flow-point full-automatic water meter calibration apparatus, comprising a water pipeline system and a water meter fixture; a water tank (11) of the water pipeline system is communicated sequentially with a water pump (12), a filter (13) and a main water supply pipe (14), the main water supply pipe (14) being communicated with a total outflow pipe; a branch inflow pipe (21), a piston hydraulic meter and a branch outflow pipe (22) are parallelly connected with the main water supply pipe (14); an outlet of the total outflow pipe is communicated respectively with an inlet of a high-precision outflow pipe (16), an inlet of a low-precision outflow pipe (17) and an inlet of a relief outflow pipe (18), and an outlet of the high-precision outflow pipe (16) is communicated with the water tank (11) through an inverted U-shaped pipe (28); the low-precision outflow pipe (17) is communicated with an inlet of a divider (30) through an L-shaped pipe (29), a first outlet of the divider (30) is communicated with a measuring tube (19), and the measuring tube (19) is rested on a scale (20). The intelligent full-flow-point full-automatic water meter calibration apparatus is suitable for household and public precision water meters.

Owner:NINGBO DONGHAI GRP CORP +1

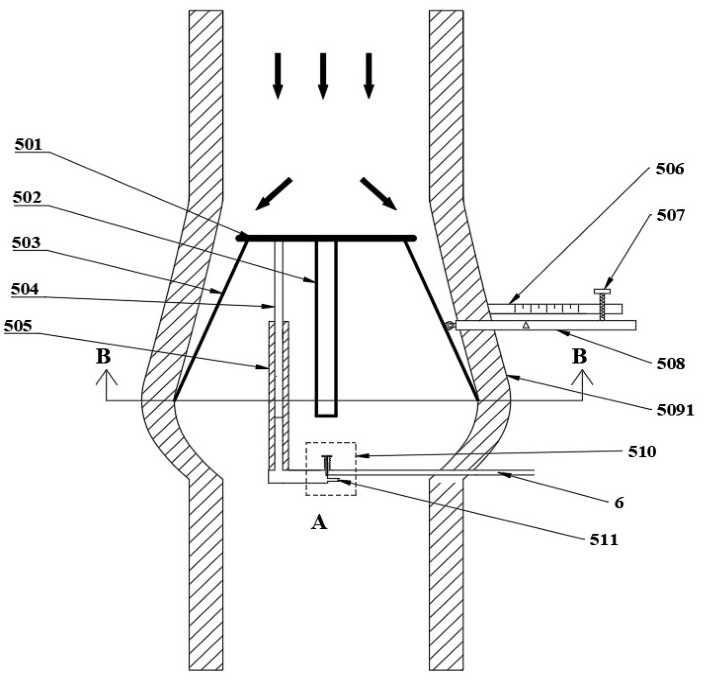

Clash pulse-jet filter cartridge ash removal system with automatic synergistic change of jet pressure

PendingCN112892102ARealize automatic resetReduce openingDispersed particle filtrationTransportation and packagingEngineeringAir purification

The invention discloses a clash pulse-jet filter cartridge ash removal system with automatic synergistic change of jet pressure. The clash pulse-jet filter cartridge ash removal system comprises a dust remover box body and a clash pulse-jet pipeline; a filter cartridge is sleeved in the dust remover box body, and the top of the filter cartridge is provided with a tubesheet to divide the interior of the box body into an air purification chamber and a filter chamber; the air purification chamber is provided with an air outlet, and the filter chamber is provided with an air inlet; the clash pulse-jet pipeline comprises an upper jetting pipe, a lower jetting pipe and an air bag, an air guiding pipe branch is further arranged between the upper jetting pipe and the air bag as well as between the lower jetting pipe and the air bag, and the air guiding pipe structure connects a gradually-opened circulating valve on the upper jetting pipe with the air bag, and connects a gradually-closed circulating valve on the lower jetting pipe with the air bag. According to the invention, through a plate baffle and a slide bar matched with the plate baffle, the opening degree of the valves is automatically and cyclically changed under the impact of pulse airflow, so that the outlet pressure of nozzles at the top and the bottom is controlled, the pulse airflow circularly acts on each part of the filter cartridge through collaborative collision jetting, the structure is simple, and more uniform dust removal of the filter cartridge can be realized.

Owner:NANCHANG UNIV

Gas supply pipeline

InactiveCN108261647AImprove convenienceIncrease inhalationFire rescueRespiratory apparatusGas supplyCivil engineering

The invention discloses a gas supply pipeline. According to the technical scheme, the pipe wall of the gas supply pipeline is provided with a linear opening in the direction of an internal hole of thegas supply pipeline, all or part of the pipe wall is made of an elastic material, the pipe wall at one side of the opening is fixedly connected with a sealing strip, the other side of the sealing strip is movably connected with the pipe wall at the other side of the opening, and the sealing strip can be moved to open the opening.

