High-position water source drip-irrigation gravity turbine desilting filter system

A filter system and sand settling technology, applied in the direction of settling tanks, etc., can solve the problems of increasing input costs, constraints on agricultural development, and high prices, and achieve the effects of improving work efficiency, small footprint, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

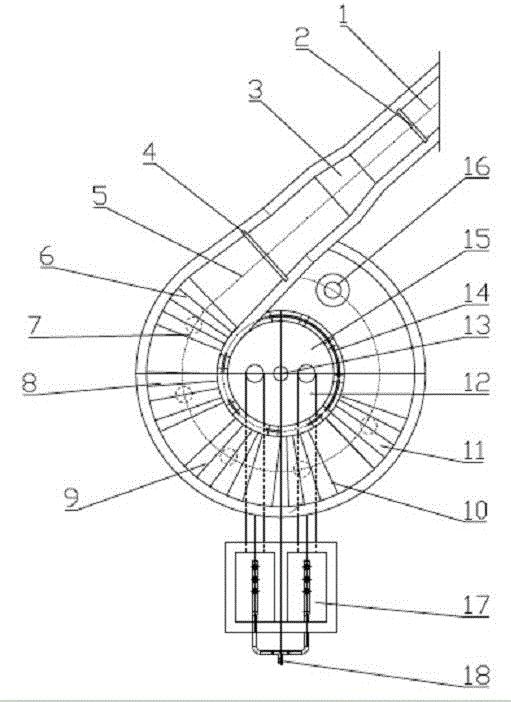

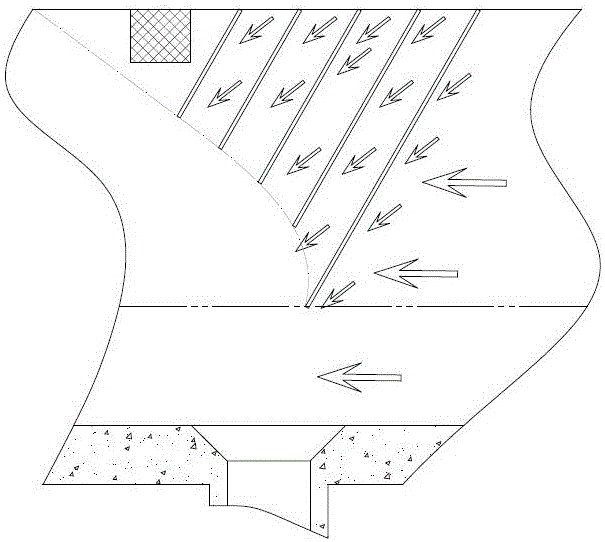

[0024] Such as Figure 1~2 As shown, a high-level water source drip irrigation gravity turbine sand filter system includes a diversion channel 1, a circular sand filter tank 5, a sand discharge tank 7, a clear water tank 15 and a laminated filter system 16.

[0025] The entrance of the front end of the diversion canal 1 is connected with the sediment discharge pond 7 through the coarse filter screen 4; The sand filter pool 5 is connected; the settling sand filter pool 5 is successively provided with a section of five-stage filter group 6, a second section of five-stage filter group 8, three sections of five-stage filter group 9, four sections of five-stage filter group 10, Five-stage five-stage filter group 11; the inner wall of the sedimentation filter tank 5 is provided with an overflow filter screen 14, and is connected with the clear water tank 15; the bottom of the clear water tank 15 is respectively provided with two clear water tank outlets 12 and a clear water tank Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com