Owner:吴超然

Air supply pipe

InactiveCN108261649AImprove convenienceIncrease inhalationFire rescueRespiratory apparatusClosed stateEngineering

The invention discloses an air supply pipe. The pipe wall of the air supply pipe is provided with a linear opening, wherein the linear opening is formed in the extension direction of the air supply pipe. Pipe wall bodies at the two sides of the opening are closed to form a rupture gap and can be opened. The opening can contain multiple ventilating pipes at the same time and allow the ventilating pipes to move therein. When the air supply pipe is not subjected to external force, the pipe wall bodies at the two sides of the rupture gap are in the closed state, or the pipe wall bodies at the twosides of the rupture gap are in the staggered overlapping state. The pipe wall is wholly or partly made of an elastic material. The pipe wall body at one side of the opening is fixedly connected witha seal strip, and the other edge of the seal strip is movably overlapped with the pipe wall body at the other side of the opening. The seal strip can be moved to open the opening.

Owner:福州市鼓楼区撰歌亿自动化设备有限公司

Air supply system

PendingCN107185121AWon't leakReduce leakageFire rescueRespiratory apparatusEngineeringBreathing process

A gas supply system, including a breathing air source, the gas supply system also includes a gas supply pipeline, the gas supply pipeline is connected to the breathing air source, the wall of the gas supply pipeline is provided with linear openings, The pipe wall on one side of the above-mentioned opening is directly or through a chain belt connected with an array of chain teeth I, and the pipe wall on the other side of the above-mentioned opening is directly or through a chain belt connected with an array of chain teeth II, and the above-mentioned chain teeth I and chain teeth II can be closed together or separated open.

Owner:吴旭榕

Membrane type sealed gravity compressed air energy storage system and energy storage method

ActiveCN114810262ASolve technical problemsStable outlet pressureEngine componentsSteam engine plantsPhysicsEnergy storage efficiency

The invention provides a membrane type sealing gravity compressed air energy storage system and method. The energy storage system comprises a closed air cavity, a communicating pipeline, a multi-stage compressor unit and an air expansion unit, wherein the multi-stage compressor unit and the air expansion unit are connected in series. A flexible sealing film is installed in the middle of the inner wall of the closed air cavity in a sealed mode and divides the closed air cavity into an upper air cavity and a lower air cavity, and the upper portion of the flexible sealing film is filled with gravity liquid. The two ends of the communicating pipeline are connected with the upper air cavity and the lower air cavity respectively, and a valve is arranged on the communicating pipeline; the multi-stage compressor units connected in series are connected with the lower air cavity through energy storage pipelines, and middle-stage air suction ports of the multi-stage compressor units connected in series are connected with the upper air cavity through air suction pipelines. The air expansion unit is connected with the lower air cavity through an energy release pipeline. Constant pressure of the air storage device in the inflation and deflation process can be achieved, stability of the outlet pressure of the air compressor and the air inlet pressure of the air expansion machine is guaranteed, then the operation efficiency of the air compressor and the expansion machine is improved, and the energy storage efficiency of the system is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD +2

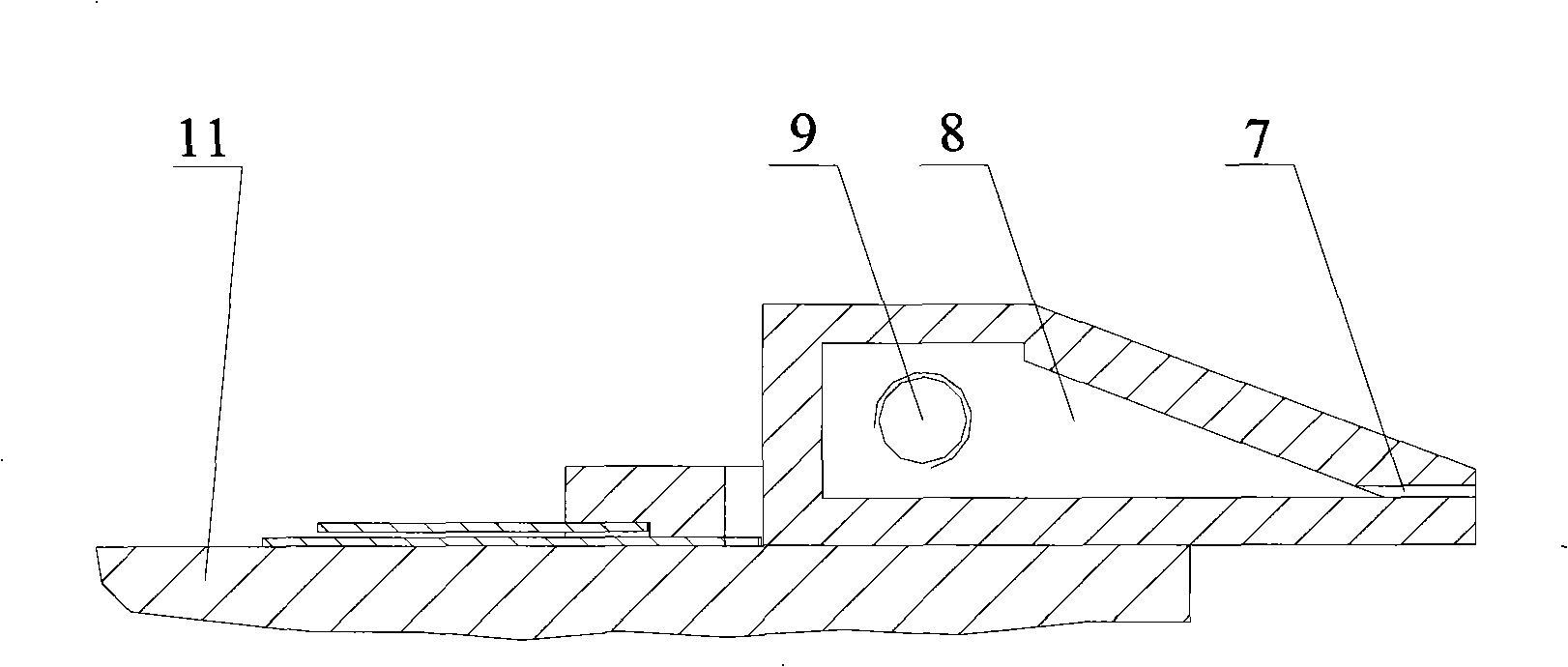

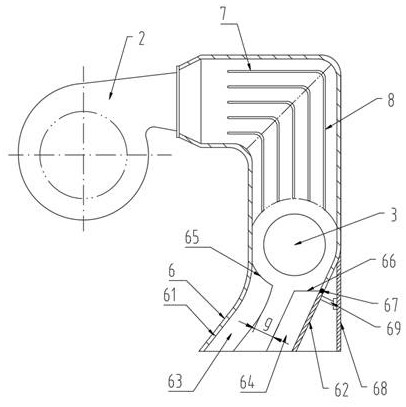

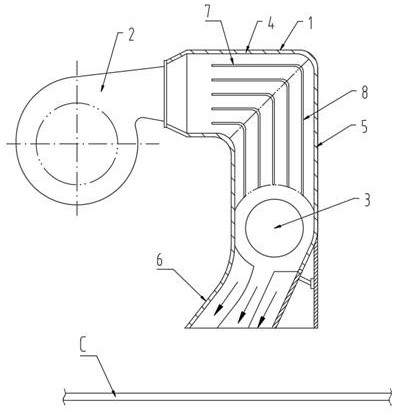

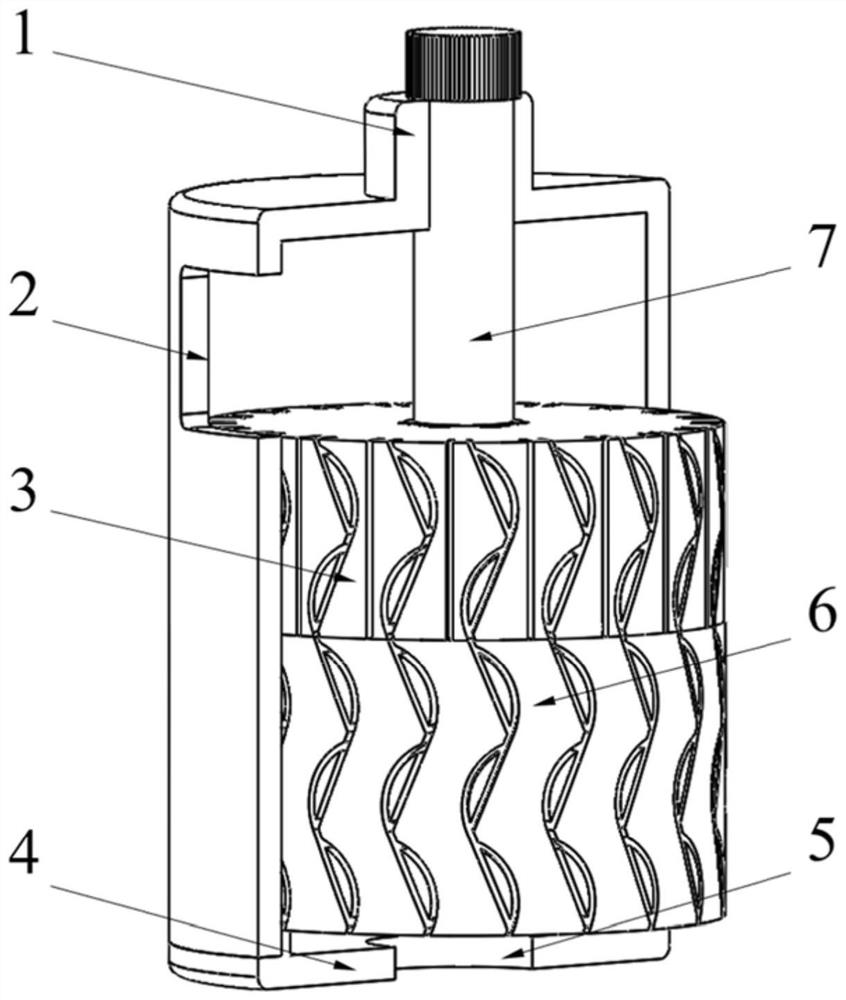

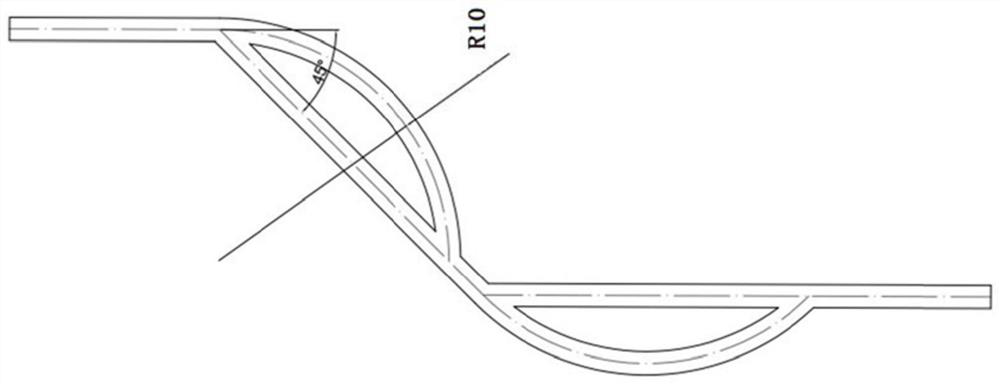

Curing device for spraying production line

ActiveCN112024325AHigh trafficReduce traffic lossPretreated surfacesCoatingsThermodynamicsEngineering

The invention discloses a curing device for a spraying production line. The curing device comprises an air supply pipe (1), a centrifugal blower (2) and a heating device (3). The air supply pipe comprises a first pipeline (4), a second pipeline (5) and a third pipeline (6) which are sequentially connected. The first pipeline is perpendicular to the second pipeline. The third pipeline is obliquelyarranged relative to the second pipeline. A plurality of first flow deflectors (7) are arranged in the first pipeline. A plurality of second flow deflectors (8) are arranged in the second pipeline. The curing device is characterized in that the downstream ends of the second flow deflectors are located on the same arc line, and the heating device is of a cylindrical structure and is located in thesecond pipeline; and the third pipeline comprises a first side plate (61), a second side plate (62), a third flow deflector (63) and a fourth flow deflector (64), and a gap g is formed between the third flow deflector and the fourth flow deflector. According to the curing device, heated airflow is ensured to have large flow, the flow loss of the third pipeline is reduced, the heated airflow near the first side plate and the second side plate can be rectified, the outlet pressure is stable while the airflow is homogenized, and the pressure loss is reduced.

Owner:万载鹏威实业有限公司

A regulating valve capable of maintaining stable outlet pressure and its outlet pressure control method

ActiveCN112032364BStable outlet pressureImprove adaptabilityCheck valvesEqualizing valvesEngineeringValve stem

The invention discloses a regulating valve capable of maintaining stable outlet pressure and a method for controlling the outlet pressure thereof. The regulating valve comprises a valve body, an upper valve plate, a valve cover, a lower valve plate, and a shaft of a valve stem. There are several first Tesla valve-shaped flow passages arranged vertically evenly, and each first Tesla valve-shaped flow passage is connected with the inlet chamber; the upper valve plate is coaxially arranged on the upper part of the lower valve plate, and the upper valve plate A plurality of vertically arranged linear flow passages and a plurality of second Tesla valve-shaped flow passages are distributed evenly and alternately on the circumferential wall surface. The present invention applies the Tesla valve structure with the function of one-way conduction and reverse pressure loss fixation to the valve core structure of the regulating valve. When dealing with upstream pressure fluctuation conditions, the regulation can be changed without changing the outlet flow rate of the valve. The flow resistance of the valve stabilizes the outlet pressure of the regulating valve and improves the adaptability of the regulating valve to the actual working conditions; the execution stroke is short and the rotation displacement is small, and the switching of different stable pressure states can be realized.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com